First Full Winter in 1890 Minnesota Home - Help Requested with 7 Questions

Heading into another winter (they happen every year) we resolved to learn as much as we could so we could better address the issues. We found Heating Help and read posts, watched videos and bought the book We Got Steam Heat! All the resources have been helpful, but we need some professional advice. We’re planning to hire another contractor, but we want to make sure they know what they’re doing and know the right questions to ask.

The house is a 4-level townhouse, including the basement. There are 5 radiators on level 1, 5 on level 2 and 4 on level three. The boiler is a Weil McLain Series 5 Gas-Fired Boiler EGH. It was installed in 2016 and seems to be working fine. We do blowdowns a couple of times a month in the winter. There are two main vents in the basement, one next to the boiler and one about thirty feet away.

Here are our questions:

1. We plan to insulate the pipes in the basement. Should we insulate the pipes in the living areas too?

2. How thick should the insulation be around the pipes be – 1 inch, 1.5 inch or 2.5 inch?

3. Should we insulate the elbows and tees?

4. Should we insulate the pipes before or after the contractor looks at it?

5. Any recommendations for a contractor in the Twin Cities?

6. Should we add more main vents in the basement?

7. The radiator air vents are a mix of Gortons, Hoffman Specials and ? Should we replace them with Vent-Rites or another model?

Here are a few photos of the basement pipes and vents.

https://www.dropbox.com/s/saqjdbdx7agx366/2020-10-20 15.02.09.jpg?dl=0

https://www.dropbox.com/s/1vwwlq2wfr6miix/2020-10-20 15.01.01.jpg?dl=0

https://www.dropbox.com/s/drlfw53s9e315cc/2020-10-20 10.43.57.jpg?dl=0

https://www.dropbox.com/s/dq16fudh87kvevd/2020-10-20 10.46.05.jpg?dl=0

https://www.dropbox.com/s/i778ns9whrmcre9/2020-10-20 11.55.29.jpg?dl=0

https://www.dropbox.com/s/ney26z463go37jy/2020-10-20 14.23.51.jpg?dl=0

Thanks so much for any advice you can share!

Jenn

Comments

-

1. We plan to insulate the pipes in the basement. Should we insulate the pipes in the living areas too? Yes, if there is easy access. The more heat that stays in the pipe before the radiator the better. Exception: does the pipe contribute to the heat of that room?

2. How thick should the insulation be around the pipes be – 1 inch, 1.5 inch or 2.5 inch? The thicker the better but there is a law of diminishing returns. 1" is better then nothing and easier to work with. You will need fiberglass insulation, not the foam stuff from the big box store. That stuff will melt on a steam pipe.

3. Should we insulate the elbows and tees? Yes they make fitting covers for fiberglass fittings

4. Should we insulate the pipes before or after the contractor looks at it? AFTER

5. Any recommendations for a contractor in the Twin Cities?

6. Should we add more main vents in the basement?

7. The radiator air vents are a mix of Gortons, Hoffman Specials

and ? Should we replace them with Vent-Rites or another model?

On the last three, I have no suggestion for a contractor in your area.

Ask the contractor you choose to recommend his preference. ask for how he will handle warranty on call-back if his fix does not resolve the problem.

Don't use the foam insulation on steam pipes. Use fiberglass:

here is the insulation You order by the pipe diameter you wish to cover.

https://www.grainger.com/search/plumbing/insulation/pipe-insulation?attrs=Fits+Pipe+Size+-+Pipe+Insulation|1+in~~Insulation+Body+Material|Fiberglass~QP~~Insulation+Temp.+Range|0++Degrees+F+to+850++Degrees+F~~Type+-+Pipe+Insulation|Hinged+with+Self+Sealing+Lap~QP&filters=attrs&searchQuery=hinged+with+self-sealing+lap+fiberglass+pipe+insulation&sst=4

hear are the fitting covers

https://www.grainger.com/search/plumbing/insulation/insulated-pipe-fitting-covers?searchQuery=fiberglass+pipe+insulation+fittings&tv_optin=true

Ordering the fitting covers is tricky. you need to order the fitting cover based on the outside diameter of the insulationEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

As usual -- I agree with @EdTheHeaterMan .

But a few additional points.

If you have hammering and knocking, as you have probably read already, a common reason is that the "horizontal" stretches of pipe either don't have enough pitch, or even reverse pitch, or have sags in them. Therefore... before you put insulation on them, check ever single length of level or near level pipe for the correct pitch and no sags. Old houses settle... and it's much easier to check and adjust pitch before you put insulation on!

Oddly enough, the venting may be adequate on the mains. The best way to tell is to find out if steam gets to the ends of the mains reasonably quickly (again, easier to do without insulation!).

The radiator vents hissing... don't mess with the radiator vents until you are reasonably happy with the main venting. Then check the pressure at which the boiler is running. It's probably find, but it should be less than a pound or so until really late in a cycle. Then... you can think about radiator vents. The idea here is to get the vents such that the various rooms heat more or less evenly -- or at least to the degree you want them to (some folks like bedrooms cooler, for instance). When you start playing -- if you do -- remember that it's better to slow down a radiator which is too enthusiastic than it is to try speed a radiator up. Gortons are good, as are Hoffmans -- but neither is adjustable. Vent-Rite and Maid-O-Mist make adjustable vents, which can be handy when balancing. Avoid cheap vents like the plague they are.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

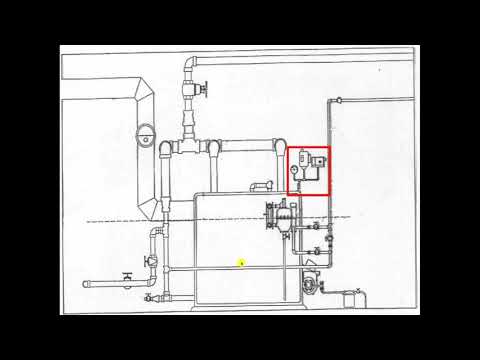

Looking at the first picture of the boiler.

The large steam riser out of the boiler goes up and has 2 90 elbows then the tee where your steam main is connected.

After that tee connection then the pipe goes horizontal (steam header) and drops down (equalizer pipe).....is that horizontal part sloped to drain water down the equalizer pipe?

The entire horizonal header should slope to drain water into the equalizer drop pipe.

Then is the elbow feeding the house piping (steam main) above the header the high point of the steam main??

If so then all the piping from that point should slope so as to drain empty when the boiler is off.

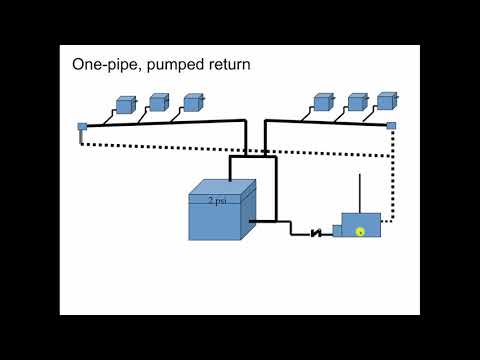

You have one steam, but 2 air vents seem to indicate you have 2 returns. Where are they connected together??

Or was that just an easy place to put a second vent?...not necessarily bad.

So all piping must have continuous slope back to the bottom of the boiler. It may look like it has slope but you need a long level and maybe a tight string stretched .

Old pipe can develop a "belly" from it's own weight and have a trapped pocket of water.

IIWM, I would remove all the foam insulation and check for proper continuous slope to drain.

Also I always add more hangers, almost double of the original install.

Then what pressure does the boiler run at?

The existing gauge is nearly worthless as you want to see less than 2 PSI.

Then have you cleaned the pigtail under the pressure control?

Your Steam Heat! book will talk about that.1 -

Seems like you need the Near boiler piping redone frist and foremost.0

-

Header looks to low you maybe pulling water out of the boiler and sending it out to system.0

-

Hello, I'm a distant neighbor from up north (Grand Forks, ND).

As far as a contractor, I would maybe call State Supply - 877-775-7705 or just go drop in - 5255 East River Road, Suite 206, Minneapolis, MN 55421 and ask them for a recommendation.

I have a 2-pipe vapor system and I've ordered a number of things from them and they are super helpful. They might be able to point you to a reliable contractor since they sell a lot of boiler and steam stuff.1 -

The tees on mains are exiting incorrectly. Sorry, but insulating that piping won't help. You did say that they replaced boiler recently correct? But looks like near boiler piping was not change. If you are handy you can do this work get Dan Holohan book the lost art of steam heating, watch his videos, etc. Stick it out one more winter and plan it out for summer project. Try to keep the steam system it's great heat and looks awesome hope I was of some help. Good luck1

-

Can you tell where the hammering is coming from-boiler-supply pipes-returns?

I would say that hissing radiator vents indicates, inadequate main venting, coupled with over high pressure. A good low pressure gauge, (0-3 psi, graduated in ounces), On the pressuretrol tee, will enable you to keep the pressure low, and tell you if you need a vaporstat.

Check the Boiler installation manual, and see if your particular boiler needs two risers instead of just one.

After checking the slope of the pipes, replace the foam insulation with fiberglass, before it melts onto the pipes. Even rolls of foil-backed fiberglass will be better than bare pipes.

Contact State supply, (an excellent suggestion Garret!), for the names of experts, or at least knuckleheads to avoid.

Maybe Jugne can be persuaded to come over from northern Nebraska to work some magic!—NBC1 -

I did blowdowns once a month, it took less than a gallon before it ran clear.JUGHNE said:Looking at the first picture of the boiler.

The large steam riser out of the boiler goes up and has 2 90 elbows then the tee where your steam main is connected.

After that tee connection then the pipe goes horizontal (steam header) and drops down (equalizer pipe).....is that horizontal part sloped to drain water down the equalizer pipe?

The entire horizonal header should slope to drain water into the equalizer drop pipe. I believe it does, yes.

Then is the elbow feeding the house piping (steam main) above the header the high point of the steam main??

If so then all the piping from that point should slope so as to drain empty when the boiler is off.

You have one steam, but 2 air vents seem to indicate you have 2 returns. Where are they connected together??

Or was that just an easy place to put a second vent?...not necessarily bad. Second vent on the wet return- It sputtered dirty water when we bought the place, a contractor replaced it in Jan/Feb which was nice because I had to add water every week before that.

So all piping must have continuous slope back to the bottom of the boiler. It may look like it has slope but you need a long level and maybe a tight string stretched . I strung as much string as I had- I am not impressed with the slope...

Old pipe can develop a "belly" from it's own weight and have a trapped pocket of water.

IIWM, I would remove all the foam insulation and check for proper continuous slope to drain. We removed most of the foam insulation and I ran string in the area where the most hammering occurs. its really close to level in that area.

Also I always add more hangers, almost double of the original install. It sure seems like we don't have enough hangers...

Then what pressure does the boiler run at?

The existing gauge is nearly worthless as you want to see less than 2 PSI. yep it never leaves the rest pin on the gauge. its either broken or useless

Then have you cleaned the pigtail under the pressure control?

Your Steam Heat! book will talk about that.

1 pipe steam system, 2014? Weil-McLain EG-75-PDIM S5, 2 Hoffman75 vents on main0 -

https://www.dropbox.com/s/ha9lmx5kuiuuvyv/Video Oct 22, 7 33 40 PM.mov?dl=0

Thanks for everyone's amazing advice! In the video above you will see that I spent some serious time checking the slope of the main in advance of a new contractor's initial visit (this Tuesday)

so far we have:

We removed all the brittle foam

I ran string lines in the worst hammering area (see video above)

We are waiting till a contractor sees it to insulate with fiberglass

Found a spot where a sheetrocker butted the rock so tight they had to gouge a dent to make it fit- I can hear the pipes slam into it most start-ups. I'll be removing that rock (its just a laundry room!)

Found the water and gas lines all rest directly on the main pipe (we can hear all those jump around when it hammers too)

I am starting to suspect that we may have gunk in our wet return1 pipe steam system, 2014? Weil-McLain EG-75-PDIM S5, 2 Hoffman75 vents on main0 -

Wet returns are pipes below the water line, yours are at the boiler.

"Dry" returns are pipes above the water line of the boiler and should be such that they drain back to the boiler.

Air vents can only work on dry returns.....as yours are.

Wet returns are all filled with water and often sludge impeding the return of the condensate and having it back up into the dry returns and even the steam mains.

On the horizontal steam main where there may be a reduction in pipe size, an eccentric coupling should be used.

Each end of which is off center so that the bottom (should be on the bottom) does not have a place to hold water.

The radiators should be sloped to drain back to the inlet valve, that might be the problem with the sloshing sound.

IIWM, I would have that small section of wet return cleaned out and also the pigtail to the control and gauge.

A 0-5 PSI gauge could be added under the control for better observation of the operation.

Both of your air vents could be located where the one near the boiler is. That might be beneficial. An antler on that 3/4" pipe could handle both vents.

Larger vents such as Gorton 2 are available that pass about 3X the air of your Hoffman's.

With the expansion and contraction of the steam mains, they will always break any sheetrock mudding. The better method is to allow a large enough opening and install pipe flanges to cover the oversized opening....if important.

It looks like all of your rad takeoffs are piped with single 90 elbows.

Standard practice is to use swing elbows....twice as many....to relieve a little expansion and have the riser thru the floor plumb in both directions.

This will cause the main to swing a little and give you a crooked riser pipe at the radiator.

Not a major issue but would explain the main cracking the SR as it comes thru the wall.

0 -

-

-

-

These videos are very informative.0

-

We got a local recommendation for a good contractor and I was around for the appointment. There was a lot of explaining of the situation to the new guy and what I overheard I was comforted to recognize from Dan's book and all the advice gleaned here. The contractor also measured every radiator since our tenants have complained that the heat is 10-15 degrees lower on their side of the house (single thermostat on our side). The diagnosis: all near boiler piping needs re-doing AND boiler needs resizing to reduce it.

I had not realized it was a red flag that the water in the sight glass drops quickly and completely upon start-up. That led to the diagnosis that the oversized pipes are sucking water out of the boiler.

This is the work that is planned for Monday (my husband thought it was a good idea to run it by y'all):

1.This is to rebuild steam lines to help with reducing

water hammering and water carry over

2.This is to repair the Main line going to second floor

radiators thought the kitchen with steel line

3.We will remove old steam riser (3") from top of steam

boiler and replace with 2" pipe for proper steam

travel

4.We will remove old steam line equalizer tee to proper

location for proper drain back, make sure there is a

close nipple for steam return

Huh, upon typing this up I realize that although he said that they need to down size the boiler it is not listed on the invoice (I already put half down) I better call them to clarify.

Do you agree or disagree that the above work plan is warranted?

1 pipe steam system, 2014? Weil-McLain EG-75-PDIM S5, 2 Hoffman75 vents on main0 -

The riser being oversized is not causing any trouble. In fact, some really great installers purposely oversize the risers because it's a benefit.

There are several things that can cause the boiler water to get thrown up into the system, but a large supply pipe is NOT one of them.

What do they mean by "resizing" the boiler? Replacing it with a smaller one? Or modifying the firing rate?

Now I'm nervous about this new contractor.NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Verbally I was told they contacted the manufacturer and after that discussion decided to reduce the size of the existing boiler- I apologize I don't have the proper terminology since it was verbal and not written on the work plan- modifying the firing rate sounds right.ethicalpaul said:The riser being oversized is not causing any trouble. In fact, some really great installers purposely oversize the risers because it's a benefit.

There are several things that can cause the boiler water to get thrown up into the system, but a large supply pipe is NOT one of them.

What do they mean by "resizing" the boiler? Replacing it with a smaller one? Or modifying the firing rate?

Now I'm nervous about this new contractor.1 pipe steam system, 2014? Weil-McLain EG-75-PDIM S5, 2 Hoffman75 vents on main0 -

I'm not sure that near boiler piping is what is causing it to throw water up in to the piping. Has the boiler been skimmed? Does the water line bounce around a lot while it is steaming?

What is the pressuretrol set for and what pressure is it actually running at? Enough pressure could push the water out of the boiler through the return and in to the header.

I wold get some of the real steam people on here to comment on the near boiler piping before going for surgery. It is funky but I'm not sure it wouldn't work ok.0 -

I agree that the boiler supply piping is good enough, just not very conveniently placed as far as the equalizer/Hartford loop goes. The important thing to verify is that the size and layout of the pipes are as required by the manufacturer.

What sort of main vents do you have?

Are all the colder radiators on one line, maybe needing more venting? Proper generous main, (not radiator) venting will allow the steam to reach all radiators simultaneously.

I see a plug where the skimming port would be, so I would think its removal, and skimming should be first on the list.

Maybe the thermostat could be in a better location, with a remote sensor placed in a more exposed part of the building, and the control in your unit.

What is your pressure set to?

--NBC

1

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements

https://youtu.be/L11ywcjSOFA

https://youtu.be/L11ywcjSOFA https://youtu.be/tpA1epqFMCw

https://youtu.be/tpA1epqFMCw https://youtu.be/VR6u_71FKGU

https://youtu.be/VR6u_71FKGU