Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Oil to gas retrofit/ tune to max efficiency

Options

griffinbr

Member Posts: 7

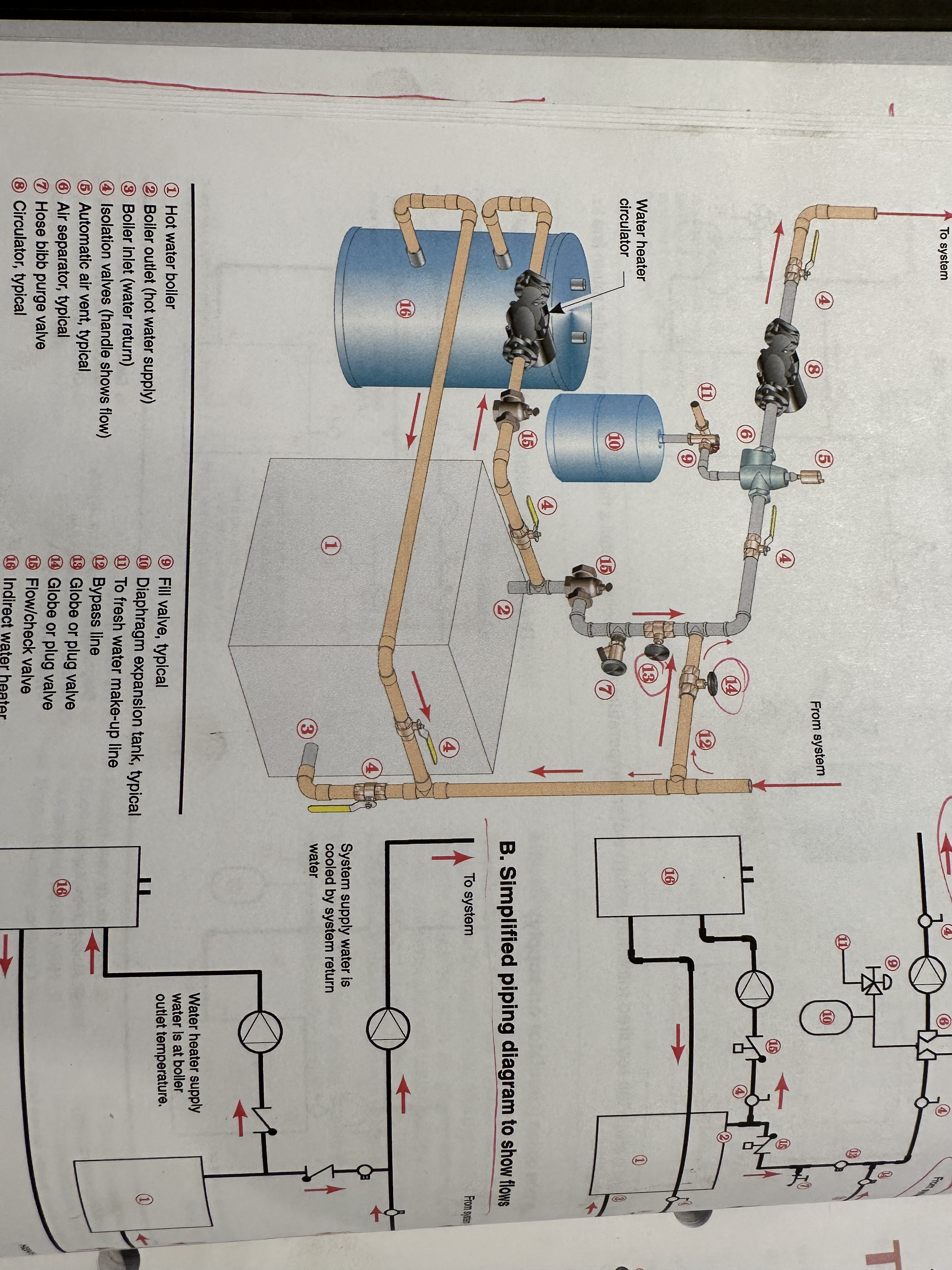

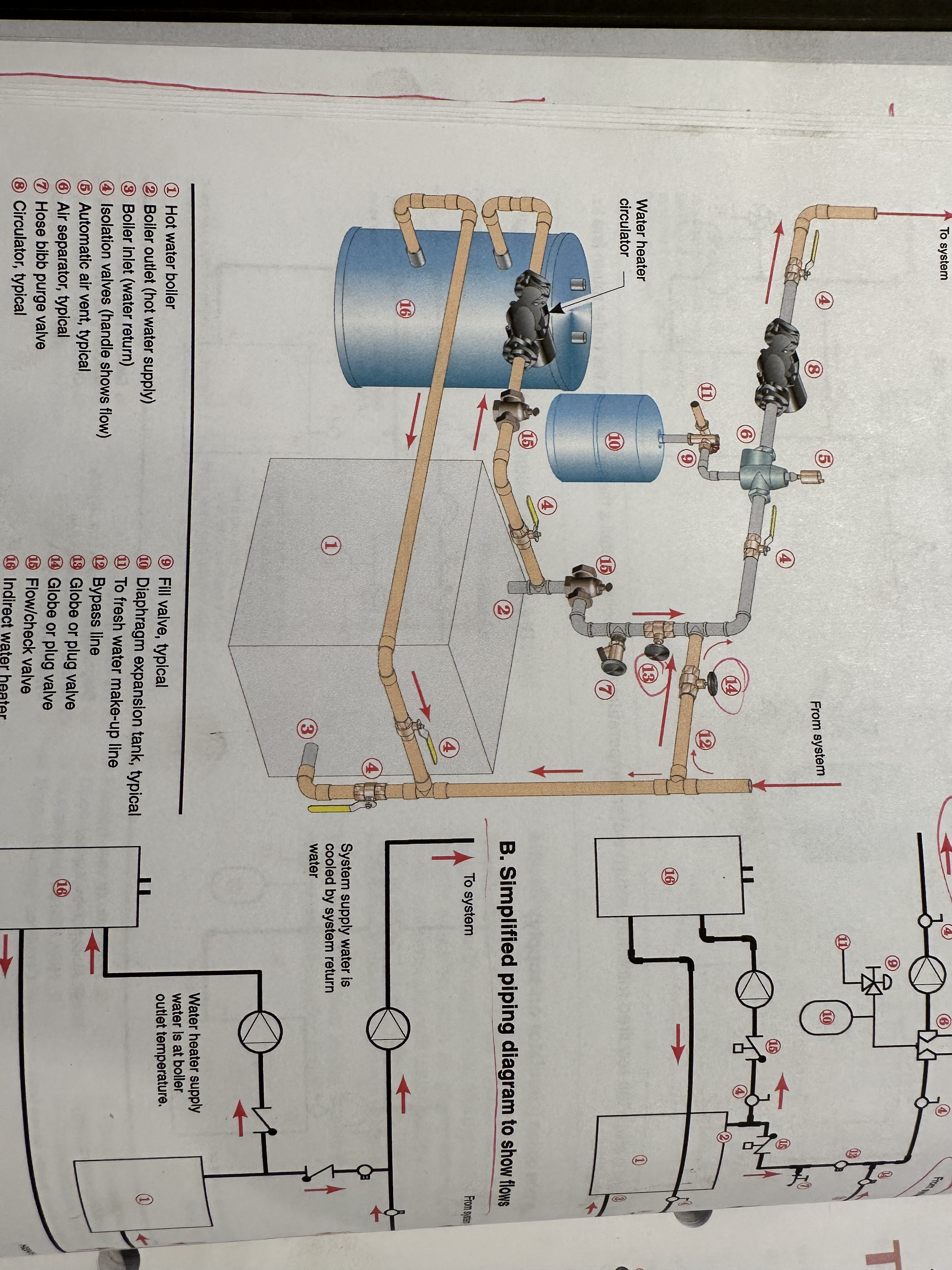

Top of the morning everyone been following Dan Holohan and I am a fan! Love hydronic’s !!..I am planning on adding a boiler buddy or buffer tank not sure if anyone has any other ideas that would be more cost effective…? but wanted to get any direction on how I can have this 300 PB purefire running most efficiently, should I change the piping to go directly off of the boiler to the indirect, like in the IBR photo?

. The delta T with just the Indirect is 30, with firing rate turned down down. Using a three speed GF circulator. Not sure if I should pipe indirect Like the photo IBR references? Any feedback would be greatly appreciated.

*

*

. The delta T with just the Indirect is 30, with firing rate turned down down. Using a three speed GF circulator. Not sure if I should pipe indirect Like the photo IBR references? Any feedback would be greatly appreciated.

*

*

0

Comments

-

-

-

0

-

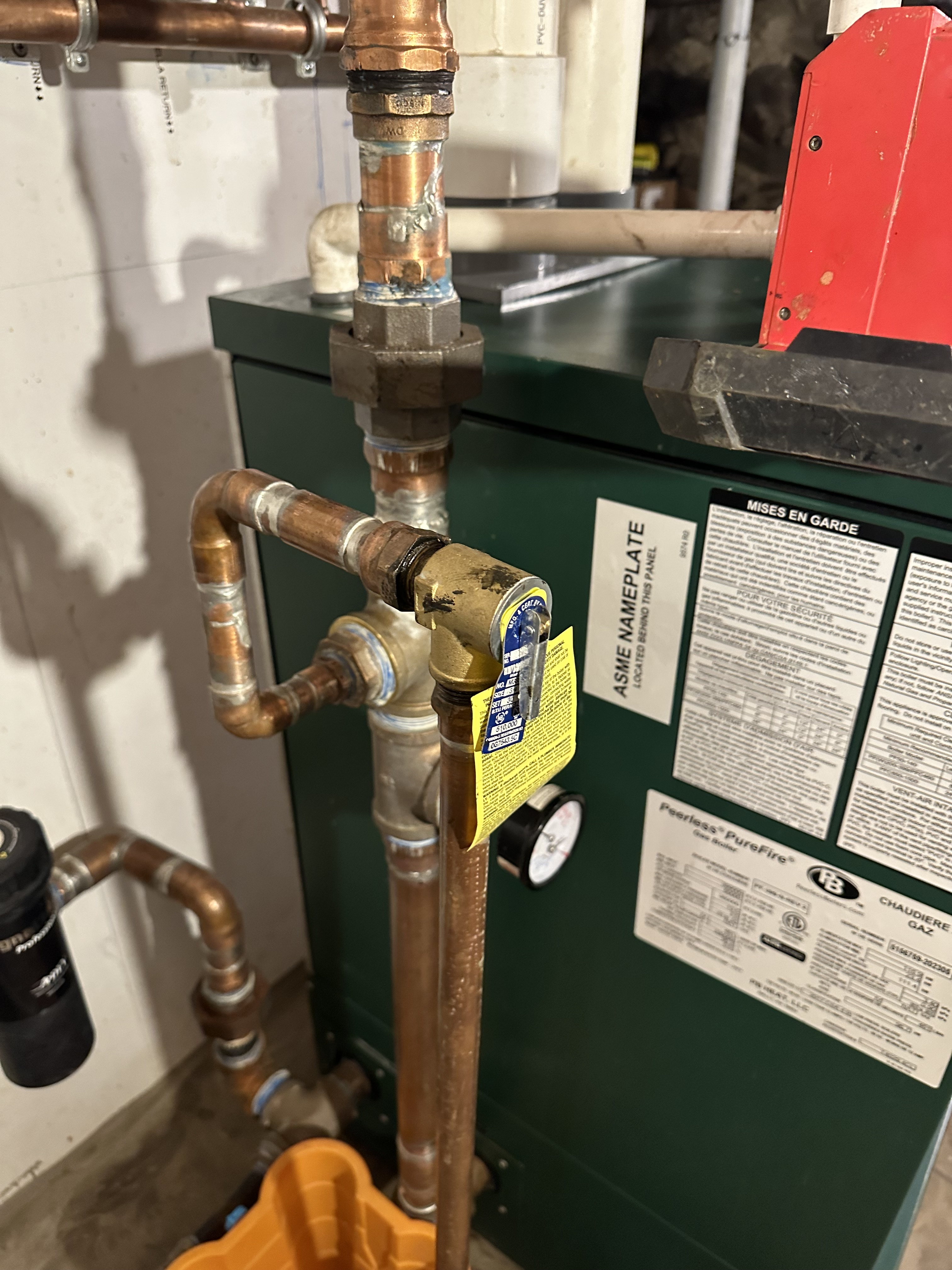

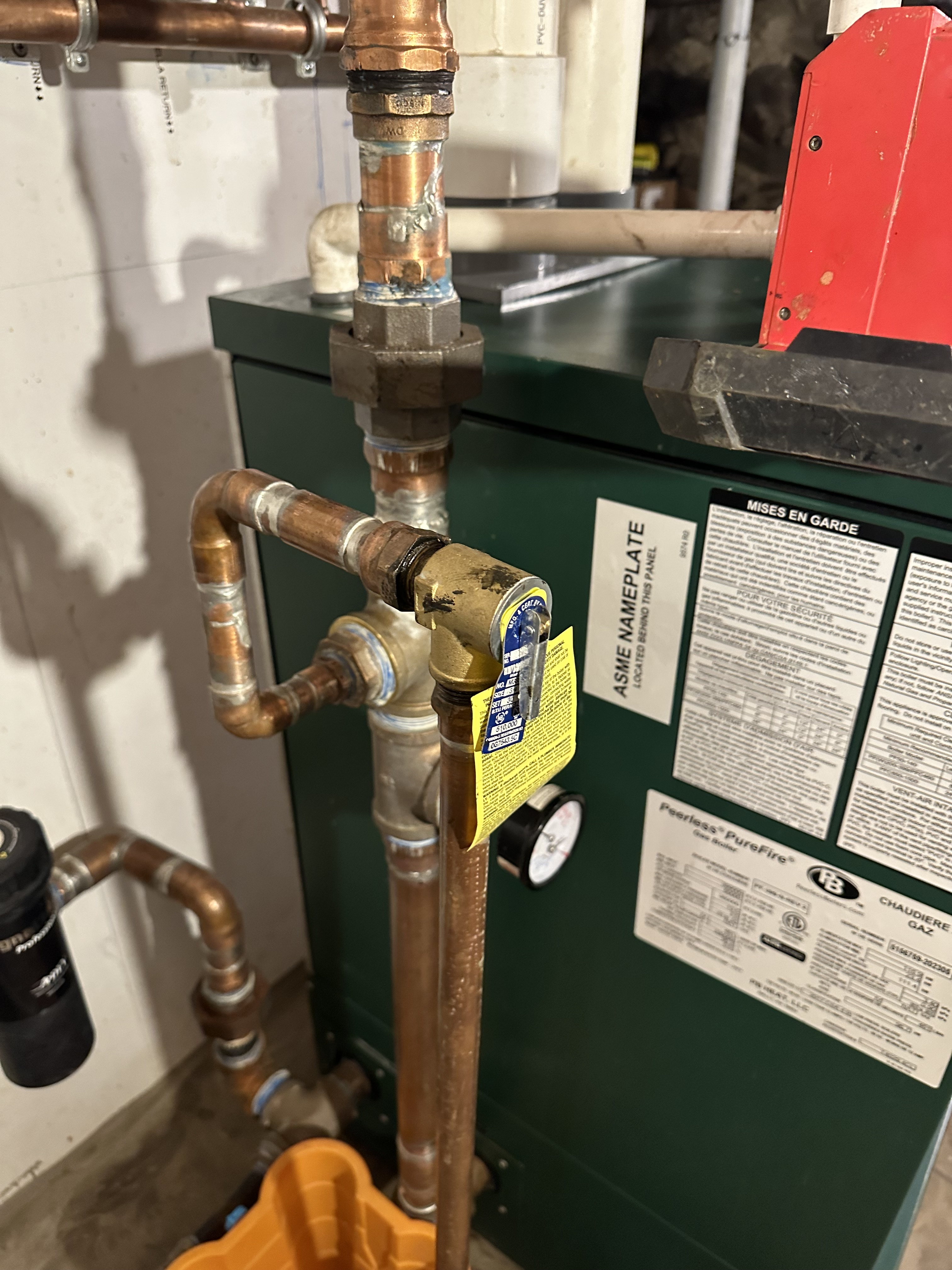

So the manual specs have the pressure relief valve mounted on the return side for pf300 and 399*?(

So the manual specs have the pressure relief valve mounted on the return side for pf300 and 399*?(

Little confusing) however, these differ from the other one *this PB pf300 is a rev2 does anyone know if that means safety relief valve should be mounted on the return side?

0 -

-

If the goal is to lower fuel cost, start with the efficiency if the structure.

Next operate the boiler at the lowest, safest temperature.

Short cycling kills efficiency, ODR can help with thatBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

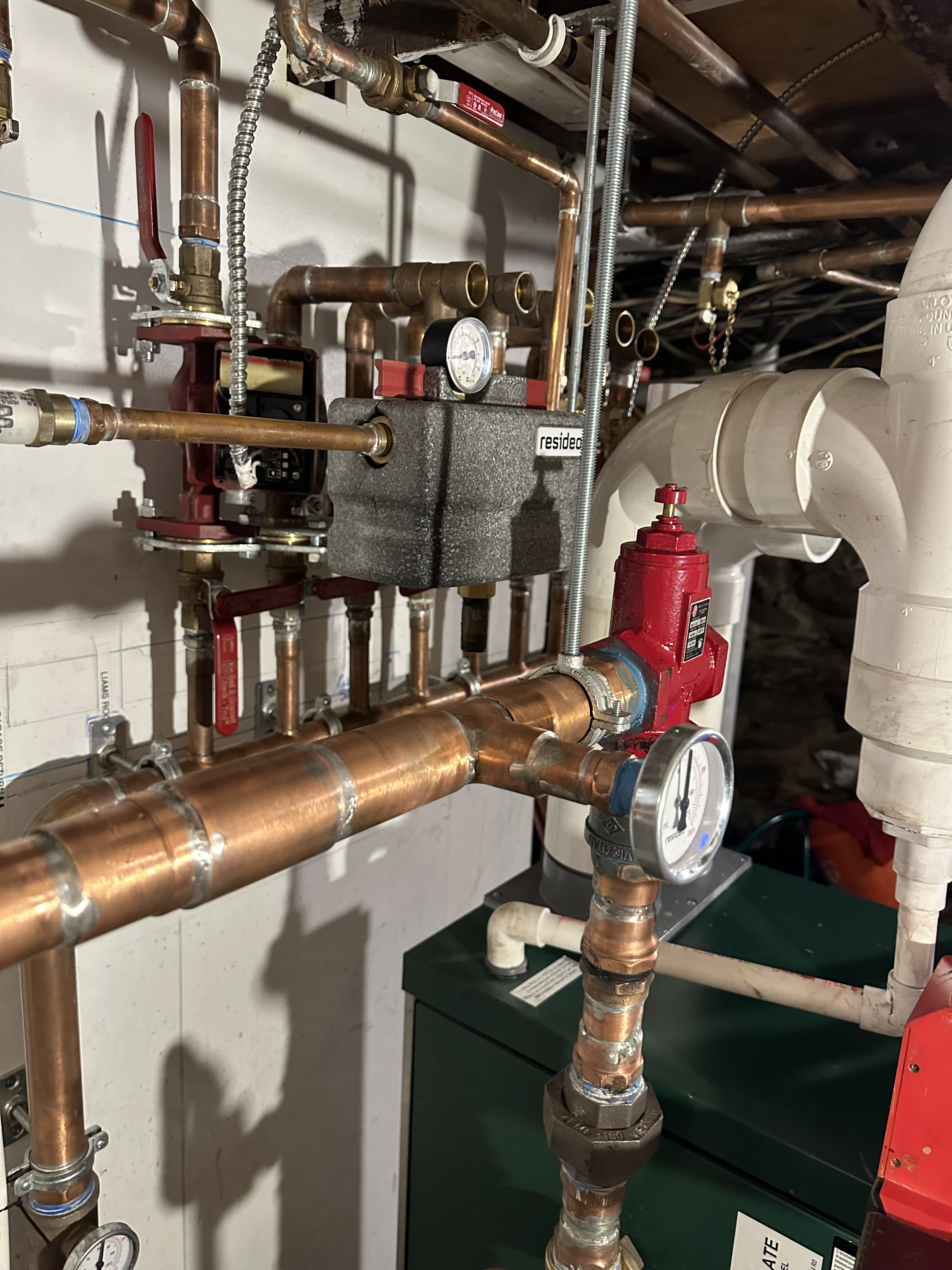

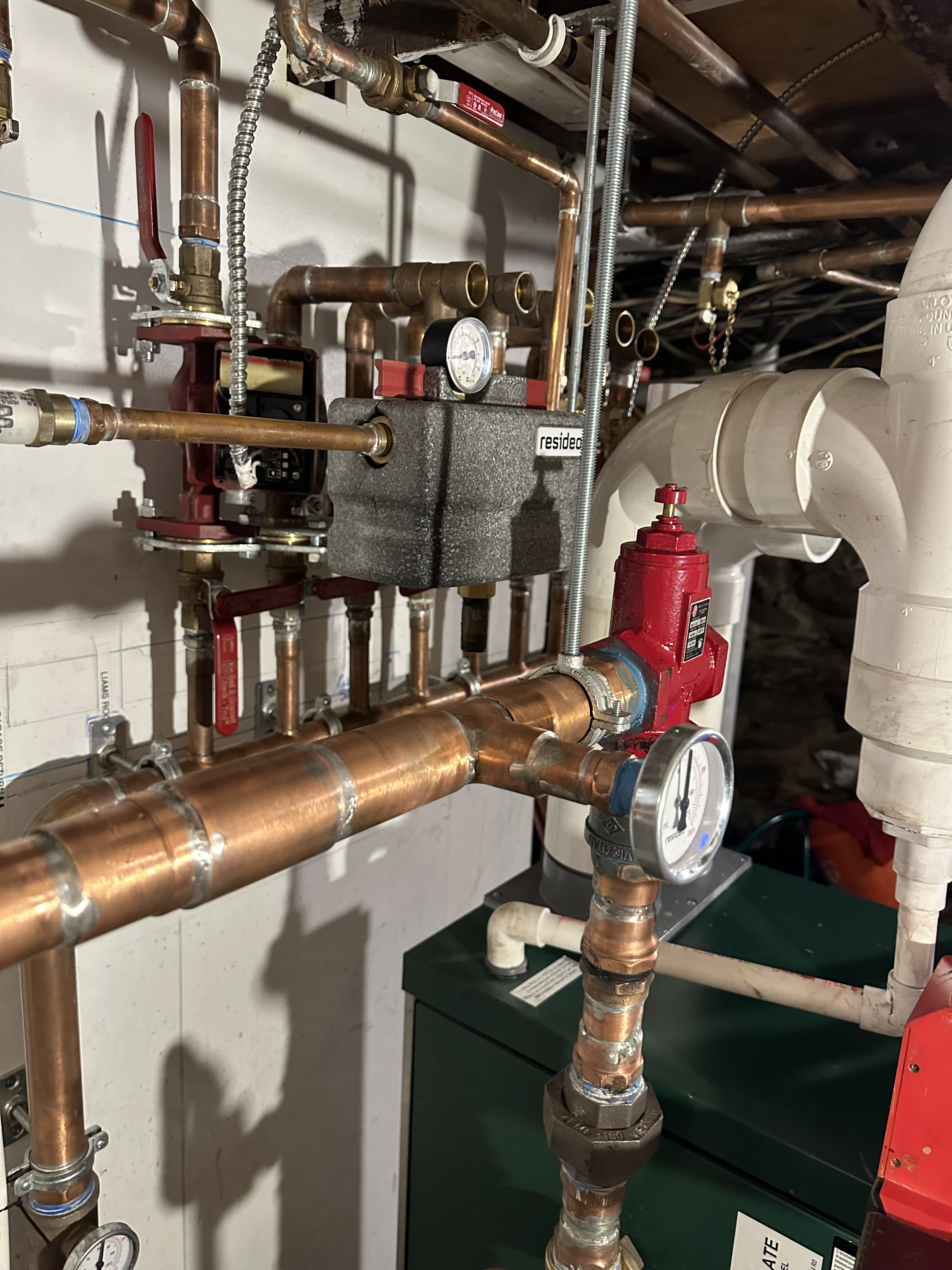

RE-piped to Peerless specifications running like a Champ 💪🏼!! Appreciate the support and feedback fellas.. excuse the wiring just had to get hot water back on.. flushed with sentinel 400 and about to drain system to do X 100 treatment. This baby just chugs along and the condensate it spits out is unbelievable improvement from what It was doing before.

RE-piped to Peerless specifications running like a Champ 💪🏼!! Appreciate the support and feedback fellas.. excuse the wiring just had to get hot water back on.. flushed with sentinel 400 and about to drain system to do X 100 treatment. This baby just chugs along and the condensate it spits out is unbelievable improvement from what It was doing before.

0 -

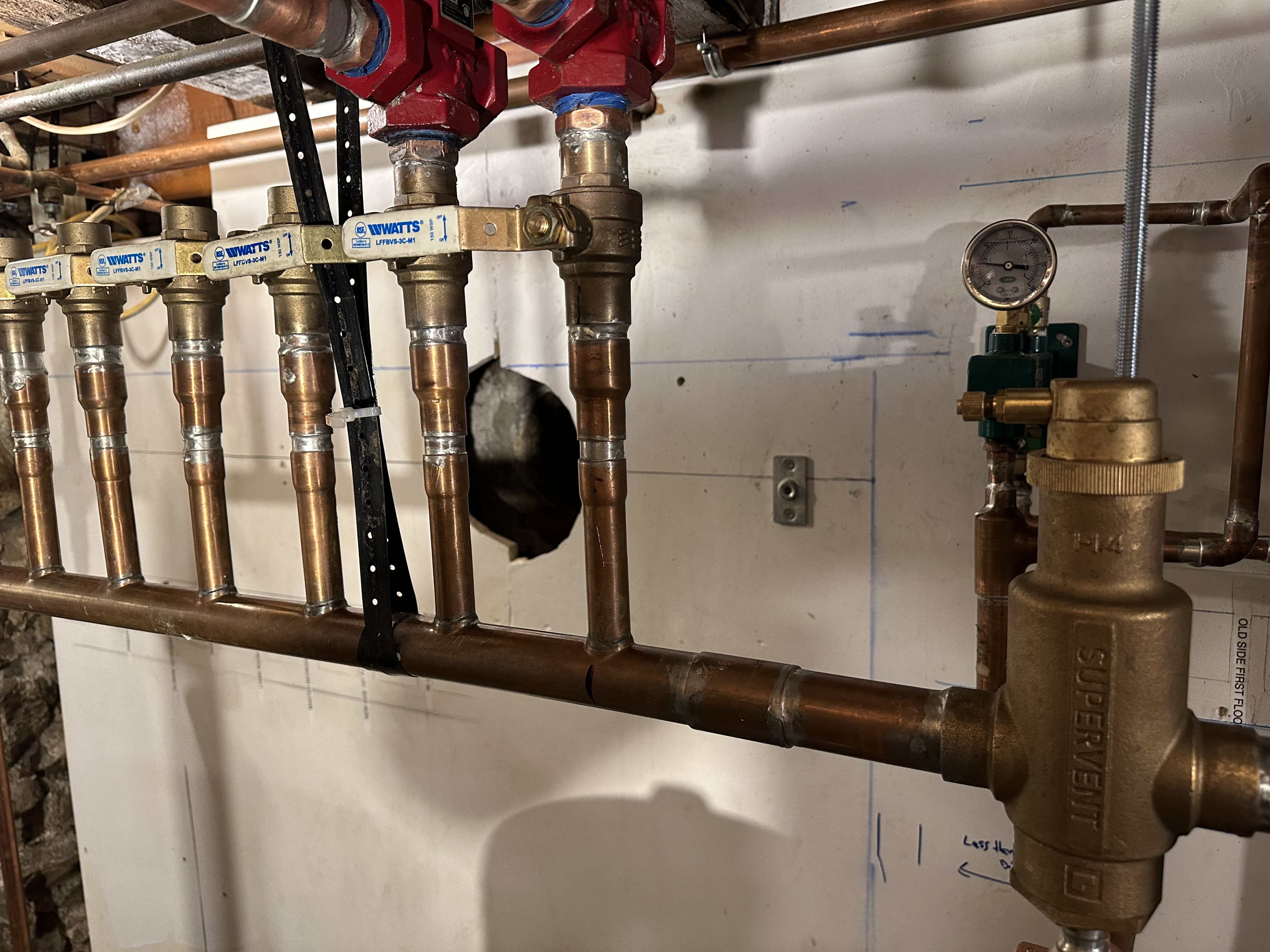

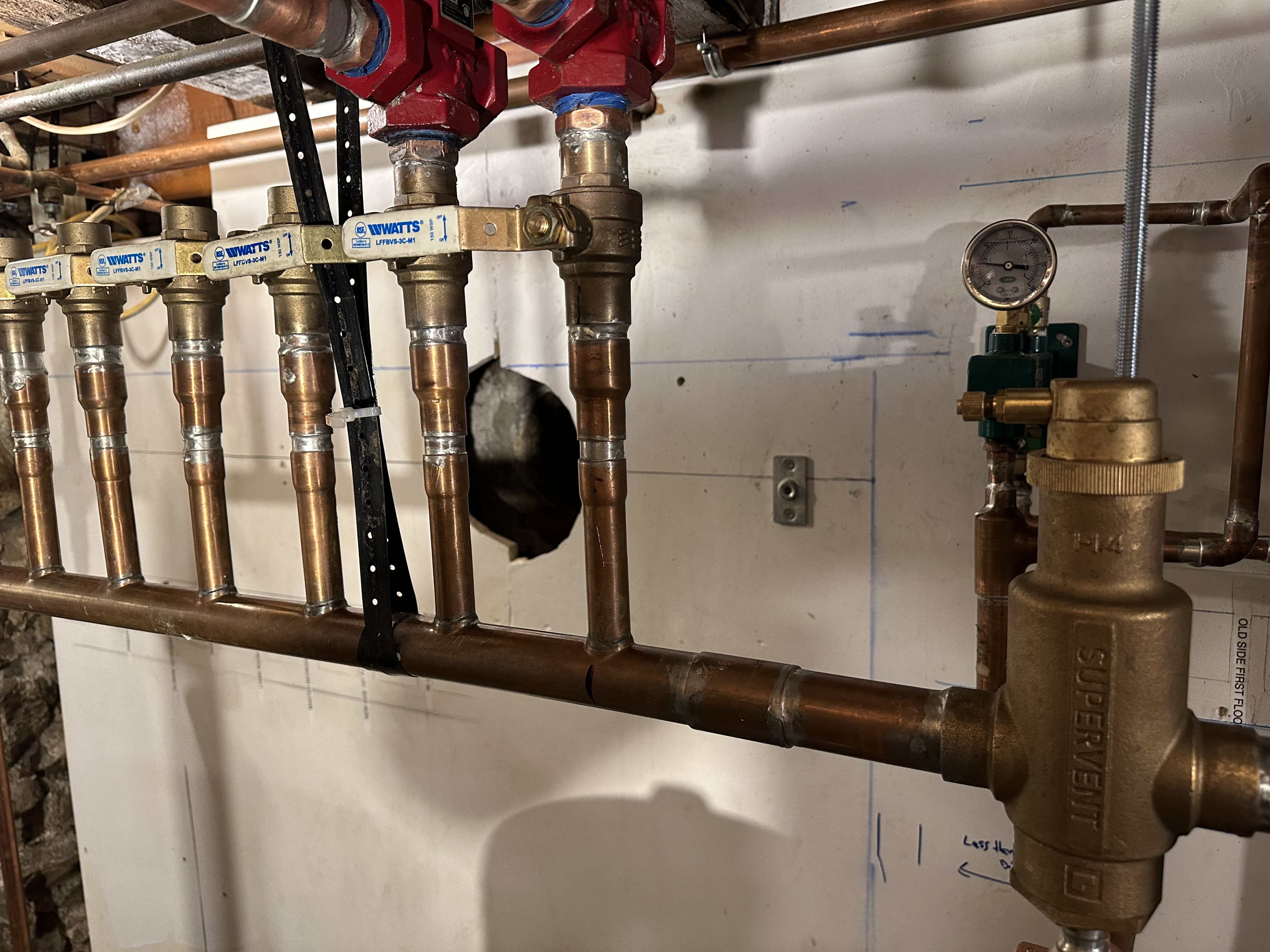

Having some trouble with the returns off the manifold, the Bell and Gossets circulator flanges they are check, trolls so having pump on the return I can’t get a solid flow. Any suggestions; I was thinking swap out for regular circulation flange’s and possibly run into ghost flow? Or mount circulators on supply side and pump away? Any help would be appreciated

0 -

The check flanges need to be on the discharge side of the circ, not the inlet. Is that how you have them?Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Yes Hot Rod the flanges are on the discharge side. I tried it this morning first thing and it started purging perfectly. Not sure what had happened.0

-

I think your check valves are likely airlocked. It's a good idea to have purge ports on both sides of a loop with check valves.

A few tips on your installation:- Wet-rotor circulators should be installed with the shaft oriented horizontally.

- Less is more when it comes to solder and flux, Once the entire fitting has taken solder, try filling gaps as the pipe cools. You will end up with less solder inside the pipe and a cleaner look.

- Allthread pipe supports are better used vertically or in very short lengths. Unistrut might help in your installation.

- MC wiring would give you a more durable and professional installation over Romex.

"If you can't explain it simply, you don't understand it well enough"

Albert Einstein2 - Wet-rotor circulators should be installed with the shaft oriented horizontally.

-

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements