No heat boiler won't turn on - McDonnell Low Water Cutoff ? Switch ? Override ?

In attempt to fix it, I removed the float from the low water cut off and cleaned it. I reassembled it and verified that it can move up and down freely but unfortunately when I put everything back together I still get no power.

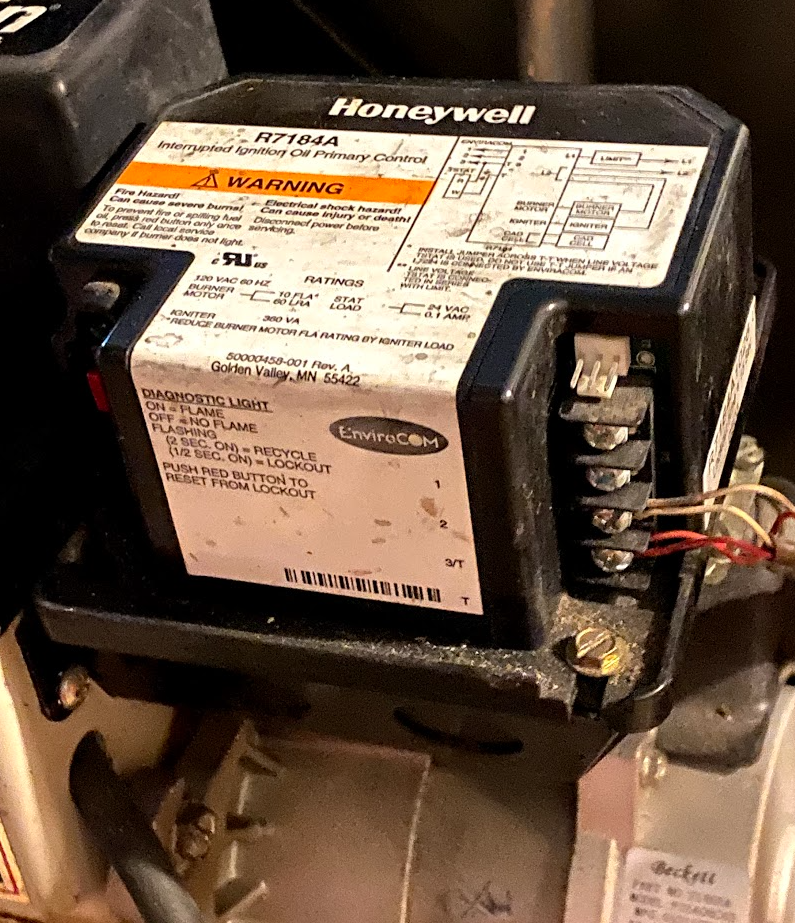

Is there a way to override the switch to verify that it is the switch or to see if there is another issue? Is it as simple as jumping the two wires together? Only the top two screws were connected to wires on the switch. Attached are photos - any help is greatly appreciated.

Thank you

Comments

-

0 -

-

Thank you for the reply!! The site glass shows it is 3/4 full - I have tried draining and refilling with no luck.JUGHNE said:What does your sight glass show?

When you open the drain does anything come out?

Back up to take more pictures......

0 -

Check the sight glass. Is there water in it? Then check the blowdown on the LWCO. Does water come out of it freely?

If the answer to either one of those questions is "no", turn off the boiler with it's power switch and leave it off. Then set about figuring why there either is no water in the boiler or the LWCO isn't seeing the water level -- either situation in very dangerous.

On the other hand, if the answer to both those questions is "yes", then make sure there really is power to the boiler and turn up the thermostat. There should be zero voltage between the two terminals you have wires attached to. If that shows 24 volts, or anything close to or above that (and watch out -- the size of the wires makes me think that maybe this thing is wired into the 120 volt supply, rather than the 24 volt control circuit -- so there may well be 120 on one or both terminals) the switch is open and shouldn't be. Either the float is stuck down, or it has sunk, or the switch is defective.

Do NOT under any circumstance jumper that switch. That is a primary safety control, and unless it is working properly you are just asking for a spectacular end to your experiments.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Thank you! I can confirm that the answer is YES to both of those questions. There is water in the sight glass and water does flow freely from the LWCO. I confirmed the switch is ON for the power and that the everything in the breaker box is on.0

-

Any other ideas on how I can test if this is LWCO switch or a different issue? Cold showers aren’t fun regardless of the time of year!0

-

@steamheatnewb , call a pro. Where are you located?steamheatnewb said:Any other ideas on how I can test if this is LWCO switch or a different issue? Cold showers aren’t fun regardless of the time of year!

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

I gave you an instruction for testing the switch in the LWCO... that's the next step.steamheatnewb said:Thank you! I can confirm that the answer is YES to both of those questions. There is water in the sight glass and water does flow freely from the LWCO. I confirmed the switch is ON for the power and that the everything in the breaker box is on.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

-

By back up and take pictures......we mean so we can see the whole boiler and piping......from several sides.0

-

THIS WAS IT!!!!!!! The pressuretrol! I took the cover off, cleaned it and the whole thing fired right up!! THANK YOU!!!! Incredibly simple fix once you told me what to check. AGAIN - Thank you!Fred said:Make sure the pigtail that the Pressuretrol is mounted on is clean. If it is clogged, the Pressuretrol may be holding pressure and not letting the boiler fire. Pigtails mounted on the top of the LWCO are notorious for clogging and should be cleaned a couple times a season.

0 -

Thank you all! I am very happy that I have heat again tonight! I appreciate all the help0

-

you cleaned under the cover?

or the looping pipe under the Ptrol?

make sure that pigtail is clear, or that the boiler is shutting off when done heating the domestic,

and clean your pigtailknown to beat dead horses0 -

I cleaned it by removing the top cover where two wires are connected to the slanted board and reassembled. Did I just get lucky? Should I clean the pigtail pipe leading upt o the Ptrol too?neilc said:you cleaned under the cover?

or the loping pipe under the Ptrol?

make sure that pigtail is clear, or that the boiler is shutting off when done heating the domestic,

and clean your pigtail0 -

You took the cover off of the control and cleaned under it or did you unscrew the control off of the pigtail and clean the pigtail??

So when the boiler is firing and you drain down the LWCO does the burner shut down?

Truly, it could be a mater of life and death.....that is the entire intent and purpose of the LWCO safety control.0 -

I took the cover off of the control and cleaned under that. I did not unscrew the control off of the pigtail.

I confirmed that if the water gets below the line on the LWCO the burner shuts down again.0 -

You probably just jiggled it enough to come on.

To clean the pigtail you must unwire it and unscrew it.

Then you should be able to blow thru the pigtail into the boiler,

without much resistance. It is most likely partially plugged and you will have problems again. IMO

What is the setting on the front of the control?1 -

@steamheatnewb

Both the low water cutoff and pressure control are safety controls. Unless you know what your doing you shouldn't be fooling with either of them.

We are here to help, not assist with a catastrophy

You need to know when to call a pro0 -

The setting is about 2 PSI:JUGHNE said:You probably just jiggled it enough to come on.

To clean the pigtail you must unwire it and unscrew it.

Then you should be able to blow thru the pigtail into the boiler,

without much resistance. It is most likely partially plugged and you will have problems again. IMO

What is the setting on the front of the control?

0 -

1. If you feel that you can do it safely, take the pressuretrol off the pigtail (you will have to disconnect it -- take a photo so that you get it connected back correctly) and make sure that the pigtail is open. You should be able to blow through it easily. Clean it -- or replace it -- as needed.

2. The pressure setting is too high. There is an adjusting screw on the top of the pressuretrol. Turn it so the indicator is just above the 0.5 marking.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Jamie - thank you!! I will try this - I dont think it will be too difficult to remove the pressuretrol. Hopefully the pictures and detail responses from the forum members will help others as well!Jamie Hall said:1. If you feel that you can do it safely, take the pressuretrol off the pigtail (you will have to disconnect it -- take a photo so that you get it connected back correctly) and make sure that the pigtail is open. You should be able to blow through it easily. Clean it -- or replace it -- as needed.

2. The pressure setting is too high. There is an adjusting screw on the top of the pressuretrol. Turn it so the indicator is just above the 0.5 marking.

0 -

I'm not a pro, but I had a bad experience with a Pressuretrol mounted atop the LWCO like that. The problem is that it puts the Ptrol pressure-sensing diaphragm at or below the water line of the boiler (not good for the diaphragm), and the pigtail clogged. I'd get a taller pigtail that puts the bottom of the Ptrol above the water line as marked on the boiler.

1950 Bryant boiler in a 1-pipe steam system at 7,000 ft in northern NM, where basements are rare.

0 -

For educational purposes, does anyone have a photo of what a clogged pigtail would look like and where would it clog? Does it typically clog in the pigtail loop or where it connects to the LWCO? Is the clog from typical radiator junk or water?0

-

You know, I don't think I've ever seen a picture... the clogging -- which is from corrosion and crud in the boiler water (not radiators) can be anywhere in it that water can reach -- but the loop is the usual culprit.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Newb, you will know it when you see it.

There is a good chance you can post a picture of one yourself.

Check the bottom of the control itself, do not puncture the bottom of the control.

One thing that might go thru the pigtail is a large cable tie.

That looks to be an iron tail screwed into the iron LWCO.

I would consider some PB plaster to soak in on the LWCO threads, twice at least. Then you could stick the handle of a wrench thru the loop and carefully unscrew. If it breaks off that is then another problem.

The entry opening needs to be clear.

Replace with copper pigtail when you have a chance....prime the loop with water before installing the control.

We await your results.0 -

Withe the pressure control mounted on the low water cutoff (which I don't recommend) you don't need a pigtail.

The pigtail's purpose is so the pressure control is not exposed to steam.

If it's mounted on the lWCO as shown it's already below the water line and will never see steam. I would move it to the boiler with a brass pigtail. But you can leave it as is and replace the existing pigtail with a brass nipple0 -

@steamheatnewb The pigtail will clog anywhere along the inside of the pipe, but when it is mounted on top of the MM67 LWCO, it will also clog at the opening in the LWCO, where the pigtail screws in. The best thing to do is take the Pressuretrol off, unscrew the pigtail from the LWCO and clean both the pigtail and the opening into the LWCO. If you can, add a 4 inch straight 1/4" pipe into the LWCO then a 1/4" coupling and then the pigtail. That will get the Pressuretrol up above the normal waterline. It's a simple fix. When you took the cover off of the Pressuretrol, you giggled it enough to release the pressure but it will fail again unless you clean that pigtail.0

-

Newbe, is your LWCO mounted on the sight glass fittings?

The pictures from farther back as mentioned above would show that??0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements