Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

are my boiler pipes backwards?

Options

jtompkins

Member Posts: 12

I just had a new Green Mountain oil,

steam boiler put in. It is attached to a 189 liter storage booster tank. The boiler is set for 160 and the booster is set for 120. My problem is the water going to the sinks and showers are way to hot its boiling steam. I never had this problem with the old boiler. they are trying to sell me a mixing valve. I never needed one before. Here are pictures of the install. I could be wrong but it looks like the water flow is backwards and the cold water pipe is in the wrong place.

steam boiler put in. It is attached to a 189 liter storage booster tank. The boiler is set for 160 and the booster is set for 120. My problem is the water going to the sinks and showers are way to hot its boiling steam. I never had this problem with the old boiler. they are trying to sell me a mixing valve. I never needed one before. Here are pictures of the install. I could be wrong but it looks like the water flow is backwards and the cold water pipe is in the wrong place.

0

Comments

-

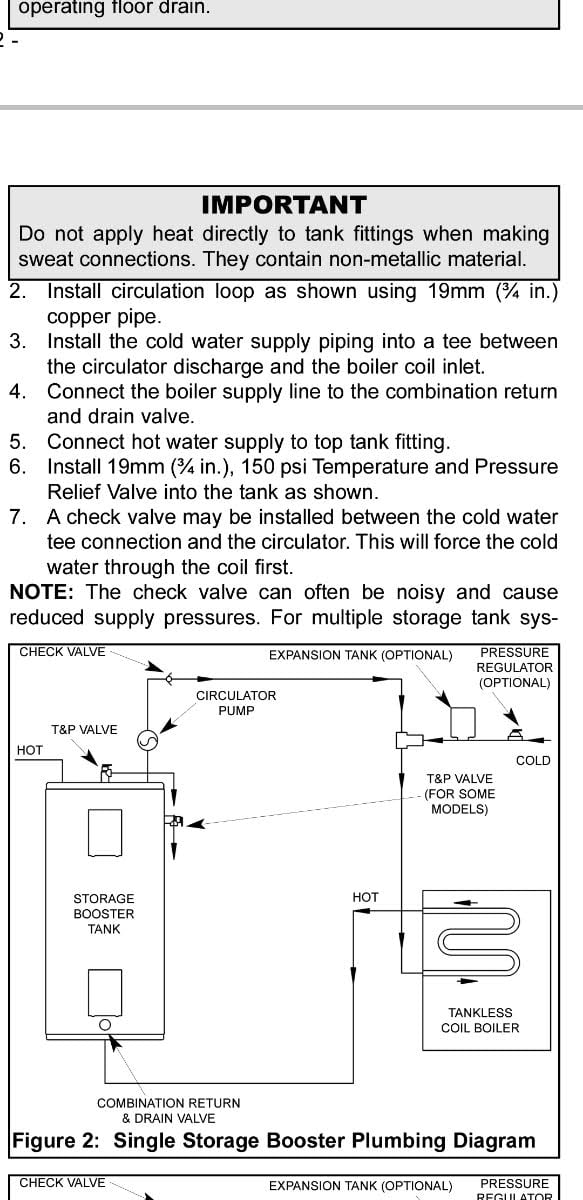

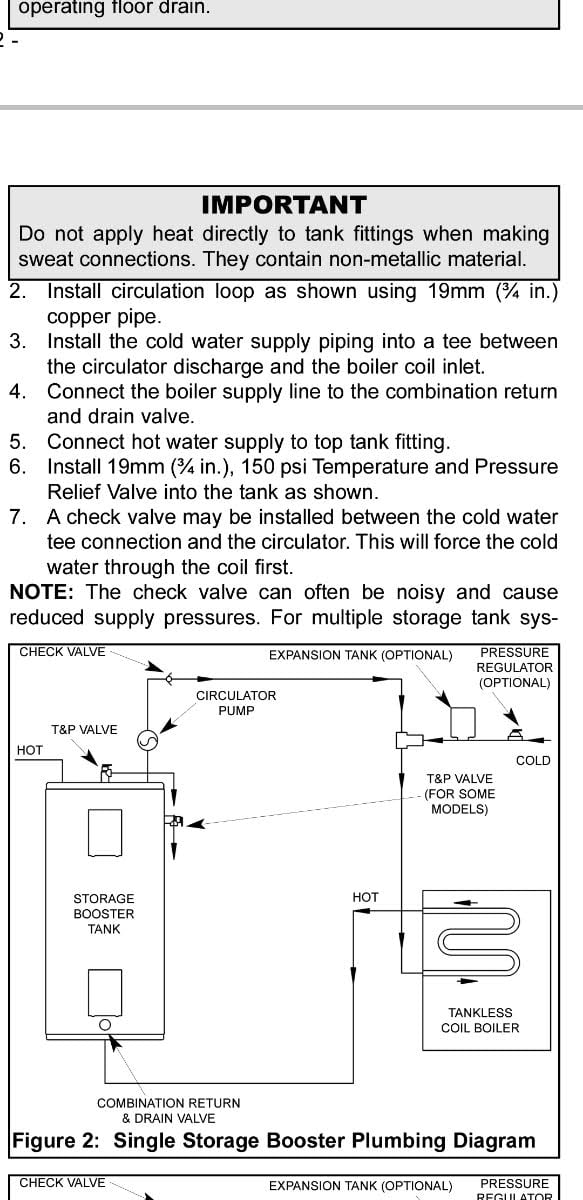

I can't see the volute on the pump and can't tell the direction of flow. The diagram is definitely different than your hook up. The cold water supply appears to be entering thru the port on the bottom of the storage tank and the pump is moving water to the coil on the boiler. It appears that the pump is mixing cold water with the hot circulating water when there is a demand for hot water.

I don't know the design of the storage tank (whether it has a dip tube). It appears to be an electric water heater with the electric parts removed, so I assume it has a dip tube.

Does it work in the present configuration? I think it should.0 -

You may well need a mixing valve -- probably do. A tankless coil in your boiler can create very hot water indeed, depending on flow requirements, and that can create real problems. A good thermostatic mixing would solve the problem.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

When i look at the diagram for the booster tank it looks like the top pipe of the tankless coil should go to the bottom of the booster tank and not to the top of the booster tank. what should the temperature setting be on the boiler and the booster tank?0

-

-

Gravity circulation occurs when hot water in the bottom of the tank moves up to less hot water at the top of the tank, cools then fall to the bottom of the tank. I don't think that's the case here. But, Alan, you may be on to something. With out a check valve there may be gravity circulation between the coil and the tank, raising the tank temperature above 125 deg. hmmm Of course there may be a hidden check valve in the volute of the pump.

The temperature appears to be set by that aquastat in the coil which turns on the pump?0 -

I just spoke with the plumber who installed the boiler. He said because its a steam boiler there is not much we can do about the temperature coming out of the sink until we put a mixing valve in. I was told when the house calls for heat its heating the coil as well. Sound Right?0

-

It does indeed, depending somewhat on the way it is piped.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I would put a spring loaded check valve on the line between the coil and the top of the tank close to the coil even if there is a check valve in the volute. This would stop thermo-siphoning.

I am still not sure what turns the pump on and off. What monitors and regulates the tank temperature? If the pump runs all the time? it need to be switched. There must be a relay like a fan center that the aquastat turn on and off that controls the pump. If that is so, I would still put a thermodisc that snaps onto the input pipe to the pump that would turn off the pump if the supply water to the pump was over 120 deg. If you needed more heated water capacity, a mixing valve would work and the tank temperature could then be raised higher.0 -

I can't tell from the pic the direction of flow, but you should have a stainless or bronze circulator, not an iron one in a potable system.

An AMSE 1070 tempering valve is require by code on any install that derives domestic hot water from a boiler.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

When i get home i will look to see the direction of flow0

-

I would wager that the flow is from the top port of the coil to the top of the tank. A pic of the back of the volute would tell the tale.0

-

-

The direction of flow is opposite of the drawing an how it should be.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

That tank is piped the way Energy Kinetics has done for years( system A), and the circulator unions look like the isolation valve type they used to use with a screw slot (usually didn't work after a few years). Without a check valve , or if the check valve fails, you will get scalding hot water. The circulator should only be powered when the surface mounted aquastat ( behind the lower uncovered insulation) is calling for hotter water( which probably doesn't happen often. Ask your plumber if he removed it when he installed the boiler so he could pipe to the coil without creating a trap.0

-

Is this the aquastat you were asking if removed?

With the way it is piped now where would i put the check valve?

0 -

You should find some one who know what they are doing installing a portable storage heater off a coil without a mixing valve is a liability on the installer and against code and using a iron pump is the case of a installer who does not care or know no better in any case I wouldn’t let the guy do anything else form what he has all ready has done ,he does not have a proper education except how to hook up pipes from point a to b does not make a tech or a knowledgeable installer . Not the guy I would want doing any thing for anyone I know . Also when you stated the domestic was to hot he should have been over to install what he forgot a quality mixing valve Peace and good luck clammy

R.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating1 -

Is this what you are talking about being removed?Alan Welch said:That tank is piped the way Energy Kinetics has done for years( system A), and the circulator unions look like the isolation valve type they used to use with a screw slot (usually didn't work after a few years). Without a check valve , or if the check valve fails, you will get scalding hot water. The circulator should only be powered when the surface mounted aquastat ( behind the lower uncovered insulation) is calling for hotter water( which probably doesn't happen often. Ask your plumber if he removed it when he installed the boiler so he could pipe to the coil without creating a trap.0 -

Is there anyone on this page that works in long Island New York. I am in Suffolk county0

-

I stand by my earlier post--put a spring check valve on the output of the coil. I think thermo siphoning is raising the tank temperature above 125 deg. Running off the boiler, tank recovery should be quick. The pump shouldn't run until the tank temperature drops below 125 deg. There isn't any sensor on the tank that I can see. The FMC into the top of the tank is from a relay, I suspect, to the pump. Is it just a junction box? The aquastat turns on the pump which would require a flow from the tank to measure the tank temp. All this is supposition, of course, but I would want to prevent thermo siphoning and have the pump more responsive to tank temp rather than coil temp.

Would I put in a thermostatic mixing valve, definitely.0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements