Steam boiler pH level opinion

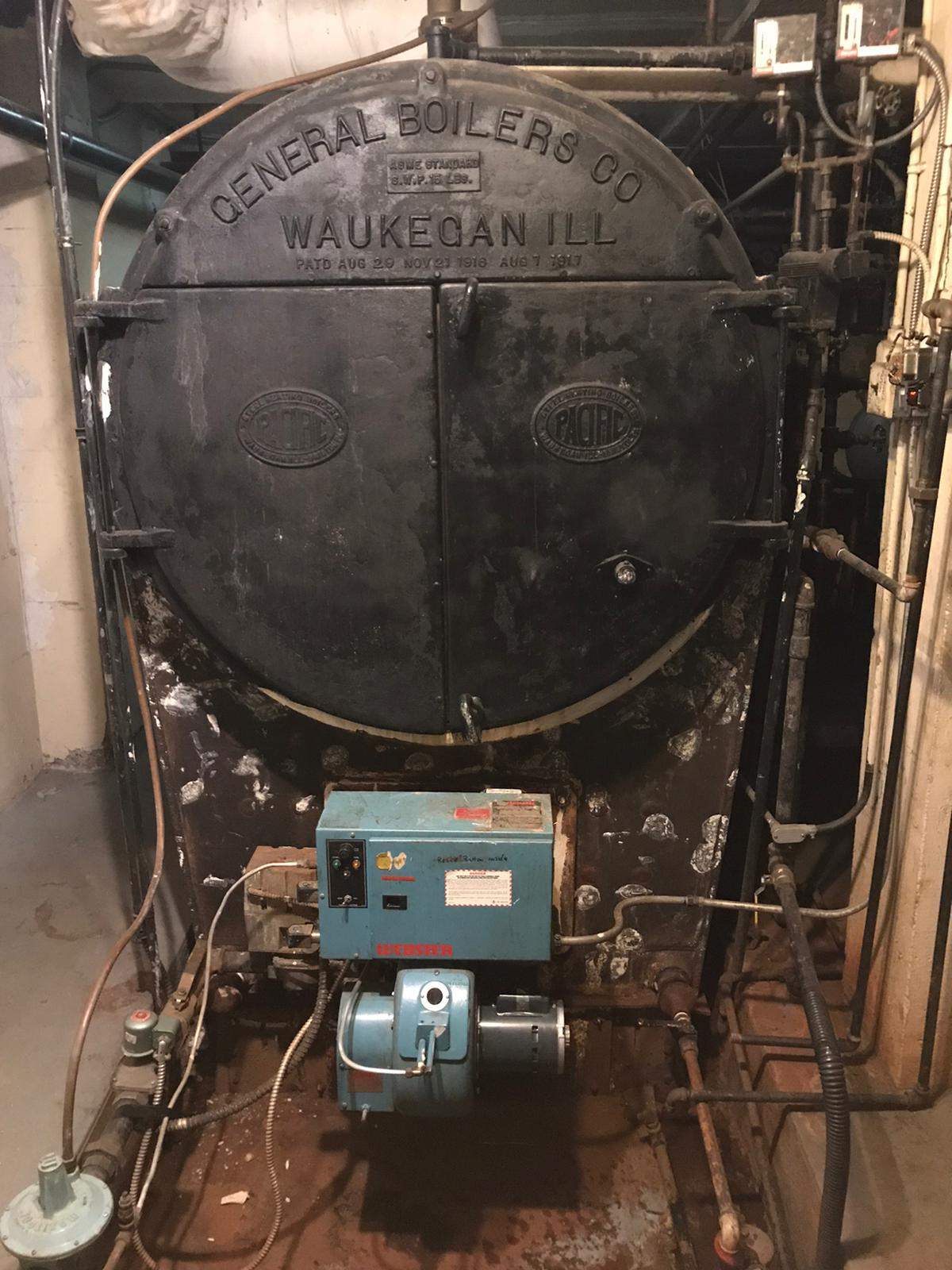

We heat our 54 unit Portland OR condo building using the original steam heating system installed when the building was built in 1928. The heating is generally well maintained but we have been experiencing excessive mid-fire water hammering in the steam pipes during the past 3 months. Our regular heating engineers are trying to locate the source of the water hammer and various steam traps and condensate return valves have been checked/serviced. Each condo units and the corridors and lobby are heated by two pipe steam radiators and each bathroom is heated by a large bore steam pipe running from floor to ceiling. The steam boiler dates back to 1917 and was originally oil fired but was converted to gas about 30 years ago (see photo)

We have a water treatment/chemical dispenser hooked into the system and the most recent report from the treatment service provider showed pH at 11.41 in the boiler.

Portland's city water has a pH of 8.2. and can vary from 7.4 to 8.4, with a median value of 7.8 to 8.1.

I recently read an article on HeatingHelp.com, written by Dan Holohan that suggested boiler water with a pH that's too high could cause water hammer and this type of hammer usually happens during the middle of the firing cycle. It recommended a good pH for a steam heat system ranges between seven and nine. If the pH gets to 11, the water will start to prime and foam and carry over into the system, causing water hammer in the pipes. It went on to say that back in the day apparently superintendents working in large buildings would add vinegar to steam heating systems to lower the pH and lessen the priming and surging…..!”

I am posting this note to enquire if we should consider reducing the pH of our boiler water from 11 to be between seven & nine to fall within Dans recommendation?

Any suggestions or comment would be most welcome. Regards, Michael

Comments

-

Indeed you should. Optimum pH varies, but somewhere between 7.5 and 9 seems to be the range people shoot for. Your city water is probably fine -- so far as pH goes -- just as is. You may want to add a minimal amount of corrosion inhibitor as well -- but keep it minimal.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

you've done your research, and that PH is a good place to start, you pretty much answered your own question.

you also need to chase down that water management company to dial back their product, and explain why it got that high,

also, who is in charge of the boiler?

daily checks? water levels?

what pressure is it running at when it's been running?

known to beat dead horses0 -

Watch the gauge glass when it is steaming. Is it steady or bouncing. It shouldn't move more than an 1"-1 1/2". Knowing that boiler it is probably rock steady.

I would suspect you have a bad trap not draining something or a pipe out of pitch.

Keep in mind with two pipe steam sometimes it won't hammer where the bad trap is. It might hammer 20 feet away. The bad trap blowing steam pressurizes the return line and causes hammering elsewhere.

Steam coming out the vent on the condensate return or boiler feed vent is a teltale sign

Nice Webster Burner!!0 -

I believe the Peerless manuals say to aim for 11. I'm very fortunate in that I have installed sight glasses on my steam risers so I can see if there's any surging. The industry should probably start using them, it's like being able to open your eyes.

see https://www.youtube.com/watch?v=MhUM2vRyGBE

https://www.youtube.com/watch?v=MhUM2vRyGBE NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

@ethicalpaul

seeing is believing. I like what you have done. The gauge glass usually tells the story though1 -

I can also add that high pH, above around 9 or so, can cause corrosion to bronze pump impellers or other bronze components in the steam system. Another reason to dial back on the pH.Dennis Pataki. Former Service Manager and Heating Pump Product Manager for Nash Engineering Company. Phone: 1-888 853 9963

Website: www.nashjenningspumps.com

The first step in solving any problem is TO IDENTIFY THE PROBLEM.0 -

Luckily, pumps are way cheaper than boilers

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Thanks for the various comments related to the recommended pH for our steam heating boiler.

In response to Neil C’s questions: Three members of the HOA board (including myself) have been trained to perform twice weekly boiler blow downs and water level checks, this group works on a roster, we also adjust the heating controller temp levels as required. The boiler is annually serviced and problems with the heating/boiler are handled by Portland based HVAC contractor Hunter Davisson, the steam pressure is currently set at 5 psi.

As suggested I emailed our boiler water treatment service with a request to lower the pH to the range of 7.5 to 9, in response I received the following message and am hoping you guys might wish to comment on what this service provider is saying about boiler pH.......

.........“Please ask the source/reference that advised boiler pH of 7.8 -8.1 and the purpose? I respectfully ask because that pH is exceedingly low for the type of boiler, water, and chemistry in use. So, if we understand the back story, we can certainly do our best to help achieve the goal/s.

Without getting overly technical, American Society of Mechanical Engineers (ASME) consensus for low pressure steam boilers is up to pH of 10.0 so long as there is no more than 0.03 ppm of hardness entering boiler. If hardness is present then the pH should be adjusted according to the type of chemistry program. Per Association of Water Technologies (AWT) these programs require pH well above 10.0 some even into the mid 11s – depending on various other factors. Since the boiler at your buildingHamilton does not have a water softener, the chemistry program pH should run for example 10.5 to 11.5 or so to work properly.

Having said that, some boiler systems due to their design and operation don’t like pHs in those normal ranges – which is why I inquire about the source and purpose of the unusually low pH advisory. Again, if I understand what is driving the conversation, I can likely offer a solution or understanding that is agreeable to all.......”

Once again, any input you guy can provide to help inform our vendor would be much appreciated.1 -

I agree with your water vendor

But I don't agree with your pressure of 5psi. Did you miss Mr. Holohan's recommendations regarding pressure? I would be much more worried about 5psi than I would be about any PH level.

5psi can push water 138 inches up toward your mains from the normal water level, so I'd forget the PH and look at your pressure. I'll be interested to see what the pros here have to say about this.NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

-

@MichaelPDX

A PH of 7-9 is usually what't recommended. Below 7 causes metal corrosion. Nobody want's that. Above that may cause foaming. If your running higher than 9 and your water level is stable then I don't see an issue.0 -

Respectfully, Ed, I don't see above 7 causing foaming (within reason-- I mean, 14 is above 7 and I'm not saying that's OK

Do you see foaming at 8 or 9?

Do you see foaming at 8 or 9?

I'm going to make a video showing what happens at different levels of treatmentNJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

@ethicalpaul that video would be much appreciated. I use Rectorseal 8-Way as a treatment and have made a couple observations on my small boiler:

1. 8oz of Rectorseal raises my pH to 10.5-11. I get no corrosion, no foaming and no surging. When I go to drain any junk out of the LWCO there is NO rust. Just light violet colored water.

2. At 5oz of Rectorseal my pH is around 9-9.5. Less corrosion than without treatment but if I drain the LWCO I get some rusty water. Not quite as bad as no treatment, but bad enough.

I vote for a pH between 10-11 if it doesn't cause surging or foaming.

From the Peerless manual:

Steam Boilers

a. Boiler water pH should be in the 7.5 to 11

range.

b. Boiler water chloride concentration should

be less than 30 ppm.

c. The water hardness should be less than 7 grains

per gallon to prevent scale build-up and foaming.2 -

just fyi there's a more general thread about this kind of boiler here: https://forum.heatinghelp.com/discussion/178443/requesting-some-historical-expertise-please0

-

also if you're interested, i believe these are the patents referenced on the front of the boiler. this was the only inventor/invention i could find with 3 different patents on those 3 dates.

0 -

@SlowYourRoll

That's a Pacific steel boiler. Long out of business but they were made on the west coast I think. Don't know if Mr Nelson worked for Pacific or what that connection is.. They were quite popular even this far east we had a lot of those or similar Pacific boilers around here (I am in MA.) lots of schools had those boilers, maybe some of them are still running they held up pretty well0 -

With regard to pH values. Numbers are numbers, and machinery is remarkably bad at arithmetic. What the real question is is -- is the boiler performing satisfactorily? Minimal surging? Minimal foam? Minimal corrosion? Then be happy and stop worrying about it.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

@Jamie Hall

Agreed. If that 1928 Pacific is still running how bad can the water be? On steam no less.1 -

he probably wasn't working directly for them, because the patents would've said "assigned to Pacific Steel Boiler Co..." or something like that. some inventors secure the patents and then sell or license them afterward. if your passion was engineering/inventing and you had no interest in running a business, you could either get hired by a company or get your own patents and sell/license them. the second way was higher risk but higher reward.EBEBRATT-Ed said:@SlowYourRoll

That's a Pacific steel boiler. Long out of business but they were made on the west coast I think. Don't know if Mr Nelson worked for Pacific or what that connection is.. They were quite popular even this far east we had a lot of those or similar Pacific boilers around here (I am in MA.) lots of schools had those boilers, maybe some of them are still running they held up pretty well0 -

Iron is corrosive below pH 8.3. Maintain Boiler pH at 8.5 or higher. A few drops of phenolphthalein will quickly tell you if you are 8.3 or higher. If it’s pink you are above 8.3. Clear and you are below 8.3. Foaming occurs at that pressure generally speaking at Total Alkilinity of 1000 ppm. PH is logarithmic and imprecise as an upper control point. I rarely check it and have 40 years as a water treatment professional

Keep pH above 8.5 and total alkalinity below 1000 ppm and you will have minimal corrosion and no chemical foaming. If you experience foaming it’s mechanical in that range. That’s priming. If you have corrosion it’s either from the pre boiler section or the condensate0 -

Some hood reading in this manual regarding water qualityBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Ethical Paul....thats sick. I love it. Always thought a window to the steam soul would reveal alot. Where did you get those glass columns? They're beautiful 😍. I want to install a few of those....right away. Please let me know. Thanks and Merry Christmas 🎅 🎄 Mad Dog1

-

I replied to a PM from Mad Dog, but for posterity, here is where I get them, do a search on Ebay or Amazon for "Tri Clamp Sight Glass".

I get the 2.5" ones which basically match our 2" pipe. They go even larger but they start to get $$ over 3"

You can get NPT tri-clamp adapters for them to attach to your steel piping. They are basically a union so not having to buy a union offsets some of the costNJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

I needed a "window-to-the-soul" years ago. Gonna git me one. Thanks again. Mad 🐕 Dog1

-

I believe you have to be careful if PH starts getting over 9.5 or so. I believe somewhere in that range, you start to corrode brass and copper. I have been looking for the graphs I once saw showing corrosion of various typical metals but haven't been able to find them again. I have found with Chicago water, that using about 1/2 the recommended rate of 8-way gets the Ph in a good range.waterisi said:Iron is corrosive below pH 8.3. Maintain Boiler pH at 8.5 or higher. A few drops of phenolphthalein will quickly tell you if you are 8.3 or higher. If it’s pink you are above 8.3. Clear and you are below 8.3. Foaming occurs at that pressure generally speaking at Total Alkilinity of 1000 ppm. PH is logarithmic and imprecise as an upper control point. I rarely check it and have 40 years as a water treatment professional

Keep pH above 8.5 and total alkalinity below 1000 ppm and you will have minimal corrosion and no chemical foaming. If you experience foaming it’s mechanical in that range. That’s priming. If you have corrosion it’s either from the pre boiler section or the condensateTo learn more about this professional, click here to visit their ad in Find A Contractor.0 -

@AdmiralYoda Also have a Peerless (1 year old) 63-4L. I keep the PH at 9.5 with about 4 to 5 ounces of 8-Way and it seems to do a great job.0

-

Been a while but this thread got me to test my boiler water again. See attached photos. I got a reading of 10.5 in bottom boiler water and 7.5 on tap water. The paper resolution isn't great but I think it is safe to conclude that the water is not acidic.

It's not hard to find opinions that left untreated steam system condensate will become acidic. If that were true I don't see how I could get these results. I have never dumped the water out of this boiler or had any cleaning done to the inside in the 30 seasons I have run it. I have never added any chemicals. The system is still quite tight and holds vacuum 4 hours or so after a firing. I might add 2-3 gallons of new water a season. And yes, this is what the water looks like coming out of the bottom (I did dump the first 1/2 cup with rust in it). I don't see a reason here to clean it, and my Bryant manual says don't change the water unless there has been some event which causes it to become dirty. It never has so I never do.

This system is still 1926 original with a 1957 cast iron boiler. Seems to me pretty good evidence here that standard components and steam does not make acid. It is also decent evidence that naturally occuring higher PH isn't necessarily a problem. I suppose if the high ph is chemically induced it might be.

1926 1000EDR Mouat 2 pipe vapor system,1957 Bryant Boiler 463,000 BTU input, Natural vacuum operation with single solenoid vent, Custom PLC control2 -

I've never added any chemicals to Cedric, either, @PMJ . Doesn't seem to be a problem... the tap water (a well) is slightly acidic, but very little gets added -- maybe a bit more than you, as he does have a float type LWCO which gets blown down now and then. But the chemistry is stable, and so's the water levels, so what's not to like?Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Agreed. I think oxygen is the biggest problem, and the primary source of that is raw water. I have not identified any reason to add more of that beyond what is needed to replace LWCO blow downs, which isn't much.Jamie Hall said:I've never added any chemicals to Cedric, either, @PMJ . Doesn't seem to be a problem... the tap water (a well) is slightly acidic, but very little gets added -- maybe a bit more than you, as he does have a float type LWCO which gets blown down now and then. But the chemistry is stable, and so's the water levels, so what's not to like?

1926 1000EDR Mouat 2 pipe vapor system,1957 Bryant Boiler 463,000 BTU input, Natural vacuum operation with single solenoid vent, Custom PLC control0 -

@Jamie Hall

Mr Garrity installed your current boiler (s) correct?

What was there before and what happened to it?Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Tested mine today and added more treatment because I like the PH higher. Boiler sample taken from the sight glass drain, wet return sample taken from the very end of the wet return. Boiler is basic, wet return is indeed acidic. Pictures of test strips to judge for yourself.

Tested mine today and added more treatment because I like the PH higher. Boiler sample taken from the sight glass drain, wet return sample taken from the very end of the wet return. Boiler is basic, wet return is indeed acidic. Pictures of test strips to judge for yourself.

1 -

Correct. The immediate predecessor was another Weil -- same model. Installed by a local "HVAC contractor" who hadn't a clue as to what he was doing... and one of the section to section gaskets was twisted. Which caused a leak which became catastrophic after a couple of years.ChrisJ said:@Jamie Hall

Mr Garrity installed your current boiler (s) correct?

What was there before and what happened to it?Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements