I just Noticed Dripping Peerless Boiler .. VIDEO

I feel like I can never get ahead ... couple weeks ago the expansion tank of the hot water heater and P & T valve replacement, then three days ago, the washing machine hoses were leaking and now today I heard "sizzle" sound when I walked by the boiler ... huh what??

I was in the basement talking on the phone while my girlfriend was taking a shower. I kept hearing this "sizzle" sound and thought it was strange. Turns out there's a very minor but constant drip coming from the plate that's attached to my domestic hot water coil. From what I gather the Peerless boiler is from 1992, so maybe it's time?

I guess it could have been going on for some time because the cast iron piece has that white discoloration on it.

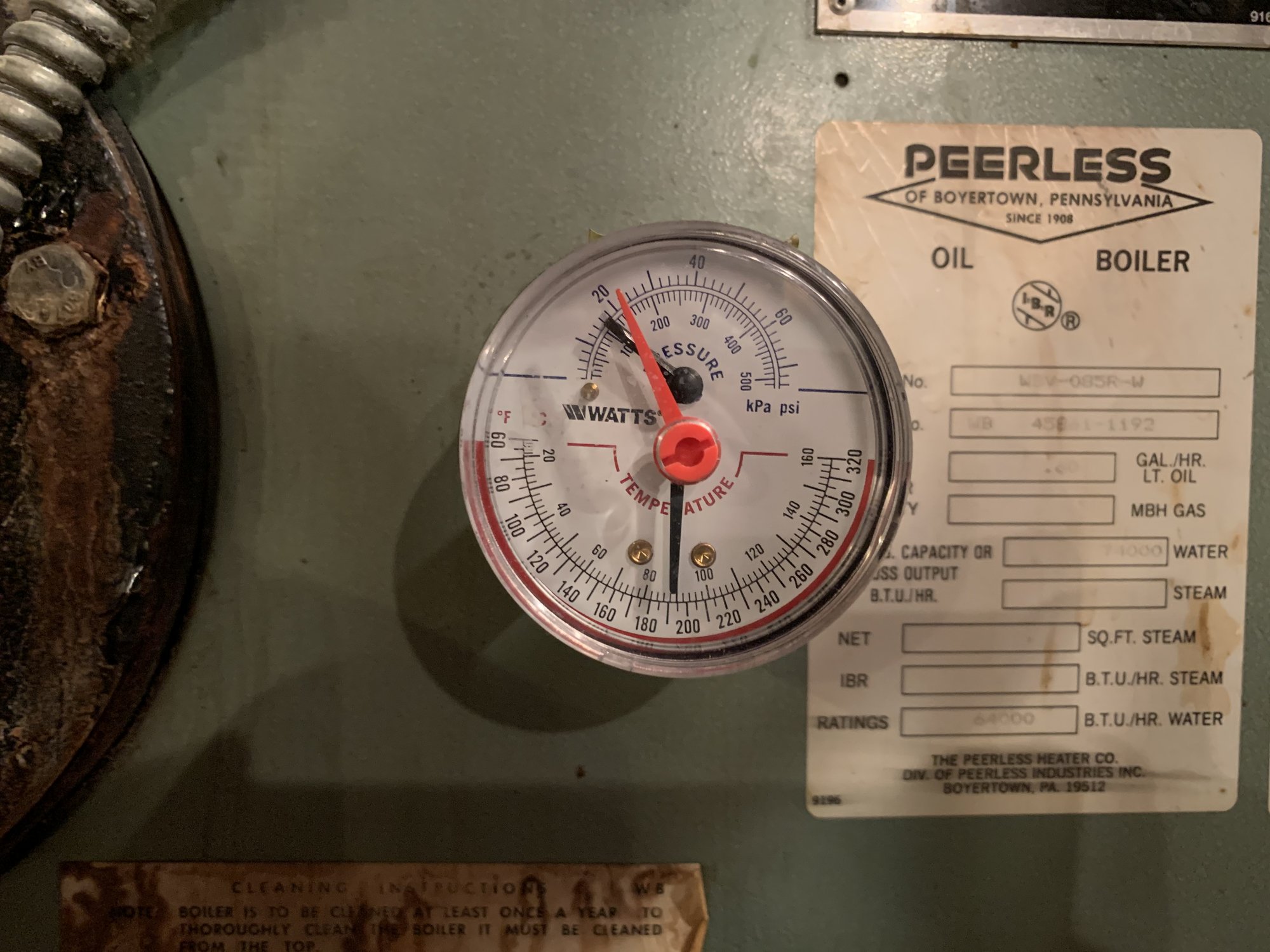

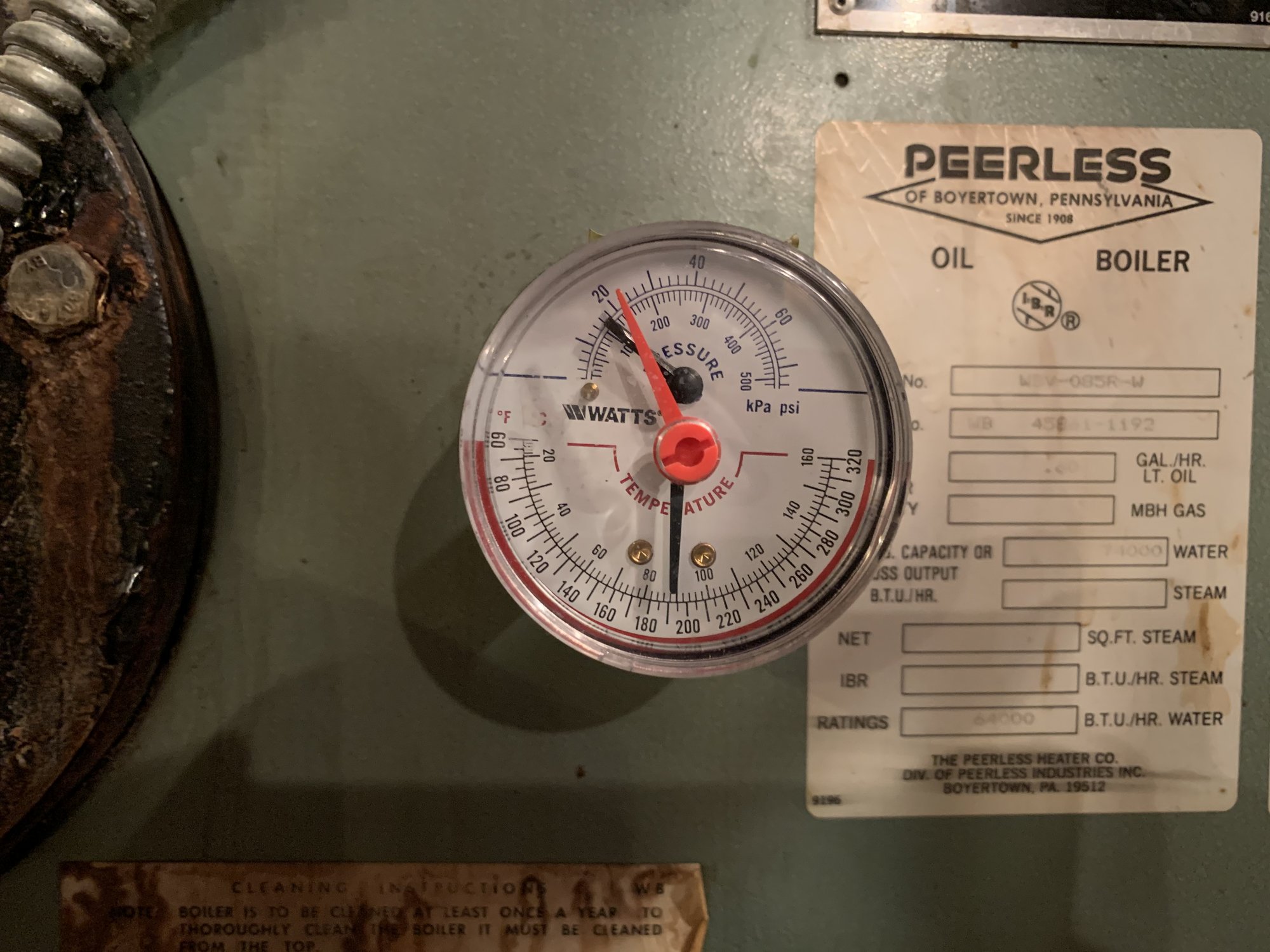

I also noticed on the gauge the water is 190 degrees, is that right? I am reading the gauge incorrectly? Seems a bit high, right? If indeed its too high, how would I lower that? Is it just a simple oil nozzle swap out? The oil company (Petro) we have a service contract usually does that one per year with the annual cleaning, I wonder if the guy put in a nozzle that was bigger?

Any help is appreciated.

Fred from Long Island, NY

VIDEO of Dripping

Peerless Boiler Dripping

Comments

-

@FredoSP

You need to have the tankless heater gasket replaced. It's a thankless job the bolts are probably rusted in and might break.

It takes a technician with a little patience, some Kroil rust breaker spray and a little luck.

I would set your boiler high limit at 190 degrees. The low limit setting should be 140, but you may have to set it (the low limit) a little higher if you run out of hot water1 -

Its assumed you have an Aquabooster? A tank that gets heated by the tankless coil?

Since theres no drain valve and probably no isolation valves at the coil, and along with what @EBEBRATT-Ed wrote, it seems hardly worth the effort. But something needs to be done. This is one of the jobs that blows my mind. With potentially having to step drill and tap, maybe dig out the grinder, you can easily take 5 hours of prep for a 10 minute application.

I use Zoom Spout electric motor oil when I need to tap. The telescoping spout gets right in there.

The boiler is from 1992. The WBV is a good boiler for a pinner. And yes a new 3 pass boiler with an indirect water heater or an Energy Kinetics EK-1 Frontier will drastically reduce your fuel consumption. Eliminating the tankless coil alone will save. Getting rid of the dual aquastat (ALWAYS maintains the Hi limit setting) will save Bigly. What a waste.

See if you can get a fixed price quote to replace the gasket.

Take that quote and see if it's worth it to repair, or put it towards upgrading.

The domestic extrol and T&P valve can be salvaged.2 -

@HVACNUT

Don't know if you remember but the older Smith Boilers 1100,2000, 3500 were cast with a flange so the tankless coil was held in by nuts and bolts.... it was so nice worst case was cutting bolts and buying new ones. I am sure it was more expensive to make so you know what happened to that.......out the window.

I used to drill and tap a lot of that stuff....never fun. I used to use brass bolts if I could get them, less likely to rust and if they did break you could drill them out easily the bit will follow the brass because it's softer.

If people would pull the bolts on a new install and use never seize it would solve some of the problem. I did used to drill them oversize sometimes 3/8 bolts move up to 7/16 bolts eetc

Only once I did one (Confession Time) the old bolts were different lengths so I drilled too deep on one of them and yup right into the water.

I jammed a piece of red rubber gasket in their and put the bolt in and it didn't leak. It was a friends house and he sold it with the same boiler 6 years later1 -

Who hasn't at least once?EBEBRATT-Ed said:...

Only once I did one (Confession Time) the old bolts were different lengths so I drilled too deep on one of them and yup right into the water...

There was an error rendering this rich post.

1 -

To me, in the video, the front of the round plate looks wet.

Or maybe it is blistered paint?

Could it be leaking at the piping ports or temp sensor well?0 -

X-2EBEBRATT-Ed said:@HVACNUT

Don't know if you remember but the older Smith Boilers 1100,2000, 3500 were cast with a flange so the tankless coil was held in by nuts and bolts.... it was so nice worst case was cutting bolts and buying new ones. I am sure it was more expensive to make so you know what happened to that.......out the window.

I used to drill and tap a lot of that stuff....never fun. I used to use brass bolts if I could get them, less likely to rust and if they did break you could drill them out easily the bit will follow the brass because it's softer.

If people would pull the bolts on a new install and use never seize it would solve some of the problem. I did used to drill them oversize sometimes 3/8 bolts move up to 7/16 bolts eetc

Only once I did one (Confession Time) the old bolts were different lengths so I drilled too deep on one of them and yup right into the water.

I jammed a piece of red rubber gasket in their and put the bolt in and it didn't leak. It was a friends house and he sold it with the same boiler 6 years later0 -

@FredoSP

The water temp is controlled by the aquastat (gray box), not the size of the nozzle. It should be set as Ed recommended. 190* high limit is quite normal for an oil burner.

As also mentioned: this repair can be quite time consuming and costly. Due to the age of the boiler, I'd recommend that you get some quotes on replacing it.

There are some very good men on here that cover LI. Use the contractor locator above to locate some of them.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Hi All,

Thank you for all of your suggestions. I was planning on responding yesterday but had too many errands.

I've seen a video on YouTube with steven lavimoniere and it looked fairly procedural, but those bolts are the big unknowns.

Again, I'm all new to this stuff so I'm learning as I go. The current Peerless boiler does my domestic hot water and also the heating for my baseboard. I guess there are many solutions out there, I need to educate myself on all of those. If I decide to rip everything out, I will be ditching the oil and going with gas when the time comes.

EBEBRATT-Ed

Why do you think it could be the gasket? I never knew what the coil looked like until I saw pictures online. Since the coil is a closed loop, I would think the coil probably has a pinhole leak in it and that's what is causing the water to run down the side of the gasket?

If I chose to replace the coil, do you think PB Blaster would work too?

I have to open the Honeywell Aquastat unit to see what my low and high limits are.

HVACNUT

I never heard of the Aquabooster term, but I guess I do have one in my current setup. After the (DHW) water leaves the boiler it goes directly into my gas hot water heater. I've often thought that was a bit redundant because I'm heating up the water in the coil with oil, just to have it sit in the hot water tank to be reheated by gas.

JUGHNE

I doubled checked this morning and of course no leaking. I didn't notice any water dripping from the copper fittings or the temp probe when I took the video. I do agree that at one point in time there must have been an issue because the black plate is rusted/white deposits and some paint has blistered off. I think it could also be the reflection in the video. I took more images where I can show you more a detailed view of the plate, please see below.

Ironman

Thanks, I'll have to give that a look over. I'll also call the company we have a service contract with for a quote.

Of course I have more questions:

Why do I see three different stickers on the boiler? I get that one is probably for the DHW and the other for the heat, but whats the other one for?

I also noticed the Taco Hy Vent looks nasty, that's the least of my problems. No signs of any leaks from that, but it looks like at one point it was.

Long Island, NY0 -

Someone at work suggested I use my 18V Snap On cordless impact gun on those bolts. I dunno, that seemed a sure way to snap them.Long Island, NY0

-

0

-

> @EBEBRATT-Ed said:

> @FredoSP

>

> From your pictures it looks like water has been leaking round a few of the bolt holes

Not that I can currently see, but if it was leaking around the bolt holes, is that consistent with a gasket failure like you suggest above ?

Unless it is in-fact leaking from the bolt holes and drying instantly. That cast iron is hot as heck.Long Island, NY0 -

Also, if I was to attempt to do it myself, could I temporarily take the cold water line that is going into the coil and temporarily connect it to my gas hot water heater? My logic is that if one or all of the bolts do break, I’ll at least have hot water in the house to shower, etc.Long Island, NY0

-

You are right. That will snap them. I have replaces several tankless coils on Weil Mclain and Burnham boilers. Never on a Peerless. But my approach is to use an acetylene turbo torch to get the bolts cherry red. then cool them down with PB Blaster. Then repeat several times. after the 3rd time, try to break the bolts loose.

If you even want to bother.

it is time to replace that old boiler. forget the tankless coil. for now, just cut the pipes and connect cold water pipe directly to the gas water heater. If there is a pinhole leak in the tankless coil, you can plug the coil openings. Just abandon the tankless coil.

You can remove the wire that maintains water temperature or just set the low limit at the lowest setting. in the summer, turn off the burner. Any extra money spent on this old oil guzzler is a waste. Save up for a new modulating, condensing gas boiler.Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thanks Ed. I'm going to wait and watch for now, hopefully the minor leak doesn't turn into anything more. If I decide to go the full replacement route, I will wait until the summer when we don't need the heat. I'll use the time to familiarize myself with the different options. I will most definitely ditch the oil and go gas.

I still don't understand how the gasket can fail letting water pass through. Isn't the inside of the coil a closed loop? So there must be some soft of leak in the coil for it to drain down on the outside of the plate?Long Island, NY0 -

-

Ahhh, so you're saying the copper coil is submerged in water, hence the term "boiler water"? I'm sorry if this is trivial but I had no idea; my talent is writing computer softwareJUGHNE said:The water you see leaking is boiler water, which is under less than 30 PSI, probably only 15.

If the internal coil was leaking then house pressure of 50 PSI or so of water would enter the boiler and open your 30 PSI pressure relief valve.

Look at your picture of the replacement coil. Long Island, NY0

Long Island, NY0 -

This might be sacrilege, but could I possibly put a RTV sealant around the spot where the small drip is coming out of? I'm just looking to buy myself a couple of months till Summer when I'll have the time and not need the heat on.

High Temp. RTV Silicone Sealant, -65 to 650°F Temp. Range, Full Cure 24 hr., Red, 3 oz. Long Island, NY0

Long Island, NY0 -

I don’t think you can get it sealed without removing the plate, and putting in some sort of gasket, or sealant.

For bolts like that, try to turn clockwise a tiny bit before then loosening in an anti-clockwise direction.

Tapping on the head while putting pressure on the wrench can be helpful.

When putting it back together, stainless bolts with anti seize might be the way to go.—NBC1 -

Pressure on the boiler would need to be 0, and open to the atmosphere (drained down below the leak) before any sealant could be applied and cured.

If its not too bad, watch it until spring. Cut the coil out then and use the gas water heater only. You could probably order a WBV coil plate, gasket and bolts. Penetrating oil, a flat chisel, lump hammer, 9/16 six point socket, coffee, let's roll.0 -

I'm going to clean off the cast area where the water is dripping onto. If the leak is continuing I will eventually see that area turn white and will have my answer.

I'm also going to pick up spiral sockets, so in the event the bolt head is rounded off, I will be able to remove the bolts, assuming they don't snap on me.

Correct, my plan would be to shut off the boiler for 24 hours prior and make sure the pressure is 0. Drain the boiler, maybe have a priest come to the house and bless the six bolts and see where it goes. I thought the bolts were 1/2 but I'm not 100% sure.

Definitely a summer project. I will have a conclusion to this thread in the summer with pictures.

Would you happen to have an image of a cross section of a typical boiler? Now that I've learning my coil is surrounded by water, I'm curious what the "inside" of the boiler looks like.Long Island, NY0 -

IIWM, and one was to wait until the heating season is over before repairing, I would not clean the flange or bolt heads until ready to shut down for repairs.

The corrosion and minerals may be helping to seal against a larger leak.

As the water leaks out of a hot boiler, much of it may be evaporating and leaving minerals behind.

What pressure shows on your boiler when hot?

How much does it rise from cold to hot?0 -

Good call, I didn't think about it that way.

Here's a picture I took just after the boiler shut off. I would have to see what it is when it's cold.

Long Island, NY0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements