Steam pressure control

So I was home today for a change, and noticed more hissing from the upstairs vents than usual. It's been pretty cold, so the system was at full steam, and when I went down to check the pressure was up to 3 PSI. I figured that would kill the vents so cycled the boiler off manually. Apparently the pressure cut off that came with the boiler isn't sensitive enough to stop at 2 PSI. Can an ordinary homeowner change this gizmo out for a more sensitive one? Do I even have the right one identified?

Comments

-

Here's the controller model.

0 -

The scale on those controls is inaccurate….they all are. Take the cover off the control and set the white wheel inside to 1 psi. Set the scale on the outside with a screwdriver as low as you can go.

Caution you have to try this. If you go to low you may back the screw out of the control or if the pressure setting is too low the boiler may not fire.

make small adjustments at a time.

2 -

I should have searched better first. In a different thread was the advice to open it up, set the inner wheel to 1, and then use the screw to drop the cut-in all the way to the bottom. So I did that and will report back later.

0 -

Two other comments: that 0 to 30 psig gauge is required by code — but is almost useless for figuring out what a boiler is really doing. I would add a 0 to 3 psig gauge somewhere — the easiest thing to do is to mount it above the existing gauge in much the same way, and then the pressuretrol on top of that.

And while you are doing that make sure that the pigtail — the pipe going from your gauge and control into the boiler — is clear.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

question, I was always taught to have a gauge at least double what your testing for best accuracy. This was a general rule of thumb for plumbing applications not steam boiler obviously. Wouldn’t you want a gauge a little higher then 3 in case the pressure spikes so you know it’s over 3 & maybe have an issue with the pressure troll

0 -

Good practice would say yes. Many people put a valve on the gauge, to protect it. And "accurate" gauges are out of the price range of many of the folks who make a hobby out of this. A cheap gauge reading in their expected range with Chinese accuracy is sufficient for their use.

Remember that most all small systems are operated at a pressure of 1-1/2 pounds or less.

2 -

Can an ordinary homeowner change this gizmo out for a more sensitive one?

A handy homeowner could change it out for a vaporstat, a device by the same company that costs a lot of money and operates at a lower range of pressure.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

A new control may not give you any better accuracy. A Vaporstat will, but the improved accuracy will only be cost effective if your boiler is grossly oversized and/or regularly cycles on pressure.

Follow Jamie's advice if you want to improve the accuracy and lower the operating limit of your boiler. Then if you can't get the control to ycle at a lower pressure, and still want to do that, look at Paul's suggestion to install a Vaporstat.0 -

Good advice. A valve on the gage is great for service and as you say, for protection. Turning the valve off to protect the gage?

However this might not be protection. Go one step further and install a brass pig tail below the gage and fill the pig tail with water during the install. This will protect the gage from steam damage and allow you to get a reading at any time. This is what a pig tail is for. To protect controls from steam flashing into the control. Does steam always cause damage? No. The steam will turn to condensate in the pig tail during use. That water will also protect the gage. That one step further, by adding water, is the most thorough way.

1 -

A gauge like this?

0 -

That gauge should work. While adding it with a Tee under the pressuretrol with a valve and a elbow to the new gauge, also make sure to not forget to verify the pigtail all the way back to the boiler is not blocked or plugged up as advised previously.

If the pressuretrol can't monitor the boiler's pressure it can't shut off the burner to limit the pressure.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

What's the valve for?

0 -

If for protection as said a couple of time in the thread, would I only open it when I want to read the gauge? If so, won't that be when the boiler is at max pressure and temp? So what is is protecting against?

0 -

You could open it slowly. With a system that should not go over 1.5 PSI a 3 PSI gauge should have some margin for error. And if the 0-30 PSI gauge is reading greater than 3 PSI just don't open the valve, no valve, no protection at all.

Personally I use a Dwyer Magnehelic Gage which is more expensive, even used or NOS, than the 0-3 PSI gauge mentioned above. The Dwyer Magnehelic Gage which displays in inches of water column yet it is rated to tolerate up to 15 PSI so I don't worry about it. My system never goes over 0.072 PSI (2 inches of water column) anyways. 1 PSI = 27.68 inches of water column.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

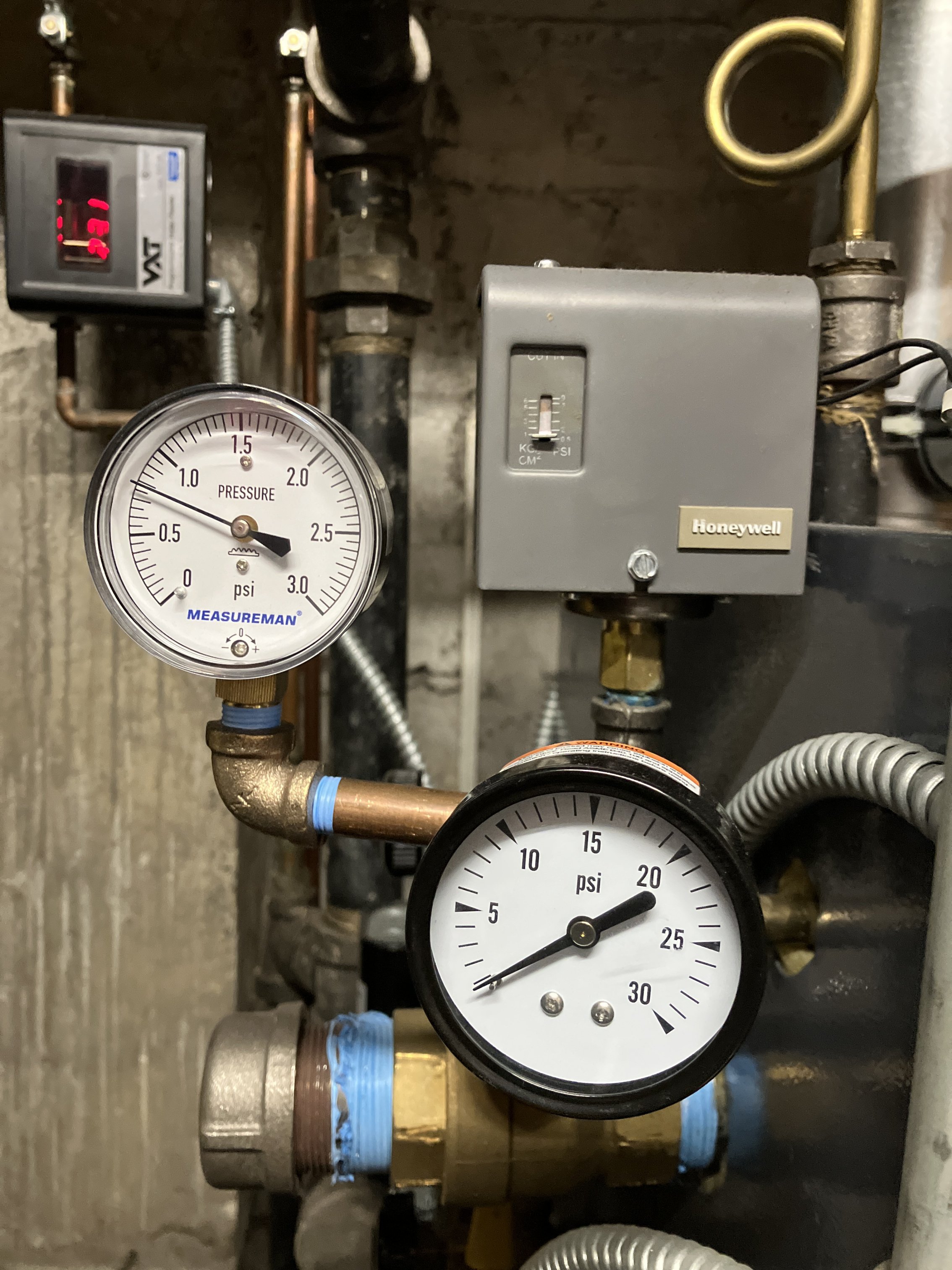

I finally got the gauge in place and working:

As predicted, when I turned the screw all the way down it popped out and I had to re-thread it to get the boiler to start again. So that's as low as it will go — and it still didn't trigger at 2 PSI.

I guess I'll need a vaporstat after all? This would explain why my radiator vents don't last more than a couple of years.

0 -

I am also interested in swapping out my pressuretrol for a vaporstat. Is there a recommended one (model number)?

0 -

https://www.supplyhouse.com/sh/control/search/~SEARCH_STRING=Vaporstat

Supply House seems to have two general series — one that goes up to 1 PSI (and which a comment says is "knucklehead proof") and the other up to 4 PSI. Unclear what the difference is between the two models in each series.

0 -

Did you verify the pig tail clear ??? If it is blocked it does not matter what pressure switch you have on there, it won't work.

The difference is the pressure range and the maximum pressure.

With a quick look I'd buy this one L408J1009, but maybe clean out the pig tail and buy nothing.

EDIT: Actually if the new gauge is after the pig tail the pigtail is probably clear. I just looked at the other pictures in the thread.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

What number is on that VXT ? Looks like a lot of water.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

It's 231. The first year we went through a lot until I replaced all the vents, tightened leaky valves and connections, then skimmed the boiler. This season started at 223 in November.

And yes, I cleared the pigtail with a long zip tie when I installed the new gauge. I suppose just the pressuretrol could be clogged, but that seems unlikely, it's at the top of the stack and gravity would be against it.

0 -

-

-

Last season it was 28 total from mid-October to mid-May. So yes, this is about double that rate. I am hoping it will calm down, as it did that second year.

0 -

Thank you so much for this! My system rarely runs long enough to build up beyond 1 PSI, so if I can get the pressuretrol to behave it will be good enough.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements