Natural gas heater help

When I try to light the heater the pilot goes out as soon as I lift my finger off control knob, pilot will stay on as long as I keep control down. I noticed the pilot flame does not reach the thermocouple causing pilot to go out. I shut off my furnace and tried to light the heater, the pilot was now working properly. I let it run for 20 minutes and then kicked on my furnace, heater then went out.

I'm wondering if I need to call gas company and have them increase pressure or what may be the issue. I bled the air from heater, furnace, and hot water tank. I didn't bleed the pipe I capped for the other heater I don't have yet, do I still need to crack the cap in order to bleed it even though there's no appliance hooked up? Wondering if maybe air in that line would affect this heaters performance. Heater has a 630 Eurosit. Any input is much appreciated, thanks!

Comments

-

This sounds like insufficient pressure. What method did you employ to determine the proper gas pipe size?

I prefer the longest run method. https://www.youtube.com/watch?v=1fpy9NrE21c

https://www.youtube.com/watch?v=1fpy9NrE21c Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

EdTheHeaterMan said:This sounds like insufficient pressure. What method did you employ to determine the proper gas pipe size? I prefer the longest run method.

https://www.youtube.com/watch?v=1fpy9NrE21c

https://www.youtube.com/watch?v=1fpy9NrE21c

I used the longest run method, actually watched that same exact video. Pipe I used supplies more than enough.

Used the charts from the Pennsylvania code book.1 -

-

What is the Gas pressure at the problem appliance with all appliances OFF.mattmia2 said:Then the manometer is the next step.

What is the gas pressure at the problem appliance with it operating, and all other appliances OFF

What is the Gas pressure at the problem appliance with all appliances ON.

With those three measurements, the problem can be diagnosed.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

EdTheHeaterMan said:

Then the manometer is the next step.

What is the Gas pressure at the problem appliance with all appliances OFF. What is the gas pressure at the problem appliance with it operating, and all other appliances OFF What is the Gas pressure at the problem appliance with all appliances ON. With those three measurements, the problem can be diagnosed.

Appreciate all the replies!! I have the manual for the 630 Eurosit, do I want to test inlet pressure, outlet pressure, or both? There's 2 screws easily accessible on side of gas control valve to take these measurements.

Also want to add that I have a gas water heater that works just fine with furnace on and supplement heater works fine with water heater on, furnace is the only thing that will kick off supplement heater. I even shut off water heater and turned furnace on, no change with water heater off.

0 -

-

ratio said:Did you get the li'l plastic cap out of the end of that pipe before you threaded it into the fitting?

The plastic cap inside of the supplement heater where the fitting threads into? Yes I removed it.

0 -

When I try to light the heater the pilot goes out as soon as I lift my finger off control knob, pilot will stay on as long as I keep control down. I noticed the pilot flame does not reach the thermocouple causing pilot to go out. I shut off my furnace and tried to light the heater, the pilot was now working properly. I let it run for 20 minutes and then kicked on my furnace, heater then went out.

When there is a large demand on the gas pipe (the heater) the space heater pilot will not stay lit. When there is no large demand the pilot stays lit. That is the definition of insufficient pressure resulting from small gas pipe diameter. IF the pipe is the correct size and the threads and cuts are properly reamed at each end, then there is a blockage in a pipe somewhere.Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

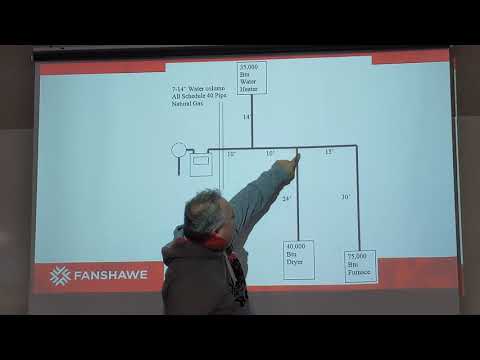

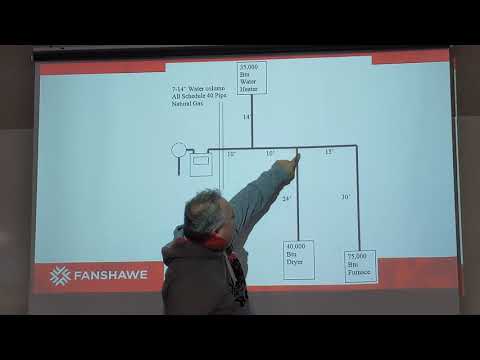

Here is a diagram of my pipe, please review my work. Maybe I miss calculated.EdTheHeaterMan said:When I try to light the heater the pilot goes out as soon as I lift my finger off control knob, pilot will stay on as long as I keep control down. I noticed the pilot flame does not reach the thermocouple causing pilot to go out. I shut off my furnace and tried to light the heater, the pilot was now working properly. I let it run for 20 minutes and then kicked on my furnace, heater then went out.When there is a large demand on the gas pipe (the heater) the space heater pilot will not stay lit. When there is no large demand the pilot stays lit. That is the definition of insufficient pressure resulting from small gas pipe diameter. IF the pipe is the correct size and the threads and cuts are properly reamed at each end, then there is a blockage in a pipe somewhere. 0

0 -

Depending on the additional pipe needed to connect the new appliances, you may need to enlarge some of the existing pipe. In the video example a 3/4" pipe from the meter to the first Tee fitting would be acceptable.

However If someone adds additional pipe to the end of the line, furthest from the meter, then the longest run, might be longer than the original design, and require the use the next line on the chart. (In this case the 70 ft line is too short)

You also need to add the additional capacity of the new appliances to the existing design. When I applied this new information to the diagram, some of the existing pipe needs to be enlarged.

The 75,000 BTU heater now needs 3/4" pipe when the existing pipe was 1/2"

When this happens, It is sometimes easier to make a home run from the new equipment to the gas meter (or source).

I can't tell if you have actually accounted for ALL those variables in your gas piping design.

If you can provide the piping diagram you used with BTU of the connected appliances "as built" we can see if the problem can be resolved.

Also. there are many charts in the code book and selecting the correct one can sometimes be difficult. I remember when I moved from Philadelphia to Southern NJ, I needed to use a different table. PGW was extremely low pressure mains so the pressure past the meter was 5"wc, and South Jersey Gas had mostly high pressure lines to the meter and the regulator at the meter could often be set at 7" to 9"wc.

What is the gas pressure on the inlet side of the appliance when you do the test I asked about previously?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Here is a diagram of my pipe, please review my work. Maybe I miss calculated.

What is your gas pressure at the meter? with all appliances off.EDIT:

based on the most conservative chart I would change the pipe between the meter and the first Tee fitting to 1"

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I don't have a manometer and no one local has one for sale so I can't test the pressures right now.EdTheHeaterMan said:Depending on the additional pipe needed to connect the new appliances, you may need to enlarge some of the existing pipe. In the video example a 3/4" pipe from the meter to the first Tee fitting would be acceptable. However If someone adds additional pipe to the end of the line, furthest from the meter, then the longest run, might be longer than the original design, and require the use the next line on the chart. (In this case the 70 ft line is too short)

You also need to add the additional capacity of the new appliances to the existing design. When I applied this new information to the diagram, some of the existing pipe needs to be enlarged.

However If someone adds additional pipe to the end of the line, furthest from the meter, then the longest run, might be longer than the original design, and require the use the next line on the chart. (In this case the 70 ft line is too short)

You also need to add the additional capacity of the new appliances to the existing design. When I applied this new information to the diagram, some of the existing pipe needs to be enlarged.  The 75,000 BTU heater now needs 3/4" pipe when the existing pipe was 1/2"

When this happens, It is sometimes easier to make a home run from the new equipment to the gas meter (or source).

I can't tell if you have actually accounted for ALL those variables in your gas piping design.

If you can provide the piping diagram you used with BTU of the connected appliances "as built" we can see if the problem can be resolved.

Also. there are many charts in the code book and selecting the correct one can sometimes be difficult. I remember when I moved from Philadelphia to Southern NJ, I needed to use a different table. PGW was extremely low pressure mains so the pressure past the meter was 5"wc, and South Jersey Gas had mostly high pressure lines to the meter and the regulator at the meter could often be set at 7" to 9"wc.

What is the gas pressure on the inlet side of the appliance when you do the test I asked about previously?

The 75,000 BTU heater now needs 3/4" pipe when the existing pipe was 1/2"

When this happens, It is sometimes easier to make a home run from the new equipment to the gas meter (or source).

I can't tell if you have actually accounted for ALL those variables in your gas piping design.

If you can provide the piping diagram you used with BTU of the connected appliances "as built" we can see if the problem can be resolved.

Also. there are many charts in the code book and selecting the correct one can sometimes be difficult. I remember when I moved from Philadelphia to Southern NJ, I needed to use a different table. PGW was extremely low pressure mains so the pressure past the meter was 5"wc, and South Jersey Gas had mostly high pressure lines to the meter and the regulator at the meter could often be set at 7" to 9"wc.

What is the gas pressure on the inlet side of the appliance when you do the test I asked about previously?

My last post had the piping diagram, I'll attach to this post as well. Used charts in Pennsylvania code book.0 -

0 -

The company who installed my furnace is coming tomorrow to take a look. My furnace doesn't run right when it's 25 degrees or less so I had to install the supplement heat because they couldn't figure out why. I'll see if they can give me answers tomorrow and if not, I'll at least get the measurements you are requesting to help further diagnose this issue.

I really appreciate your help, I tried a couple other forums and all I got was contact a professional. I appreciate you actually trying to assist me in figuring out my issue.0 -

I guess I'm confused then, I have 138,000 btu and 3/4 at 50 gets me 151,000 btu. What am I missing? What if I change the 1/2" to the supplement 18,000 btu heater to 3/4".EdTheHeaterMan said:Here is a diagram of my pipe, please review my work. Maybe I miss calculated.What is your gas pressure at the meter? with all appliances off.EDIT:

based on the most conservative chart I would change the pipe between the meter and the second Tee fitting to 1"

based on the most conservative chart I would change the pipe between the meter and the second Tee fitting to 1" 0

0 -

Start with the gas company, make sure you have enough pressure under load at the regulator. I suspect that is the problem with your furnace.0

-

The furnace installer is coming tomorrow to look. I had a 1980s Lennox pulse and never had a problem, heat exchanger then cracked and I had a brand new runtru put in and problems ever since.mattmia2 said:Start with the gas company, make sure you have enough pressure under load at the regulator. I suspect that is the problem with your furnace.0 -

This shows that the first pipe from the meter to the first tee fitting needs to handle more than 151 ccf of gas flow per hour. When you use 80,000 BTU (about 80 ccf) that leaves only 71 ccf left to do the rest of the system. If all the pipes are not properly deburred or if there are excessive elbows that are not accounted for, then the total capacity of that pipe might be further restricted and therefore insufficient for the space heater(s)

All things being perfect... the pipe "as is" should work with the furnace and the space heater but it will not be sufficient when all present and future appliances are commissioned. That said, I believe there may be a blockage somewhere.Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Did all the valves get opened all the way when then new furnace was installed?0

-

I made an edit back to my original picture. Just the first 17' of 3/4" pipe needs to be changed to 1"chris16371 said:

I guess I'm confused then, I have 138,000 btu and 3/4 at 50 gets me 151,000 btu. What am I missing? What if I change the 1/2" to the supplement 18,000 btu heater to 3/4".

I was thinking about the 72 on the 1/2" pipe was actually on the 3/4" pipe. Then I looked at it and realized my mistake. Sorry for the mistake.

As it exists, It should work. When you add the second supplement heater it will be close,

That is why I believe there must be a blockage in the pipe. It happens, as the pipe gets put thru a hole in a wall, or floor some junk gets picked up and that junk gets pushed into an elbow and just sits there.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I agree the gas pipe is too small. But the extra heater should light and run with the other units off so there are at least 2 issues0

-

The extra heater does run with the hot water tank on and furnace off, the furnace is the only one appliance that shuts off the extra heater.EBEBRATT-Ed said:I agree the gas pipe is too small. But the extra heater should light and run with the other units off so there are at least 2 issues0 -

I should of added that the other heater I will be hooking up won't be the same 18,000 btu but a smaller 10,000 btuEdTheHeaterMan said: This shows that the first pipe from the meter to the first tee fitting needs to handle more than 151 ccf of gas flow per hour. When you use 80,000 BTU (about 80 ccf) that leaves only 71 ccf left to do the rest of the system. If all the pipes are not properly deburred or if there are excessive elbows that are not accounted for, then the total capacity of that pipe might be further restricted and therefore insufficient for the space heater(s)

All things being perfect... the pipe "as is" should work with the furnace and the space heater but it will not be sufficient when all present and future appliances are commissioned. That said, I believe there may be a blockage somewhere.0

This shows that the first pipe from the meter to the first tee fitting needs to handle more than 151 ccf of gas flow per hour. When you use 80,000 BTU (about 80 ccf) that leaves only 71 ccf left to do the rest of the system. If all the pipes are not properly deburred or if there are excessive elbows that are not accounted for, then the total capacity of that pipe might be further restricted and therefore insufficient for the space heater(s)

All things being perfect... the pipe "as is" should work with the furnace and the space heater but it will not be sufficient when all present and future appliances are commissioned. That said, I believe there may be a blockage somewhere.0 -

The pilot light is an exceedingly small load. Undersized gas lines might be responsible if the main burner of the space heater can't light properly or drops out when the furnace comes on, but to effect the pilot the gas pressure (& hence volume) must be dropping to near zero.

It sure sounds like a restriction to me, like I mentioned above. You really need a manometer diagnose much further further. A Magnahelic (with the buna-N diaphragm) if you like analog, or a Fieldpiece if you like digital.

2 -

ratio said:The pilot light is an exceedingly small load. Undersized gas lines might be responsible if the main burner of the space heater can't light properly or drops out when the furnace comes on, but to effect the pilot the gas pressure (& hence volume) must be dropping to near zero.

It sure sounds like a restriction to me, like I mentioned above. You really need a manometer diagnose much further further. A Magnahelic (with the buna-N diaphragm) if you like analog, or a Fieldpiece if you like digital.

I have the furnace installer coming tomorrow and I'll have them take the pressures. I'm definitely going to buy a manometer myself, such a valuable tool that I should of had before the install.

Here is pics of the pilot with the furnace on and also with it off.

0 -

0 -

Hold the pilot knob down for 10 min lit and try it. May be air in the line.0

-

Furnace installer was just here. I have 10" wc and when the furnace kicks on it drops to 1" wc so I'm losing 9" wc. Time to call gas company0

-

By all means call the gas company. But, the static pressure of 10"W/C that drops to 1"W/C could be because of pressure loss in the piping because of a restriction, too long of a run, or faulty gas valve. Where was the measurement made, that's the question.0

-

Note that if the service regulator is bad, the gas company would not have charged you to test and replace it.0

-

Where did he test the pressure at, the new heater? The furnace would not run normally on 1" any more than the heater does. If he was checking the pressure at the new heater, it still sounds like a restriction (hunk of dirt in the end of the pipe, plastic cap stuck somewhere, etc.). If he was checking it at the meter, IDK what's going on.0

-

Gas company came out and did their own tests. Main from street to meter in basement is leaking. I was also told it is my responsibility and not theirs and is going to cost me $2500. I looked it up and right on Columbia gas of PA website it says western PA (where I live) is my responsibility from street to meter but if I lived in central PA then they own all the way to meter and customer just after meter. I just now got a call and they are replacing it for free!!!!ratio said:Where did he test the pressure at, the new heater? The furnace would not run normally on 1" any more than the heater does. If he was checking the pressure at the new heater, it still sounds like a restriction (hunk of dirt inn wes the end of the pipe, plastic cap stuck somewhere, etc.). If he was checking it at the meter, IDK what's going on.1 -

-

I agree idk how the furnace was running. I have had many issues with it throwing codes with the condensate trap hose on it but stopped throwing codes with it off. With temps 25 or less it has a hard time keeping up and if it gets to cold the temp will actually drop with furnace running. I'm guessing this repair will take care of that issue.ratio said:Glad they're going to take care of it. I still can't see how the furnace is running ok, but it's hard to argue with facts.

Also the 9" wc drop was measured at the inlet port of the supplement heater which is the furthest line/appliance from meter.0 -

The furnace was very likely very much underfired.0

-

Gas company just finished and wow, my furnace is actually working how I expected to in the first place. They moved the meter to the outside and changed a couple other things. The supplement heater is working properly now.

Gas company just finished and wow, my furnace is actually working how I expected to in the first place. They moved the meter to the outside and changed a couple other things. The supplement heater is working properly now.

Below is picture of the pilot now, does this seem to big or about right? Just asking because when the tech from the furnace installer was here, he messed around with the heater regulator a little bit and I'm not sure if he put it back where it should be.1 -

Looks about right, much less than that and it isn't going to heat the thermocouple.

I bet the furnace is adequate now that it is firing properly.0 -

The temperature is going to drop here in a week and a half, then I'll know for sure if I need the additional heaters. The room I have the current heater in, that's the longest vent run and it doesn't blow very warm air so I may still need it but the other room I was going to install one in does blow warm air now so I may not need to get one for there.mattmia2 said:Looks about right, much less than that and it isn't going to heat the thermocouple. I bet the furnace is adequate now that it is firing properly.0 -

You might need to balance the forced air system, open the dampers for the long runs, close the dampers some for the short runs. you should also check the supply and return temp and compare the difference to the ratings plate on the furnace now that it is firing properly.0

-

The furnace tech that was here today said dampers should of been installed at time of furnace installation so he is going to order them and install them free of charge and I'll have him check the supply and return temps at that time. Last year, one of the techs checked them and kept making adjustments and the best he could get was the minimum rating.mattmia2 said:You might need to balance the forced air system, open the dampers for the long runs, close the dampers some for the short runs. you should also check the supply and return temp and compare the difference to the ratings plate on the furnace now that it is firing properly.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements