Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Tools and Tables for easily determining the Steam Velocity in boiler risers.

Options

ted_p

Member Posts: 67

Hi All,

The discussion in 1 or 2 risers (@scott_block's recent thread) sparked my interest in this; I suddenly wanted to compare the velocity of the steam in the risers of the various configurations being suggested, along with that of other boilers cited in this thought-provoking discussion.

I found (as @The Steam Whisperer pointed out) the formulas for calculating Steam Velocity in my copy of @DanHolohan's The Lost Art of Steam Heating Revisited. Being mathematically challenged (I'm fully capable adding the same column of figures five times on a calculator, and getting five different results), whenever I have an algebra problem I build a quick-and-dirty tool on an Excel spreadsheet and let the computer do the math for me. This I did, and after working with this tool for a bit realized that it could be of value to others in the HeatingHelp community.

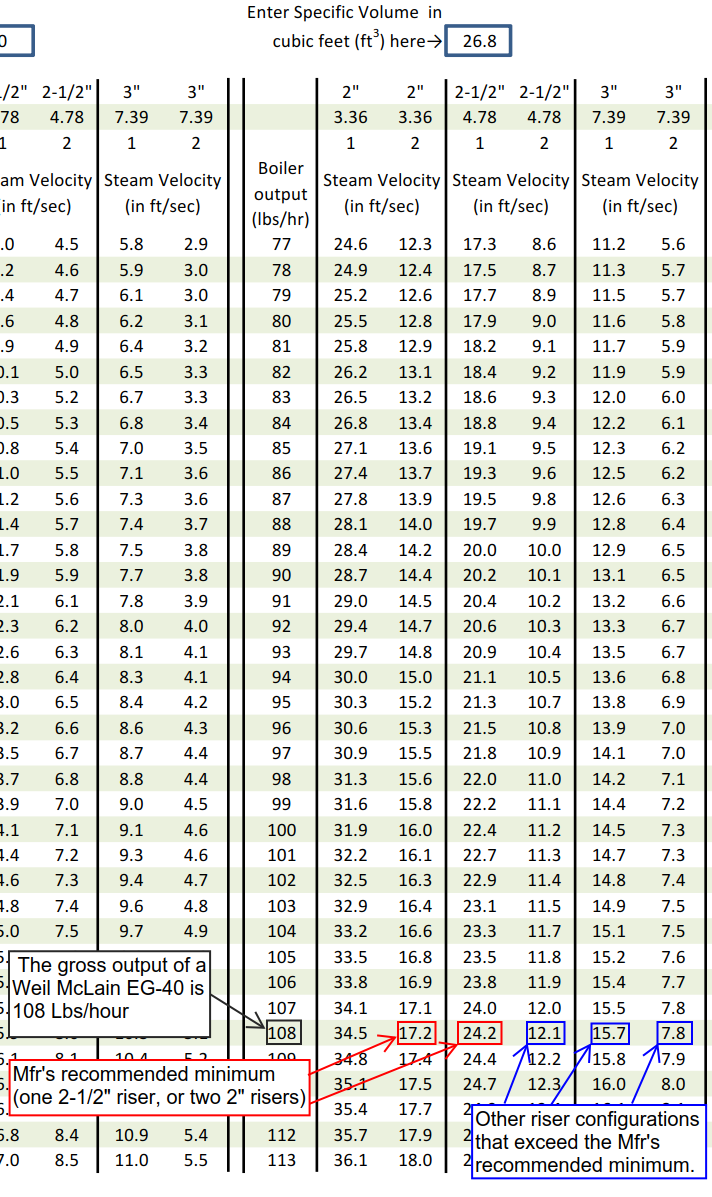

So I prettied-up the spreadsheets, added tabs with a Specific Volume look-up, and a tool to calculate Gross Output in lbs/hour from other types of gross and net boiler outputs. The result is the attached Excel workbook (Steam velocity.xlsx). Anyone who has Excel, or any other program that can open and run Excel workbooks is encouraged to download and try it; comments and suggestions are most welcome. For those who lack the software or inclination deal with an Excel workbook, I've also attached three tables, in .pdf format which can be viewed and printed using Adobe Reader. Here's what one of those tables look like:

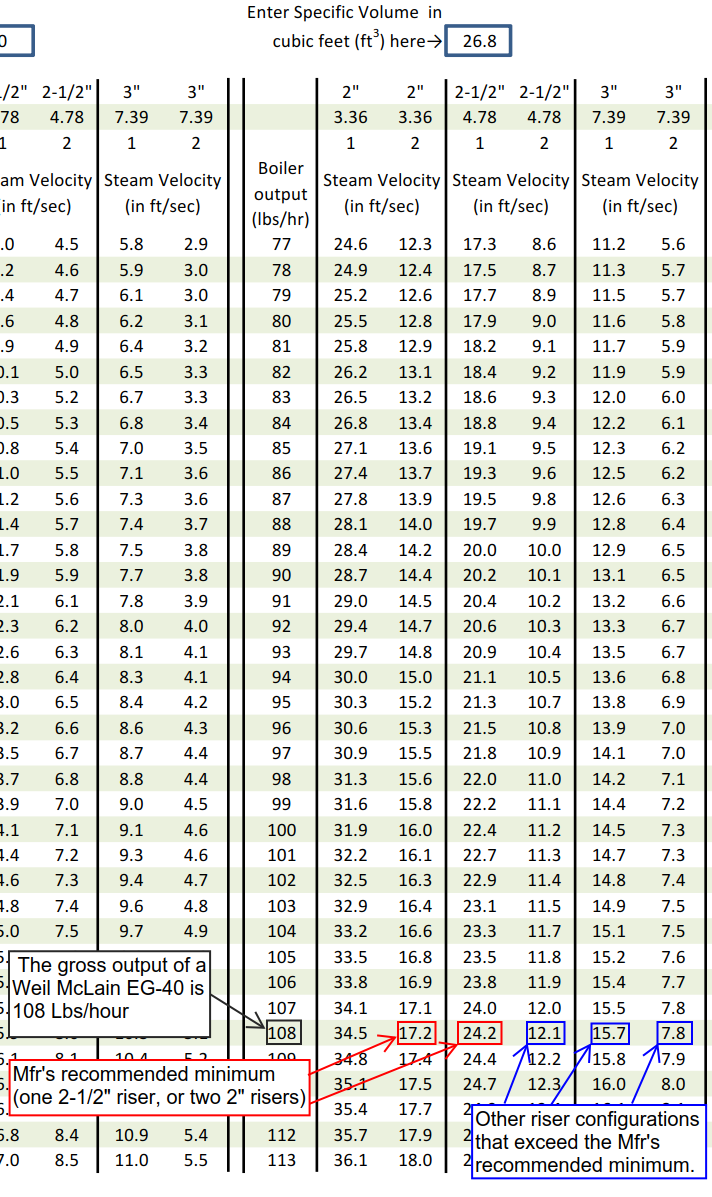

And here's are examples of using the tables:

I plan to add more tables and such, as I have time, and upload them here. This will likely include tables with the data for popular residential-size boilers already filled in. This is a small way of giving back to the HeatingHelp community.

Please let me know what you think.

Ted

6/26/20 - Uploaded table for WM EG Gas Boilers in pdf format

The discussion in 1 or 2 risers (@scott_block's recent thread) sparked my interest in this; I suddenly wanted to compare the velocity of the steam in the risers of the various configurations being suggested, along with that of other boilers cited in this thought-provoking discussion.

I found (as @The Steam Whisperer pointed out) the formulas for calculating Steam Velocity in my copy of @DanHolohan's The Lost Art of Steam Heating Revisited. Being mathematically challenged (I'm fully capable adding the same column of figures five times on a calculator, and getting five different results), whenever I have an algebra problem I build a quick-and-dirty tool on an Excel spreadsheet and let the computer do the math for me. This I did, and after working with this tool for a bit realized that it could be of value to others in the HeatingHelp community.

So I prettied-up the spreadsheets, added tabs with a Specific Volume look-up, and a tool to calculate Gross Output in lbs/hour from other types of gross and net boiler outputs. The result is the attached Excel workbook (Steam velocity.xlsx). Anyone who has Excel, or any other program that can open and run Excel workbooks is encouraged to download and try it; comments and suggestions are most welcome. For those who lack the software or inclination deal with an Excel workbook, I've also attached three tables, in .pdf format which can be viewed and printed using Adobe Reader. Here's what one of those tables look like:

And here's are examples of using the tables:

I plan to add more tables and such, as I have time, and upload them here. This will likely include tables with the data for popular residential-size boilers already filled in. This is a small way of giving back to the HeatingHelp community.

Please let me know what you think.

Ted

6/26/20 - Uploaded table for WM EG Gas Boilers in pdf format

6

Comments

-

Very nice @ted_p

There is no way you could build this if you are math challenged.

Great job. I am sure may will find this very useful1 -

Nice work!All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

This is great. My only suggestion would be maybe sort by the total value(s) so as you go from left to right you see the ways that various values can be achieved in order (with steam velocity maybe being the key value to compare)

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Thanks, but sadly it is true. Dyslexia....EBEBRATT-Ed said:........

There is no way you could build this if you are math challenged.....

Thanks @Steamhead!

Thanks for the suggestion; that makes sense to me.ethicalpaul said:...... My only suggestion would be maybe sort by the total value(s) so as you go from left to right you see the ways that various values can be achieved in order (with steam velocity maybe being the key value to compare)

Here's one with the order of some of the columns changed, so velocity decreases as you go from left to right.

Is that more like what you had in mind?

1 -

I have always wondered if there are any rules of thumb on the length of the nipples between the tees on the header.

I understand boiler riser--boiler riser--steam main riser (s) and then equalizer drop.

Is there an optimum spacing on the various tees. It seems more would be better as the more time of steam traveling horizontally in the oversized header would drop out more water.

I understand there are room limitations around boilers, but have visualized a "L" shaped header using a 90 and taking up no more footprint than the top of the boiler itself.

Can the horizontal nipples be too long?0 -

@JUGHNE

I think with a border line sized header the space between the tees could be an issue. Probably less of an issue with a good sized header.

Some on here have posted pictures of 90 degree headers. No issues that I know of0 -

Ted, That looks great. I have enclosed some of the charts I made for steam. I have it based on 40 fps.Ray Wohlfarth

Boiler Lessons1 -

Hi @RayWohlfarth,

Many thanks for the charts!

I spot-checked the tables that my tool (for 4" to 10" risers) generates against the your chart named "steam velocities.pdf", for 4, 6, and 8 inch pipes, and in each case the velocity came in just under the 40 FPS mark, as expected.

But when I spot-checked my tables against the your chart named "2 psi velocity.pdf", for the same pipe sizes (4", 6", & 8"), the numbers for 6" and 8" pipes agreed with your chart, but my figure for the 4" pipe was way off.

So what am I doing wrong???

Ted

0 -

Ted,

Perhaps it was my mistake. I can double check mine and let you know

rayRay Wohlfarth

Boiler Lessons0 -

Very cool @ted_p can you tell me the calculation for my setup. Eg45 with 2 x 2 inch risers and a 3 inch drop header.0

-

Thanks @RayWohlfarth.

@scott_block:

I just uploaded a table for Weil McLain EG Gas boilers @ 0 PSI, the download link is now in the first post of this thread.

Open the file, and look in the 2 x 2" risers column, drop down to the line for your boiler, and you'll see that the velocity in the risers will be 20.7 fps. Then look in the 3" header column, drop down to the line for your boiler, an you'll see that the velocity in the header will be 18.9 fps. That's all there is to it.

Your choice of two 2" risers is the better of the two Mfr's recommendations for your boiler. And with those risers, the 3" header looks to me like a very nice upgrade from the Mfr's recommended 2-1/2", in that it keeps the velocity in the header lower than the velocity in the risers.

0 -

Very useful Ted. Much appreciatedgwgillplumbingandheating.com

Serving Cleveland's eastern suburbs from Cleveland Heights down to Cuyahoga Falls.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements