Brand new Vaporstat doesn't seem to work - pigtail question

The Vaporstat is what is controlling this pressure -- I know because I have listened to it with my ear against it as the pressure rises and falls, and it's clicks correspond to the boiler activating and deactivating.

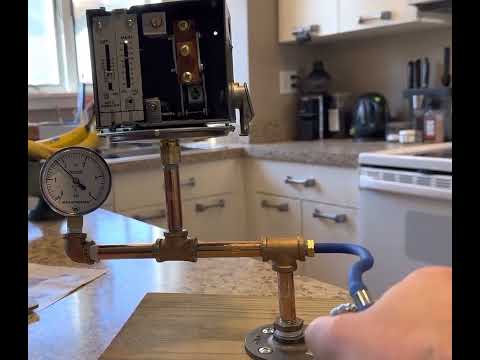

I am in the process of building a bench testing rig to independently verify what pressures at which the Vaporstat activates, but those parts won't be here for a few days. In the meantime, the support team from the Honeywell distributor suggested that the amount of air gap between the water in the siphon loop and the vaporstat may have an effect. Does anyone else have any thoughts on this? Should there be no air gap at all in the nipple leading up to the Vaporstat? Does it matter at all?

The control tree is filled with water, and no steam gets up to the controls and gauges. I have verified this by confirming the nipples leading up to the controls are room temperature.

Some pics are below. Thanks in advance for your help!

Comments

-

Water has weight and that may be the reason for the difference.

I have looked at different posts and have found this to be a problem. There is a water seal that is designed to protect the controls and gauges from the high temperature of the steam. This is usually accomplished by a pigtail that is filled with water to keep the steam from the gauges and controls. In your case it is the "control tree" with a series of 90° fittings to create a trap for said water to accumulate.

Some of the old timers and dead men have actually used an air gap to protect the gauge from steam. If you have an 18" vertical pipe off the top of the boiler with no vent. There is air trapped in that vertical pipe so no steam will get to the gauge. I'll see if I can find the articleEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

3 -

the support team from the Honeywell distributor suggested that the amount of air gap between the water in the siphon loop and the vaporstat may have an effect.

L O L

With the controls they have been shipping out for the last several years, I'd be looking to blame ghosts as wellNJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Hello @Fdarby82,

The water in the pigtail, or in your case the "control tree" pipes does bias the readings. In my case it is only about 0.25 Water Column, the boiler is the higher pressure. If you really want to know if you are playing with junk controls connect your Manometer right under the new Vaporstat with a 'Tee'.

The pipe connection to the Vaporstat is air tight ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

This is where I found the idea.

https://forum.heatinghelp.com/discussion/comment/1680198#Comment_1680198

Ask ChrisJ about this idea, seems he has used it before.

This is what I was talking about referring to the water seal in the pigtail or in your case the "control tree".

The blue section of the piping should be charged with water to create the water gap. the red arrow is the steam pressure pushing down on the water. The white arrows are pushing up on the individual gauges and controls. The water gap has weight and when you are speaking of ounces of pressure, then only inches of water weight will make a difference in the pressure actually measured by the most sensitive control.

Another explanation: If you did not charge the water gap with water to protect the gauge or control and the raw steam found its way to the sensitive control and knocked it out of calibration.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

3 -

-

All 3 controllers are indeed connected in series, and if a wire is disconnected from any, the boiler will shut down. I guess the middle one was a secondary controller just in case the first one blows out, but before the high limit shutoff, however as I discovered in this investigation, that middle pressuretrol is apparently doing nothing, because if I remove the new Vaporstat and connect its two wires together, the pressure will build until the high limit shutoff is triggered. So, this is a good case to build a bench pressure testing setup to use once a year on each controller.JUGHNE said:If you remove one wire from the new control will the boiler fire?

You have a lot of switches there, at least 5, to connect in series.

Could one got left out of the loop?

Last desperate idea is that you have a small air leak under some controls.

RE: Air leak: This was also suggested by @109A_5 , and I agree its something I need to test next. I did not tape or dope these connections because I thought at these pressures, it wouldn't be necessary and I wanted to make it easy to get these on and off for testing. But, maybe even then it needs thread sealant.

0 -

Thanks for this great diagram, @EdTheHeaterMan . I did charge the water gap, and I keep double checking it by feeling the nipples leading to the controls and gauges to make sure they are not hot. I think I will adjust the nipple length on all of them to be the same, and higher than the riser coming from the boiler, so that the water gap is always consistent for each instrument. I don't think I'll try the long vertical riser without an air gap just yet, because my 32" WC gauge works just fine with this setup, and roughly matches what I read on the manometer.EdTheHeaterMan said:This is where I found the idea.

https://forum.heatinghelp.com/discussion/comment/1680198#Comment_1680198

Ask ChrisJ about this idea, seems he has used it before.

This is what I was talking about referring to the water seal in the pigtail or in your case the "control tree".

The blue section of the piping should be charged with water to create the water gap. the red arrow is the steam pressure pushing down on the water. The white arrows are pushing up on the individual gauges and controls. The water gap has weight and when you are speaking of ounces of pressure, then only inches of water weight will make a difference in the pressure actually measured by the most sensitive control.

Another explanation: If you did not charge the water gap with water to protect the gauge or control and the raw steam found its way to the sensitive control and knocked it out of calibration.

Also, it was @Chris_L that gave me the idea for my sight glass drain manometer!0 -

I really appreciate the diagram! I figured out another way to test whether the water in the control tree is biasing the readings -- I swapped the 32" WC gauge and the new Vaporstat, and I am getting the same results. The 32" WC gauge continues to work fine in the Vaporstat's old position, and the Vaporstat continues to let the pressure go to 18oz+ when set at 2oz. So, I think I'm satisfied that my Vaporstat is bad.109A_5 said:Hello @Fdarby82,

The water in the pigtail, or in your case the "control tree" pipes does bias the readings. In my case it is only about 0.25 Water Column, the boiler is the higher pressure. If you really want to know if you are playing with junk controls connect your Manometer right under the new Vaporstat with a 'Tee'.

The pipe connection to the Vaporstat is air tight ?

I appreciate you taking the time to assist me!

0 -

1.7 inches of water is one ounce per square inch so if there is an air leak and some of the nipples are filling with water and some are not, the weight of that water could cause an ounce or 2 difference between devices but not the 10+ oz/square inch you are seeing.

You do need some sort of sealant on the threads, even at that pressure they are likely to leak without something to fill the valley of the threads (but I don't want to start that discussion again).

I'm not sure what happens if an air leak means water is getting to the diaphragm of the controls.1 -

Hello @Fdarby82,

That test to me only proves that the control tree piping is not plugged. If the Vaporstat pipe fitting still leaks in the other location it still would not work properly. The Manometer connected directly under the Vaporstat verifies the pressure that the Vaporstat is actually seeing.Fdarby82 said:I figured out another way to test whether the water in the control tree is biasing the readings -- I swapped the 32" WC gauge and the new Vaporstat, and I am getting the same results. The 32" WC gauge continues to work fine in the Vaporstat's old position, and the Vaporstat continues to let the pressure go to 18oz+ when set at 2oz. So, I think I'm satisfied that my Vaporstat is bad.

I can trip a Pressuretrol set at 1.5 Lbs. with my mouth I would think a 16 Oz. Vaporstat (set a lot lower) would be much easier. If your are going to try to more precisely verify the calibration of the new unit and / or the old one you will have to wait for your test setup build.

I agree it is probably the Vaporstat with their poor track record. However I think there is more test you could do to prove it.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

I think I see what you mean.... but if there was an air leak in the Vaporstat connection to the nipple, wouldn't it eventually consume the air bubble in the nipple and either stop when the water well comes up to the Vaporstat (due to the higher viscosity of the water than air), or wouldn't I see water leaking out then?109A_5 said:Hello @Fdarby82,

That test to me only proves that the control tree piping is not plugged. If the Vaporstat pipe fitting still leaks in the other location it still would not work properly. The Manometer connected directly under the Vaporstat verifies the pressure that the Vaporstat is actually seeing.Fdarby82 said:I figured out another way to test whether the water in the control tree is biasing the readings -- I swapped the 32" WC gauge and the new Vaporstat, and I am getting the same results. The 32" WC gauge continues to work fine in the Vaporstat's old position, and the Vaporstat continues to let the pressure go to 18oz+ when set at 2oz. So, I think I'm satisfied that my Vaporstat is bad.

I can trip a Pressuretrol set at 1.5 Lbs. with my mouth I would think a 16 Oz. Vaporstat (set a lot lower) would be much easier. If your are going to try to more precisely verify the calibration of the new unit and / or the old one you will have to wait for your test setup build.

I agree it is probably the Vaporstat with their poor track record. However I think there is more test you could do to prove it.1 -

I appreciate the advice... I'm going to be removing these and reseating them with sealant. Better safe than sorry on that, as I guess if there was a leak, the water well might drain out through it and eventually expose all those controls to steam.mattmia2 said:1.7 inches of water is one ounce per square inch so if there is an air leak and some of the nipples are filling with water and some are not, the weight of that water could cause an ounce or 2 difference between devices but not the 10+ oz/square inch you are seeing.

You do need some sort of sealant on the threads, even at that pressure they are likely to leak without something to fill the valley of the threads (but I don't want to start that discussion again).

I'm not sure what happens if an air leak means water is getting to the diaphragm of the controls.0 -

Hello @Fdarby82,

The leak may only leak air and not water, within the runtime of the Boiler (before thermostat is satisfied). Since you are on your second Vaporstat and both I believe act the same, I would want to know the actual pressure as close to the Vaporstat as possible. With a few additional nipples and miscellaneous fittings you could connect your gauge and/or Manometer just below the Vaporstat giving you the best information to troubleshoot this situation. If you see 10 Oz. there and the Vaporstat is set for 8 Oz. and the Boiler is not shut off something is not right with the Vaporstat. If you never see 8 Oz. there, I would think something is leaking, either the pipe fitting or the diaphragm / diaphragm assembly.Fdarby82 said:I think I see what you mean.... but if there was an air leak in the Vaporstat connection to the nipple, wouldn't it eventually consume the air bubble in the nipple and either stop when the water well comes up to the Vaporstat (due to the higher viscosity of the water than air), or wouldn't I see water leaking out then?

Steam condensing in the cooler water filled pipes of the "control tree" may replenish the water barrier faster than it can leak out if the leak is tiny.National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

I would assume it is the L408J1009, Which is a "Vaporstat Controller (Steam), 0 to 16 oz/in2" and has the correct SPDT switch.reggi said:Yes... which 16 oz Model # did you purchase ?

From the Honeywell product data sheet...

https://s3.amazonaws.com/s3.supplyhouse.com/manuals/1296597322000/46822_PROD_FILE.pdf

Honeywell's Brilliance, Note "a" wouldn't that just make it an SPST switch ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I know I’m gonna get some poo poo for this but I really not a fan of a water seal just ain’t my thing . After I don’t know close to 40 years working I still don’t like them I prefer using pigtails but mounting them above and off the skim tapping w a tee facing vertically using a few cross tees to clean occasionally. Just as a example I finally convinced a customer who’s boiler I replaced about 15 years ago to do maintaince ,pig tails off the skim as clean as the day I left the job 15 years early .it may be a pet peeve but I ve never had a issue in about 15 to 20 years of doing it this way . Nothing replaces what a pigtail does it gives a air seal to prevent moisture and water from clogging and damaging the diaphragm of the Pressure troll . When a boiler is piped correctly and clean ,muck and crap will never make it up into the manifold when piped off the skim and pigtails remain clean . Just some food for thought peace and good luck clammy

R.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating2 -

Sounds a little too advanced and different from the way it was installed for my comfort, but it's interesting hearing about your use of it!clammy said:I know I’m gonna get some poo poo for this but I really not a fan of a water seal just ain’t my thing . After I don’t know close to 40 years working I still don’t like them I prefer using pigtails but mounting them above and off the skim tapping w a tee facing vertically using a few cross tees to clean occasionally. Just as a example I finally convinced a customer who’s boiler I replaced about 15 years ago to do maintaince ,pig tails off the skim as clean as the day I left the job 15 years early .it may be a pet peeve but I ve never had a issue in about 15 to 20 years of doing it this way . Nothing replaces what a pigtail does it gives a air seal to prevent moisture and water from clogging and damaging the diaphragm of the Pressure troll . When a boiler is piped correctly and clean ,muck and crap will never make it up into the manifold when piped off the skim and pigtails remain clean . Just some food for thought peace and good luck clammy

0 -

It is indeed the L408J1009, with a subtractive differential. Previous to that, I had the 4psi Vaporstat equivalent model, L408J1017, which was wired and piped in the same way as this new one.109A_5 said:

I would assume it is the L408J1009, Which is a "Vaporstat Controller (Steam), 0 to 16 oz/in2" and has the correct SPDT switch.reggi said:Yes... which 16 oz Model # did you purchase ?

From the Honeywell product data sheet...

https://s3.amazonaws.com/s3.supplyhouse.com/manuals/1296597322000/46822_PROD_FILE.pdf

Honeywell's Brilliance, Note "a" wouldn't that just make it an SPST switch ?

One thing I just noticed from your post on this sheet is that the differential is supposed to be a minimum of 4oz, and I have mine turned down past that on the scale, so I'll try increasing it a bit. I have the new part on the way, arriving Monday anyway. @reggi

0 -

Hi Clammy, in the set-up you describe here you are saying that steam can’t get past the air in the pigtails so they don’t fill with condensate? What purpose does the pigtail serve, could you use just a nipple to accomplish the same thing?clammy said:I know I’m gonna get some poo poo for this but I really not a fan of a water seal just ain’t my thing . After I don’t know close to 40 years working I still don’t like them I prefer using pigtails but mounting them above and off the skim tapping w a tee facing vertically using a few cross tees to clean occasionally. Just as a example I finally convinced a customer who’s boiler I replaced about 15 years ago to do maintaince ,pig tails off the skim as clean as the day I left the job 15 years early .it may be a pet peeve but I ve never had a issue in about 15 to 20 years of doing it this way . Nothing replaces what a pigtail does it gives a air seal to prevent moisture and water from clogging and damaging the diaphragm of the Pressure troll . When a boiler is piped correctly and clean ,muck and crap will never make it up into the manifold when piped off the skim and pigtails remain clean . Just some food for thought peace and good luck clammy

Paul0 -

Your not piping a water seal just locating the pigtail off of a tee off say off a 1 1/4 x3/4 tee added to the skim port face it vertical add a 6 inch nipple and cross tee a 3/4 x1/4 tee pigtail on that and a couple of 3/4 nipples and plugs . It pretty easy your still using a pigtail but off the block utilizing a bigger opening larger piping connecting to the pigtail and higher off the water line very unlikely to get debrie up there also great location for all your required pressure gauges and low pressure . Peace and good luck clammy

R.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating0 -

Hello @Fdarby82,

In this Vaporstat case, I think I would have the Subtractive Differential as high as the Vaporstat will allow for stable operation of the Vaporstat. Having a small differential would just make the burner cycle on and off a lot. With a higher differential it takes advantage of a longer time for the pressure to dissipate or drop further down and with that wait time the thermostat may become satisfied. For example with a Main setting of 8 Oz. I would have a differential of 6 or 7 Oz. So 8 - 6 = 2 the pressure has to drop down to 2 Oz. before the boiler restarts. If the differential is set too low maybe the mechanics get weird and it won't trip at the Main set pressure.Fdarby82 said:One thing I just noticed from your post on this sheet is that the differential is supposed to be a minimum of 4oz, and I have mine turned down past that on the scale, so I'll try increasing it a bit. I have the new part on the way, arriving Monday anyway.

A PA404A Pressuretrol for example is different story, Cut-Out equals Cut-In PLUS Differential (Additive Differential). So with a Cut-In of 0.5 and a differential of 1, Cut-Out = 1.5 PSI which about as low as a PA404A Presuretrol will go. So in the Presuretrol case you want the differential as low as it can go.

With oversized boilers that want to make excessive pressure some folks add a delay timer. So when the Vaporstat or Pressuretrol shuts the boiler down on pressure it will not restart for many minutes and the thermostat may become satisfied in that delay time.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Micro-switches are very handy but they are not nearly as reliable or repeatable as the old mercury bulbs were especially in a production environment when any testing done is probably on a AQL basis.

https://www.qima.com/aql-acceptable-quality-limit

Try moving the manometer test point up to just below the vaporstat and see what that reading is.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge1 -

I hear and take to heart your comments about avoiding a small differential on a vaporstat. One of the intricacies with my system is that our pressure falls very rapidly once the boiler turns off (possibly because we have no radiator steam traps anywhere in the building, read my other posts if you want to hear about that). It also goes into vacuum after it turns off, dropping to about negative 6oz of pressure until the condensate stops draining. I've never had a pressure controller capable of such precision tuning as the 0-16oz Vaporstat, so I'll have to do some experiments once I get the new one working to determine the right mix of pressure and differential to heat the building. Using your example of 8oz main pressure with a 6oz diff, with how rapidly my system loses pressure, by the time the boiler fired again (probably a 6 second delay after the vaporstat activates), it would be firmly in vacuum territory. Is going into vacuum on every Vaporstat cycle bad for performance? (asked hypothetically) I'm not sure yet.109A_5 said:Hello @Fdarby82,

In this Vaporstat case, I think I would have the Subtractive Differential as high as the Vaporstat will allow for stable operation of the Vaporstat. Having a small differential would just make the burner cycle on and off a lot. With a higher differential it takes advantage of a longer time for the pressure to dissipate or drop further down and with that wait time the thermostat may become satisfied. For example with a Main setting of 8 Oz. I would have a differential of 6 or 7 Oz. So 8 - 6 = 2 the pressure has to drop down to 2 Oz. before the boiler restarts. If the differential is set too low maybe the mechanics get weird and it won't trip at the Main set pressure.Fdarby82 said:One thing I just noticed from your post on this sheet is that the differential is supposed to be a minimum of 4oz, and I have mine turned down past that on the scale, so I'll try increasing it a bit. I have the new part on the way, arriving Monday anyway.

A PA404A Pressuretrol for example is different story, Cut-Out equals Cut-In PLUS Differential (Additive Differential). So with a Cut-In of 0.5 and a differential of 1, Cut-Out = 1.5 PSI which about as low as a PA404A Presuretrol will go. So in the Presuretrol case you want the differential as low as it can go.

With oversized boilers that want to make excessive pressure some folks add a delay timer. So when the Vaporstat or Pressuretrol shuts the boiler down on pressure it will not restart for many minutes and the thermostat may become satisfied in that delay time.

RE: Delay timer - this is an interesting thought, I may consider this. Due to the above issues, I do have some serious short cycling. If it turns out going into vacuum repeatedly in a thermostat cycle (which would definitely happen if I had a delay) isn't bad for performance, then this may be a great solution.

-1 -

I'm building a bench test rig, so hopefully this will answer any questions about functionality of the controls.BobC said:Micro-switches are very handy but they are not nearly as reliable or repeatable as the old mercury bulbs were especially in a production environment when any testing done is probably on a AQL basis.

https://www.qima.com/aql-acceptable-quality-limit

Try moving the manometer test point up to just below the vaporstat and see what that reading is.

Bob0 -

@Fdarby82 ... As you now have 2 Vaporstats alleged "Failures" virtually simultaneously ( with the same condition) I would reevaluate the "Drop manifold" you modified from the original and ask myself.. What maybe did I do or didn't do that may of changed the manifold that the pressure now perhaps changed? For example that is..

The electrical box is now behind a gage riser as you extended that side of the tree .. have you checked your wiring as your pressuretrol wasn't functioning and we never heard back of what caused the failure.. that would be your 2 primary over pressure device not functioning at the same time...

You've taken on a lot of responsibility for that building.. I wouldn't hesitate getting a pro to sort out the issues.. you're responsible..

One way to get familiar something you know nothing about is to ask a really smart person a really stupid question1 -

Hello @Fdarby82,

It has been said by others and I agree that burning fuel to create more pressure than is actually needed and maintaining it is a waste of fuel. My boiler Square Foot rating is less than my EDR so my system never builds any excessive pressure that I have seen, even at 2 degrees outside it has not gone over 2 Inches of Water Column (1.156 Oz). The radiators condense the Steam faster than the boiler can produce it.

Are the radiators getting hot before the pressure starts to rise ?

Dropping into a vacuum is normal and is beneficial since with the lower pressure the boiling point of water is reduced so the boiler steams longer. Sadly the vacuum fades away too quickly, usually because air comes back in through a vent or vents (the air was pushed out earlier in the cycle).

The Vaporstat should be designed to tolerate the vacuum without being damaged. But as you noticed the Vaporstat only has limited benefits in this situation.

Check out this, it may help. It just gets wired in series with your Vaporstat.

ICM203 Delay on Break Timer (.03-10 Minute Knob Adjust. Delay)

https://www.supplyhouse.com/ICM-Controls-ICM203B-ICM203-Delay-on-Break-Timer-03-10-Minute-Knob-Adjust-Delay

or

ICM203F Delay on Break Timer, 6" Wire Leads (.03-10 Minute Knob Adjust. Delay)

https://www.supplyhouse.com/ICM-Controls-ICM203FB-ICM203F-Delay-on-Break-Timer-6-Wire-Leads-03-10-Minute-Knob-Adjust-Delay

You do have to get the Vaporstat working correctly. BTW with the delay timer the Vaporstat differential value is almost irrelevant.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Agreed that there is a lot I don't understand about these systems. The problem with calling a "pro" to evaluate is that none in the area here actually know the theory behind steam setups. They will come out to replace a part, sure. However, when it comes to determining the "why" something failed, or delving any deeper than fixing the immediate problem they were called for, as opposed to fixing the underlying causes, I've had no luck. When I first moved in 2 years ago, our system had lots of problems. The most obvious was water hammer so terrible that I had visitors tell me I should sue the seller for nondisclosure. This boiler was new in 2011, yet we had spent nearly $60,000 over just the last *4 years* to our local "pros" to maintain it and fix problems.reggi said:@Fdarby82 ... As you now have 2 Vaporstats alleged "Failures" virtually simultaneously ( with the same condition) I would reevaluate the "Drop manifold" you modified from the original and ask myself.. What maybe did I do or didn't do that may of changed the manifold that the pressure now perhaps changed? For example that is..

The electrical box is now behind a gage riser as you extended that side of the tree .. have you checked your wiring as your pressuretrol wasn't functioning and we never heard back of what caused the failure.. that would be your 2 primary over pressure device not functioning at the same time...

You've taken on a lot of responsibility for that building.. I wouldn't hesitate getting a pro to sort out the issues.. you're responsible..

When I took over management here, I had the 3 most prominent boiler companies in the area come out here to try to figure out the problems. The system was running at 7psi. None of the pros even questioned this pressure. They measured the slope of the basement horizontal pipes, on my orders to do so; those were fine. They suggested parts I could replace that might help, and gave responses like "well, its an old building...". I can't tell you how many times I heard that phrase as the summary of all of our problems. So, I turned to learning about steam boilers myself. It took me a while, but eventually I tried experimenting with the pressure. Dan Holohan's book said to run at the lowest pressure that will heat the building. So, I thought, "why 7psi?". Turns out, that pressure was set nearly 10x too high. It runs at 12oz now, and every radiator is heated. The water hammer is completely gone.

These pros also had us on an outdoor thermostat-- so the boiler ran 24x7 when it was under 55 degrees outside. Everyone in the building was sweltering during fall and spring, and most of winter, with windows and balcony doors open. Even with our thermostatic radiator valves, there was just no way to contain that much heat from the boiler. (As an aside, this is mostly due to the peculiarities of our setup -- we have no radiator steam traps anywhere, so with the boiler on all the time, steam went back into the condensate lines to heat the rads, regardless of the thermostatic valve setting. But again, no boiler pro thought to investigate this problem.) I had one boiler pro tell me that steam boilers are SUPPOSED to run all the time, and that it is bad for a steam boiler to turn off. That didn't sound right to me. So, I moved us to an indoor thermostat which now cycles on and off. We saved over $6,000 last year in gas, and most people are far more comfortable; now that the boiler cycles rather than on 24x7, steam is rarely able to build up in the condensate lines to heat rads that were turned off. The thermostatic valves finally work like they were intended to maintain the temperatures people wanted.

When our condensate pump failed two years ago, and at the same time two boiler cells cracked, we spent over $11,000 to pros to replace those (again, before I took an interest in the boiler). We got quotes from all three of these major companies who are known in the area for steam boilers. They were all happy to replace the parts that had failed. We spent that money, and later I discovered that the cause of both of those issues was a failed electrical relay which caused the pump to sporadically fail-on, which flooded the boiler with cold makeup water, causing the cracked cells, and the eventual failure of the pump. This electrical relay problem was not discovered or replaced in that $11,000 job, so the pump continued to sporadically fail-on after the repair, in one instance filling the boiler and mains with water up to the 1st floor, causing a radiator to leak into the basement like an overfilled bathtub. That made it crystal clear the $11,000 repair didn't fix the underlying cause, so I made it my mission to figure it out, and I didn't want to call these same pros again. Once I discovered that electrical relay as the problem, it cost me $9 to replace myself. If it had been discovered before, we could have avoided the $11,000 repair. Lucky we caught it before the pump failed again, and caused the boiler to crack again.

So, you can see why when we are facing a minor problem like "these pressure controllers don't seem to behave exactly like they are supposed to", I don't turn to these same pros anymore, and there is no one else here in this small community. I imagine where you live, there are pros that understand steam setups more deeply. But here, the local pros would replace the part, we would have a $1,500 bill, and I'd still have no answers about "why", or confidence that the problem wouldn't repeat.

As for the problems I'm experiencing now: The only mod I've made to the control tree (apologies if this is incorrect terminology) from install is to extend it to allow installation of the low pressure gauge. That did block the electrical box, as you've noted, but I've since opened that and ensured that those wires are all securely connected. I have swapped the vaporstat and pressure gauge position on the control tree for testing, but could that really compromise them? The tree is filled with water and the upward facing nipples are room temp, so those sensitive instruments aren't getting steamed. I had one pro not understand that this setup acts as a pigtail and tell me I needed to add a separate pigtail for each control and gauge, but that didn't sound right to me. But, if there is something about this control tree setup that is inherently bad for the controls, I would love to know that so I can fix it. But to reiterate, this IS how it was originally installed, and I believe consistent with the installation diagram Weil Mclain provides, except for the extension I made for the second gauge.

I've now bench tested the old 4psi vaporstat, and it does cycle with pressure, but not consistently. If I turn up the pressure above 1psi, it is much more consistent. I think this device is just more likely to operate properly when not turned when not turned down to the bottom of its range. It did work for 18 months though.

It is coincidental that the new 16oz vaporstat doesn't seem to operate properly, I concede. I'm hoping its just a bad part, but my new vaporstat will be here today, so I'll have a chance to bench test the one I'm returning. I will also test the pressuretrol then.0 -

Thanks for these links and the info about your boiler! I will check them out. RE: radiators getting hot: I haven't had a low enough pressure control to test below 12oz until this new vaporstat arrives. At 12oz they all get hot though, and I ran a quick-and-dirty experiment at 6-8oz, and noticed a substantial degradation in heat performance. So, I think I'm zeroing in on ideal max pressure between 8-12oz.109A_5 said:Hello @Fdarby82,

It has been said by others and I agree that burning fuel to create more pressure than is actually needed and maintaining it is a waste of fuel. My boiler Square Foot rating is less than my EDR so my system never builds any excessive pressure that I have seen, even at 2 degrees outside it has not gone over 2 Inches of Water Column (1.156 Oz). The radiators condense the Steam faster than the boiler can produce it.

Are the radiators getting hot before the pressure starts to rise ?

Dropping into a vacuum is normal and is beneficial since with the lower pressure the boiling point of water is reduced so the boiler steams longer. Sadly the vacuum fades away too quickly, usually because air comes back in through a vent or vents (the air was pushed out earlier in the cycle).

The Vaporstat should be designed to tolerate the vacuum without being damaged. But as you noticed the Vaporstat only has limited benefits in this situation.

Check out this, it may help. It just gets wired in series with your Vaporstat.

ICM203 Delay on Break Timer (.03-10 Minute Knob Adjust. Delay)

https://www.supplyhouse.com/ICM-Controls-ICM203B-ICM203-Delay-on-Break-Timer-03-10-Minute-Knob-Adjust-Delay

or

ICM203F Delay on Break Timer, 6" Wire Leads (.03-10 Minute Knob Adjust. Delay)

https://www.supplyhouse.com/ICM-Controls-ICM203FB-ICM203F-Delay-on-Break-Timer-6-Wire-Leads-03-10-Minute-Knob-Adjust-Delay

You do have to get the Vaporstat working correctly. BTW with the delay timer the Vaporstat differential value is almost irrelevant.0 -

one thing you might try,

take the operating Vstat from the tree and relocate it to one of your non treed (tree-ed?) cleanout plugs on a regular pigtail, or to that plugged pipe to the right,

I'm still hung up on that body of water in your existing tree.

maybe you move or add a low pressure gage over there also to keep an eye on thingsknown to beat dead horses1 -

Here's a video of the 16oz Vaporstat which I'm returning. It's set at 10oz, with about 8oz differential. Besides the "clicking" sound I expect to hear when it hits pressure and returns under the differential, there's a distinct sound of metal popping, like a metal diaphragm flexing forward, then backward. I don't think that's supposed to happen, right? Anyway, this part is being returned, but if anyone has input about the popping sound (not the clicking on pressure, the separate "popping" sound), I'd love to hear it!

https://youtu.be/onMgSHqt3kY 0

https://youtu.be/onMgSHqt3kY 0 -

New vaporstat is here! I already had the bench test setup ready, so I tested it before installation, and it works exactly as I expect it to. It doesn't do the metal "popping" sound like the one I'm returning does. Video is below. If anyone knows what the metal "popping" sound is, I'd love to know. Next up after this: Bench testing the old pressuretrol which serves as a secondary pressure controller before the high limit cutoff. I suspect this is not working at all, but we will see!

https://youtu.be/4Bs36rkVUgg 1

https://youtu.be/4Bs36rkVUgg 1 -

Hello @Fdarby82,

"Are the radiators getting hot before the pressure starts to rise ?"

What I was getting at here with this question is, does the Boiler pressure rise very soon after the Boiler starts steaming or does the pressure rise after the radiators are hot and your limited venting may close ?

You may need to vent better so the steam moves better. It maybe lethargic and just makes pressure quickly. If the steam is not readily moving away from the Boiler it is building pressure.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

You are not the only one who's experienced a popping vaporstat. Here is one thread that describes the same problem:https://forum.heatinghelp.com/discussion/173993/honeywell-l408j1009-vaporstat-pop-sound and you can likely find others.1

-

-

Pressuretrol bench test. We had an old pressuretrol as our secondary pressure controller, in theory it would cut out before the high limit cutoff. But, even though it was set to minimum with a minimum additive differential, it still doesn't cut out until after our high limit control does. So, it's working, but it seems like 3.2psi is just the minimum pressure it can cut out, which is much higher than I thought, given it's settings.

Here's the vid: https://youtu.be/bDRyU92p-4o 0

https://youtu.be/bDRyU92p-4o 0 -

Very interesting. Good to know there are others. I hope there is nothing about my setup that is going to break Vaporstats. I am just about to install this new one.Chris_L said:You are not the only one who's experienced a popping vaporstat. Here is one thread that describes the same problem:https://forum.heatinghelp.com/discussion/173993/honeywell-l408j1009-vaporstat-pop-sound and you can likely find others.

0 -

@Chris_L, I'm bench testing the old 4psi vaporstat now (the one which "went bad" after 18 months, which prompted me to order the 16oz vaporstat which failed the bench test). It turns out this 4psi one is popping too, although almost inaudibly, and only when I set it to less than 1psi or so. On the tests when I hear the gentle popping noise, it doesn't cut out at the right pressure, and will go much higher. However, on the tests when I do not hear the popping noise (generally tests where the cut out is set above 1psi), it cuts out on the pressure it is supposed to. So, it appears a popping diaphragm is what went wrong with this one, too, because the pressure it was set at before was 12oz. This popping diaphragm seems like a big manufacturing problem with these devices.0

-

Ah, I think I see what you meant now. When starting from cold, the boiler gets to a boil in only 2-3 minutes, and the pressure immediately starts to rise long before any of the rads begin getting hot. This building has 59 radiators, a total of about 2040 EDR, and each floor is about 3000 sq ft. Once the pressure starts rising, it does so very haltingly as the condensate feed pump refills it with cooler water, so it goes up and down a lot. It seems like the first few oz of pressure go up very quickly, (probably because at those low pressures it isn't filling any rads, just the mains?), but then from about 4oz - 10oz it feels like there is a lot of friction to rise further (I guess because this is the pressure at which most of the radiators are starting to fill?).109A_5 said:Hello @Fdarby82,

"Are the radiators getting hot before the pressure starts to rise ?"

What I was getting at here with this question is, does the Boiler pressure rise very soon after the Boiler starts steaming or does the pressure rise after the radiators are hot and your limited venting may close ?

You may need to vent better so the steam moves better. It maybe lethargic and just makes pressure quickly. If the steam is not readily moving away from the Boiler it is building pressure.

I have some smart probe thermometers attached to the condensate return of a few rads, so I have a very precise reading of when they get warm. The radiators I track don't reach full heat until about 20-25 minutes after the boiler starts firing. That being said, now that I have a working 16oz vaporstat, I'm going to see if I can lower the pressure further and still achieve the same heating.

0 -

Hello @GBC_illinois,

With the Pressuretrol you may be able to calibrate it now. There is a small set screw under the microswitch on the linkage going to the diaphragm. I think it uses a 0.050" hex key (Allen wrench). There has been other posts on this subject.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements