Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Steam boiler for a dummy (me)

Options

jlo1029

Member Posts: 33

I'm suddenly responsible for a steam boiler (gas) and I can't get a pro in for 4 weeks.

I suspect there has not been maintenance done for a few years.

I'm hoping in the meantime someone can explain what the parts are to me and tell me if I have any urgent problems?

The boiler in question is a Weil-McLain EG/PEG-35 series 4. I believe it was installed in 2005.

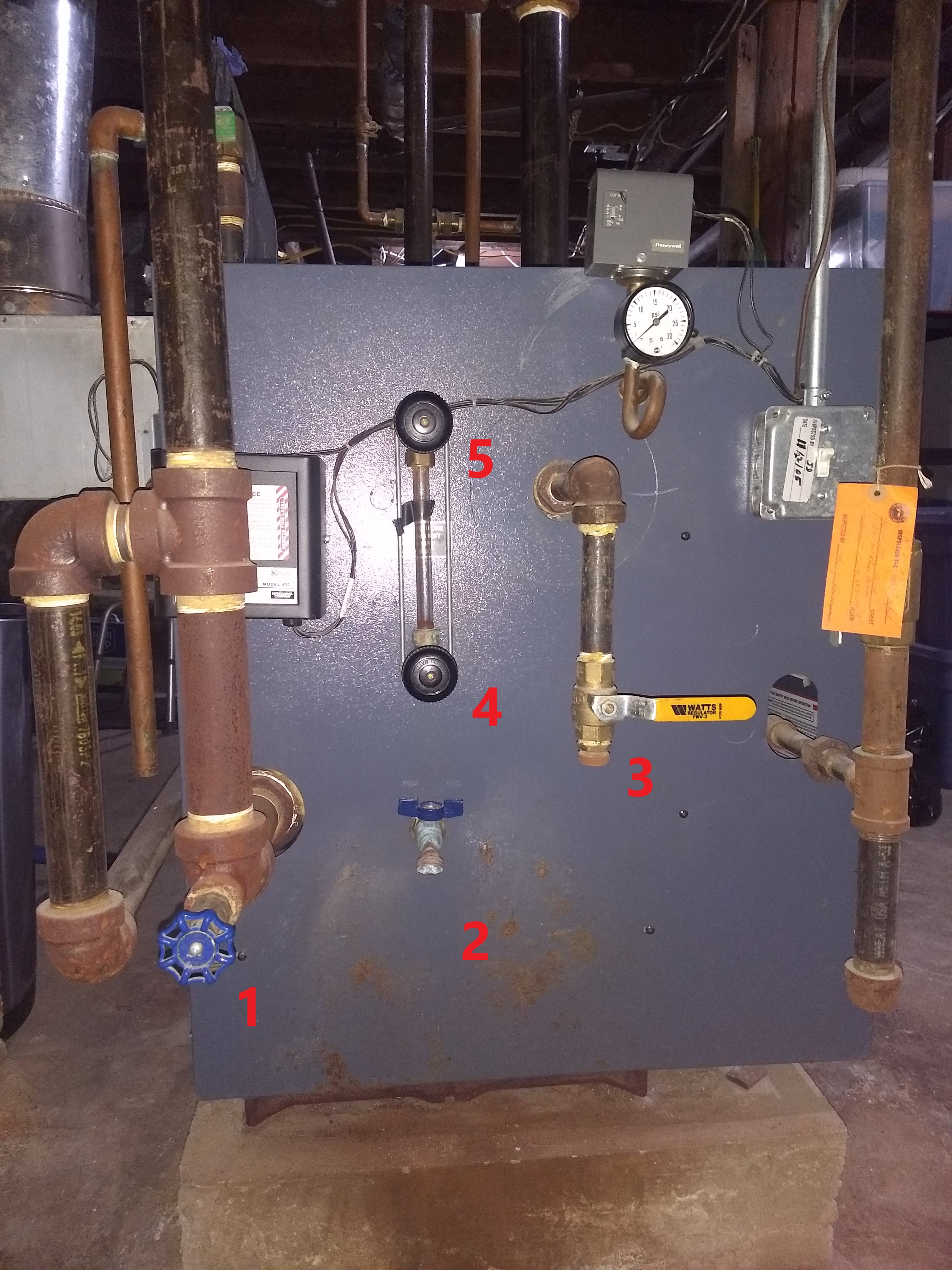

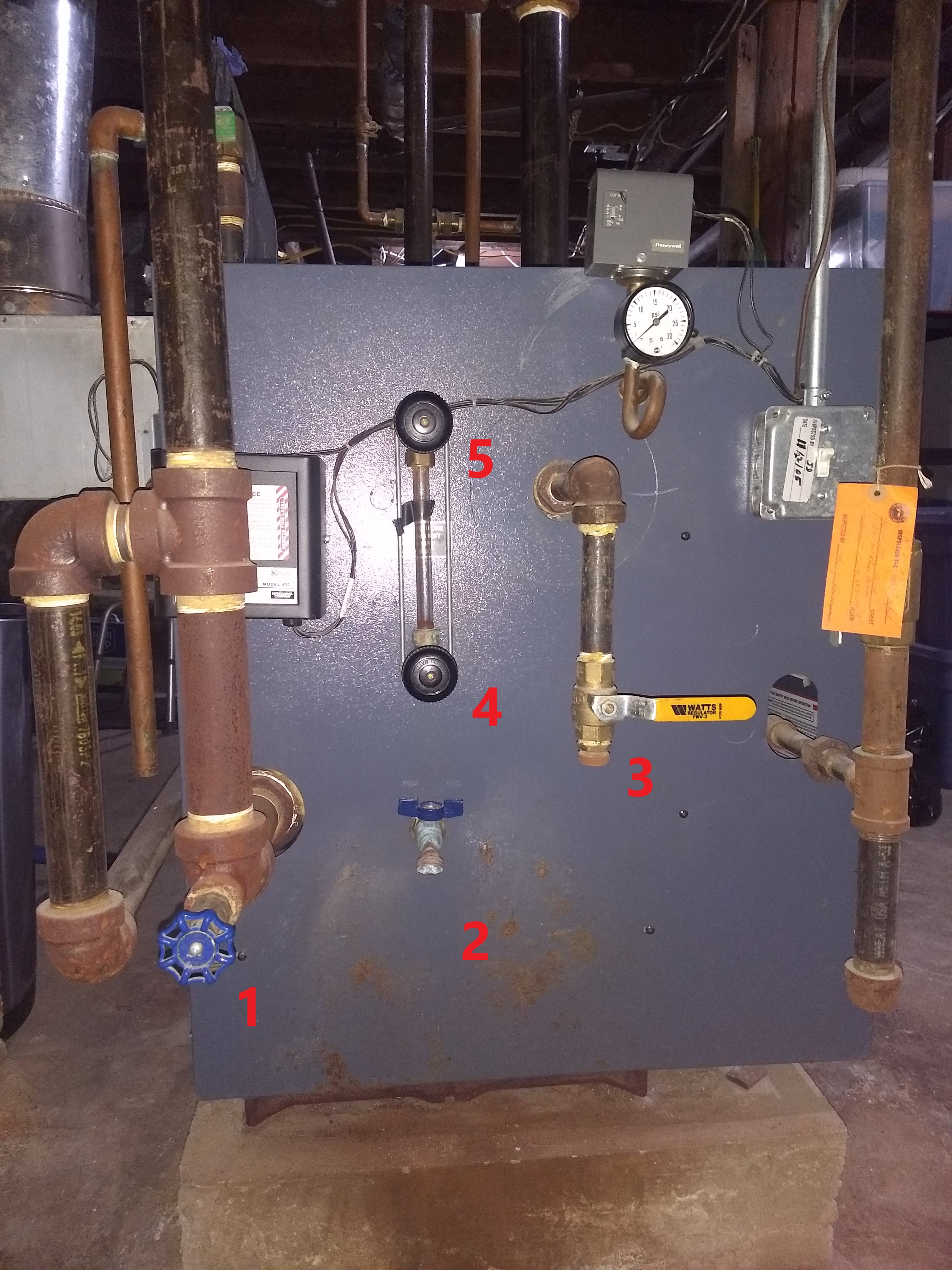

I have enclosed photos below with annotations.

My main concerns are:

1. What are all these valves for? (numbered in photos)

2. When I turn valve #1, a LOT of very dirty water comes out. Am I draining the boiler, or draining the pipes/radiators when I do this? If I drain enough, the low water alert light comes on, so I know that part works at least.

3. Valve #2 in first photo will not open, totally corroded. I'm not inclined to force it. What's this for? Will it need to be replaced? How urgently?

4. Valve #3 will open, but nothing comes out. What is supposed to?

5. Valve #4 (bottom of sight glass) is stuck. Knob won't turn. I don't know if it's open or closed. Valve #5 (top of sight glass) I can open, but when I do, tons of sediment pours into the sight glass. Should I keep it open or closed?

6. Sight glass is full of water even if low water light is on. I assume because the bottom valve is clogged? Possible for tech to clean or does it need replaced?

7. I have heat! But it's a bit noisy especially when starting up. Hissing, banging. Also it seems to turn on and off quite frequently. Normal?

The fill valve is manual and is in the last photo (6). I filled it up until the low water light when off and then some but I have no way of telling how much to do, since the sight glass is clogged, right? I just have to guess?

Any help for this steam newbie is much appreciated. Or if the advice is "find a professional ASAP" that's good too - I can keep calling around.

I suspect there has not been maintenance done for a few years.

I'm hoping in the meantime someone can explain what the parts are to me and tell me if I have any urgent problems?

The boiler in question is a Weil-McLain EG/PEG-35 series 4. I believe it was installed in 2005.

I have enclosed photos below with annotations.

My main concerns are:

1. What are all these valves for? (numbered in photos)

2. When I turn valve #1, a LOT of very dirty water comes out. Am I draining the boiler, or draining the pipes/radiators when I do this? If I drain enough, the low water alert light comes on, so I know that part works at least.

3. Valve #2 in first photo will not open, totally corroded. I'm not inclined to force it. What's this for? Will it need to be replaced? How urgently?

4. Valve #3 will open, but nothing comes out. What is supposed to?

5. Valve #4 (bottom of sight glass) is stuck. Knob won't turn. I don't know if it's open or closed. Valve #5 (top of sight glass) I can open, but when I do, tons of sediment pours into the sight glass. Should I keep it open or closed?

6. Sight glass is full of water even if low water light is on. I assume because the bottom valve is clogged? Possible for tech to clean or does it need replaced?

7. I have heat! But it's a bit noisy especially when starting up. Hissing, banging. Also it seems to turn on and off quite frequently. Normal?

The fill valve is manual and is in the last photo (6). I filled it up until the low water light when off and then some but I have no way of telling how much to do, since the sight glass is clogged, right? I just have to guess?

Any help for this steam newbie is much appreciated. Or if the advice is "find a professional ASAP" that's good too - I can keep calling around.

0

Comments

-

Well, let's see here.

Valve 1 -- the main boiler drain. Not surprising if you get dirty water out -- it's the nature of the beast. You might want to drain and flush the boiler using it -- but wait until summer time!

Valve 2 -- another little drain. Don't worry about it.

Valve3 -- Nice of somebody. That valve can be used for "skimming" the boiler. Look up skimming -- it's a way to get oils out of the boiler if need be. If nobody's played with your system for a while, you can leave it be for the time being.

Valves 4 and 5 -- those allow the water in the sight glass to mimic the water level in the boiler. The fact that they don't operate properly means that you, the operator, have no good way of knowing how much water is in the boiler. This is not good. They should be open at all times! This is not something I would suggest for your first project on boiler maintenance -- but I would get the tech. to fix the problem as a matter of real priority when he or she does come.

Valve 6, as you found, allows you to add water to the boiler if it needs it. Without the sight glass, controlled by valves 4 and 5 as noted above, you really don't know how much is in there, and are depending on the low water cutoff to actually work. As I said... get that sight glass cleaned out and back in operation as a first priority.

As a second priority, since the sight glass is clogged, I'm going to bet the "pigtail" -- that curly pipe that holds the pressure gauge and the pressuretrol (the blue grey box above the pressure gauge) may also be clogged. Have your person clean that out too.

The pressuretrol is hard to see clearly, but I suspect that it is set too high -- what does the indicator on the sliding scale point to? It looks like about 2. It should be about 0.7... there is a screw on top you can use to move it, and if it is where I think it is, that may be where some of the hissing is coming from.

The banging almost certainly comes from water not being able to drain properly from the pipes.

The turning on and off frequently could have many causes...

But.

First things first: that clogged sight glass is a real safety hazard, and you should get a good steam person in to work on it as soon as you can. Where are you located? Let us know, and we may know someone in your area -- or you could try the "Find a Contractor" tab or highlight. Or both...Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Where are you located that you can't get anyone over there for 4 weeks?Contact John "JohnNY" Cataneo, NYC Master Plumber, Lic 1784

Consulting & Troubleshooting

Heating in NYC or NJ.

Classes0 -

Where are you located? The best are right on this sight.

I see no immediate serious issues, but you do need the valves fixed, the boiler skimmed, returns flushed in the very near future.

Then the steam pro can walk around, check pitch of pipes, vents and traps, and evaluate your entire system, explain all the components and recommend what else needs to be done to have your system performing quietly & efficiently.

In the meantime, it would be a great idea to head over to the store and get one (or more) of Dan's books on steam heat.There was an error rendering this rich post.

0 -

You could use #3 (the skimming valve) to locate the water level. With the boiler off, open it and see if water comes out. If not, the water level is below where it taps into the block. If it's low, slowly add water with it (valve 3) open until water trickles out. Then shut both of them.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

More pics from farther back showing the boiler and it's near piping would be helpful.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

This all is helpful. I like the idea of using #3 to figure out where the water level is. Sounds like I probably need more!

I'm located in the Boston area. Most places seem to not be taking new customers this time of year if you have heat, which I do. Any suggestion for someone specific to try?0 -

-

Is it safe to run the boiler in the meantime? Or do I need to pull out all the stops to try to get this addressed asap?0

-

As long as you maintain a safe water level and the LWCO functions, you should be okay.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Update: 15 phone calls later, I got someone to look at it for me. The sight glass works now. Unfortunately, it seems the lwco actually does NOT work... The light goes on but the boiler does not actually shut down. They replaced it but no dice.

So. Now I need an electrician. Anyone have experience with this problem?

They also recommended I add an auto feeder. Worth it for a 2005 boiler or will I be needing to replace this anyways?0 -

This is not good. The LWCO is an essential safety control; you can't be expected to sit there and watch your water level all the time! And you shouldn't, you really truly shouldn't, run the boiler without it...

It is remotely possible -- considering the state of the sight tube -- that some rocket scientist bypassed the LWCO. Or there may be a time delay on it. Whatever, you need Ryan... @New England SteamWorks .Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I contacted Ryan yesterday. Hope I hear back soon...0

-

When they replaced the LWCO, did they also replace the probe that goes into the boiler or just used the one that was there? Replacing it would have required them to drain the boiler. If they didn't, it is most likely a bad or very dirty probe.

Yes, you can add an auto feeder. It is reusable with the next boiler, just be sure to get one with a water meter on it so that you can monitor the amount of water going into the boiler, on a regular basis. Too much fresh water is the enemy.0 -

I am in Brookline, call New England Steam Works. Ryan is a dead man of steam reincarnated. He is the only one I have found in the area that actually understands how steam works on new systems. He will be ale to address your issues.0

-

Supposedly they replaced the probe first, then the whole thing. But I wasn't there. Plan to call to clarify in the morning.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements