Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Short Cycle / Vaporstat Problems?

Options

Jakek

Member Posts: 57

I'm noticing something new this year: I'm hitting the set point of the vaporstat quickly and only when the radiators are basically still cold. Venting across the system is good.

I started the year with the vaporstat set to 8oz, measured by separate gauges. It hits this level quickly. If I increase the cut-off pressure I notice the boiler gets to ~11oz for a few seconds before quickly dropping down to 4oz and slowly rising with that rise/drop cycle continuing.

This is a newer Honeywell vaporstat with the microswitch and springs.

I had been on the impression I wanted as little pressure as possible but now I think I've been going so far down as to short cycle. I've yet to find the sweet spot.

I'm wondering if a better method is to attach a temperature sensor to the far end of a radiator (1-pipe) and use that as the shut-off indicator. When the rad is fully hot, turn off the system for 30 min before resuming a call for heat. (Keeping the existing vaporstat and pressuretrol for safety.)

Thoughts?

I started the year with the vaporstat set to 8oz, measured by separate gauges. It hits this level quickly. If I increase the cut-off pressure I notice the boiler gets to ~11oz for a few seconds before quickly dropping down to 4oz and slowly rising with that rise/drop cycle continuing.

This is a newer Honeywell vaporstat with the microswitch and springs.

I had been on the impression I wanted as little pressure as possible but now I think I've been going so far down as to short cycle. I've yet to find the sweet spot.

I'm wondering if a better method is to attach a temperature sensor to the far end of a radiator (1-pipe) and use that as the shut-off indicator. When the rad is fully hot, turn off the system for 30 min before resuming a call for heat. (Keeping the existing vaporstat and pressuretrol for safety.)

Thoughts?

0

Comments

-

Before you do anything drastic, take a little time and, starting from a cold boiler, compare what the pressure is doing with where -- and if -- steam is going in your mains. If the venting really is good, no pressure or very little should build until the vents (or crossover traps if you have those instead) see steam. The vapourstat can only respond to what it sees in the boiler -- and if the steam is having trouble leaving the boiler, it will see a rapid pressure rise once the boiler starts to steam.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

-

Check that the pigtail on your control isn't partly clogged.0

-

The system is fairly small and basic. The main splits into two legs, each with 5 rads that are collectively equal. At the end of the dry return of each leg is a Gordon #2 and they are both fairly new.

I just did a test where I removed the #2 entirely from the East leg and called for heat. I could feel air being released from the open pipe. Pressure built to around 10oz when the vaporstat cut in but still no visible stream. Once it reset I waited until I actually saw steam before reinstalling the vent. Pressure didn't build as high this time.

I did the same test on the West leg. Pressure built to about 8oz before I could see steam.

There are two pigtails, each connected to its own low pressure gauge and they move in sync. There's the vaporstat on one pigtail and a pressuretrol on the other.

I should add rads are all getting hot once I increased the cut-off on the vaporstat slightly to ~11oz. So thankfully this isn't a real problem, just something I find curious.0 -

is the vaporstat new for this season?

or did it run last season also?

are you getting used to a new control here?

and you said the Vstat tripped off while you had vents off and pipe open?

post a picture of one of your main vents, too small pipe / nipple connection?known to beat dead horses0 -

Vstat is about 3 years old and I haven't made any changes to the system recently. Last year it would take about 35-45 min to build up enough pressure to trip from a cold start. At the same setting it would only take a few minutes this year.

Near boiler piping isn't great although it hasn't changed in the past 32 years. I'm guessing the vent location and piping is original to the house. (1925)

FWIW, I'm assuming the setting on the Vstat is useless and my gauges are ballpark accurate. Going by just the Vstat the cut-off pressure is 2oz.

0 -

Don't rule out a bad vaporization. I miss my mercury ones. Much better. Had several new types go bad after short time. MD0

-

-

Hello @Jakek,

It would be interesting to know what has changed. I would venture to say that every steam system has a unique pressure signature depending on how it is built. And that pressure signature may change with time (aging) and the dynamics of system loading and other influences. Since it appears you are using the gauges as your reference the actual calibration of the Vaporstat may be irrelevant.

Do your gauges always return to the same place when the boiler cools ? (hopefully zero)

Could the quality of your fuel be better this season putting more BTUs into the boiler faster ? (faster pressure rise)

Do all the radiators heat as expected ? (no plugged vents for failed shut off valves)

Any change in pipe insulation ?

I would set the Vaporstat high enough that the steam gets to the end of the main and starts to fill the radiators reliably. Once most or all the vents close I don't think there is much reason to continue to run the boiler.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Old buildings are not static, things can settle over time and pipe hangers can snap. Any settling in the wrong place can cause an iffy pipe slope to go negative and cause no end of mischief. use a level on the header and mains to make sure nothing has shifted.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

@109A_5 No changes to any of those factors and rads heat fully and evenly. There might be more BTUs in the gas but I don't have a way of measuring that. I did use a little bit more 8-way this year although still below the recommended amount. (Light purple in the sightglass.)

@BobC Maybe you are onto something. The pipes are all pitched well but it's the boiler that's changing. The genius who installed the boiler in 1989 used a 1" nipple to level the boiler. That nipple is buckling and the level of the boiler is shifting slightly. This is something I've been concerned about just from a piping standpoint. The question is how to fix this. I was thinking maybe put a crowbar w/cheater and gently lift while someone puts something more solid underneath?

Another datapoint: The high/low pressure cycle only happens when the system is cold. Once things heat up it levels off to around 8oz and stay there.

0 -

Have you tried flushing the water out of the boiler. You might have too high a level of TDS in the boiler and its effecting the quality of your steam. considering that you have changed nothing except add water to the boiler then this would be worth a try. Its very simple and cost nothing. Remember if your running a vapor system the quality of the steam needs to be real good or it will condense before it reaches the radiators0

-

um, wuchya got going on there ?

I see a 3 wire Vstat,

and a transducer(?) on the Ptrol piping?

1st question,

why isn't Vstat cutting out at 2 OZ ?

is wiring mixed up?

maybe water is too purple ?

and surging?

and, well, wait a minute,

why isn't Vstat cutting out at 2 OZ ?

(or 4 , 6, 8, oz)

known to beat dead horses0 -

Hello @Jakek,

I think at this point I would just replace the pipe with a new piece. The original lasted this long.

As far as the higher pressure from a cold start, you are pushing out colder denser air and the steam is condensing in the process of warming up the pipes slowing the steams progression, so the air gets pushed out slower so a bit higher pressure until things warm up.National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

@109A_5 I'm going to replace it with something that won't rust.

It's more a matter of lifting the boiler enough to do that.

It's more a matter of lifting the boiler enough to do that.

@neilc The wiring is correct for this system. As far as the boiler goes, everything is in series and is tested periodically. The extra connections you see are going to a datalogger to record when the Vstat trips and when there is a call for heat. The transducer is not currently connected but was intended to log pressure as well.

The Vstat is new as of 2 years ago and it never corresponded to the setting on the side. I've been adjusting it by noting what is being displayed on the pressure gauges when it trips. Adjusting the limit screw on the Vstat changes the cut out pressure accordingly. It's possible both gauges are bad but that seems unlikely.

Thanks everyone for the comments. I'll try flushing the boiler.0 -

Hello @Jakek,

A Stainless Steel nipple probably won't rust. As far as lifting it a bit, if I did not have a 3 foot pry-bar and a a block of wood to slide under the handle end of the pry-bar to hold the position, I would use a 3/8" fine thread (SAE) bolt of the appropriate length, a nut and a stack of flat washers or fender washers and two wrenches. The flat washers extend the length of the bolt a bit while not running the nut off the end of the bolt. Many ways depending on your resources.National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I was going to ask if you used any chemicals as I experienced (experience) the same (similar) issue with my 60 yo Burnham and mercury Vaporstat....(I thought maybe because I still run in vacuum it may of amplified any pinhole leaks or seals around the valves etc.. though most likely after using them for cleaning, then flushing and putting "maintenance" dosage in ....It became apparent that clear water after flushing doesn't mean a clear system...My Vaporstat was climbing like I never saw before... the long and short is it took a lot of flushing, skimming and running the system to purge all that pink/purple stuff out and get my boiler back to normal operation...Jakek said:@109A_5 No changes to any of those factors and rads heat fully and evenly. There might be more BTUs in the gas but I don't have a way of measuring that. I did use a little bit more 8-way this year although still below the recommended amount. (Light purple in the sightglass.) @BobC Maybe you are onto something. The pipes are all pitched well but it's the boiler that's changing. The genius who installed the boiler in 1989 used a 1" nipple to level the boiler. That nipple is buckling and the level of the boiler is shifting slightly. This is something I've been concerned about just from a piping standpoint. The question is how to fix this. I was thinking maybe put a crowbar w/cheater and gently lift while someone puts something more solid underneath? Another datapoint: The high/low pressure cycle only happens when the system is cold. Once things heat up it levels off to around 8oz and stay there.

Again it's a 60 yo Burnham and I'm running vacuum but I see yours is 35 yo so flush and skim might be your answer also..

And stick with water for running your boiler..

Just my opinion from my experience and observationsOne way to get familiar something you know nothing about is to ask a really smart person a really stupid question0 -

To close out this thread-

Thanks for the advice a few weeks ago. I drained and refilled the boiler and also got it closer to level at the same time. (Crow bar with a cheater; was easy.) Within the past year that nipple support had really compressed and I didn't realize just how unlevel it had become.

Either due to one or both of the changes it's back to operating on a low and consistent pressure. Normally it will satisfy the TStat before reaching pressure shutoff.1 -

- Have you turned any radiators off that were open last year? Closing even one radiator can have an impact on how much over-sized a boiler can be and increase pressure.

- Try draining the boiler and run it without the 8-Way in the water. That stuff can do very strange things if there is too much in the boiler. If that fixes the problem, only add enough back into the boiler to slightly tint the water.0 -

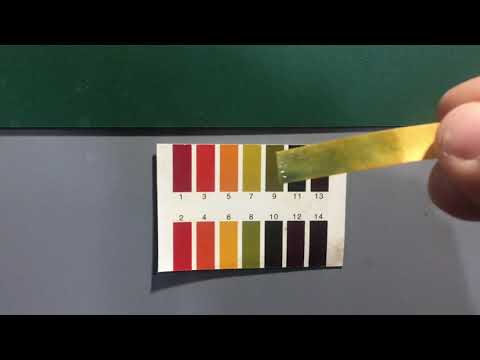

I agree with Fred, don't add too much. Although I did add way too much and it didn't do anything:

https://youtu.be/_JFfO_VgvNQ

https://youtu.be/_JFfO_VgvNQ NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Looks like a Burnham Boiler. I gotta tell you, I don't know what it is about the design of Burnhams (I have one too) but they seem far more sensitive to oils and additives than any other boiler I've seen. I have added more water conditioners to my boiler a couple times and it creates havoc almost immediately. For the conditioner, drain some water, add enough water to dilute it and it's good to go. For any oils in the water, it takes a very, very slow skim to stabilize the water bounce.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements