Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Need help with an underfloor radiant system using a tankless water heater.

Options

Parknride

Member Posts: 10

First and foremost I joined to gain help with a particular project. I hope I'm not offending anyone with this situational post. Unfortunately I'm really struggling. Well for anyone that can help here is the issue.

The project is a 5 loop, single zone, radiant floor heating system. Each loop is approximately 300 ft for approximatley 1500 feet of 1/2 pex tubing.

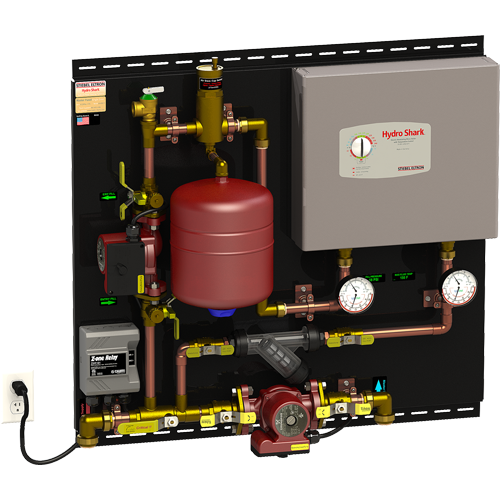

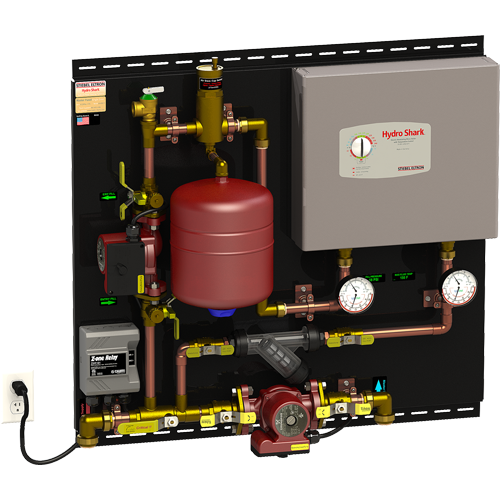

The boiler is a Eco smart 18kw tankless water heater. The system is based on a hydroshark radiant floor system using a primary and secondary loop. There are two pumps (Taco 007s)

The issue is that the tankless water heater will not stay on. If i engage the pumps it will turn on for a short while, before it stops working and turns off. It feels like the water heater is not getting enought flow to continue activating.

I have tried both pumps on with the closely spaced tee open (This was how the system was designed to work)

Both pumps on with the tee closed (This has worked the best and the system had remained on for maybe 15 minutes before the water heater stops turning on)

Either pump on with tee either open or closed.

None of these scenarios changes the outcome.

I have bled the system numerous time, running the system on a 1/2 horsepower pump past the pointer where any bubbles appear in the system.

When I was doing this, I accidentally left the tankless heater on and realized that It was continuing to run for as long as the bigger pump continued to circulate the water. In the bleed setup, I am in essence bypassing the system pump and filling the system below this pump and having the system drain above it.

I pressurized the system to approximatley 18 psi.

Any ideas would be greatly appreciated.

Thank you.

The project is a 5 loop, single zone, radiant floor heating system. Each loop is approximately 300 ft for approximatley 1500 feet of 1/2 pex tubing.

The boiler is a Eco smart 18kw tankless water heater. The system is based on a hydroshark radiant floor system using a primary and secondary loop. There are two pumps (Taco 007s)

The issue is that the tankless water heater will not stay on. If i engage the pumps it will turn on for a short while, before it stops working and turns off. It feels like the water heater is not getting enought flow to continue activating.

I have tried both pumps on with the closely spaced tee open (This was how the system was designed to work)

Both pumps on with the tee closed (This has worked the best and the system had remained on for maybe 15 minutes before the water heater stops turning on)

Either pump on with tee either open or closed.

None of these scenarios changes the outcome.

I have bled the system numerous time, running the system on a 1/2 horsepower pump past the pointer where any bubbles appear in the system.

When I was doing this, I accidentally left the tankless heater on and realized that It was continuing to run for as long as the bigger pump continued to circulate the water. In the bleed setup, I am in essence bypassing the system pump and filling the system below this pump and having the system drain above it.

I pressurized the system to approximatley 18 psi.

Any ideas would be greatly appreciated.

Thank you.

0

Comments

-

There’s a lot going on here.1. That’s a large heater for only 1500 feet of tubing. I’d probably expect something half that size or less. How did you arrive at that size?

2. You used something not built for central heating as a central heater. A tankless DHW is typically used for heating water that’s at 60+PSI. Your 007 cannot do that. Nor do you want the pump that can! In a closed system you can use low pressure - like 18psi, but even less would work. I think the surest way to fix this is to remove the Ecosmart and replace it with an electric boiler not an electric domestic water heater. You might not even need the primary secondary piping with a boiler - which would clean everything up and save you operating costs.For example, this boiler has almost no head loss, so moving ~2-3 GPM through it is easy, you could use something much smaller than a 007.1 -

Just off thee top here, first thing I'd look at is the flow through the tankless heater. They aren't designed to be heating boilers, and they don't like high return temperatures and they have a very high head loss. They're great for heating your shower... but not your house.

You may be able to recover the situation with much higher head pumps, to force the flow through the tankless heater and the system to get the return water temperature down to where the heater will continue to operate and at the same time keep the temperature it rises to down.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Thank you for the responses. This system is based on the hydroshark and they recommend a pressure around 18-24 psi. I'll see if I can link a picture. The tankless boiler is designed to turn on at about .25 gpm of flow. also in the times, i get the system to run, the input temp to the manifold rises to 120 degress and the return that enters the tankless water heater is around 65 degress.0 -

-

"Based on the Hydro Shark."Parknride said: Thank you for the responses. This system is based on the hydroshark and they recommend a pressure around 18-24 psi.

Thank you for the responses. This system is based on the hydroshark and they recommend a pressure around 18-24 psi.

I'm not familiar but it seems Hydro Shark offers an electric boiler while you opted for an electric water heater. So, you missed the most important part.

So, you missed the most important part.

We see this a lot here.

Unfortunately you put the cart before the horse here.

3 -

Thanks for your replies.0

-

-

A tankless water heater has a flow meter which it used to PWM the heating elements while simultaneously monitoring the inlet and outlet temps.

There is too much restriction for a hydronic circulator to overcome. As well as a water heater usually has plastic and is designed for intermittent use. A boiler is designed for low restriction and continuous use.

I've seen this before, a guy thought he'd save a pile of money and used a 40 gallon electric water heater to heat his new garage radiant floor... well the water heater's thermostat melted after the first winter, and his electric bill was so high he removed it. And....you guessed it, put in a standing pilot propane water heater instead. 60% efficiency on a radiant floor.... couldn't convince him that a condensing boiler would pay for itself in a couple of years in propane savings alone.Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0 -

Thanks for everybody who chimed in. The consensus seems to be go with an electric boiler, of the appropriate size. I'll beging looking to source that and go from there. It's actually for a rental property and I have other means of heat until I get this up an running. I may go with the hydroshark 14kw as it appears to line up with my heating needs.4

-

And if your not sure of something, come here before any work is done and ask. I probably won't have the answer on design and installation, but a lot of great people here do it every day and they've seen just about everything. So to reiterate; horse, then cart.Parknride said:Thanks for everybody who chimed in. The consensus seems to be go with an electric boiler, of the appropriate size. I'll beging looking to source that and go from there. It's actually for a rental property and I have other means of heat until I get this up an running. I may go with the hydroshark 14kw as it appears to line up with my heating needs.0 -

-

Thank your for your reply. I did think it would work as plumbed. It's primary / secondary and should generate enought flow to activate the "boiler". I understand that the closely spaced tee should be closed for filling and purging. I did do this with a 1/2 hp pump. I filled, pressurized and then opened the air bleeder. I then repeated the process until no air exited the bleeder with a static pressure of 19psi. I then ran the system with the closely spaced tee open. The pumps circulate the fluid fine and the pressure maintained a static pressure of 19 psi. Unfortunately the boiler will not activate in this configuration, it's like it isn't receiving any flow even though it's supposed to turn on with a flow of .25gpm. Here is a picture of my manifold flow meters in this configuration (closely spaced tee fully open and both circulator pumps running).rick in Alaska said:Well nobody else has said it so I will. If you are running it with the valve between the closely spaced tees closed, it won't work. You need to have it open.

Also, I know this isn't the "proper" setup for heating, but it should work just fine when you get everything flowing right.

Rick

0 -

See if any flow is making it through the boiler. I’d be surprised if more than .25gpm was.0

-

How would I check that? As a side note, you must be right because it won't turn on. If I use the 1/2 horsepower to purge the system, the "boiler" turns on without issue. Clearly these pumps aren't capable of overcoming the bottle neck the heater represents.Hot_water_fan said:See if any flow is making it through the boiler. I’d be surprised if more than .25gpm was.

0 -

You could have flow meters on the boiler loop. Either way, you know the problem - wrong appliance.0

-

Not too surprised that the normal circulating pumps can't over come the bottleneck as you call it of the tankless heater. A heating boiler at normal flow rates might have a head loss of a few feet -- 5 or 6 psi, maybe. A tankless water heater will have a head loss at the same flow of 20 to 50 psi...Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I'm back. I spoke to a representative from radiant made simple and he speced out a thermolec 11kw electric boiler. He indicated that there should be significantly reduced pressure drop through this boiler. My question is, can I just plug and play the boiler in for the tankless water heater? He suggested that the primary secondary system should not be necessary, but does leaving it in place have any advantages or downsides. Thanks for your time.0

-

There is no harm in leaving he primary/secondary setup."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

Hello all,

I'm beginning the wiring stage of the Thermolec Boiler. I wanted to reach out before I began the process. I have a Taco SR 501 that I was using with the tankless water heater. I've noticed that the Thermolec boiler has its own Thermostat connection and has a relay for the circulating pump. A couple questions? Should I use the Taco SR 501 or just connect the Boiler to the thermostat and the pump relay to my primary and secondary pumps? Or should I use the SR 501 with N/0 6 and 5 com connected to the themostat connections of the boiler and the circulators connected to the hot and neutral of the SR 501? Thanks for your input.0 -

Can you post a pic of the wiring diagram?0

-

A single zone system? Just use the relay in the boiler to start the circ, as you suggested.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Just take your end switch wires from the XX terminals in the SR501 and run them to the thermostat terminals in the Thermolec. All done. The pumps should already be wired through the switching relay, so nothing else needs to change besides that end switch wiring. Leave the pump contacts in the Thermolec empty.0

-

Thanks! This worked perfectly.GroundUp said:Just take your end switch wires from the XX terminals in the SR501 and run them to the thermostat terminals in the Thermolec. All done. The pumps should already be wired through the switching relay, so nothing else needs to change besides that end switch wiring. Leave the pump contacts in the Thermolec empty.

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements