General advice and checkup request (also water hammer)

Comments

-

Someone is almost always home and the pinging noise was NOT anything we've heard before so I'd say that this was the first time. The boiler was not skimmed, they were satisfied with flushing it. I told them I'd put the 8-way in myself.ethicalpaul said:

The first time you had the problem, or the first time you saw it? It's possible that it took some days for enough of the oils from the new pipes to collect in the boiler.

Your cleaning process although filled with many steps, may have been performed before the oil from your new pipes made its way to the boiler. But even if all the oils were already in the boiler, your process does not include skimming which may be required to get all the oil out. (edit: I read the whole thread and I thought you said the contractor was going to skim...did they come back and skim a week or two after their work?)

For nice venting I always recommend one or two Maid O Mist #1's unless you have a really large volume in your mains in which case I would say Gorton #2. But hold off because it's possible that the vent is making noise due to all the water in your mains. Maybe you can clean it, or maybe it will quiet down on its own.

I'm having them drop the left side return down as well because the condensate seems to be getting into the rad behind it. By that time I expect the heating season to be mostly over, so I'll have to resume this process in the fall. I just ordered a Maid O'Mist #1, we'll see what happens meanwhile. That should be fine as that is the "warm" side of the house and the shortest part of the steam mains... only about 15 feet or less.

I've been threatening my heating system with a complete tear-out and replacement with mini-splits and a heat-pump water heater. Maybe it will behave now. I'd certainly gain a lot of space in the house without a boiler, oil tank, piping, and rads. I could go all Office Space on the boiler in a field as well.0 -

It's not the boiler's fault. It's these guys' fault: "The boiler was not skimmed, they were satisfied with flushing it."

So a bit more about the noise. Water hammer can make a ping noise that would have nothing to do with your vent. Any pinging or "clunking" in the pipes is usually water where it shouldn't be getting contacted by steam.NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Is flushing the boiler with a bit of Dawn sufficient to break the surface tension and allow any surface oil to drain with the water?0

-

I would think if putting a little detergent in the boiler were enough, we and manufacturers wouldn't still be talking about skimming for the last 100 years

In fact, I think most manufacturers recommend boiling for awhile with TSP in there which is probably better than Dawn (who wants a bunch of suds shooting out of their radiators?)

So that's a "no" for me

There are some products that claim to encapsulate (or some term--emulsify?) the oil and let it drop to the bottom of the boiler so it can be flushed, but I've never heard much good about them.

Here's what was probably happening in your boiler from the oil: https://www.youtube.com/watch?v=jvt8qxBaRJU

https://www.youtube.com/watch?v=jvt8qxBaRJU NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Yea, I imagine that exactly what was happening. It sounded like the lower returns were dry somehow as well because I distinctly heard some debris bouncing down inside the left return.ethicalpaul said:

Here's what was probably happening in your boiler from the oil:

I had wanted to try some TSP, but my experiment with it on the pipe plug from my boiler showed that it left an oily residue that was very difficult to remove (I couldn't flush it off under running water) and the plug seemed to corrode more after a day spent drying as well. I didn't want to deal with that in the boiler so I went with some premixed dawn with the bubbles skimmed away and several thorough flushings followed by a cleaning dose of 8-way and another flushing.ethicalpaul said:

In fact, I think most manufacturers recommend boiling for awhile with TSP in there which is probably better than Dawn (who wants a bunch of suds shooting out of their radiators?)

I have a maid o' mist vent coming in in a few days, and I asked the guys to come back out and lower the left return. I guess I'll be picking up some black iron hardware to do some skimming as well. I'm wondering about blaming it on oil however, if the problem went away by removing the 8-way. In theory, the oil would still be there as it was not skimmed.0 -

@ethicalpaul I know this is off topic but how did you get that video that you posted made. I have a video I took on my iphone I want to post on this site but don't know how?0

-

Draining will remove some of the oil, but often it won't remove enough of the oil, and (as you experienced) you have to fill, wash, drain, repeat several times. And if you are having more work done, that will likely introduce more oil again. So I'd recommend run the boiler for a few days after the work is done, then skim the system. If your skim pipe is set up right you can watch the oil escaping.

@aperson I recorded it on my iPhone then uploaded it to Youtube with their app. When you post a link to youtube, the site here will usually display it like that kind of embedded video.NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

The other condensate return was lowered two days ago, and the radiator behind it is now heating evenly and without gurgling or spitting. So that's good.

The 8-way was definitely a major contributor to making the boiler water surge and was causing the main vents to ring from the tempest raging in the pipes. I drained it and filled it with clear water and it's been behaving fine.

I'm going to try a lower dose of 8-way and see if it boils ok. I noticed an improvement in domestic hot water delivery after cleaning and dosing with 8-way. I presume from removing some scale or corrosion from the coil, so I'd like to keep it dosed if possible.0 -

The 8-way itself doesn't seem to cause any surging, even when massively overdosed. I have another video where I put in way over even the directed amount and saw no surging at all. But that was in a new, clean boiler.

But yes, if it removed some scale, and/or there were other issues with the water like oil, then anything goes.

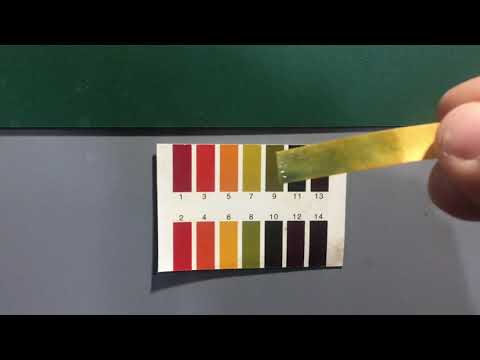

I would add enough 8-way to get the ph up to 10-11 and monitor it. If the water still looks dirty or cloudy in the gauge glass then that would tell me that more scale or rust has broken free and the water needs to be drained again. Eventually you should get to a place where you can have the 8-way in there and the water will stay tinted and clear.

On my old boiler, which didn't see a lot of maintenance in the decades before I owned it, I never could get all the sediment/rust out of the nooks and crannies (at least before I replaced it) so the water would never stay clear.NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Second floor radiator vents should be set at the smallest opening possible.

Water hammer is caused by the un-insulated piping.

Main vents need to be installed at each vertical drop of the steam main. install at 6-12"from the vertical drop. Dot over kill with super high capacity vent valves. no larger than Gorton #1. you a small amount of steam main and no large pipe.

Insulate all the steam piping with 1" thick fiberglass insulation.

Jake

Steam: The Perfect Fluid for Heating and Some of the Problems

by Jacob (Jake) Myron1 -

8-way is a cleaner and after it has been in a system awhile, particularly one that was dirty, we always have problems with the boiler misbehaving after a few weeks or even days. The cleaning action has loosened up enough junk to foul the water bad enough to cause the boiler to prime. This is very likely why your boiler started acting up. I tell most clients that start boiler treatment on an untreated boiler to expect issues like priming for the first season or two until the system gets good and clean.To learn more about this professional, click here to visit their ad in Find A Contractor.2

-

As far as using boiler chemical.

A PH 10 & 11 is overkill. Those high PH numbers cause a sudsing effect in the boiler.

Using a high ph like that should only be used in the summer.

For cleaning real dirty boilers in the summer set the boiler aquastat to 200 degrees and run for a month.

If no aquastat is on the boiler have one installed for temporary use.

After the boiler is drained fill with clean water again and repeat the process.

When using the boiler chemical to treat the boiler water install only 1/3 of the recommended amount of chemical and test the PH, No more 8.5.

JakeSteam: The Perfect Fluid for Heating and Some of the Problems

by Jacob (Jake) Myron1 -

With respect @dopey27177 I can show you that PH 10 or 11 or even way higher does not by itself cause sudsing. I agree with you it's a great idea to start with a low dose to see what breaks free because odds are you're going to be draining quite a bit regardless in the beginning.

Check out my experiment here: https://www.youtube.com/watch?v=_JFfO_VgvNQ

https://www.youtube.com/watch?v=_JFfO_VgvNQ

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

I've put in a half-dose of 8-way. The main vents are ringing again, but not as badly as before with the 3/4 dose I had in it. It's also surging again, but not as badly as the higher dose which had emptied out the sight glass during a boil.dopey27177 said:

When using the boiler chemical to treat the boiler water install only 1/3 of the recommended amount of chemical and test the PH, No more 8.5.

Jake

I'm going to let that stew over the summer when it's running just for DHW and see how it behaves in the fall after a good flush just before the heating season.0 -

I believe there is another problem with a PH of 10 to 11, it starts corroding brass and copper. I shoot for 9 to 9.5. Also, 8-way has anti foaming agent to prevent foaming at higher Ph levels, so you shouldn't get foaming and surging unless the cleaner has fouled the water with contaminants it has loosened.To learn more about this professional, click here to visit their ad in Find A Contractor.1

-

That's important info because my returns are copper!The Steam Whisperer said:I believe there is another problem with a PH of 10 to 11, it starts corroding brass and copper.

0 -

It's not important, because your returns won't see the treatment. They only will see distilled water. Also even if so, the boiler is a bit more expensive to replace than some copper fittings. But if your ph measurement can get you to 9.5 instead of 10, that's great!kflory said:

That's important info because my returns are copper!The Steam Whisperer said:I believe there is another problem with a PH of 10 to 11, it starts corroding brass and copper.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

The summer time is the best time to clean out the boiler.

As I said before drain the boiler after 1 month and refill with fresh water and chemical cleaner.

Because it is summer fill the boiler with water to the top of the steam drum.

After two flushes the boiler should be clean. Fill for winter operation with 1/3 the recommended amount of chemical treatment, check for a PH of 8.5 to 9.

JakeSteam: The Perfect Fluid for Heating and Some of the Problems

by Jacob (Jake) Myron0 -

I may be a little lost here (I have wet returns). The hartford loop is below the full water-line so therefore as you fill the boiler with treated water, the water rises above the top of the loop and it will begin filling the returns until they also are level with the boiler water-line. Once the returns are filled, then the boiler water-line will begin rising again. The top end of the sight glass should be well above the top of the hartford loop, yes?ethicalpaul said:

It's not important, because your returns won't see the treatment. They only will see distilled water. Also even if so, the boiler is a bit more expensive to replace than some copper fittings. But if your ph measurement can get you to 9.5 instead of 10, that's great!kflory said:

That's important info because my returns are copper!The Steam Whisperer said:I believe there is another problem with a PH of 10 to 11, it starts corroding brass and copper.

The condensate will surely dilute the treated water in the returns as the system runs over time, but for the period over the summer it's not going to be producing steam and therefore, no distilled condensate. So that boiler treatment is going to be sitting in the returns at full strength all summer long. That's everything to the best of my reasoning.0 -

Yes, and many treatment components are designed to go out into the system as they boil out of the water in the boiler. I think a common one is the Amine family of chemicals. Anything with a boiling point below that of the water will go out into the system as a vapor.To learn more about this professional, click here to visit their ad in Find A Contractor.1

-

No. When you drain your boiler, the distilled water condensate remains in the wet returns. When you fill your boiler, the condensate in the wet returns is not replaced by the boiler water. When you run your boiler, there is a constant flow of distilled water into the boiler (not boiler water into the returns).

And if you do have a treatment that goes into vapor (not advisable for 1-pipe steam in my opinion unless you want to breathe it), it surely isn't doing so at a concentration that will bring your wet return condensate into any danger zone for PH level.

Yes, there will be a small amount of mixing right at the Hartford loop, but by no means will boiler water at 10-11 ph result in "treatment is going to be sitting in the returns at full strength all summer long"NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements