Can you balance a system with no measurable pressure ever?

My boiler NEVER reads any pressure, and it seems erratic which risers are getting heat. I don't live there, so I try and gather info with logging thermometers. I don't want to go chasing venting when there's a different problem!

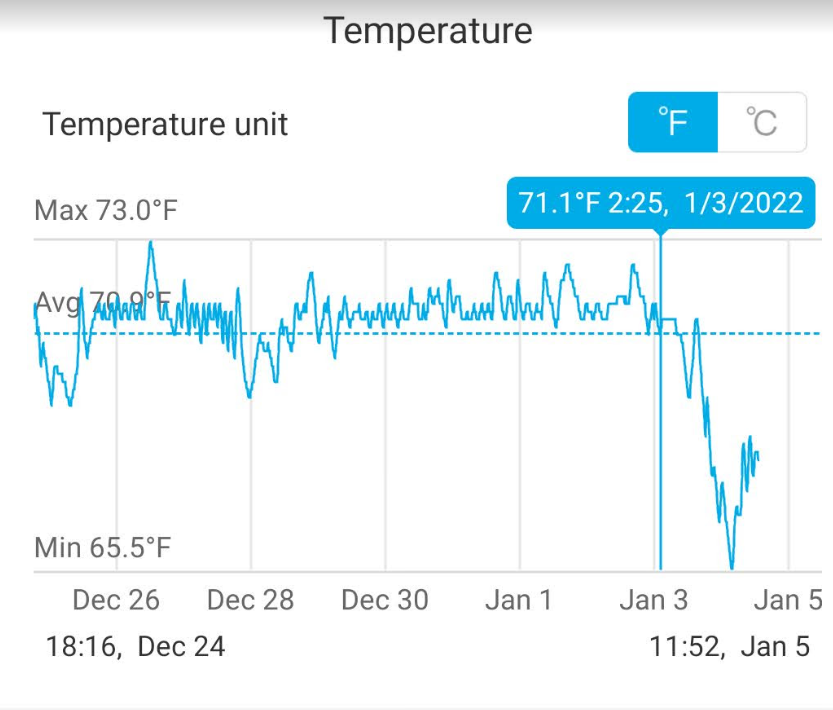

How can you direct steam when there's no pressure? It seems to be cycling reasonably according to a recording thermometer I put on top of the thermostat. Bu it was unable to hold temp during the cold snap last weekend. The boiler was serviced & cleaned last year by a HH member. Any ideas?

Comments

-

Could this be the mythical undersized boiler?

Steam needs some pressure to push the air out of the system (through the main vent(s) and then through the radiators--in the case of single pipe systems)

Without enough pressure, it just won't travel to all radiators. The only way for it to have not enough pressure that I can think of is for it to be quite undersized (the actual EDR would have to be at least 30% higher than the plate rated sq ft of steam for this to occur I think). In this scenario it will flow where the flowing is easiest and can totally ignore a radiator or a whole main.

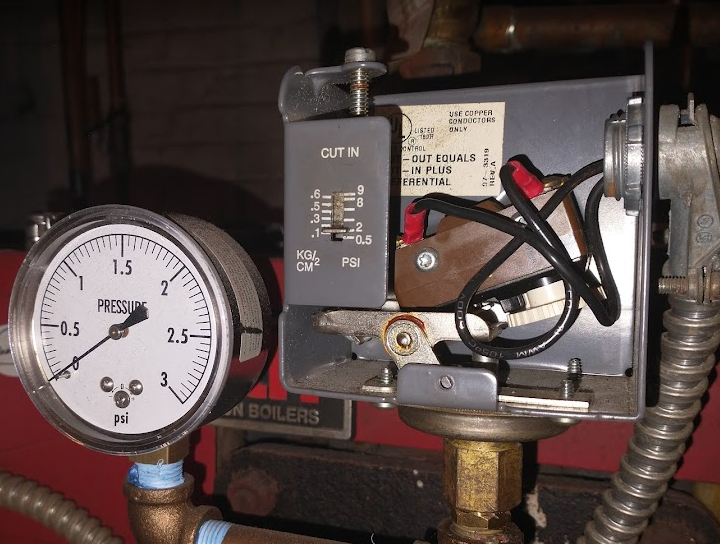

Even though your gauge is a nice low pressure one, it's still too high to show nice low operating pressures, and certainly too high to show a too-low pressure scenario I described above. So don't assume your pressure is too low...we can't tell from the existing information.

Your post gives me some questions. I understand you may not be able to answer them because you weren't there, but maybe you can add a couple internet devices to monitor when the boiler is firing.

1. Sounds like you had a possibly knowledgable steam contractor do work for you...what do they say about this situation?

2. Was your boiler firing continuously from Jan 3 to Jan 5? Or was it intermittent? (you can fasten a smart thermometer device to an uninsulated section of main pipe to help you know this)

3. If it was intermittent, it sounds like the thermostat was never satisfied (but it's dangerous to assume), so did the pressuretrol shut it off on pressure ever? (you could put a network camera on your pressure gauge to see this perhaps, or maybe you already have an internet-enabled thermostat)

4. Do you know your actual, measured EDR of your total radiation? And what is the sq ft of steam rating of this boiler?

Finally PS: even though we're pretty sure that high pressure isn't your problem here since you've never seen any pressure build, I would still lower that pressuretrol down closer to the bottom of that front scale.

PPS: I like your test removal of that MoM orifice to see if there is any steam appearing at a particular radiator. I like the way you think.NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Is the boiler using much water?0

-

ethicalpaul said:

Could this be the mythical undersized boiler?

It was sized and installed by a reputable former HH member, Jstar.

Steam needs some pressure to push the air out of the system (through the main vent(s) and then through the radiators--in the case of single pipe systems)

Without enough pressure, it just won't travel to all radiators. The only way for it to have not enough pressure that I can think of is for it to be quite undersized (the actual EDR would have to be at least 30% higher than the plate rated sq ft of steam for this to occur I think). In this scenario it will flow where the flowing is easiest and can totally ignore a radiator or a whole main.

Even though your gauge is a nice low pressure one, it's still too high to show nice low operating pressures, and certainly too high to show a too-low pressure scenario I described above. So don't assume your pressure is too low...we can't tell from the existing information.

Your post gives me some questions. I understand you may not be able to answer them because you weren't there, but maybe you can add a couple internet devices to monitor when the boiler is firing.

1. Sounds like you had a possibly knowledgable steam contractor do work for you...what do they say about this situation? He did not assess the global situation, the dirty boiler and vent pipe were a serious enough issue at the time.

2. Was your boiler firing continuously from Jan 3 to Jan 5? Or was it intermittent? (you can fasten a smart thermometer device to an uninsulated section of main pipe to help you know this)

3. If it was intermittent, it sounds like the thermostat was never satisfied (but it's dangerous to assume), so did the pressuretrol shut it off on pressure ever? (you could put a network camera on your pressure gauge to see this perhaps, or maybe you already have an internet-enabled thermostat) Given the jagged graph, it appears so, but I'm planning on installing a Nest E with all the 'smarts' turned off, so I can monitor the situation there better. It's too bad these don't actually record the temps in addition to the heat cycles. I had a logging thermometer on the boiler last year, and it appeared to cycle properly, as per the pic below of the week right after it was serviced. I have a cam I can try and put on the gauge, but the wifi there is iffy

4. Do you know your actual, measured EDR of your total radiation? And what is the sq ft of steam rating of this boiler? No idea

Finally PS: even though we're pretty sure that high pressure isn't your problem here since you've never seen any pressure build, I would still lower that pressuretrol down closer to the bottom of that front scale.

PPS: I like your test removal of that MoM orifice to see if there is any steam appearing at a particular radiator. I like the way you think. Thanks, but it seems a pretty low bar of cleverness! 1

1 -

Might have more data monitoring and control options with the Ecobee4 vs the Nest.0

-

I already have the Nest, my utility is giving them away! But it's the 2020, which doesn't allow lockout on the device to keep tenants from messing with it, so I may swap it for the E in my own home, which does do lockout.dabrakeman said:Might have more data monitoring and control options with the Ecobee4 vs the Nest.

0 -

There has to be enough pressure to get steam to flow.

"Enough" pressure on a one-pipe system by general agreement seems to be about 4 0z/in2.

Balancing a system when there is not enough steam is like trying to sail when there is too little wind...

The tiller doesn't answer.

Could it be you are underfired or there is a gas main supply problem?

All Steamed Up, Inc.

"Reducing our country's energy consumption, one system at a time"

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Baltimore, MD (USA) and consulting anywhere.

https://heatinghelp.com/find-a-contractor/detail/all-steamed-up-inc0 -

Jells said:

That's exactly what it feels like! You take the port off a vent and nothing happens just like a tiller with no way! It's like with no pressure the steam just keeps going up the riser without being diverted into the rad.Gordo said:Balancing a system when there is not enough steam is like trying to sail when there is too little wind... The tiller doesn't answer.

0 -

@Jells

I would start with your connected edr load

add 20 % to that for boiler efficiency

add to that 1.33 piping and pickup

The total should be you approximate firing rate in BTUs

Example:

200 EDR=200 x 240=48000 btux 1.20=57600x1.33=76606

=76 cf of gas per hour or .54 gallons of oil/hour0 -

My system has been perfectly balanced since 2012 and since sometime around 2014 I've been running between 0.25 to 0.5" WC at times. Or 0.14 to 0.30 ounces.

Not only is it always balanced it stays balanced with 5 TRVs changing all over the place. I've had it work both with and without TRVs.

You will not be able to measure pressures this low with a pigtail. But whatever you do make sure you keep the proper pigtail, 30 psi gauge and pressurtrol in place. This cannot be changed. Anything you do must be done in addition to the basic controls and must be done safely.

Even on the coldest days I do not run at a full once.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

@Jells

What works on one job

( @ChrisJ ) (extremely low pressures)

may not work on your job.

(did the original fitter ream all the piping?) How much did designer #1 oversize the pipe and radiation compared to designer #2?

Who knows? You have to work with what you have. You have to have enough steam pressure to overcome the pressure drop of the piping the longest run usually or the one with the least venting.0 -

I calculated the pressure drop to each radiator.EBEBRATT-Ed said:@Jells What works on one job ( @ChrisJ ) (extremely low pressures) may not work on your job. (did the original fitter ream all the piping?) How much did designer #1 oversize the pipe and radiation compared to designer #2? Who knows? You have to work with what you have. You have to have enough steam pressure to overcome the pressure drop of the piping the longest run usually or the one with the least venting.

As far as who knows, I knows.

If the pressure is too low to get to the condensers it'll increase until its not.

I understand systems vary. No disagreement there.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

So I'm still struggling. I followed the suggestion of @Chris_L in this thread https://forum.heatinghelp.com/discussion/186633/adding-a-low-pressure-gauge-to-my-steam-boiler and made a simple 'inches of water' scale with vinyl tubing to a ball valve at the bottom of the sight gauge. According to this I have no pressure at all, much like I suspected. But a reputable heating guy I chatted with says this is not a valid way to measure! I'm not sure he's right, seems to me as simple as a glass barometer, pressure causes water to go up the tube. If there's no pressure, water won't go up the tube.

There's so much that's explained by no pressure. I've got a radiator hot whose pipe comes off the main 6" from the branch to a cold riser with 2 rads on it. There's no excessive makeup water, it's burning 130k BTU continuously, no leak in the system detectable, nothing obviously wrong at all except I can't get pressure to direct the steam! 0

0 -

Do you have the EDR numbers from JStar’s sizing?

can you turn some radiator vents upside down, closing them temporarily, just in an effort to lower the EDR enough to see if you can get any pressure to build on your water column?NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Unfortunately I don't have the numbers and jstar went incommunicado on any contacts I had when they sold their company. Without bothering tenants I have access to 1/3 of the radiators. Perhaps that might be enough but I doubt it, this thing is just not creating any pressure!

I did find this article by Dan that doesn't leave very many options open

https://heatinghelp.com/systems-help-center/reasons-why-you-cant-raise-pressure-on-the-gauge-and-where-to-look-for-solutions/0 -

You're right, there aren't really any possibilities other than:

- boiler very undersized (unknown) -- What is the sq ft rating of this boiler?

- gas delivery not working correctly (bad valve/blocked burners/etc) (you reported it's 130K BTU)

- Hole in boiler sending steam up the chimney (you report no leak)

- Hole elsewhere in system (could a tenant have removed a vent?? Like in a misguided effort to increase humidity?? But you say there is no unusual water usage)

I do think that temporarily disabling those 1/3 of radiators would be enough to tell you something--a boiler would have to be ridiculously (really) undersized to STILL not build any pressure with 1/3 of its radiators off. I would try it--it's free and easy.

Just spitballing here, but if there was a bad situation with the water or near-boiler piping, it could be throwing enough water in the system to really foul up the steam...but that would normally show symptoms like banging or water spewing out of some vents. I would also expect that to show up on your 0-3psi pressure gauge, at least as some quivering, so that one doesn't seem too likely.

About that 130k BTU you reported...did you clock your gas meter to get that value? If not, how did you get that value?NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

@ethicalpaul I clocked the 2 cu ft dial at 55 seconds.0

-

I will want to hear what the pros say about this clock rate...But when I plugged that into my spreadsheet it comes out as 28k BTU/hour net (with 83% efficiency).

It's possible that I'm clocking a different dial than you, I will have to check that also.

Can you show your math that got you to 130K btu?

Edit: my spreadsheet was set up for the 1/2 cu ft dial so my comment above should be ignoredNJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Nope, that's what the contractor said. I have not dived into the conversionethicalpaul said:.Can you show your math that got you to 130K btu?0 -

What vents are on all of your radiators?

I'm sorry if I missed it or if this is a 2 pipe system.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

@ethicalpaul I think I got the math. If it's burning 2 in 55, that means one in 27, that means one every 0.45 minutes, which works out to 133 an hour. At 1,037 Btu per cubic foot that 138k btu/hr0

-

OK ignore my post above (I'll edit it so it doesn't mislead anyone). I clock the 1/2 cuft dial because I have a tiny boiler so I think you're looking at about 113 BTU/hr net give or take. What is the plate rating of net BTU or net sq ft of steam on your boiler?Jells said:Nope, that's what the contractor said. I have not dived into the conversion

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

This is not a technical answer by any means, but my low pressure gauge rarely shows anything greater than 1 or 2 oz of pressure and the two-pipe system heats fine. That may be within the margin of error on other gauges and may be therefore be undetectable. Notably on my system, I suspect that I have no operational traps (failed open) and I have adjustable inlet valves that I've worked to balance over the past two season so maybe there isn't much to build pressure against in my case.New owner of a 1920s home with steam heat north of Boston.

Just trying to learn what I can do myself and what I just shouldn't touch0 -

55 seconds on the 2 cu ft scale gives me 130,909

(3600 x 1000)/seconds = BTUH Since he did the 2 cu ft scale divide the seconds in half

3,600,000/27.5=130,909

What size vents are you using on the radiators? If I was guessing I'd say your radiators are over vented across the system, but without knowing sizes it's hard to say.

Also I don't see mention of what your main venting is? It starts there.

0 -

I'd really like to know approximate EDR and the rating of the boiler.

Also KC & Jells is that 130K Input BTU or output?

I have 200 EDR (7 rads in a tiny 1200 sq ft house) and clocked Input BTU of 89K

My old boiler (oversized by a size) was about 117K input

So a four family house seems like it should be a lot more than 130K but again, we don't have enough informationNJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

@KC_Jones @ethicalpaul

I don't know the EDR, but at this point I must trust that Jstar knew what he was doing and calculated properly. I have no idea how to figure the rated BTU of the system, it's a Carlin gas burner on a oil type boiler. Where does one even start?

Venting. Assuming they're all working it seems to me that an over-vented system would get all the vents closed at SOME point and build pressure if the therm is not getting satisfied? There's no evidence of water loss due to failing valves or leaking boiler according to the VXT. Most of the vents are MoM with various port sizes.

The main vents could use work, the furthest serving 6 bedrooms is only a single Gorton 2, and the 2nd furthest serving just the 3 kitchens seems non-operational. I've been unable to remove it to place a Gorton 2.

@Zipper13 1oz would be 1.75". My primitive vinyl hose gauge shows 0 inches of water pressure. Nada.0 -

This isn't about building pressure.

It's about understanding how fast you're allowing steam into the radiators. The faster you vent them the more they will suck down steam.

That means if you slow them down, it'll give time to spread to all of them before they really start to pull on the boiler. You can steer the steam to some radiators more than others by changing vent speed.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

2 -

But if the rad in the room with the therm is cold, the therm is NEVER satisfied, then the cycle doesn't end, and the steam should EVENTUALLY get to every rad. What am I missing here?ChrisJ said:This isn't about building pressure.

It's about understanding how fast you're allowing steam into the radiators. The faster you vent them the more they will suck down steam.

That means if you slow them down, it'll give time to spread to all of them before they really start to pull on the boiler. You can steer the steam to some radiators more than others by changing vent speed.0 -

Well,Jells said:

But if the rad in the room with the therm is cold, the therm is NEVER satisfied, then the cycle doesn't end, and the steam should EVENTUALLY get to every rad. What am I missing here?ChrisJ said:This isn't about building pressure.

It's about understanding how fast you're allowing steam into the radiators. The faster you vent them the more they will suck down steam.

That means if you slow them down, it'll give time to spread to all of them before they really start to pull on the boiler. You can steer the steam to some radiators more than others by changing vent speed.

For example my system if I vent certain radiators too fast, some radiators will never get steam. I had it happen when I first installed my boiler and that was actually before I downsized my boiler. So now if I did it, it would really be bad.

What vents are on the radiators?

Did the system work correctly previously?Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Yes, that makes sense if a system is otherwise operating properly. But this one isn't. Like I said, most vents are MoM. There are times it's seemed to work, or maybe I just had tenant's who didn't complain.ChrisJ said:

Well,

For example my system if I vent certain radiators too fast, some radiators will never get steam. I had it happen when I first installed my boiler and that was actually before I downsized my boiler. So now if I did it, it would really be bad.

What vents are on the radiators?

Did the system work correctly previously?0 -

Jells said:

Yes, that makes sense if a system is otherwise operating properly. But this one isn't. Like I said, most vents are MoM. There are times it's seemed to work, or maybe I just had tenant's who didn't complain.ChrisJ said:

Well,

For example my system if I vent certain radiators too fast, some radiators will never get steam. I had it happen when I first installed my boiler and that was actually before I downsized my boiler. So now if I did it, it would really be bad.

What vents are on the radiators?

Did the system work correctly previously?

Need to know the exact size of all of them. Saying the brand doesn't tell us a whole lot.

It's not working properly due to venting, Based on what you have posted I don't see any other issues.

If Jstar installed the boiler, I wouldn't suspect anything he did as being a problem.0 -

I think you're past the point where you can trust anything.

Take a photo of the rating plate of the boiler. That will tell you what the boiler will put out with the rated fuel consumption. Then we can compare that with your fuel use.

There will still be the variable of the burner, but we can kind of set that aside for the moment...if your boiler says 220K BTU we will know the burner isn't delivering enough fire.

If the boiler says around 130K we will be able to rule it and the burner out as a problem. We will know it is delivering the BTU into the house that it was designed to.

Then it would be good to know your EDR or at least a fairly accurate idea of how many radiators of what size you have.NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

From what I can tell, the Carlin burner is variable, so there's no way for me to determine it's output. Would you be able to determine the EDR from pics of the rads?ethicalpaul said:I think you're past the point where you can trust anything.

Take a photo of the rating plate of the boiler. That will tell you what the boiler will put out with the rated fuel consumption. Then we can compare that with your fuel use.

There will still be the variable of the burner, but we can kind of set that aside for the moment...if your boiler says 220K BTU we will know the burner isn't delivering enough fire.

If the boiler says around 130K we will be able to rule it and the burner out as a problem. We will know it is delivering the BTU into the house that it was designed to.

Then it would be good to know your EDR or at least a fairly accurate idea of how many radiators of what size you have.

0 -

Yes it's definitely variable, but the point I'm trying to make is if we see the BTU rating of the boiler, we can at least have a point of reference to compare it to your clocked BTUs.

Pics and dimensions of the radiators can be used to determine their EDR yes. If there are just a couple sizes that makes it considerably easier LOLNJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

@ethicalpaul

FWIW, here's pics from my photo archive. I don't know how you can figure their dims, the windowsills are lower than a typical modern window.

3 of these, master bedroom

2 of these in smaller BR, it's like a foot wide

3 of these in a middle room

3 of these in LR

3 of these in kitchen

There's also a 2.5" pipe running through the baths with a vent on top.0 -

I can't figure their dimensions...you have to do that with a ruler and then report back

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I figured as much. More of a project, I'm trying to get actual paying work done today! And of course the heat guy is slammed with people with no heat, so I'm at the back of the line since no one is actually freezing.ethicalpaul said:I can't figure their dimensions...you have to do that with a ruler and then report back

0

0 -

Yeah...Jells said:

I figured as much. More of a project, I'm trying to get actual paying work done today! And of course the heat guy is slammed with people with no heat, so I'm at the back of the line since no one is actually freezing.ethicalpaul said:I can't figure their dimensions...you have to do that with a ruler and then report back

Us too.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

Zero pressure. No water loss (per VXT). Firing continually. Where are the BTUs going? It's not like the therm is satisfied and shuts off before some rads fill with steam, its firing continually and steam should EVENTUALLY reach them all! One theory is it might be condensing and not reaching the rads, but the heat HAS to go somewhere! Either up the stack, or into the water. You can't keep shoving BTUs into the boiler and they vanish!

Steam tech wants to change out the ancient returns. I cannot disagree that it's a good idea in any case, but I'm unconvinced that it will solve the mystery of the vanishing heat.

I have now measured the total EDR as 343, excepting the 2.5" pipe that runs up through the baths. That's 82,320 BTU, right? So there's no way I'm undersized if I"m burning 130k.0 -

Bumping this rather than start a new thread with the burner specific question. But it still stands:

Where are the BTUs going? It's not like the therm is satisfied and shuts off before some rads fill with steam, its firing continually and steam should EVENTUALLY reach them all! One theory is it might be condensing and not reaching the rads, but the heat HAS to go somewhere! Either up the stack, or into the water. You can't keep shoving BTUs into the boiler and they vanish!

Can a burner be so dirty that like 50% of the gas never combusts? That seems like the only thing that could account for all the symptoms.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements