Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Replacing Copper with Black Pipe Advice

Options

Jakek

Member Posts: 57

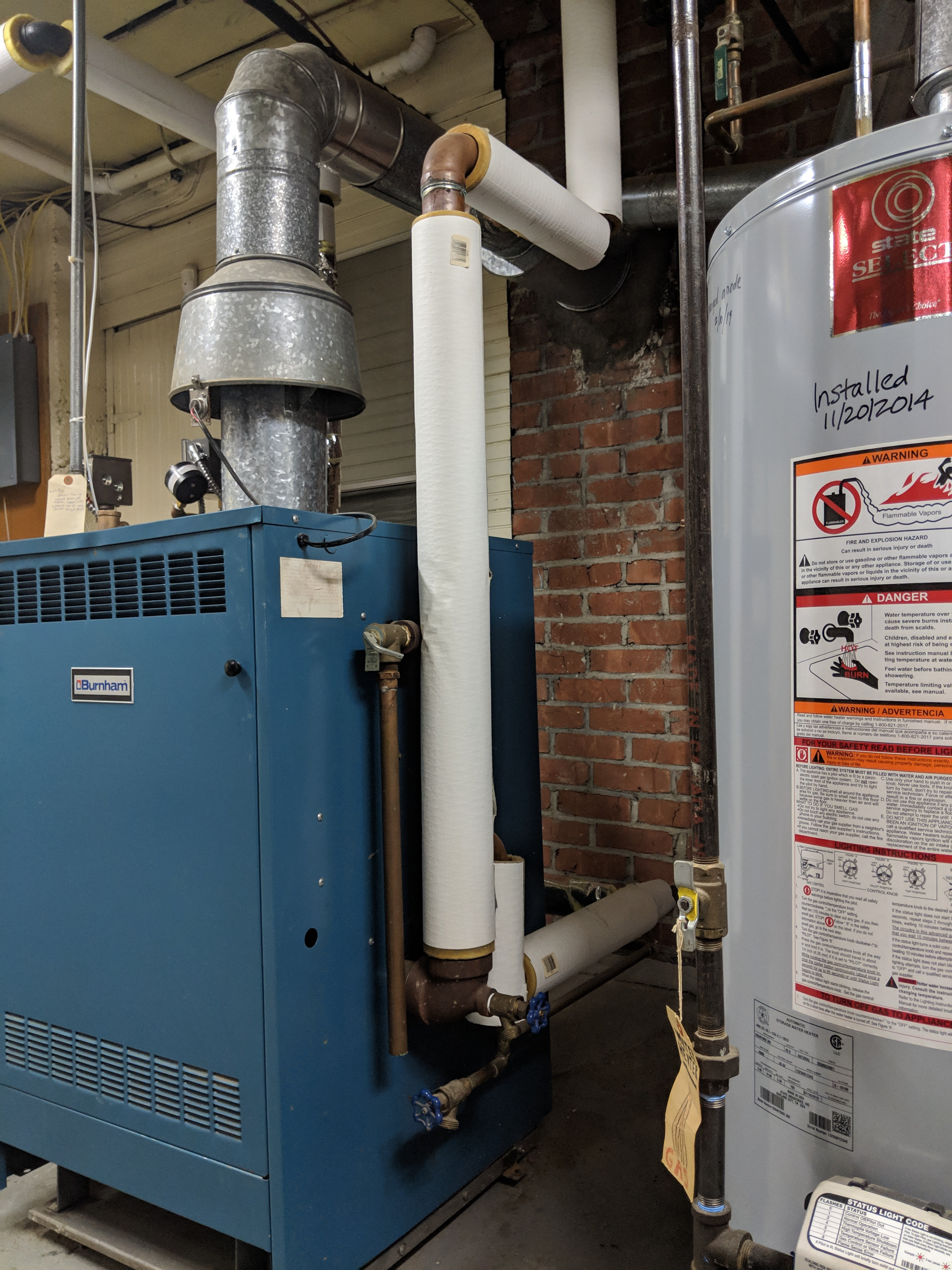

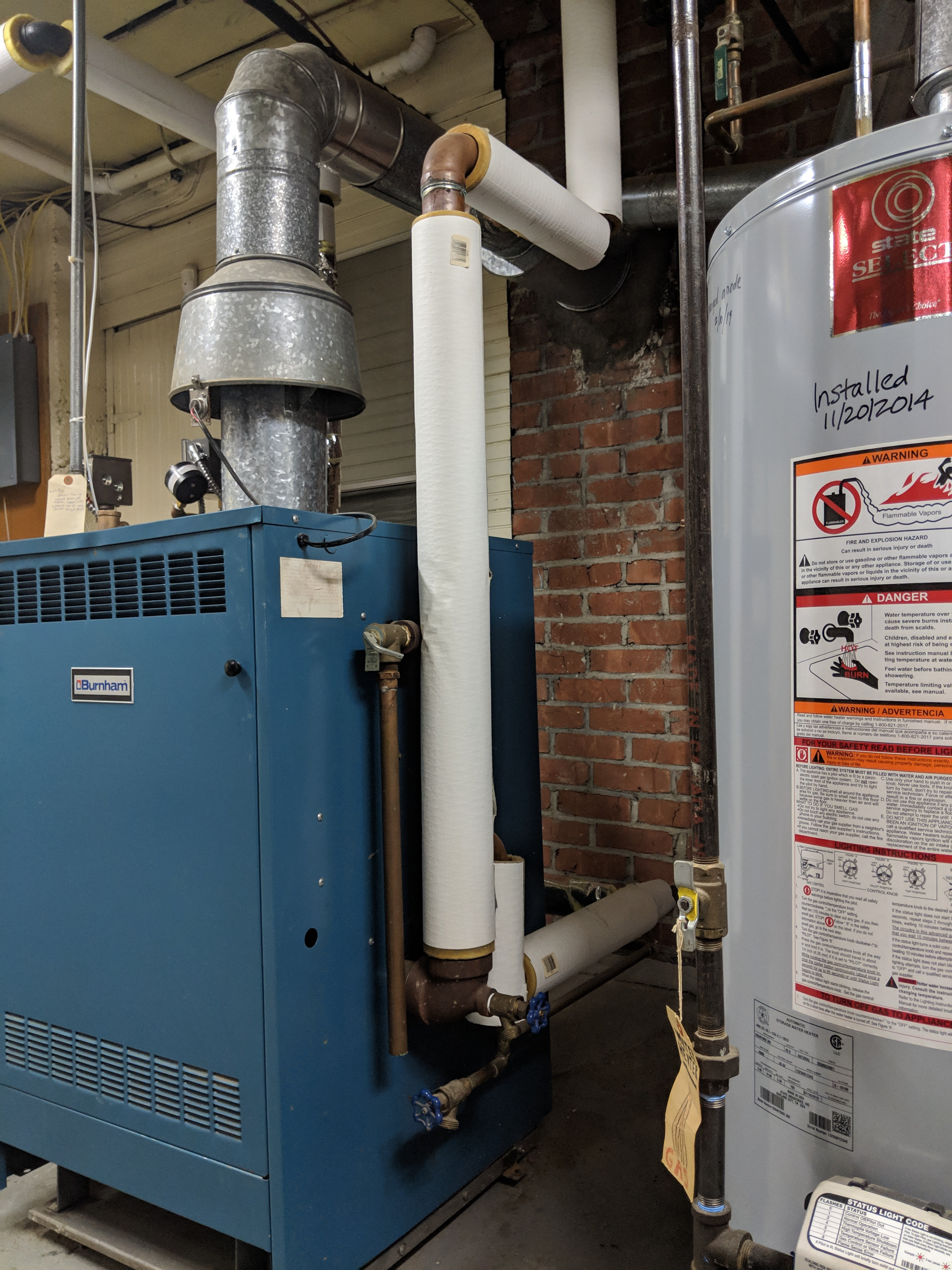

In 1989 whoever installed my boiler used copper for the near piping, regrettably. I purchased the house mid-heating season last year and have been studying Dan's books, this forum, and the system ever since. (Very enjoyable.) The system has been well maintained.

Last winter it required about 1 gallon per ~3-4 weeks in the heating season, manually added as a liter or so every week. I think one of the radiators is leaking slightly between the sections which might account for some of the loss. It has no problem getting to pressure (4oz) and cycles correctly. The boiler is sized just right for the piping and radiators. This is a parallel flow, dry return system with 320 EDR.

The copper joints don't look great, although the system works well otherwise. I don't know if they are leaking steam but the oxidization suggests that's possible. They probably aren't leaking badly, if at all, but I want to prolong the life of the system as much as possible.

So my options are to buy nipples and elbows and swap it out myself or just assume that if it's made it 30 years there's no reason to poke the bear. I think I'd be able to re-pipe without problem but I'd hate to be in a spot where I'd need to call for an expensive service visit by a pro to fix something which wasn't previously broke.

Thoughts?

Last winter it required about 1 gallon per ~3-4 weeks in the heating season, manually added as a liter or so every week. I think one of the radiators is leaking slightly between the sections which might account for some of the loss. It has no problem getting to pressure (4oz) and cycles correctly. The boiler is sized just right for the piping and radiators. This is a parallel flow, dry return system with 320 EDR.

The copper joints don't look great, although the system works well otherwise. I don't know if they are leaking steam but the oxidization suggests that's possible. They probably aren't leaking badly, if at all, but I want to prolong the life of the system as much as possible.

So my options are to buy nipples and elbows and swap it out myself or just assume that if it's made it 30 years there's no reason to poke the bear. I think I'd be able to re-pipe without problem but I'd hate to be in a spot where I'd need to call for an expensive service visit by a pro to fix something which wasn't previously broke.

Thoughts?

0

Comments

-

Don't poke the bear. Just because copper isn't preferred doesn't mean that it is forbidden! What you see around the joints may just be corrosion from leftover flux.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Building pressure isn't necessarily a good thing, more of a side effect.

That said, the header is completely wrong and isn't helping your wallet.

If you want to repipe it, I'd get a new boiler at the same time and make sure you size it well. For example if your current boiler builds pressure a bit faster than needed, consider a smaller boiler.

I wouldn't touch it unless replacing the boiler.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Thank you @Jamie Hall and @ChrisJ . You're reassured me there's need to touch the copper.

What about the header is wrong, apart from the copper? I've looked over the I&O manual and read Lost Art several times. The dimensions and layout seem to check out. I'm sure things can be improved, but I I'm missing where it's completely wrong.

I calculated the EDR and when adding the 33% factor for piping, it's nearly spot on for the boiler's DOE rating. The mains, the risers, the dry return, etc all match the charts in Dan's books. Long story short, I don't know what replacing the boiler would get me beyond a lighter wallet and some surplus copper pipes.0 -

What is wrong with your piping is the order of connections.

The boiler steam riser(s) would be first into the header, then the steam mains coming off of the top of the header (or 45 degrees) then the drop of the equalizer into the HL and boiler return.

The header would be sloped to drain down the equalizer pipe.

If it works as is I would leave well enough alone.

The only reason to change the boiler is if it starts to leak.

Then a good repipe is in order.

It is best to use both risers and drop header connections.

Most will advise against steamers with side outlets.0 -

If you don’t poke the bear now, the bear is going to eat you on Christmas Eve @Jakek. It’s done it’s service, albeit piped wrong. My advice would be to get ahead of this and start getting some prices.1

-

@Jakek

keep in mind, @Jamie Hall and I aren't in the business.

Danny Scully is and does this for a living.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

Thank you everyone. I'll admit I'm still a bit perplexed at how it should be piped vs how it currently is. Perhaps I'll make a drawing and ask for clarification. Regardless, I'm taking the advice to not touch the pipes.0

-

Picture water blowing up the pipe from the boiler with the steam.Jakek said:Thank you everyone. I'll admit I'm still a bit perplexed at how it should be piped vs how it currently is. Perhaps I'll make a drawing and ask for clarification. Regardless, I'm taking the advice to not touch the pipes.

The header's job is to keep everything flowing in one direction and to remove water. Yours goes up and the water needs to go right but the steam needs to go left. That's not going to happen.

The steam main needs to be piped into the same run as the equalizer, which is also a drain for water. Not in the opposite direction.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Then you missed the part in both publications that show steam and condensate moving in parallel toward the system take-off tees and the equalizer pipe.Jakek said:I've looked over the I&O manual and read Lost Art several times. The dimensions and layout seem to check out. I'm sure things can be improved, but I I'm missing where it's completely wrong.

My experience with those crudded-up copper joints is that they are indeed steam leaks...which never look like water leaks since it's gas that's escaping and not a liquid. I've seen steam pull copper joints apart live and in person. It's not a theory or an urban legend. When steam makes a copper joint twist, even just a microscopic amount, the joint is officially toast. Steam leaks mean more fresh water make-up which means less boiler life due to premature corrosion. Get ahead of this now.

With all due respect to the gentlemens' stated opinions in the prior posts, truly, my opinion is that the boiler looks like it's got a lot of life left in it. Change the header now and start realizing some benefits and a well-piped system. When the boiler is replaced you will re-use the good header and the installation will be cheaper.

Contact John "JohnNY" Cataneo, NYC Master Plumber, Lic 1784

Consulting & Troubleshooting

Heating in NYC or NJ.

Classes2

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements