Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Outdoor Boiler w/ Condensing Backup - Piping Arrangement

Options

Hoopman5000

Member Posts: 9

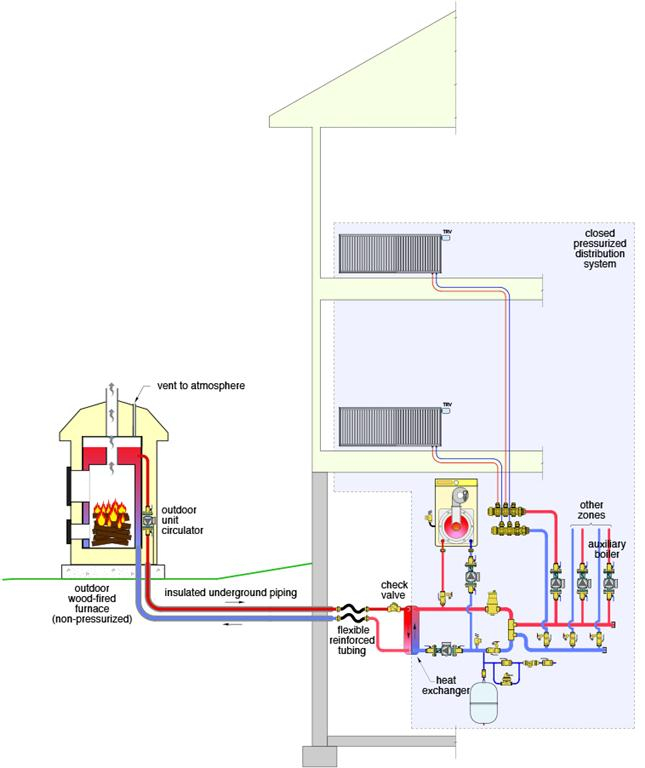

Hello, long time viewer, first time poster...I'm in the process of re-designing my piping system for a outdoor wood boiler. I purchased a condensing backup boiler and would like the house side to be pressurized. I have found an article w/ schematic that accomplishes just that but had some questions.

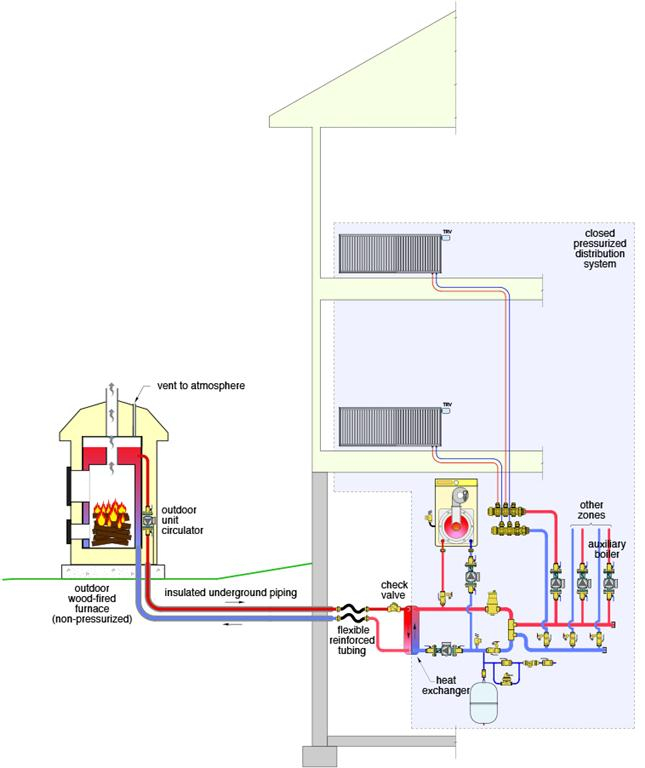

Photo 1, shows a pressurized system coupled to the unpressurized boiler. I plan on using the main circ (to the right of the plate heat exchanger) as my boiler protection, where it will turn off when temperature drops below 140F and the condensing boiler will pick up. My question arises when I look at photo 2, providing freeze protection w/ a small circulator. To the right where it says "To the heating system" it shows another circulator. Why is there a circulator in photo 2 but not photo 1? Will I need that second circulator?

thanks - Matt

Photo 1, shows a pressurized system coupled to the unpressurized boiler. I plan on using the main circ (to the right of the plate heat exchanger) as my boiler protection, where it will turn off when temperature drops below 140F and the condensing boiler will pick up. My question arises when I look at photo 2, providing freeze protection w/ a small circulator. To the right where it says "To the heating system" it shows another circulator. Why is there a circulator in photo 2 but not photo 1? Will I need that second circulator?

thanks - Matt

0

Comments

-

I like the concept. The shunt circ does a nice job preventing freezeup without the waste associated with heating the outdoor boiler to 180 degrees.

The difference between the 2 drawings on the secondary side looks like a system with zone circs on the first drawing and either a single zone or a zone valve system on the bottom drawing. You can run it either way on the secondary without effecting the primary."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

Maybe GroundUp will have an opinion on freeze protection, he does a lot of these systems in MN. I've never had an issue with freeze unless power goes out for a week? Or iso the system will be left un-supervised for a period in winter.

You really don't wasn't to use the mod con to keep the OWF from freezing

Use the heat energy from the OWF to the lowest possible temperature before bringing on the fossil fuel. What type of heat emitters do you have? Can you run down to 120F or lower?

Its the outdoor unit a gasification type that needs a min return temperature?

Keep the circulator on the OWF as low as possible to prevent cavitation.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Without any accompanying info, it appears from the drawing that the shunt circulator is to protect the wood boiler from freezing when it's not firing.

In most climates, this is not necessary if the ODWB is left on constant circulation.

If the method in the drawing is utilized, the gas boiler would be back heating the ODWB which would be quite costly.

Someone correct me if I'm wrong.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

The freeze protection component really depends on the climate and owners habits. If it is in zone 7 or 8 and the owner travels frequently, I would absolutely pipe it with the shunt and just keep the boiler water at 40 degrees or so. Running the boiler circ as the only freeze protection will eventually be an issue. Picture boiler water at 20 degrees constantly circulating and a 10 minute power outage. The whole thing will turn into a block of ice. Glycol is an option but is expensive at that quantity.

I have found that most systems installed per manufactures recommendations just pipe the 2 boilers in series and heat the OWB to 180 when it is out of wood. Talk about wasteful..."If you can't explain it simply, you don't understand it well enough"

Albert Einstein1 -

water freezes, simple as that. If you commit to owning a tank of water outdoors you also commit to some sort of freeze protection. Some folks just have a friend or neighbor maintain the fire. Any energy gas or electric to prevent freeze is going to cost $$

Maybe my dog sitter should offer that service Bob "hot rod" Rohr

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thanks everyone. Make sense that the 2nd picture is for a zone system w/ valves or a single zone. Just wasn't sure if I was missing something...

Hot Rod - Its a gasification wood boiler, heating domestic hot water w/ a plate exchanger, then my fan unit needs 140 Deg water, then my radiant floors needing 110 deg water.

Main circ will be sized to match the gpm of the wood boiler side.

I think I will install the shunt pump just incase I need it, for the little bit of extra material cost I think it would be worth the protection when/if needed (hopefully not needed)

Any recommendations on products that monitor the water temp and will turn off a circ pump?

Anything else you think I'm missing or should change?

thanks0 -

Run a pvc conduit or two in the trench for sensor wiring. I'd add a 1/2" pex for a water fill also, valved inside able to drain back.

I prefer solar differential controls, better control, digital read out, connect online, remote readouts, plenty of options. Alpha Thermal Systems usually has them, Joe or Vic, at a good price.

Victor at www.solarnetix.com in Canada.

Download Idronics 10, good piping and wiring with differential controllers.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

My ODWB holds 275 gallons of water. The simple truth is that if the power went out for an extended period of time in freezing conditions, the piping or fittings would burst long before that mass of water would freeze.

Not a scenario I’d want. Even in the mountains of VA.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Thanks for the help everyone. In regards to the first picture I posted...

If the main circ (which is the primary circ) is off, and one of the zone circs turns on, there needs to be flow in the primary loop in order for the zone circ to take heated water from the primary loop. So say the water is hot enough and the condensing boiler isn't firing, which means the circ isnt on correct? How does the zone circ get flow or am I just completing over thinking this...

Would this be why they added a 2nd pump in the 2nd photo, moving the primary loop to the heating side and making the plate exchanger a 2ndary loop?0 -

Any way to put the boiler inside? I have an indoor wood gasification boiler. Love having warm fuel and being able to check on it in my slippers.Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0

-

Is the "fan unit" just an air handler with a W2A coil in it or is this a gas furnace? Depending how fancy you want to get, there are a few options here.

1: A basic system as you describe, with the forced air being hydro-air only with the only backup source being the mod/con, I would probably run the hydro-air as a primary loop across the plate HX with the radiant pulling through a mixing valve as a secondary loop and the mod/con as an injection loop before the W2A. This would allow the cooler return water from the W2A and/or slab to run across the plate and backfeed the OWB to a median temp (depending on the tightness of the house, usually 60-90 degree OWB temp) until it's refired. This is assuming 24/7 OWB circulation.

2: If the boiler is set up with DHW capability for an indirect, I would likely run the hydro-air in place of the DHW zone and set it as priority, as DHW would be, with your 140 supply temp. Then pipe the radiant as you would normally to the boiler and set it up with ODR for the lower radiant temps, and run the return of the radiant across the plate HX prior to the close tees for the mod/con injection loop. Again backfeeding the OWB via the 24/7 circ on the OWB, but at a lower temp. Neither option has any temp control to the OWB unless you get a little fancy with controls and a bypass, which can be added pretty easily. It'd be an aquastat on the OWB supply line to the plate HX and a 3 way ZV to bypass the plate with the OWB water until it reaches low setpoint.

3: (My recommendation, and what I do in my own home) Put the plate HX in the back (or side, depending on the OWB) of the OWB cabinet and keep it hot 24/7 with the onboard circ but only circulate the underground lines on call for heat with an indoor circ. W2A would be in this "primary" loop to the plate at the OWB, with the radiant on a secondary loop through a mixer and the mod/con again as an injection loop to the primary before the W2A. Any call for heat would again backfeed the OWB. This DOES require glycol (for the underground lines) on the pressurized side which most will advise against, but I feel it's cheap insurance with little downfall.

4: I have this in my own system as well, but it's a trial run as of now so take this with a grain of salt and be warned that it is potentially dangerous. My OWB has a 1" MPT nipple welded into the water jacket at the bottom for a drain. I screwed a 1" tee on that nipple with the run horizontal and the branch to the side, and made the side/branch a drain using a ball valve. The run of the tee then gets a 120V water heater element screwed into it, which protrudes into the water jacket. I have mine set up with a Ranco temp controller, with the probe in a thermowell on the supply line set for 40 degrees with a 2 degree differential. Being the OWB is constant circ, this probe reads actual supply water temp and when it falls to 39 degrees, the Ranco will energize the WH element until the water jacket reaches 42 degrees. This would be the cheapest and most controllable method of freeze protection, but it's pretty shady.

5: Make friends with a neighbor to feed it for you while you're gone

With all that said, it probably makes no sense without a picture but I'd love to avoid drawing one if somebody can make heads or tails of what I said, haha. One thing I'm going to stress is that you NEEEEEED to spend the money on proper underground lines. That corrugated drain tile garbage, forget about it. If it's not a pair of o2 barrier pex lines encased in a single solid chunk of closed cell foam within a resilient plastic outer jacket, it's going to give you trouble some day. I sell Rovanco Rhinoflex brand, but have used Central Boiler Thermopex (identical to Rhinoflex but green), Rehau Insulpex, and Urecon Logstor and all 4 are great products. As far as I know, there are no other options currently available. Sizing of these lines is also of utmost importance. What is the distance from the OWB location to the heat exchangers (total loop length from OWB and back, round trip) and what are the total heat loads of the system? Not the heat loss of the building, I am looking for the actual draw of the exchangers on call for heat because they're undoubtedly oversized. This is one area that 99% of OWB dealers just toss you 1" pex and a Taco 007 and send you down the road. THIS IS IMPORTANT and more often than not, that aforementioned combination is far from ideal. The underground and circ sizing go together like peas and carrots, like Forrest and Jenny.

Sorry for the long winded post, just want to lay it all out on the table0 -

Here is how I installed the underground lines with InsulSeal insulated PVC.

This company also sells the flex type in two options.

This allows you to install whatever pipe you want, a water line also. You have the ability to remove the tube, and know if you have water infiltration.

Sensor wires in a separate PVC. I'd also throw at least 1- 1" PVC conduit in the trench for 120V wiring for future options, alarm, switched leg, etc.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I installed the boiler about 4 years ago and have learned alot along the way. I bought thermopex lines, but only 1" which I learned a few years back that they are undersized, hence the larger pump I needed to install. I'm pushing 12 gpm which is high on the velocity end but it is what it is at this point.

I'm in a redesign phase now, recently installed the radiant floor heat during a remodel, now adding a backup condensing boiler instead of the current forced air backup.

The condensing boiler says that it needs to be piped primary secondary w/ closely spaced tee's in the primary loop. If i pipe it as an injection loop as depicted in the previous photos with the condensing boiler supply not next to the condensing boiler return, is that an acceptable way to install that condensing boiler? Its a Weil Mclain WMB-120c0 -

One of my concerns is that if the condensing boiler is piped as shown in the photos above, when the main circuit pump to the plate heat exchanger turns off (for outdoor boiler protection) and say a secondary circ turns on before the condensing boiler Circ turns on, is there any risk there of somehow pulling water out of the primary loop and not having anything circulating in that primary loop? Since a key point of primary secondary is that the primary pump runs all the time0

-

How long is the loop of Thermopex and what size pump is on the OWB? How did you verify 12 GPM? Unless it's an extremely short run, 12 GPM is nearly impossible with an atmospheric system like this. The piping the photos depict is not really primary/secondary and you would need to place the tees side by side for proper hydraulic separation, but I don't see why it wouldn't be okay for the mod/con to be piped this way. Why are you installing a combi boiler when you are using the tank water heater for domestic? Once the system is complete and pressurized, there is absolutely zero chance of any portion of the system going dry without a leak somewhere. I'm not sure what you're asking about the main circuit pump shutting off for OWB protection- if you want it backheated the circ needs to stay on. If you want a true P/S system, the primary circ needs to run at the same time as any load or injection circ runs or there will be no heat transferred.0

-

Pump is a taco viridian 3452, 1/4 hp. The display On the pump shows 12 gpm at 34 ft of head. No tank hot water heater in this system. With the outdoor boiler the manufacturer wants a thermostatic valve installed to prevent firebox condensation. Instead of purchasing a new valve (since my existing is too small, 3/4”) I was planing on turning off the circ to the plate exchanger when water temp drops below 150 to decouple the outdoor boiler from the heating load. (Disregard the back heating freeze protection part for now)0

-

That is a primitive, but effective way to do boiler return protection. Toggle then circulator off when the temperature drops. It will cycle the pump quite a bit.

The readouts on this electronic circulators are not always 100% accurate, it's a calculation based on the electrical energy. An actual flowmeter is a better way to measure flow accuratly.

But if it is moving the load required you are good to go.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Advanced but typical CB setup. Still not likely anywhere near 12 GPM unless the distance is very short but either way, some diagnostics are in order. Someone needs to sit down and pencil this out with you0

-

What is the distance of the boiler 1" pex?

Here is 200' with a few fittings. 12 rpm is doable, at 34', fairly high velocity 5 fps is on the high side for hydronics.

Everything on the B side of the HX is a closed pressurized loop, tee is no way to pull water out of that loop?

The primary loop is like a conveyer belt, it needs to circulate to put heat into, and pull heat out. So with any heats call the primary circuit needs to run. When any boiler fires the primary circ needs to run.

Wiring and control logic does get complicated to enable the circulators at the proper sequence. the wiring matches the piping schematics I showed above.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements