Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Can an injection loop using ECM pump replace a mixing valve?

Options

dori

Member Posts: 16

We need to have two system water temperatures, both with reset control. The first system output goes to a floor with cast iron radiators that thrive above 160F. The second goes to radiant system with pipes in the ceiling and some in the floor. These work best at 120F to 155F depending on outside temperature.

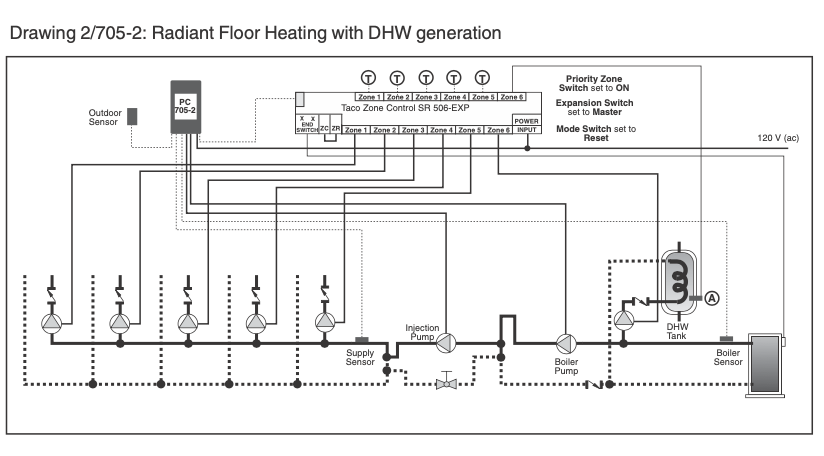

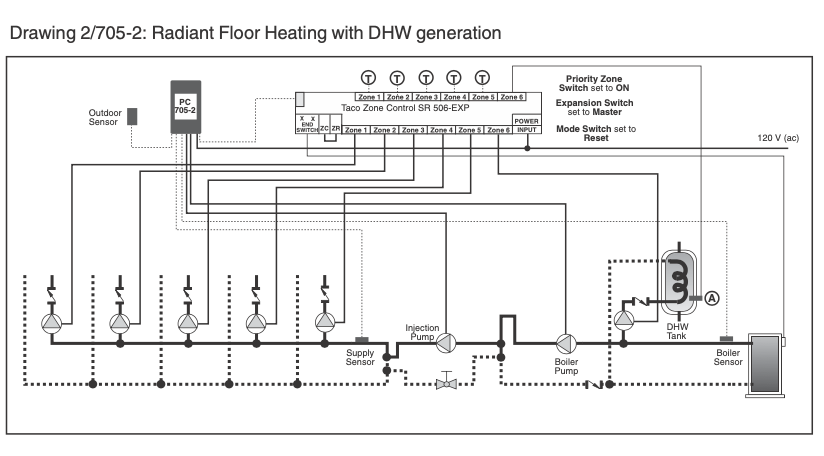

The system we are replacing using a linear mixing valve with Tekmar 360 controller. The question is whether an ECM pump with a Taco PC705-2 reset controller would be better solution. Better in efficiency, ability to handle varying zone loads and reliability.

The system we are replacing using a linear mixing valve with Tekmar 360 controller. The question is whether an ECM pump with a Taco PC705-2 reset controller would be better solution. Better in efficiency, ability to handle varying zone loads and reliability.

0

Comments

-

-

Yes this will work for your application, but as @kcopp said and I will concur, the PC-705 will not drive an ECM circ for the injection pump. All the other circs in the system can be ECM circs.

Depending upon the size (btu's of the radiant), you might be able to get away from the injection system and go with an i-Valve instead to modulate the water temp for the radiant and use a PC-700 to give reset control to the boiler and the high temp zones.

EnjoyDave Holdorf

Technical Training Manager - East

Taco, Inc

1 -

Injection mixing was the norm for a while. I have found that it can be difficult to stabilize unless you put a balancing valve in the mixing loop. The I series valves are more "plug and play", probably a little less $$$ up front as well as down the road."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

Another option another option is a manual 3 port mixer. Put the boiler on reset and the manual valve adjusts along with the changing SWT from the boiler. I have this setup on two systems at my home, works great.

A motorized actuator could be added later if you really need another ODR

KISSBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

Thank you all for the fast response.

The radiant subsystem is a BTu hog -- needs about 50 gpm at 4 ft/min.

The boiler reset curve needs to be independent of the radiant curve as each heats a different section of the house with a different type of radiators (3/4" black iron pipes in the ceiling for radiant, cast iron radiators for the other). The radiant part needs a threshold of 120F to operate due to the plaster characteristic in the ceiling. The cast iron heats fast and stays warm longer.

I will suggest to JohnNY to use the appropriate linear mixing valve for the radiant.

On a related issue, what does it mean that the boiler differential is rarely less than 50F?0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements