Vent damper opens but doesn't always close, normal? Slant Fin Gas Water Boiler

Slant fin gas water boiler's damper opens reliably but doesn't close after the flame shuts off. I have seen it closed, but when i try waiting for it to close for several minutes after the thermostat and burners shut off the damper did not close.

The damper was over 10 years old, i changed the motor part, nothing changed.

Is it normal behaviour? How long after the burns shut off does it close?

Manual says"

WHEN THERMOSTAT IS SATISFIED OR WHEN HIGH LIMIT, LOW LIMIT, OR LOW WATER CUT-OFF CONTACTS ARE OPEN, VALVE OPERATORS CLOSE, VENT DAMPER CLOSES. CIRCULATOR OFF. SYSTEM GOES TO STANDBY."

Comments

-

What does the other end of the damper cable connect to?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

the effikal damper has 4 wires

some go to Honeywell ignition control, others to the boiler transformer

tekmar 256 controls the boiler ( warms start, the zone control is independent)

when the boiler isn't firing there is no power to any of the 4 wires going to the

damper, no idea how it's supposed to close

0 -

it may have never closed for all i know, discovered the issues after hiring a pro with 30 years of experience with slant fin boiler to fix a failed flame roll out switch, he replaced the original 104Celcius one with a 125Celcius one and half way closed the gas supply ball valve, not sure if this is common practice but definitely seems like a hack

0 -

he replaced the original 104Celcius one with a 125Celcius one and half way closed the gas supply ball valve

get a different service provider.0 -

THIS!!!!

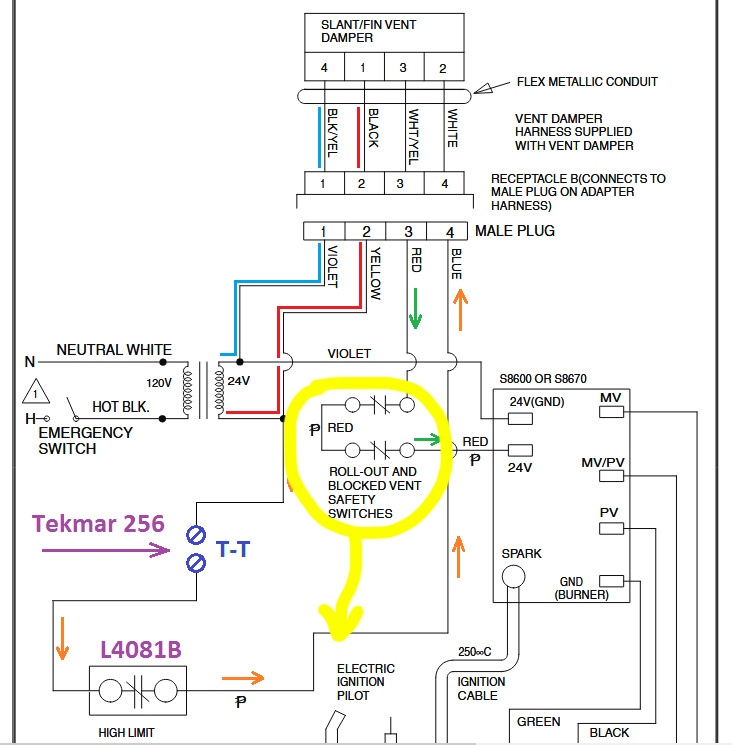

One of the wires- the one from the R side of the transformer- should have 24V on it, this is what closes the damper. Edit- this one should help- the wire colors might be different from yours, but they should be easy enough to trace:

https://s3-us-west-2.amazonaws.com/catsy.782/CGS-A+Pre+2012+IO.pdf

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

If you have a multimeter, this may help.

This may help too. Looks like Black (transformer's C wire) and Brown (transformer's R wire) wires should have a constant 24 VAC across them all the time. A thermostat call for heat connects the the transformer's R wire to the Damper's Orange wire. When the damper opens all the way the 'End Switch' closes supplying 24 VAC to the gas valve (Yellow wire).

I suspect the damper needs the constant 24 VAC across the Black and Brown wires to close when the Orange wire is de-energized.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

it's a trend in Toronto, everyone is demoralized about being a third world country nobody cares,

only thing i can do is to learn the basics myself to be able to even tell who is ok and who isn't.

0 -

1st when adjusting the air /fuel ratio a combustion analysis MUST be performed!

0 -

i don't think the problem is with the effikal damper, it's something with the way boiler was wired originally as i said bad work is all too common in toronto.

when the boiler reaches high limit the on boiler transformer shuts off the power to everything, is that normal? that's why the damper doesn't close

when the boiler is off, and i activate the circulatory via the thermostat which drops the temperature in the boiler, transformers turns back on by the aquastat, the damper DOES close at that point then almost immediately the boiler fires and it open damper again

0 -

agreed, he stuck a probe under the flue cone, measured 14ppm said it was great, signed off the posted the government stickers i don't think that's procedure.

0 -

Yes it's miswired. Opening the high limit should shut off the burners and send the close signal to the damper (or interrupt the open signal), but not shut off power to the damper motor.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

If you provide the Boiler's model and the model of the Effikal damper we may be able to better assist you with more accurate wire colors and their functions. It seems there may only be one wire misplaced. The constant power to the damper.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Boiler model is GG225HXPED

Above is the install manual (wire colours match on the damper), Page 25, left diagram is the closest match to my install, sans the constant circulation. I'm not good at reading diagrams at all.

The way it's connected is:

Water cutoff > High Limit > 24V transformer > (ignition control, gas valve, damper etc)

It's been a warm day, the boiler hasn't been hitting high limit, keeping the 24v transformer ON, and the damper closes just fine.

When it's colder and the boiler hits high limit, it kills the power to the transformer until the temperature drops below the high limit then power to the transformer is restored again and the damper closes.

Maybe it's by design to cool down the boiler?

0 -

Using the Left diagram on page 25, the Damper should have constant 24 VAC only interrupted by the emergency switch or the building's circuit breaker. This constant 24 VAC goes to the damper via the wires annotated by the Blue and Red tracer pins 1 and 4 at the Damper.

The thermostat and high limit should not interrupt the Damper's power at pins 1 and 4 at the Damper. The thermostat and high limit should interrupt pin 2 at the Damper (Orange arrow). Once the 'End Switch' is closed (Damper all the way open) the 24 VAC is passed on to the '24V' terminal of the S8600 (Green arrow).

I would suspect the Yellow wire (Pin 2 Male plug) is going to the wrong place, it should go to the transformer.

If I had to guess the Yellow wire (Pin 2 Male plug) is going to the same place as Blue wire (Pin 4 Male plug). So if either the thermostat opens or the high limit opens all power to the damper is disconnected, causing the incorrect behavior.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Wow, you're definitely much better at diagrams than me.

My boiler has the high limit wired in place of the emergency switch on this diagram, the high limits shuts everything off past it, that's the main issue the pins on the damper must be ok, because it works as long as the high limit isn't reached.

Isn't the Honeywell L4081b (my hi limit) a 120v device? according to the diagram it should work on 24v

the high limit on the diagram is basically what tekmar 256 does, it also has a high limit, this diagram doesn't specify where the Honeywell high limit / aquastat fits into the diagram.

0 -

OK the L4081b does complicate things.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Do you also have the RA832A or a relay that controls the circulator ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

No RA832A relay, I have Taco sr504-2 controlled by Ecobee.

Taco doesn't trigger the Tekmar 256 (it's in warm start mode with a jumper)

0 -

Well since you are not using the Low Limit function of the L4081B and it is not involved with circulator control. Yes you could raise it higher than the Tekmar 256 or do a slight rewire so it is not on the primary side if the transformer. Wire it in where the boiler's wiring diagram shows.

Since the Tekmar 256 sensor may not in an immersion well in the boiler and is basically an outdoor reset control and not a safety limit device and since the L4081B is a safety limit and also limits the maximum boiler temperature (economy), I would leave the L4081B set where it is and rewire it in where the boiler's wiring diagram shows. This provides the best economy, the boiler can't go 10 degrees higher and the Damper functions as designed all the time, since it will have uninterrupted 24 VAC.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I'm kind of wondering why the L4081B used as the high limit was wired away (changed) from the factory wiring in the first place. Is there another high limit sensor ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

" the high limit on the diagram is basically what tekmar 256 does, it also has a high limit, this diagram doesn't specify where the Honeywell high limit / aquastat fits into the diagram. "

Isn't the Tekmar 256 connected to where the "24V thermostat or controller" is ? The high limit is wired in series with this part of the circuit (just below the "24V thermostat or controller" on the diagram).

Page 18 shows one version where the L4081A and a Damper is used.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

" Taco doesn't trigger the Tekmar 256 (it's in warm start mode with a jumper) "

Is the boiler also used for DHW ? If not why the warm start mode ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

no idea, it's been like this for the 10+ years of my ownership

0 -

Tekmar 256 is connected to the TT terminal on the boiler.

0 -

Thought of one possible way to make it all work.

Taco Sr502-4 actually has inputs for an aquastat ZC and ZR (normally there is a jumper there)

Can connect L4081b to SR502-4, and SR502-4 to Tekmar 256 switching it from warm start to cold start. So the Tekmar should turn off the burners if the aquastat hits the high limit.

Warm start has worked for years without any apparent sign of boiler corrosion

even though the return temperature is possibly not perfect sometimes,

am i going to make things worse switching to cold start?

Single pipe system with cast iron baseboards.

Is this a hack or a good way to do it? Is there a better idea?

0 -

If you are not using the boiler to also heat DHW (Domestic Hot Water) the warm start may be inefficient as far as fuel consumption during parts of the heating season. There are other ways to minimize boiler condensation corrosion.

With a L4081A the Lo-Limit contacts simply bypasses the normal thermostat to keep the boiler warm for DHW purposes.

With the L4081B the Lo-Limit contacts disables the circulator(s) until the boiler achieves a minimum temperature. This could be used to minimize boiler corrosion without having to keep the boiler warm all the time.

Since you are only presently only using the High-Limit part of the L4081B, I would not use the ZC / ZR terminals on the SR502-4 for a High-Limit functionality, since I believe that would only disable the circulators and not shut down the boiler. The ZC / ZR terminals in concert with a Lo-Limit aquastat disables the circulators until the boiler temperature comes up to a certain minimum temperature.

" Can connect L4081b to SR502-4, and SR502-4 to Tekmar 256 switching it from warm start to cold start. So the Tekmar should turn off the burners if the aquastat hits the high limit. "

In this case, if the Tekmar 256 looses control there would not be any High-Limit to limit the boiler temperature.

Since the L4081B is a safety device I would have it wired as close to the boiler as possible, like where the wiring diagram presently shows the High-Limit.

To restore proper Damper operation I would disconnect the L4081B from the primary of the transformer and connect it basically in series with the TT at the boiler.

I suspect your Boiler's TT looks like this, since the High-Limit is presently elsewhere and the thermostat as far as the boiler is concerned is the Tekmar 256.

Presently, I suspect;

Change to;

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

was the rollout bad? 1st I would see if any obstructions in the heat exchanger (brush out) or if the burners are rusted out. Get the CORRECT temp rollout for boiler. Then check gas pressure and combustion readings. I would be way more concerned about this than vent damper closing all the way. As long as opening properly before burner starts is the main concern.

0 -

L4081 is 120v, can I use it on the 24v T T circuit or do I need to buy 8148E instead?

0 -

Rollout was bad, I put in the correct one now. Heat exchanger looks ok. Burners were slightly dirty I cleaned up. Season is almost over will seek someone competent for a checkup before the next season.

The guy who put the wrong rollout and closed the gas valve is something else.

I heard a noise and saw there was a pulsating flame in one of the gas supply orifices outside the combustion chamber due to insufficient pressure I guess. Turned the valve back on.

Do I talk to him or report him ? He did reckless work, and he's been around long enough to know better.

0 -

Since it is rated for Millivolt systems to 240 VAC it should work fine at 24 VAC.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Did he check gas pressure and combustion. Did he tell you that he put roll out in temporary until he can get right one? I would maybe talk to him first and see what he says. If that is not satisfactory up to you if you want to take further action.

0 -

we all make mistakes and how we deal with them speaks volumes.

I don’t feel closing a gas valve falls under making a mistake.

it’s your call!0 -

didn't check gas pressure. stuck a probe under the flue dome/hat (not in a drilled hole), measured 14ppi.

not temporary. he offered 2 option for the sensor, when with a reset button another that look like oem which i chose thinking it was oem.

called him specifically because he advertised himself as "slant fin specialist"

he didn't seem like it was off day for him, just the way he does things.

not one to waste my time trying to get him in trouble, but it's very sad such things happen where safety is a big factor

0 -

109A_A huge thanks to you! this is a 225,00BTU boiler in an ~400sq ft space heated only by the boiler and supply / return pipes, it was pretty chilly in there in the winter, looking forward to the next season to see if i notice a difference in that room and on the bill.

it appears we got the wrong diagram, although the wires seems to match in colour my safety and rollout switches are as pictured and not on the wire going from the red wire going to the ignition control module.

does that make any difference?

after i connected everything i tested that the boiler still shuts off on the high limit, which it did and the damper now closes just fine when that happens.

0 -

If it was up to me and it was my boiler, if possible I would have all the Safety Limits just before the 24V terminal of the 8600 (see below). Only for the reason if something weird happens inside the Damper (since it has its own 24 VAC source) all the Safety Limits are still in play. The Boiler's manufacture may have their own reasons like using less wire. Basically if all the safety Limits are wired in series opening any one of them should cut the power to the burner. The liability folks would say wire it as the manufacture designed, if something bad happens, it is on them.

The other thing to consider is the way it is now the L4081B apparently opens first before the Tekmar 256 High Limit. Moving the L4081B to the way shown below if the L4081B opens first the Damper won't close. So there are tradeoffs.

Dampers are said to reduce fuel consumption 1%, seeing this in your bill may be hard unless you also include heating degree day data in your comparison, I'm not sure if Environment Canada tracks the weather that way, I imagine they would.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

With the equipment you already have, adding the gray wires detailed below may give you better heating season economy. The boiler will not be kept at a minimum temperature (saving fuel) and to minimize condensation the circulator(s) are disabled until the boiler is at or above the minimum temperature. If you don't like it, it is easy to put back the way it was. The ZC, ZR, Low Limit circuit is 120 VAC wiring, the L4081B Jumper needs to be removed if it was installed.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Like i said i wired in the the L4081B on the blue wire (4) going into damper right after Tekmar 256 , roll out and blocked safety are on the same wire. They are NOT on the red (3) wire coming from the damper going into S8600, did someone royally miswire the hole thing? Should the roll out and blocked vent absolutely proceed 24V into s8600 as pictured?

So the safest way is to either have L4081B cut the power to the 24V transformer the way it was originally or the way your diagram depicts in series with the other 2 safety switches preceding s8600 at the expense of the damper, correct?

Seemingly ever time i check, the boiler is at the high limit, which is the root cause of the damper problem.

Tekmar 256 minimum is 130F target is 150F (There is no explicitly set high limit)

The issue is that the temperature where the tekmar probe is installed is a lot lower than boiler temp when the pumps aren't running which kick in the high limit all the time.

Should i address that and how?

(more insulation, moving the sensor closer, switching to cold starts to stop Tekmar from firing unless the pump is running)

0 -

Looks very neat and solves the problem with over heating (posted that before your new post).

Any downsides to wiring it that way as opposed to the way i have it now?

I like doing things right and once, can i purchase new equipment to make it even better / simpler ?

0 -

I would wire the Roll-Out and Blocked Vent safety switches as all the wiring diagrams show, which is between the Damper (Male plug Red Wire) and the S8600 24V. The High Limit between the one T-T terminal and the Damper (Male plug Blue Wire). This appears to be best practice giving best overall usable functionality and economy. The other wiring methods introduce other dysfunctional issues as you have seen.

Loosing 24 degrees in 3 feet of pipe is a good example why the true High Limit needs to be in an Immersion Well in the boiler, not down stream on a pipe. The Tekmar is a control device to enhance economy and not a High temperature safety limit.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

If you have not I would review, verify the wire colors at the Damper connectors and its pins to verify it all lines up correctly. It probably does and again I have no clue why someone would wire the Safety Limits different than the manufacture's documentation. Again if they (the Safety Limits) are all wired in series (as they should be) High Limit, Damper End Switch, Roll-Out and Blocked Vent safety switches. If any one of them opens the burner should shut down.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements