Air Handler Condensation Drain Issue

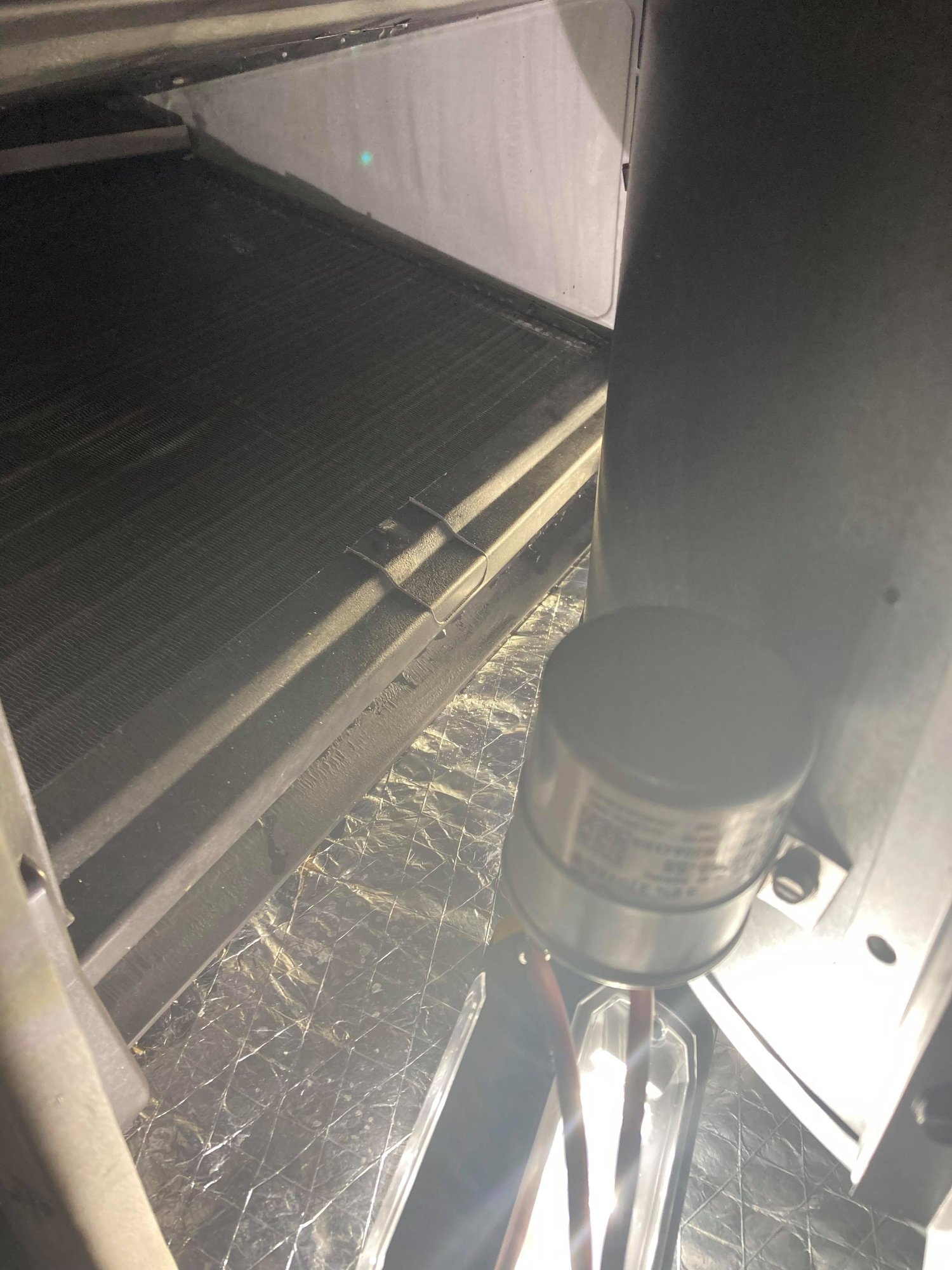

I just had a Rheem RH1P3017STANJA Air Handler installed in my attic. The installers had to change the coil configuration to a horizontal mount for the install. Soon after the install I noticed the condensate was going into the overflow catch tray and the auto-shutoff kicked in (thank God). It appeared to be leaking from where the return air duct connects to the unit. The tech came back and told me the pitch on the PVC drain was off. He made some adjustments but the problem came right back. The next time the tech came he adjusted the level pitch of the unit itself by slightly raising one end. Well the problem once again came back but this time the leak moved to the other side of the unit. So right now where the blower motor insulation is, it's soaking wet. I really wish these guys would test the fix better before leaving. Anyway, I did as much research as I could and my understanding is that when you change to a Hz configuration you must install both top and bottom coil support rails on the new coil position. I pulled the unit panels myself and I notice that they only installed the top rail but not the bottom. I can literally pour two bottle of water into the actual drip tray and they seem to disappear into the insulation or somewhere. Would not installing that bottom rail cause this problem or could it be something else? Now that the unit is in place I have no idea how they could even drill holes to put in the rail now, especially since it's all connected. Thanks in advance for your input.

Comments

-

That pan is discarded in other than horizontal configurations. Since I normally discard it I have not looked very closely at them. You may want to check to see if there is a lip on that pan that is in the right position to direct the water into the black condensate pan. As far as drilling holes, I don't recall ever having to drill any holes to change the coil around.0

-

After you make them read the instructions and install it properly make them measure static pressure for airflow0

-

Every brand of air handler is different. Get the installers back have them read the instructions and fix it. If they have to take the refrigerant out and remove the coil to do this so be it.

Or they will be paying for ceiling damage.

In an attic installation they should install an auxiliary drain pan under the air handler. It's just good insurance0 -

Check to see if you have 2" n the water seal and drill a hole in the cap above the trapSteam: The Perfect Fluid for Heating and Some of the Problems

by Jacob (Jake) Myron0 -

Drilling a hole in the cap defeats the purpose a vent down stream maybedopey27177 said:Check to see if you have 2" n the water seal and drill a hole in the cap above the trap1 -

Maybe our resident Condensate Drain Issue expert, @ChrisJ, will chime in. He's been plagued by a similar problem, and gone to extraordinary lengths to mitigate it—see https://forum.heatinghelp.com/discussion/165078/horizontal-air-handler-condensate-issue/p1.0

-

Thanks everyone. I welcome your input. You know, I went up there today and there was MUCH less condensate in the overflow than there had been. Maybe our last attempt to level the unit did help (or even fix it), and maybe what I'm seeing still in overflow was just the soaked insulation draining off. But.... it wasn't as hot today when I really needed it to so maybe the unit was not stressed enough too. Currently there is still a slight pitch to the unit so it's not perfectly level. Looking at the actual drip pan it appears that it already has a pitch inside the unit. I suppose I could try a perfectly level unit next.0

-

ratio said:Maybe our resident Condensate Drain Issue expert, @ChrisJ, will chime in. He's been plagued by a similar problem, and gone to extraordinary lengths to mitigate it—see https://forum.heatinghelp.com/discussion/165078/horizontal-air-handler-condensate-issue/p1.

My issue I think turned out to be air leakage more than anything. The evaporator does seem to drip a little where it shouldn't but it also didn't seem to be enough to actually matter.

I think the biggest issue was super hot humid attic air leaking into the blower side after the evaporator and condensing on the cold surfaces and in the cold air stream.

I would make sure you have absolutely no air leaking in after the evaporator. It's actually a huge issue up in an attic and makes me respect Trane's pressurized air handlers a lot more.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I think that's a great point about the air leakage. I went into this thinking gravity flow of condensate now I realize I need a tight seal vacuum condition to draw the condensate out the drain. Come to think of it, the tech had not put the panels back on very carefully but when I had taken a look inside I was able to seal it up better. That may have been why I'm seeing some improvement. Would it further help if I foil tape all the seams? I just took a look and I'm no longer seeing leaking condensate but now I do see sweating condensate. This is enough to deposit visible water in the overflow pan in just a few hours and on a day in which the temperature was not that warm. Before I can reclaim my bedroom closet and get rid of the ladder I'd sure like to know I don't have moisture building in my attic.0

-

I had originally had my panels on ok, but not great. Just by design I couldn't really get them on great.JWest said:I think that's a great point about the air leakage. I went into this thinking gravity flow of condensate now I realize I need a tight seal vacuum condition to draw the condensate out the drain. Come to think of it, the tech had not put the panels back on very carefully but when I had taken a look inside I was able to seal it up better. That may have been why I'm seeing some improvement. Would it further help if I foil tape all the seams? I just took a look and I'm no longer seeing leaking condensate but now I do see sweating condensate. This is enough to deposit visible water in the overflow pan in just a few hours and on a day in which the temperature was not that warm. Before I can reclaim my bedroom closet and get rid of the ladder I'd sure like to know I don't have moisture building in my attic.

Last year I made a secondary pan by plastic welding PVC together hoping it would fix the issue. It didn't really seem to make much of a difference and I've never had actual water come out of it's drain.

I then taped all of the seams using good quality duct sealant. I think it's described as "rolled mastic".

That's what improved things a huge amount. It looks terrible, but I didn't see any real easy way to fix the problem aside from that. There was a point where I decided I didn't care what it looked like anymore, I just wanted it to work. In my case, the sweating was being caused by the insulation getting soaked and becoming "not insulation". If it gets in before the evaporator it's not a huge deal but into the area after the evaporator, where it's ice cold, and bad bad things happen.

I'm assuming in real extreme conditions, the 1/2" thick insulation wouldn't be enough to prevent sweating no matter what you do.

You need a trap on systems where the condensate pan is under a slight vacuum. On these systems you'll have air flowing inward from the drain which prevents water from draining when the blower is running. It's not that you need a vacuum, you just need to stop air from flowing inward and a trap does that.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

The r value of the insulation doesn't need to be that high to keep the surface temp above the dewpoint but the vapor barrier needs to be on the outside and you need to be very careful about sealing it or moist air will get in to the insulation and condense on the cold surface of the ductwork which will soak the insulation and both grow mold and if it is fiberglass or similar will make it no longer an insulator. I suspect this is why inside the duct fiberglass board insulation is popular.0

-

Your trap is not very deep, just the bare minimum.

Also if the drain line then has a long horizontal drop without an air vent after the trap it could perhaps syphon the water out of the trap loop.

This effect happens with all drains such as a sink and would give you sewer gas at that fixture.

The air vent After the trap would break the syphon if that is the issue.

Just cut in a tee and 6" tall riser, without a cap of course.0 -

Sorry to say, but my gut feeling is the plastic condensate drip pan is cracked. Take off the service panel and flood the pan with water, drag a hose up there if you want.0

-

Thanks everyone for the input. A different service tech came back today. While this first service tech was focusing on pitching the unit slightly off level the long way (left to right), this one told me the unit was off level the short way (depth). As a result, the condensate wanted to naturally flow away from the side of the unit where the condensate drains. He said that when he pitched it slightly towards the drain side, he immediately saw condensate come from the far side of the pan. We managed to sneak a wet vac into the attic and did our upmost to dry the saturated insulation around the blower motor. We also did some testing first with bottle water and then once the panels were back on watched the unit run with the top off the condensate trap. What I can say is that it is clearly flowing MUCH better than anything I had been seeing and so far I am bone dry (only a couple hours on a mild day I know). I know some installers just want the unit perfectly level with no pitches but at this point if it's working I won't complain. Fingers are crossed. On a side note they ran the condensate line directly into the house vent pipe which unfortunately means that the only way I can confirm good drainage is the empty the closet and go back up there from time to time!0

-

The other issue is,JWest said:Thanks everyone for the input. A different service tech came back today. While this first service tech was focusing on pitching the unit slightly off level the long way (left to right), this one told me the unit was off level the short way (depth). As a result, the condensate wanted to naturally flow away from the side of the unit where the condensate drains. He said that when he pitched it slightly towards the drain side, he immediately saw condensate come from the far side of the pan. We managed to sneak a wet vac into the attic and did our upmost to dry the saturated insulation around the blower motor. We also did some testing first with bottle water and then once the panels were back on watched the unit run with the top off the condensate trap. What I can say is that it is clearly flowing MUCH better than anything I had been seeing and so far I am bone dry (only a couple hours on a mild day I know). I know some installers just want the unit perfectly level with no pitches but at this point if it's working I won't complain. Fingers are crossed. On a side note they ran the condensate line directly into the house vent pipe which unfortunately means that the only way I can confirm good drainage is the empty the closet and go back up there from time to time!

If you're in an area that gets cold like I am that trap is going to dry out every winter and in your case that means sewer gas in the duct work if that's going into a sewer vent. It's not allowed by code in most if not all areas. It is allowed to drain into a sink, or sink drain like a dishwasher as that is trapped and kept wet.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Changing the drain line to the vent pipe was the tech's 1st fix attempt. He did not tell me before he did this. It actually did no good because the condensate wasn't even making it to the drain. In hindsight he could've tested the existing line (which does run outside) with a bottle of water to ensure proper gravity flow! But the old line was still lying there right on the side of the elbow he installed to turn towards the vent pipe. I just bought a few couplers and an end cap for the vent pipe line. I've reattached the outside line and tested it. It's a far run but seems to work fine. One of the reasons I rushed to do this it because we started getting water in our basement where the vent / drain pipes come in from upstairs. Not exactly where this main vent pipe is but a few inches away where the kitchen drain comes through. And this leaking water really increased after he fixed the AC unit today. Weird too because where the PVC is connected to the vent pipe in the actual attic was dry. So I've now capped the vent pipe line and I'm back to the outside drain. I really wanted to switch this back anyway so I can monitor things from my back yard in a comfy chair. After the cooling season I was told I could fill some windshield washer fluid into the trap and through the outside line as some insurance this drain pipe doesn't freeze.

I knew I wanted to ask about this vent pipe line when I first started posting but at the time I had bigger issues.0 -

That air handler comes with separately packed brackets if flipping the coil. Check if the coil is vertical where the up flow pan is. You'll see little dimples in the cabinet on the top of the air handler where to screw the bracket. Get the installer back.0

-

Yes I agree. They did drill through the dimples for the (hz config) top bracket but left off the bottom one. On the last visit they insisted the hz config bottom bracket would not a have helped my problem and was not a big deal (they also felt tapping into the vent pipe with the drain is no big deal). The extra bottom bracket that came with the unit was carted off with their install trash. If I wanted to pursue it now we would probably have to move the original coil bracket that is still bolted within the original vertical configuration . But... If the unit is now draining normally I will probably not be able to get them to fix something that is working. As of today, we are wearing jackets in the North East on July 3rd so proving one way or the other is tough. Hopefully within the next few days the heat will return and I will know more.HVACNUT said:That air handler comes with separately packed brackets if flipping the coil. Check if the coil is vertical where the up flow pan is. You'll see little dimples in the cabinet on the top of the air handler where to screw the bracket. Get the installer back.

0 -

Tying the condensate line into a vent in the plumbing system is a violation of all plumbing codes.

If you install a trap into the system you must have at least a seal of 2" which stops the vacuum caused by the fan from drawing water back into the unit or holding water in the pan which is causing your flooding problem.

JakeSteam: The Perfect Fluid for Heating and Some of the Problems

by Jacob (Jake) Myron0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements