Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Dual-temp hydronic heat piping plans

Options

Leonc

Member Posts: 32

Hello,

I have a plan to revamp my hydronic heating which I would like some feedback on.

I currently have an oil fired boiler which also heats my DHW. I have hot water convectors in each of my rooms, all fed by a single circulator in a (mostly) reverse return piping configuration.

My goal is to remove all of the first floor convectors and have them replaced by underfloor pex heating. I have access to all of the joists/subfloor to lay down the tubing.

I also plan to remove the reverse return piping and directly connect the second floor convectors with pex to a manifold with flow controls. My main bedroom on the second floor gets the most heat, and my child's room is very slow to heat up, but it gets there. I have no controls currently on the convectors to help that.

I also want to install an indirect fired water tank in the future.

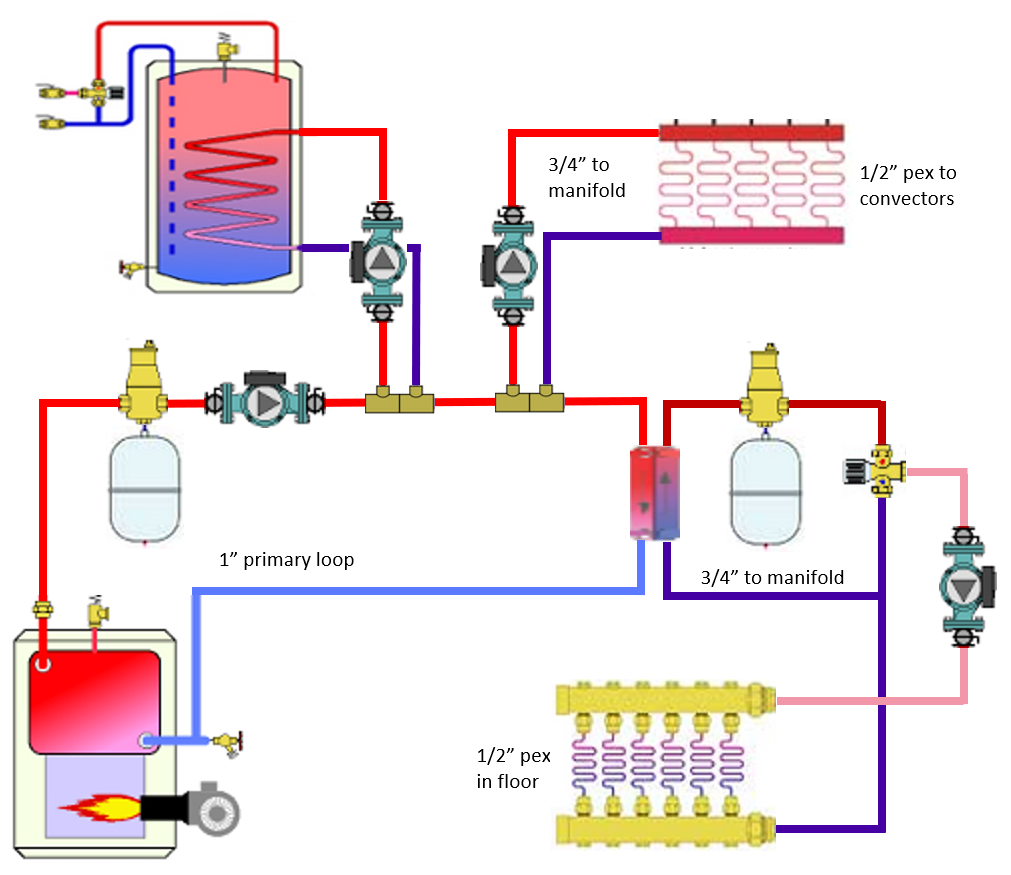

I've attached a picture of my design drawing with the main components (I left out check valves, gauges, and fill/purge). Boiler is a 125,000 BTU Slant Fin with a Beckett burner. The thinking behind a heat exchanger is an attempt to avoid the inefficiency of cooling the water down from the boiler for the in-floor heating, and then having to heat it back up to return it to the boiler to avoid condensation.

Heat loss calculations (from slant fin app and omnicalculator.com):

First Floor: 5 rooms, 830 sqft, 23000 BTU (design is for 4 loops of 300ft 1/2" pex, with a possible addition of one more loop for my basement floor)

Second Floor: 4 rooms, 600 sqft, 13000 BTU (currently 5 convectors, 17 ft total length)

Climate is Southeastern PA, house was built in 1940.

Questions:

Can I run the heat exchanger for the pex zone off of the primary pump or do I need to put it on a secondary loop with it's own pump?

How much of this can I pipe with pex? Goal is to be able to replace components or redo any mistakes without sawing pipe...

Is the Taco 007e the right circulator for this? My calculations show that I need about 2.5 gpm with 3.5ft head for my pex, and even smaller for my convectors...

Any other tips or parts I'm missing?

Thanks for reading, and looking forward to your comments!

I have a plan to revamp my hydronic heating which I would like some feedback on.

I currently have an oil fired boiler which also heats my DHW. I have hot water convectors in each of my rooms, all fed by a single circulator in a (mostly) reverse return piping configuration.

My goal is to remove all of the first floor convectors and have them replaced by underfloor pex heating. I have access to all of the joists/subfloor to lay down the tubing.

I also plan to remove the reverse return piping and directly connect the second floor convectors with pex to a manifold with flow controls. My main bedroom on the second floor gets the most heat, and my child's room is very slow to heat up, but it gets there. I have no controls currently on the convectors to help that.

I also want to install an indirect fired water tank in the future.

I've attached a picture of my design drawing with the main components (I left out check valves, gauges, and fill/purge). Boiler is a 125,000 BTU Slant Fin with a Beckett burner. The thinking behind a heat exchanger is an attempt to avoid the inefficiency of cooling the water down from the boiler for the in-floor heating, and then having to heat it back up to return it to the boiler to avoid condensation.

Heat loss calculations (from slant fin app and omnicalculator.com):

First Floor: 5 rooms, 830 sqft, 23000 BTU (design is for 4 loops of 300ft 1/2" pex, with a possible addition of one more loop for my basement floor)

Second Floor: 4 rooms, 600 sqft, 13000 BTU (currently 5 convectors, 17 ft total length)

Climate is Southeastern PA, house was built in 1940.

Questions:

Can I run the heat exchanger for the pex zone off of the primary pump or do I need to put it on a secondary loop with it's own pump?

How much of this can I pipe with pex? Goal is to be able to replace components or redo any mistakes without sawing pipe...

Is the Taco 007e the right circulator for this? My calculations show that I need about 2.5 gpm with 3.5ft head for my pex, and even smaller for my convectors...

Any other tips or parts I'm missing?

Thanks for reading, and looking forward to your comments!

0

Comments

-

I don't think that the HX is necessary in this application.

If you set up the indirect as priority over heat

and use a Taco I-series mixing valve with outdoor reset and a sensor on the boiler return to protect the boiler from condensate, you can pipe it like this pre-caffeine chicken scratch.

"If you can't explain it simply, you don't understand it well enough"

"If you can't explain it simply, you don't understand it well enough"

Albert Einstein3 -

-

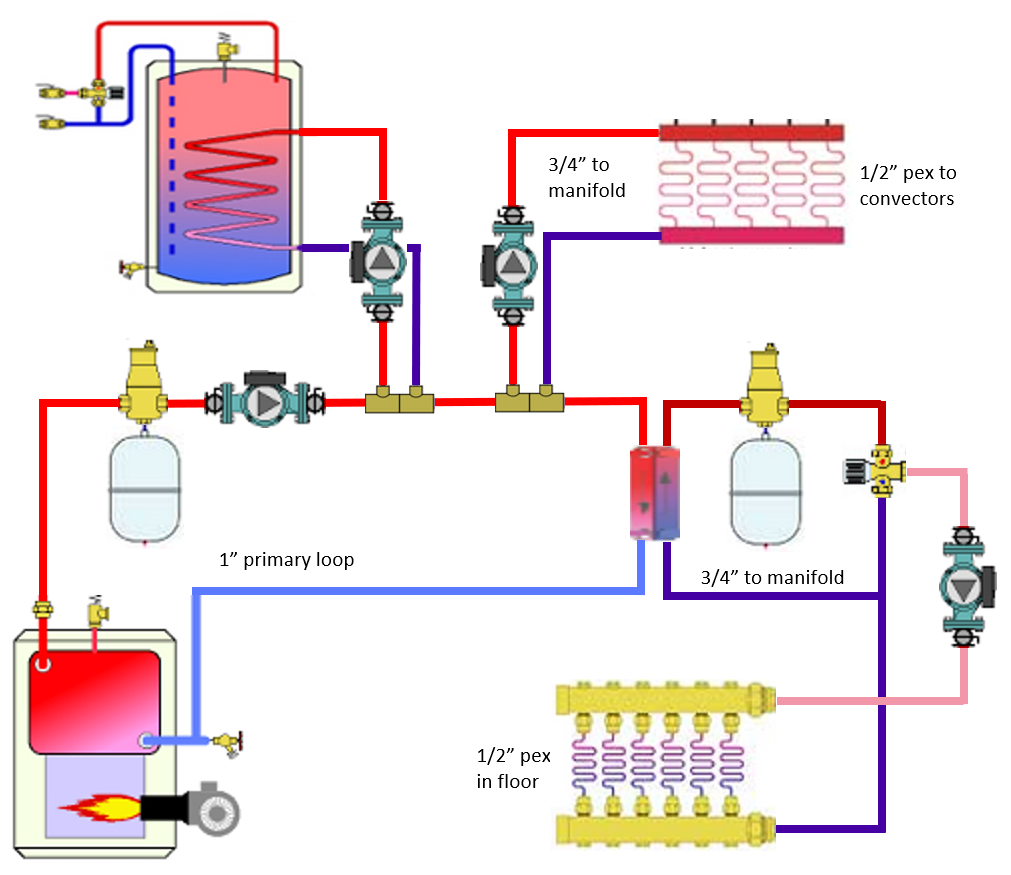

Thank you Zman and Alan for the input!

This design certainly seems simpler.

To clarify that I understand this:

1. The Taco i-valve will sense the boiler return temperature and mix down the amount of boiler water going into the low temp zone until the return temperature reaches the proper point (is 140 degrees for oil boilers, right?), after which it will allow allow more hot water to flow into the low temp zone. Is that right?

2. What happens when the radiant zone is the only one running? Just following the water path, hot water from the boiler gets cooled to somewhere around 125 to get distributed in the floor. After which, it comes back somewhere around 100, returning to the boiler. Wouldn't that mean the mixing valve will go back and forth to heat the zone, then heat the return water, then heat the zone, or will the primary loop eventually reach a consistent temperature to overcome the temperature drop of the radiant zone?

3. Sounds like there is no need to use Taco 007e, just stick with the regular 007 circulator.

Updated my picture to copy Zman's sketch:

1 -

Plumbing may even be easier using the 4 way I SeriesYou didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38331 -

Your drawing looks good. You will need check valves on the circs and misc purge and drain points.

When just the low temp loop is calling, the boiler circ will also be running. The higher temp boiler water will mix with colder water from the radiant loop and return the water to the boiler that is above condensation temp.

Those clever folks at Taco have been doing this for a while. If you read their literature I am sure it will make sense."If you can't explain it simply, you don't understand it well enough"

Albert Einstein1 -

Thank you again Zman. And thank you Rich! I'll be doing my reading up on the Taco iseries this week. I'll keep this thread updated on progress as I get the parts!0

-

A sep 4 could provide the 4 important functions, and a 4 way motorized valve foe mix.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

Thank you for the suggestion Hot Rod!

Perhaps this is a newbie question, but can you (or someone) help me understand (for this particular design) the benefits of

(a) using the sep 4 vs two closely spaced tees (1"x1"x3/4")

(b) combining the components of air and dirt/mag separation into a single device

I'm mostly looking at the cost factors of the components. The way I'm seeing it, the combined components (and a similar concern I have with 4 way vs 3 way taco ivalve) can help with saving on time and space, but if those are not factors in this project, they seem, at first glance, more expensive than extra pipe and fittings. Also, from previous projects, I tended to lean towards individual components to better troubleshoot failures individually swap out/repair.

Thank you so much for the input!0 -

Correct, the 4 or 5 in one separators provide air removal, particle removal, magnetic removal for the day when ECM circs are installed, and hydraulic separation. It reduces parts and assembly time and leak potentials. It assures all distribution sees the same supply temperature.

If the low temperature is not zoned you could use a manual mix valve, run the boiler on reset control. That way both distribution assemblies benefit from a single reset control.

I like ECM circulators for all applications, zoned or not.

Really you do not need a sep or P/S with a cast iron boiler. You could Use a single circ and zone valves for the high temperature loads, tank and radiators. A mixing station with a separator function built in for the low temperature.

The mixing center could be manual, thermostatic or motorized mixing.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I haven't yet considered the zoning valves idea. Thank you hot rod. I'll report back as I chew on it.0

-

The only thing I would change on your zman's dia is:

I would have the Taco I series mixing valve sensor on the output of the pump on that circuit.

You are going to maybe get interaction between the two radiant pumps. I would probably go with another set of closely spaced tees for hydronic separation. If not you would most certainly need two check valves on the returns to prevent thermo siphoning and back flow.

I would want a control that had priority zoning for the Indirect with the appropriate spring check valves.

The boiler is a conventional boiler and is only going to operate at a fixed supply temp which would be determined by the indirect (180 deg ?) and the convectors which would operate at the indirect temp.0 -

The drawing will work well as long as the common piping is sized correctly."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

Thank you Homer! I'll certainly be including check valves, haven't put that detail of thought into it yet.

Hot Rod, does the mixing center have a valve control built in too? I'm studying the drawing you made, and I'm curious what forces the water into one of the hot temp zones? With the mixing station separator, wouldn't the pressure want the water to just flow in a loop instead of into the zones? Would I need another zone valve for this, or does the separator on the mixing station close completely when the mixing circulator is not running?0 -

Finally had some time to think some more about this, and I started leaning more towards the zone valve idea. Added a diagram below. Reduces the number of circulators I need from four to two.

Is this a viable option?

0 -

I like your earlier work better.

This plan will make the flow balance between the high temp indirect, the high temp heat, and the bypass a challenge. Anytime the bypass is open, the indirect and heat will not get adequate flow. The same may be true of the DHW and heat. You could solve this with balancing valves, but why bother. The cost difference between a small circulator and a zone valve is negligable. From an energy use point of you, the balancing valves would make the circs work harder."If you can't explain it simply, you don't understand it well enough"

Albert Einstein1 -

-

Thank you Zman and PSB for the input. I think it will be simpler for me to use circulators. Will probably go back to the second drawing (Zman's design).0

-

Quick question about controls. Using a SR503 switching relay, would the primary loop circulator be connected to that (if so, where?), or would I continue to use the boiler aquastat to control that primary circulator?

Thank you!0 -

If you are using this layout, I think I would give the DHW priority over the heating. This would require an additional DPDT relay to disable the heating circ when DHW call is present.

Confirm your piping and intent for the controls.

"If you can't explain it simply, you don't understand it well enough"

Albert Einstein1 -

This would require an additional DPDT relay to disable the heating circ when DHW call is present.Or, instead of using the Taco SR503, you could use a Caleffi ZSR103 where you can choose to disable the primary pump when the priority pump is on.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab2 -

Yes, Zman, I am using that piping. Thank you for clarifying.

Alan, thank you for the suggestion! I'll research the caleffi and compare before purchasing. Looks like exactly the control I would be looking for, not sure if it is offered by any of the Taco models that I found first.0 -

-

I wanted to come back here and give an update, as well as big thanks to this forum and the members that provided input! The project has been a great success. First floor now has radiant pex in the joist bays, and the second floor convectors have been re-piped directly to the manifold! Been heating my house like this for about a month now.

Much more comfortable first floor, and I will soon be able to rip the ugly convectors out of my walls to make room for other renovations.

Thanks again!2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements