Restoring One Pipe -- finally

Comments

-

I know some reasons, I was curious what his reason was 😅

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

If you are designing for reliability, go with a standing pilot and float low water cutoff. You may want to nix the electric flue damper too. Have a spare thermocouple on the shelf and maintain your stuff.

This will eliminate all electronics and you'll be able to restore heat after an outage or power surge in ten minutes with a wrench and screwdriver.

Just understand the trade-offs and be familiar with the liabilities and benefits of your choices.

Most of our commercial and government work is designed this way for dependability.

——My own buildings are wired for easy backup power from portable battery/inverter packs that can enable gas controls on a steam system for a day between recharging. (Look into Jackery products). They provide 120VAC, so electronic controls are no problem.1 -

I need to clean the inside of the boiler.

i believe it was installed around the turn of the century. the neglect is impressive; the feed water pump was full of mud. I would be looking at rust, mud, scaling, definitely not as pretty as ethicalpaul's boiler

0 -

(I'm not judging here, it's not easy, that's why there's a whole trade for it)

This is not for novices, do not try this at home.

fourth attempt, still leaks between the same sections. I will try again tomorrow, I am not pulling them apart, I disconnected the piping. too many pits in the mating surfaces maybe.

0 -

Were the sections already leaking before you started this restoration? Have you seen them yet? They may be rotted out at/near the connection points.

If you did pull them apart (I kind of doubt you did), they might remain apart and leaking even with the pipes removed.

I think it being rotted out already is more likely, it looks like a lot of rust on the burners. Did you overfill it to see if it's leaking at the top of the sections?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

@ethicalpaul

Regarding the idea of keeping the pH very high — that will not work with Weil-McLain; the "O rings" between sections will disintegrate. I don't have a link but this has been discussed; I think the safe upper value was 9 or 9.5.

The point may be mute for this particular specimen…And not to sidetrack this thread: Paul, why is your water so clear if you use 8-way to set the pH? I'm at 9 or 10 and my water is also clear but appropriately "violet."

-1 -

I don't think I have ever said people should keep their pH "very high". You should put it higher than 7 for sure. And yes, WM does set a pretty small upper value. Some people have said that was because of their elastomer rings but I am highly skeptical that 10 or 11 pH hurts them. Above 11 or so a different kind of iron oxidation can start to occur so right now my sweet spot is 9-10, but even 8 is way better than 7.

I have one of WM's gasket rings sitting in high pH water for several months now with no sign of damage, but this isn't in the high heat of a boiler, either, so it's admittedly not very persuasive.

I do use 8-way but in that video I wasn't using it at that time for uninteresting reasons. At that moment I was using a pH booster used for pools that doesn't have a pH indicator marker in it.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

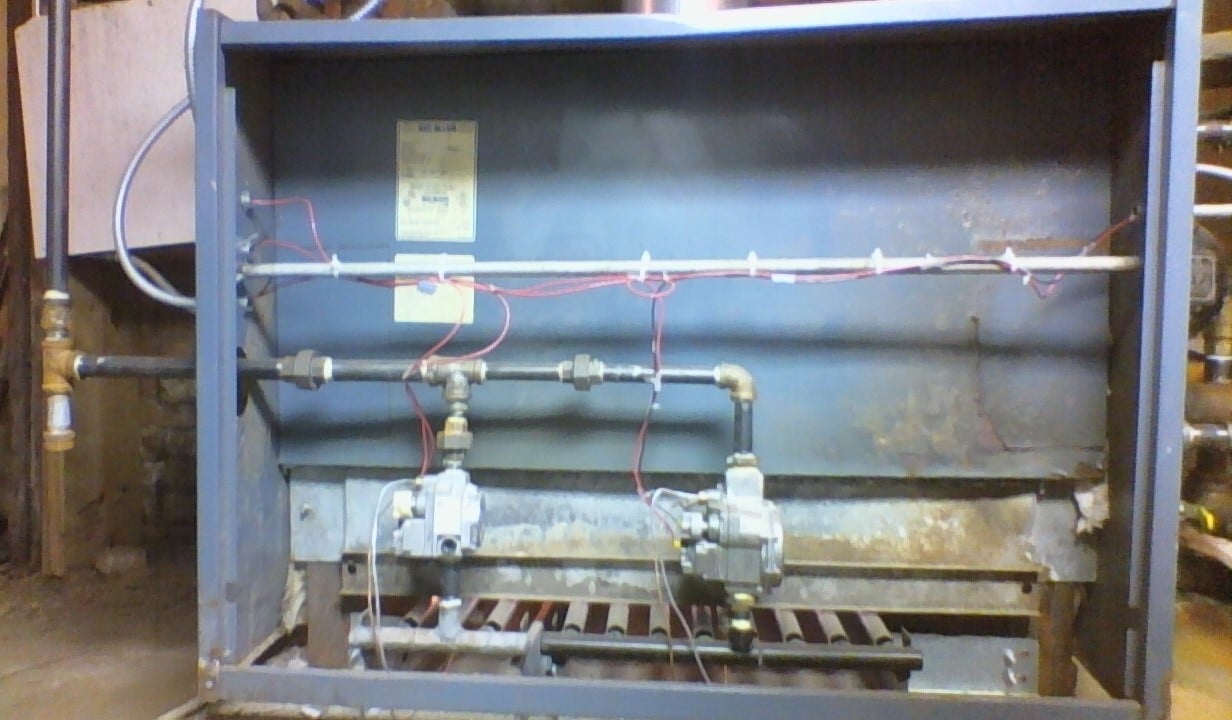

Okay, here is the stark photo. Funny how pictures tell the reality and not the image I have in mind.

Here are the details: Two 2" risers, Max output: 875 sq ft steam, or 215 lbs per hour. Elevation 1000 ft. I am using 26.78 cu ft / lb steam at startup.

Rate of steam rising out of the 2" risers: 34.3 ft / sec. Risers rise 45" above the water line, travels eight inches then drops 14". Speed in the first part of the three-inch header is 15.6 ft/sec. the second part is 31.2 ft/second.

The diagonal pipe coming out of the header is a steam separator taken from the book "Superheater" from the Superheater company, Chicago Illinois, I do not remember the printing date. The book and the library from which I borrowed it no longer exists. It is the "hump" found on steam engines. I always wanted to build one, so there it is. Dan mentioned something like this on page … well somewhere where some old timers place a copper kettle before the main. It is a separator. In this case I made it out of a two-foot 6" pipe, with a specified takeoff about two thirds the distance, the takeoff has a slit in the pipe I will have to draw a picture.

The speed of steam in this separator is 8 ft/sec.

The steam then exits into the 3" main at 31.2 ft / sec.

This wraps around the house as old coal mains did, reducing to 2" when the speed drops to 12.5 ft/sec in the three-inch main. The speed then increases to 24.5 ft/sec in the two-inch main.

Through the doorway, you can see the 14th riser. then the end tee for the end of main vent. It just happens to return between the boiler risers, and the drop header. comes to the near side of the boiler where it drops into the 2" Hartford loop, then the equalizer.

The hope is to reach the ideal where Dry steam leaves the header at 215 degrees, and Saturated water returns through the Hartford loop at or near 212 degrees.

The water makeup enters at the Hartford loop through a 3/8ths manual valve take from the hot water heaters. this will drive some of the calcium and oxygen out of the makeup water. I do not presently have a water softener, but it is in the plans. the hot water will of course be softened. The city water is alkaline at about 8 or 9 ph.

I need a few more hangers, and when it is tested, insulation.

However, my time for this winter project is up. I will be working overtime for the next month. after which time, I need to get my upstairs projects finished. (like the roof). So, since I still have a leak in the boiler sections, and i took another look at the scale, I will disassemble it again and give it an acid bath. A dirty boiler is not only inefficient, but dangerous. Why install all these energy efficient devices then use a boiler with a quarter inch scale in it? No. got to do it right.

I must admit however, all the water I have placed in her to test it has loosened the scale some.

I still have a long way to go. I have the new burners, but only half the trim. and I wonder if using the old is worth it. maybe get all new and lose any worry.

0 -

My advice, don't over-focus on the math. Just see how close to the manufacturer's recommendation the pipe is. They did the math. It's been running for decades, I wouldn't mess with the pipes until you replace the boiler. I just realized you replaced a section in this boiler? I would be highly nervous about the viability of that…another section could be about to go after all. But I wish you the best result!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

-

Yes, the first (right as I look at the front, also the inlet side) was cracked. it has been replaced. The remainder of the sections appear to be solid.

The mating surfaces are pitted, but wire brush and Forma gasket…

There is a strange phenomenon I cannot explain. when I disassemble to look for the leaks, I discover missing gaskets. I cannot imagine leaving any out, but I am the only one working on this. I do not know, maybe they fling out when I set the next section on. The alterative explanation is equivalent to Matmich's comment. Anyway, extra careful this time.

But the pitting bothers me. This might be a dead dog. Anyway, one more time,

The water in town is about 8.5ph.

0 -

Success!

This time, after wire brushing each section, I allowed 24 hours between sections. After tightening the half section to the recommended 55 ft lbs, I waited another 24 hours, then I put the two sections together, and waited. moved the core and tightened again.

It holds water. but I did not get it up to 55 psi on account of pinholes in my welds — those I can easily take care of. The core holds water. I can go on to the next step:

clean the core.

I am looking at Qwik Products Concentrated Descaler Solution QT7710 in 1 gal bottles. one gal makes six. Any comments on this?

0 -

I don't know about ND, but in Nebraska any boiler in a commercial building gets an inspection from the state. Every year or two.

And from all I have read, welding on a pressure vessel can only be done by certified companies and then a record of those repairs maintained.

So I am sure your boiler jacket will cover any obvious welds.

1 -

Jughne" To clarify: I am not welding on the boiler. I finally got the sections so they will not leak.

When I am satisfied with the entire system, I will call in the inspector. AS for my City of Omaha license, I let that lapse. But I have noticed one thing: As time passes, the skills I once had, are not as sharp as they were.

0 -

Ok, I am back. The boiler sections were laid up wet all summer. I added some descaler changing it when it turned color. the water level went down slightly, but I see no evidence of leaks. it is open at the top where I fill through the relief valve port.

I am using the Weil-McLain EGH series 5 manual for assembly. I have an EGH85. I am not certain what series I have.

on page 10, figure 6 the manual mentions Flue baffles. I do not remember having these. This is either the fault of my memory and they were damaged, or misplaced, or I did not have them. I notice that they are not part of the EG series, unless they are being used as a water boiler. These parts are also on backorder at Supply House.

Question one then is: "How important are they? what do they do? how much do they increase the efficiency?

Page 12, figure 7d, leg Refractory: again, I do not remember having these, they are on backorder, I did order them. the smaller EG does not require them.

No question here. I am going to add the extra protection.

The EGH also has a burner and base shield. I do not remember this. and was unsuccessful at locating the old burner tray in my scrap heap. again, not part of the EG, but part of the EGH series 5.

I will welcome comments of this and what is it?

The EGH Figure 7a page 11, now has a single rear base panel and refractory. however, I have a panel and a channel. I was able to clean and restore the original parts. Is this a "new and improved", difference in the upgrade to the series 5"

I know, I might have been better off starting with a new boiler, I could have gone smaller. but i am this far now.

0 -

I have the jacket on as well as most of the trim.

I am waiting for the conversion kit for the gas valve, to run LP instead of natural gas.

Now, I am preparing to order a vaporstat.

what are the differences between vaporstats?

0 -

-

no. I expect to run the boiler at as low a pressure as possible.

just following Dan's book. run at as low a pressure as possible

0 -

-

Vaporstats are $$$. I would try it with a standard pressure control but leave provisions for adding a vapor stat another tapping and a pigtail. You can always add it later.

0 -

As implied above, but I'm going to state it explicitly here—the pressure that your system "wants" to run at will be determined by the steam production (size of boiler) vs the steam usage (size of radiation), that's it.

What is the EDR of your radiation, and what is the size of your boiler in Net Sq Ft of Steam?

If the boiler is oversized (almost all of them are), it will make more steam than your radiators can condense, and that's when the pressure control will come into play.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Ah! a complicated question.

With the building newly insulated, the calculated heat loss of the building is 280k btuh at the design temperature of -40. depending on the infiltration. But with wind speeds of twenty to thirty mph or higher, this number is a guess. Without the infiltration, the heat load is less than half.

I have distributed the radiators on hand, each room getting a different radiator depending on the calculations for that room.

The EDR is 958. This should be oversized for the house. For example, the baths require EDR of twelve, but I did not have enough three column radiators to to this, so I placed four column, EDR 16, in these rooms.

I am still using the rebuilt EGH85, boiler but in replacing the burners, (they were ruined) I downsized the burners. so oversized boiler, undersized burners.

The building was originally coal fired. In coal fire, the boiler stayed on all day, possibly running a vacuum at night. here, I have a lack of knowledge, I think the vents were different. but I would like to duplicate this where the boiler stays on meeting the heat load of the building.

Because I live in an area were we have a 150 degree temperature swing, with winds ranging from zero to ninety, coming from any direction, a one size fits all heat system… well, what works one day, will not work the next.

As a high pressure boiler operator, from a factory where the heat load would vary according to the time of day, I kept the boilers balanced according to load. I want to do the same thing here.

My The Weil-Mclain EGH85 does not offer a duel burner, so I replaced the original with what will become a duel burner system. The objective is for the first burner to stay on at temperatures of thirty degrees and below, with the second cutting in and out between freezing to minus forty.

Dan covered very well how oil fired systems need to breath. and need adequate air vents. However, I am going the other way, trying to duplicate the coal fire where the boiler is on all the time. (therefore, I am guessing)

Your vacuum system might have the answer.

Thanks for all the information and expertise everyone is giving me. I have worked with high pressure steam, but have no experience in low pressure heating. not like this.

0 -

Low pressure steam heat is a fascinating thing if one actually starts getting into the physics.

Steam heat — especially systems running well on low apparent pressures — can really only be understood in terms of pressure differentials, not gauge pressure at the boiler. And those differentials are determined by the gauge pressure at the boiler, which determines the temperature of the leaving steam, the power input of the boiler, which determines pounds of steam per hour, and the temperature of the condensers (radiators!) which determines the pressure at those locations and the power output at those locations.

Now in most systems today the pressure at the condensers is fixed at 0 psig, or very close to that, in two pipe systems (in one pipe systems, when the radiator vent closes it rises slightly). In systems which can hold a vacuum, that isn't true.

Ultimately the objective of the whole exercise is to have the power delivered to the space, averaged over time, equal the heat loss of the space. In most systems you can't vary the power output of the radiation when it's on — so instead one varies the duty cycle (on time vs. total cycle time) to deliver the average power needed. Similarly going back to the boiler one can't usually vary the power of the boiler, at least in residential systems, so again one varies the duty cycle to get the desired power output.

At which point you really have a control problem, and the question becomes which parameter or parameters are you going to use to control what. And there we get pretty crude in residential systems — temperature for power matching in spaces, and pressure for power matching at the boiler.

This sort of thinking can go on and on… it's fun.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Hi Jamie,

Ya, that is the problem. If it were easy, anyone could do it.

If one pipe could be easily controlled, there would be no need for two pipe.

I also belong to Steam Automotive Club of America, or I did. Steam will work, but someone finally mentioned that the steam engine was only 5% efficient.

Making an efficient heating system is a loss when I start with an 82% AFUE boiler.

and rebuilding the 20 some year old leaky boiler was probably not the most efficient use of funds, if the parts were not already here, I would have gone with hot water radiant heat. — If I had to start from scratch. but the parts are here. The original, abandoned boiler is still taking up space in the basement.

call it a challenge under the heading of a hobby, now.

Maybe it will work, maybe it will not. it is the challenge of the journey that counts. the destination is the final reward.

the project is already five or six years behind schedule. but nearer completion than I was two years ago.

Actually, when I was playing around with steam engines, I often wondered how all that latent heat could be utilized. well, here it is. All that energy tied up in the Mollier Chart. Then Dan mentioned that that is how steam heat came about.

Oh, I still have hundreds of questions. I know that the burners are woefully undersized, I ordered the wrong ones.

as your comment mentions the physics, I do not understand fully the dynamics of what happens in the radiator. as the heat escapes, the steam condenses leaving a vacuum. more steam comes in and the condensate leaves. The heat loss is determined by the temperature differential transferred by the thickness of the cast iron and paint. Bu9t there is the air space which controls the volume of the steam pocket.

If the radiator is purged of air at 30 degrees ambient, will that volume be sufficient at -40? Will I need to force the system to breath?

yes, in the "new" gas systems, the cycle controls the temperature. but that is not the way it was back in the coal days. Is that why I have such large windows? The coal/steam simply overwhelmed the room to where everyone was uncomfortable?

In theory, if the energy in matches the energy out, the system is balanced. but will one radiator take all the energy, while another starves? one hot room and one cold? I will not know until the system goes on line. Then I will wrestle with reality, not just theory.

If it works on paper, I will give it a 50/50 chance

0 -

You are going to have fun! Steam heat is a remarkable system — but not many people, as you can gather from the various threads here on The Wall, understand it.

You wonder about the conditions in a radiator — or group of radiators. One of the more intriguing things about steam heat is that, to a limited extent, it is self balancing. If a given radiator is colder (one pipe or two pipe doesn't matter) it will condense steam more rapidly (once the steam gets to it!). This it will have a fractionally lower pressure (heavy emphasis on fractionally!) and thus steam will tend to go there preferentially (the pressure differences are fractions of an inch, water column). The volume of the radiator is — within reason — irrelevant.

Steam heat is far more efficient than steam power; you really do get more than 80% of the higher heat of combustion of the fuel showing up at the radiators. Nice of it. It's no less efficient than any other non-condensing boiler or furnace heating system that way. Steam power is limited in efficiency simply because you are not actually getting at the latent heat (except, oddly, in the verry early Newcomen engines — which had other problems!). Last thing you want in a turbine or piston engine is water droplets in there! You can improve the efficiency of steam power considerably comparing a car or most trains to a ship or a power plant) by condensing the steam at low temperature, thus increasing the available pressure differential.

Now power control is another matter — and it depends on what can be controlled. Way back in the day some vapour steam systems could hold a vacuum and were coal fired. The pressure differential was partly controlled by varying the draught over the fire using sensitive dampers controlled by the pressure differential and the total power was varied again by a thermally controlled damper in the space which acted together with the differential damper. Efficiency at part fire was horrible — but the system ran with just the right amount of fire to cause the whole system to operate at the gauge pressure needed for the space heating demand — lovely even heat, so long as the man tending the boiler kept coal in it.

Modern systems have two problems, though. First, they are not usually able to hold a vacuum, so the power output of the radiation is either full bore or nil, and the burner usually can't modulate, so the power input from the boiler is also full bore or nil — and very rarely the same as the power requirement of the radiation.

So… we use pulse modulation rather than analogue. The radiator output is controlled by the thermostat so that on the average it is what is needed for the space. The boiler output is controlled by sensitive pressure so that it's power matches the radiation demand.

There's more to it than that, but that's basically it…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

@cgutha , I remember visiting your building many years ago. The two reasons for the large windows are 1- folks liked to sleep in fresh air, especially after the 1918 Spanish Flu pandemic, and 2- there was no air-conditioning then.

ISTR since that was originally a railroad hotel, your original boiler also provided steam for the laundry, and maybe a few other things.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

The building was built prior to the open window phase. Thus the double pane / double hung windows. Actually, if they were still in good condition the infiltration rate is less than today's windows. Obviously, they were designed for cooling and ventilation in the summer. Hence the transits above the doors and high ceilings, "Natural air conditioning".

I have removed the three hundred gallon hot water tank. it leaked. But that was attached to the original coal boiler. I assume that the "new" boiler was sized according to the EDR of the building at the time. 400k btuh input. (again, I removed many radiators and shuffled them according to calculated heat loss of each room after insulating).

I have worked with modulating burners. Some of them even work. It is more fun to run them by hand, and the modern electronic ones cannot learn analog modulation. They try.

What I am attempting to do is modulate with a two burners. The smaller will be on all the time, the larger will modulate according to the pressure. (not the room temperature. the thermostat in this size of a building is simply to turn the system on and off in the fall and spring) A graph of the cycle should look like the graph of modulating DC in electronics. So the pressure at the boiler should vary between (I don't know) one and three psig according to the vaporstat.

Ethicalpaul is correct, the first burner can be controlled by a less expensive pressuretrol because it will never build pressure unless it is hot outside — and then the thermostat should cut it off.

Because I ordered the wrong burner, (yielding only 75k BTUH input, the boiler should stay just above a simmer.

There should be an efficiency boost from not having "Start up's" when the second burner kicks on. All the pipes and radiators remain at operating temperature. just adding more energy to the system.

I don't know, maybe the boiler will act more efficiently when it is not being forced.

Also the distance the condensate needs to travel from the last riser to the condensate return is ten feet. I am hoping for 214 degrees out and 212 in — saturated steam to saturated water and visa versa.

Also, I added makeup air. This comes down the chimney as the flew gas goes up. (single wall stack inside the old brick chimney) A heat exchanger (as long as I do not loose so much heat that I need to force the air out.) it might work, it might not.

Today was a good day. most of the trim is on, and the gas valves are installed. I am waiting for two parts and should be ready to test it next Saturday. Then I can lay it up wet and start on the fourteen risers.

Nevertheless, as they say: "the proof is in the pudding."

0 -

The more I get into this project, the more I know I do not know.

The question today concerns wiring. What is the best wire to use at the gas valves and around the trim work? Do I need high temperature wiring?

0 -

I found the schematics on the front cover. all wires are indicated to be black. I will use 14g THHN. that is good for 600 degrees.

0 -

The old transformer weighed in at 27.8 volts. Rather than risking my gas valves, I bought a new one which is rated at 24 volts, but I am running 120 volts input not 110, so it is a little high. — 60 v-a.

I "bench tested" the boiler today.

That is, I isolated the boiler at the king valve and ran it up to temp. The first thing I noticed is that I had a burner that did not light. I guess, letting them sit for a year or so, means the orifice needs cleaning. Got that working.

The second stage did not light at all. This is the old original gas valve, but the pilot lit so I checked the voltage. I bypassed the vaporstat. All burners lit. I will leave the vaporstat problem for later.

It came up to temperature fairly quickly considering I now have eleven burners instead of the original fourteen. I found a plug I had forgotten to tighten. Then a charge of water burped out of the future end of line air vent piping. I had forgotten to close the return valve.

I turned off the burners, did a bottom blowdown, and refilled.

Partially, successful, I still have some work to do on the piping,

Now, I know that most of you would do a complete rebuild or replace in a day, not multiple years. but for me this is like rebuilding an old car in my spare time.

I have worked as a boiler operator on a variety of boilers and pressures, Never one that was dedicated solely for heat, and although I have cleaned and prepared many boilers for inspection, This is a complete whole-house rebuild, starting with insulating the building. Heat loads in every room have changed. The main was once two loops with a return that went underground — and had a condensate pump.

No more. Now it is one perimeter loop, fourteen risers: where the loop ends where the boiler begins. I have some work to do on the near piping, and I need to figure out how to tell my vaporstat that it is ok to turn the valve on when there is no pressure, Then, when I am satisfied, the work begins on the risers.

First the engine, then the transmission, then the rest of the car…

1 -

I cycled the boiler again. This time I closed the isolation valve on the return as well as the king valve. all went well. I have a 3" union to tighten, that is no problem.

I see that the vaporstat is "normally open" rather than normally closed. That is a problem.

Why do they make so many different everythings? I suppose they make this style to turn pumps on after the boiler is up to steam. but this is a one pipe, I eliminated the pumps.

nest project is to clean the room and take pictures.

0 -

Hello cgutha,

All I can say is keep calm and carry on my friend. I have enjoyed watching your progress with this work.

OH, how I wish I could put a dual fuel AHS S500 coal stoker in your basement to make dry steam with a double drop header!!!!!

0 -

Leonz: Unfortunately, I am still battling coal dust.

0 -

Hello and good morning cgutha,

It would be worth it for you to order a box of "Green Sweep" sweeping compound from ULINE to collect and keep the coal dust solidified together to make it easier to collect and dispose of.

The natural oils in pine needles act like a vacuum cleaner and holds all the coal dust and fly ash together which made for easier cleaning and the quarry tile floor was left with a very bright wax shine.

We used the PINE AX brand it as a sweeping compound to collect all the fly ash that settled on the turbine floor of the generating station that I worked in as a temporary laborer 38 years ago.

0 -

Leonz: Coal dust is above the metal ceiling. It lives everywhere. Every time I touch the room, some filters through the cracks and comes down. but I will keep in mind any secrets on cleaning. thanks.

0 -

Hello and good morning CGutha,

Now I can really help you with your fugitive dust problem!!,

The Onieda Dust Deputy is what you need to corral your fugitive lignite coal dust. I have the original dust deputy and it works very well.

0 -

Steam is painfully honest.

If I were to ask it, "How is my welding? Are there any holes in my header?"

It would dutifully go around and point out every hole. It might even whistle to get my attention.

I ran the boiler several times last week to allow the steam to clean the holes. I have discovered finally, that I no longer have the same eyes I had when I was young. I am still making adjustments.

I had one union that leaked because the pipe angle was different in its new location.

So I cut the pipe to adjust the angle. I have a stick welder, but work has a MIG I can use. The MIG does a better job. I tacked the pipe with the stick, then took it to the shop.

I built the header with a number of unions so it is easy to take apart in manageable sections and carry it out to the car. I define easy as less than one hundred pounds.

It is interesting, the header did not go back together the way it came apart. but after a little adjustment it fits together better now. Then I turned on the gas, lit the pilots, awaited for the answer: did I get all the holes?

Steam is honest.

I found and corrected all the holes in the separator. One small one and two micros in the header. I'll see if I can get it with the stick after it cools.

It is interesting, After the boiler got up to three pounds, and the secondary burner shut off, the boiler still went up to five pounds. Then after a few minutes the pressure dropped enough to restart the secondary. but it stayed on for only forty-three seconds,

After the near pipe passes the tests, I will start on the risers.

1 -

Update: I found three more holes, but this time, I cheated: Drill, tap, and plug.

The air vents arrived. End of main is a Gorton #2, The risers are either Gorton 6, or Gorton c. abut 50/50 of each depending on the riser.

The risers fell into one of four categories: 1) risers I did not touch; 2) risers I touched and worked on; 3) abandoned risers; and risers which will be capped until I have time to work on them. I guess there is a fifth category: the riser I did not find.

Today, the boiler is purring, and the king valve is open. I went through the house closed the valves to the radiators in rooms I am not going to heat; checked for leaks. checked to see if the risers are getting warm. Went to get my computer to write this report and found the #4 riser which I could not find before.

Steam notifies us when there is a hole.

I am still waiting for pressure to build. I am heating rooms which I have not been heating before. The house is also getting warmer. A second check of the system found a few unions what were not tightened.

Also, I guess finger tight is not good enough for the vents. The steam has made it around to the end of line. I see a loose fitting in the main. That's going to be a big disassemble project — from the Hartford loop back to the fourteenth riser.

Someone told me they would never go with steam because it is too noisy. I bit my tongue because i know what noise in steam heat means. I am amazed at how quiet the vents are. I expected more than a whisper. The slow vents on the radiators are definitely slow. the radiators are getting hot. Even though I designed this to not cycle off, I still designed the main and the risers to vent quickly.

Let me give you a tour.

The boiler body is a EGH 85 Weil-Mclain. 400,000 BTU input. Which, I am certain was needed before I insulated the house. The boiler leaked. the burners were toast. the right section cracked. I chose to rebuild the boiler rather than buying new. Whether or not I chose wisely is immaterial at this point.

I replaced the burner with two burners: EG-30, and EG-55. I was suppose to order the 35, but I messed up. That would have been 4 burners and 8 burners. I have 3 and 8. These replace the fourteen of the EGH85. Oh, I also went with standing pilots. some people say that it is a waste to have a standing pilot. Let me ask something. Where does the pilot heat go?

Stage one burner is controlled by the pressuretrol, Stage two by the vapor stat. At present, I am running three pounds minus 6 oz. That is the way it came out of the box.

I had a couple of float valves laying around, so I used them. I also have two electronic low water controllers, but the one I installed made sparky noises, so I removed it for now. I will try the other one later. I will probably revert to running two floats. duplicating the float and sight glass on the other (left) side. This will allow me to supply a battery backup with the load being only two 20ma valves as the electric load.

I quick tour upstairs leads me to believe I have a cracked radiator with a valve that will not close, also, another problem in another room.

end of test,

0 -

yes, one broken radiator. it was a three column, 12 edu. I removed it and plugged the pipe.

the other problem is my new gorton-6 was allowing steam to pass. is this common?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements