Bypass for a Buderus G115/3 boiler?

Comments

-

@hot_rod Thanks for that diagram. I understand the concept. My two problems are (1) very limited headroom to add the circs and hydraulic sep, and (2) I may not be here long enough to implement.

So I am trying to focus on getting a very basic plan together for boiler replacements with minimum re-piping, that the other owners can hand to our heating company when the time comes.

The Minicals you see are because I just removed our old plain steel tank and installed an SX-40V behind the far boiler. So now we are one step closer to modern plumbing. The Minicals were the best I could do without cutting into a supply or return, which I don't want to do until a boiler needs replacing. At that time we can upgrade to a real air separator.

0 -

OK thanks, but I'm still trying and perhaps failing to understand your suggestion above where you said:

"Circ turns on at say 150F, off at 80f. Heat call resets circ aquastat. Bypass is set so when circ is running with your expected low RWT (probbly around 80F), the boiler sees 130F. That will get you a supply swing from 150F to 180F and return swing from 80F to 110F. This gets you quick boiler warmup and should keep it from bouncing off the high limit."

I understand the concept of circ holdoff until the boiler hits 150, but as soon as the circ turns on, it starts pumping 65 degree return water towards the boiler. If I have the bypass set to mix 2 gallons of 150F supply with, say, 1 gallon of 65F return, that's a mixed return temp of 122F.

So now the boiler needs to maintain a delta T of 28 (150-122) to keep the mixed return temp from dropping too low. For a delta T of 28 across an 85,000 BTU output boiler, that's about 6 gpm through the boiler.

Then to maintain the 2-to-1 flow ratio through the bypass for high return temps, I want 4 of those 6 gpm going through the bypass, and 2 of those 6 gpm going out to the system and coming back into the return.

So in order to maintain a minimum 122 mixed return, I'm flowing 6 gpm through the boiler, 4 of which goes through the bypass and into the mixed return, and only 2 gpm goes out to the system.

So now I have only 2 gpm crawling through a system of 100+ gallons. It would take almost an hour for one complete circuit, which means high temperature gradient and poor heat distribution.

My situation seems to support @Ron Beck 's opinion that CI boilers sometimes should be piped P/S because of this bypass problem and the resulting flow mismatch. He talks about it here:

0 -

-

@EBEBRATT-Ed I'm sure those valves and controls are super nice. I just worry about the electronics getting zapped. And the other owners here are not going to be able to understand/maintain them.

I would just put the ESBE thermic valve on the return with a 122F or 131F element. If I did that with a bypass as I described above with a 2-to-1 flow ratio and a 150F hold-off on the circ, that should work fine.

The only problem then is the low flow rate out through a high-volume system, which is going to be bad for heat disctribution.

0 -

-

Here's a better diagram that compares a plain bypass with a bypass plus primary/secondary. The plain bypass only puts 2 gpm through the radiator loop, which seems too low for a system with 100+ gallons of water and 10 large cast iron radiators. That flow problem is solved by the addition of primary/secondary piping, which allows a higher flow rate through the radiator loop for better heat distribution, without upsetting the temperature balance through the boiler loop.

All temperature are shown at cold start with circulator hold-off until the boiler temp reaches 150. At that point, the circulator starts, and the mixed return temp is 122. The average temp through the boiler is 136. These temps will climb slowly throughout the burn, so condensation is no longer a concern.

This bypass diagram with primary/secondary is based on a diagram I saw on @Ron Beck 's comfort-calc.com website, so I don't take credit for it. But it seems to solve my problem with the flow mismatches that would result from maintaining a high enough return water temp.

0 -

Normally there isn't so much water so the RWT gets up to above 100F pretty quick so you don't have to mix that much.

In your case, with the large volume and oversized rad, your proposed PS makes sense. If you want to get fancy, you can do continuous circulation on the secondary loop and run outdoor reset on it (ie outdoor reset and thermostat control boiler fire). This will keep the water temps there more even which eliminates pipe expansion noises.

1 -

What is missing in those bypass drawings is the fact that the water temperatures are mot fixed in the boiler or distribution loop.

So you set the bypass when the system return is 65F? Then if the system rises to say 150F then your bypass is not blending the same.

Which is why dumb mixing valve or pump, for boiler return makes little sense.

If you have a copy of Modern Hydronic Heating, it goes into great detail about boiler return concepts, as well as options for piping and control.

On a system like yours a mod con along with a conventional boiler would have been an option, for those low SWT conditions.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

And some, maybe many worked for years.

It's one thing for the "flexible" cast iron block to be able to handle cool return, but the flue gasses may be condensing in the flue.

Especially high mass masonry chimney.

That damage often goes unnoticed. Most service techs do not scope out the entire flue system.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I doubt 2 gpm is going to heat well with the oversized piping. Air removal will be difficult as well as distribution.

I would do primary secondary with a pump on the house loop equal to what your pumping now because you know that is enough flow. Then an injection loop from the boiler to the house loop. The primary secondary will help keep the boiler return up but you still need a valve to control return water temp. I would put the house pump on an OA sensor and let it run. The injection pump will feed the house loop as much as possible to keeping the return temp where it needs to be. With the house loop pumping more than the boiler primary pump and the injection the water in the house loop will always flow in the right direction across the closely spaced tees.

2 -

Fortunately we have an interior chimney, so condensation in the flue doesn't seem to have been a problem. We just had the chimney inspected by a good local sweep about 2 years ago when considering gas conversion. He said it was in good condition. I looked also. Not an expert myself, but the terra cotta liners showed no evidence of deterioration. So we've dodged that bullet so far.

0 -

Thanks Ed. After further analysis it seems the G115/4 would be a safer option vs the G115/3 because the higher output will heat our large water volume faster. A G115/4 would take only about 6 minutes longer to heat up to 120 degree supply water temp, vs our existing WGO-5's at 1.18 gph input.

The G115/4 is 2 times our design heat load, so it's still overkill for the building, but I'm realizing that the 800-pound gorilla here is the 100+ gallons of water that by itself takes 40,000 BTU to heat up to 120 degrees. The high water volume is a double-whammy because of how long it takes to heat the rads, and also how long it depresses the return water temp.

So I think G115/4's piped the way you say would be a good compromise.

PS—Thanks to @LRCCBJ for suggesting the G115/4. Not my idea, but I think he is right. The input rate is only 30% lower than we have now, but it's almost 50% less cast iron than our WGO-5's, so that has got to help.

1 -

It all goes back to what every boiler MFG puts in the small print for HW boilers.

PU factor of 1.15. Consult MFG for systems with more PU or extensive piping (or words to that effect).

0 -

Keep it simple …

The bypass is needed for combustion reasons ….. Maintaining a minimum 120* boiler temperature while firing …

I assume there is no zoning , then thermal shock is impossible .

You don't want to heat a gravity up too fast and She is a beast if you over feed her..

There was an error rendering this rich post.

0 -

Extensive piping?….Check! 😂

0 -

@Big Ed_4 said:

"You don't want to heat a gravity up too fast and She is a beast if you over feed her.."

Over feeding? LOL. I've been trying to "starve the beasts" ever since I realized our boilers have 3x the output of the house's heat loss. So far the beasts are on a 1.2 gph diet, but now I'm trying to get them down to 0.9 gph with G115/4's.

0 -

The system was designed for a gravity flow with a hand fed coal burner .The G115-3 , I believe is the smallest 3 pass positive pressure oil fired push nipple boiler on the market.. It would be my choice .

You can use the system bypass to cut down on the flow rate .. . Too much flow you will get radiator bypass ..

Changes in the pass 100 years on the systems pipe work most likely will force you in to using a circulator .. The guys of know were the highest bids :)

To tie in the boilers incase of emergency , pipe the supplies and returns together using 6 valves . You can heat both side most days of the year …

There was an error rendering this rich post.

1 -

I would not bump up the boiler size, it doesn't get you anything. With PS piping and reasonable secondary loop temperature swing an oversized boiler will cycle more than a right sized one, no way around that without increasing the swing. Cycling always reduces efficiency a bit.

The challenge will be convincing the installer to put a boiler they consider way undersized.

1 -

Reminds me of a cold winter night , coldest day of the year . A no-heat call in my early years… I walked in and the lady stated the burner broke down … From outside walking in a 60* house feels warm . .. Coil boiler converted to oil .. She called because the boiler reached limit and the burner shut down.Thought it broke down ..

She wanted a few more degrees so I raised the limit to 165* .. Setting the boiler temperature needed on the coldest of the year …

There was an error rendering this rich post.

2 -

@Kaos said:

"The challenge will be convincing the installer to put a boiler they consider way undersized."

And that's the real problem. If I'm not here to show them pages of actual heat loss data, they'll just go ahead and do whatever they want. So I can make all the fancy plans with a smaller boiler piped P/S, and they will tell the other owners I was wrong and ignore the plan.

So I figure there's more chance that they'll follow a plan with a boiler that's only "one size" smaller (4 section vs 5). The larger size means less of a time lag for heat to the rads, and also that we might not have to do P/S.

"Don't let the perfect be the enemy of the good…"

1 -

-

But the radiators are going to dictate the boiler operating condition. Going larger, if the radiators cannot exchange the energy into the space doesn't make a lot of sense. The more you oversize, the more you will cycle. Unless you have a modulating type boiler. Clever piping doesn't change that.

It's all about the thermal equilibrium, matching boiler output to heat emitter size.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Going larger, if the radiators cannot exchange the energy into the space doesn't make a lot of sense.

Actually, it does make quite a bit of sense in this specific application. Due to the system having 100G of water, it takes significant time to bring the mass of water combined with the mass of CI up to a realistic temperature to provide sufficient heat to the space. In this case, that value is 140F. Once the boiler, the 100G of water, and all the CI reach 140F, the the 'stat will satisfy in short order. The HL can be set at 160F and the system WILL NEVER REACH IT. So, cycling is not a consideration even with the G115/4.

If you use the G115/3, it takes the better part of forever to reach 140F and the additional buffer that it allows is not required.

This specific application has an effective buffer that far exceeds any typical hydronic installation with 1" or 3/4" copper piping and it demands a different approach.

This is one example of how not to size the boiler to the heatloss!

1 -

@hot_rod Just to clarify what I meant about "larger." I didn't mean larger than our existing WGO-5's running at about 1.2 gph input. I meant larger than the smallest boilers that we might install based on envelope heat loss, which would probably be 0.7 gph input boilers like the G115/3 or WGO-2.

We have so much radiation that even with the WGO-5's, the thermostats typically satisfy at 140 water supply temp or lower. So any smaller boiler we install is going to take longer to heat up, and will satisfy at even lower temps.

So by "larger" I meant larger than the "small" G115/3 or WGO-2, for example the G115/4 with an input of 0.90 gph or a WGO-3 with an input of 0.95 gph. Those would still be 25%-30% lower output than our current boilers, and again would typically satisfy with sub-140 water temps.

0 -

Thanks, Eric. Can you give me some more details about your system?

Boiler gross output, radiation type, water volume, circulator, Caleffi thermostat temperature? And is the boiler piped direct or primary/secondary?

0 -

The amount of water in the system doesn't effect boiler sizing. You don't need to bring the system water up to temp, you need to keep it near the temperature where the rad output matches the building load. A modcon does this through modulations, a CI setup needs to cycle on off.

If your heat loss is 25k and your boiler is 50k, the boiler will run at 50% duty cycle. A system with more water will have a longer period between cycles but will still run at the same 50% duty cycle.

Where you can run into issues with high volume setup is if the thermostat has too high of a temperature swing. I've run into this with older mechanical bellows type thermostats where the house needed to cool too much before each heat call. Due to high volume, this warmup phase took a long time so the place was too cold for a while. A simple change to a better thermostat with lower hysteresis fixed it. Burn times were still long enough, radiator temps were much more even and the chill completely gone.

0 -

OK, thanks. Swing is not a problem. Ours are set now at 1.5 to maximize boiler run times for better efficiency and fewer overall cycles. But I can reduce as needed for smaller boilers. And the ecobees I have are very good at eliminating overshoot, undershoot, etc.

I hear what you're saying, but at some point reducing the swing backfires, because then the boiler runs are shorter, with more total start/stop cycles in a season and some efficiency loss. Also, the shorter cycles end in lower water temps, which is worse for the boiler. So I'm struggling to find the right balance.

0 -

-

-

The boiler will reach high limit in winter , and a smaller boiler will deliver more comfort…

There was an error rendering this rich post.

0 -

@EricPeterson I found your thread about the Caleffi 280 here, along with specs and a diagram of your system, so thanks for that informative thread:

I see you have a 115F element that closes fully at +18F, so 133F. That may be closer to what I need, but most of the time my water temp would not get high enough to fully close the bypass.

0 -

I'm afraid the reality is that unless you or I are there to argue with our heating company (preferably you), they would probably not install a G115/3. I guess I could leave a note asking them to install a G115/3, knowing that in reality they'll probably install a G115/4 or /5…

0 -

-

Here's a graph showing how I think a Caleffi 280 with a 115F element would work in our system. The Caleffi would start to close at 115F and would fully close at +18 degrees, or 133F.

A Buderus G115/4 with a Taco 007 on our system would have a delta T of about 10 degrees across the boiler. Most boiler cycles would end with a supply temp in the range of about 135-140F, with a mixed return temp of about 125-130F, and the mix valve between 50% and 75% closed.

By this time, the boiler would have run 45+ minutes, so the heat exchanger would be quite hot regardless of return water temp, and any early condensation would have burned off. So I think the Caleffi 280 would work well for us, as it seems to be for @EricPeterson .

0 -

Yes, the valve starts letting flow out to the system when it meets the temperature based on the sensor temperature you chose. Then complete close off of the bypass when the sensor and differential is met.

If the boiler were sized perfectly, on a design day it will run non-stop, that would be the ideal situation, giving you constant circulation.

That what you can get across a wide load condition with a mod con, by the way. It constantly tries to match output to load. Without needing a mixing valve.

If it were my property….

Two mod cons sized to the calculated load would get you 20-1 turn down, running 90% some of the heating season. So two 80,000 btu/hr boilers could modulate from 8,000 btu/hr- 160,000 btu/hr.

With ODR it could get close to a non stop run condition, which is the ideal condition to run equipment, the least amount of on/ off cycles.

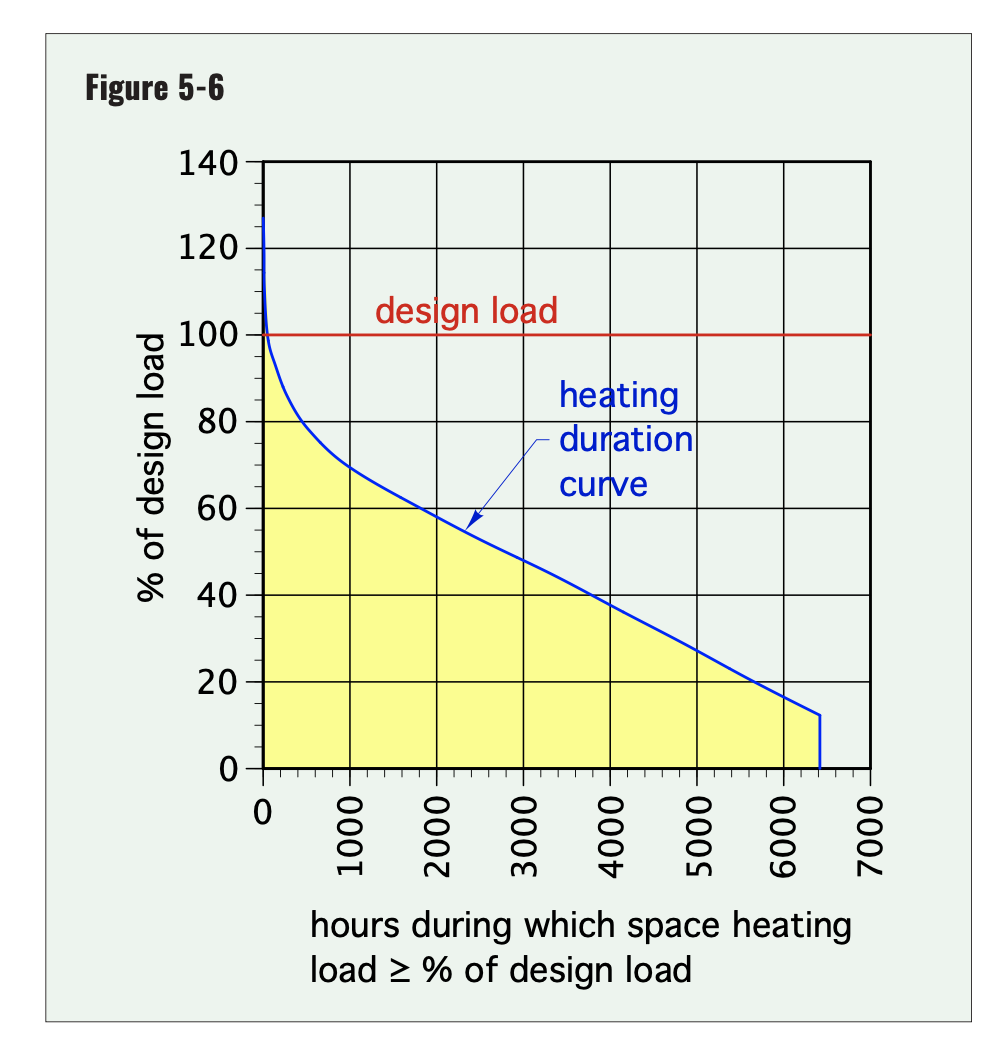

Since you are a graph builder :), grab the weather data and build a graph like this to see where you would be as far as loads throughout the heating season.

This is for the Boston, MA area. which spends about 35 hours at design temperature of 5°!

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Here is the information:

- Boiler is a Burnham ES27 (specs below)

- radiation - three zones (converted gravity system + addition):

- zone1: 9" CI baseboard

- zone2: three free-standing CI radiators, 9" CI baseboard

- zone3: 7" CI baseboard, six free-standing CI radiators

- Grundfos ALPHA 15-58FR circulator

- Caleffi 140F thermostat initially, replaced with 115F (Burnham spec says 110F return temperature)

- water volume: LOTS (radiators spread across three floors plus basement)

- system is piped direct

—Eric

1 -

-

All CI boiler MFGs use a 1.15 PU factor. The system holds a lot of water. They all say to use a larger PU factor if the system contains excessive piping which this system does.

If it were me I would use 2 boilers each sized to 80% of the heat loss and tie the two systems together. On a cold start both boilers would fire then dump the lag boiler at 125 system temp.

1 -

@EricPeterson Thanks for that info.

I think you mentioned that you didn't put a Dirt Mag in, but that you might want one for the Caleffi 280. Has it been running OK so far without one?

Also, because you have several zones, you may have some relatively short boiler run times relative to us. For us a typical run is 45 minutes or so. What is an average run time for you, and what is your typical boiler water temp at shut down?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements