Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Nitrogen Purge- three zones with only one service port?

Options

NY_Rob

Member Posts: 1,370

Got my new LG 36K BTU minisplit mounted on the stand over the weekend.

Next step is to mount the lineset cover bases then mount the three indoor units and connect the linesets.

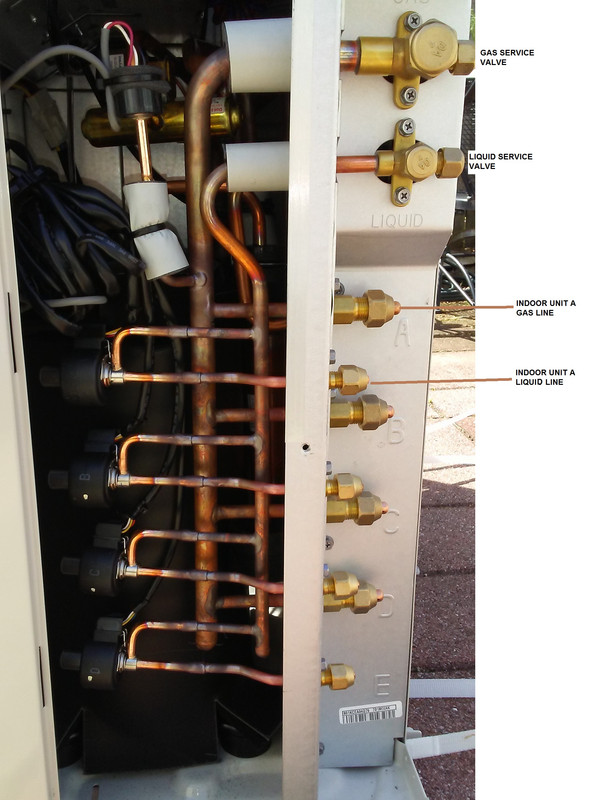

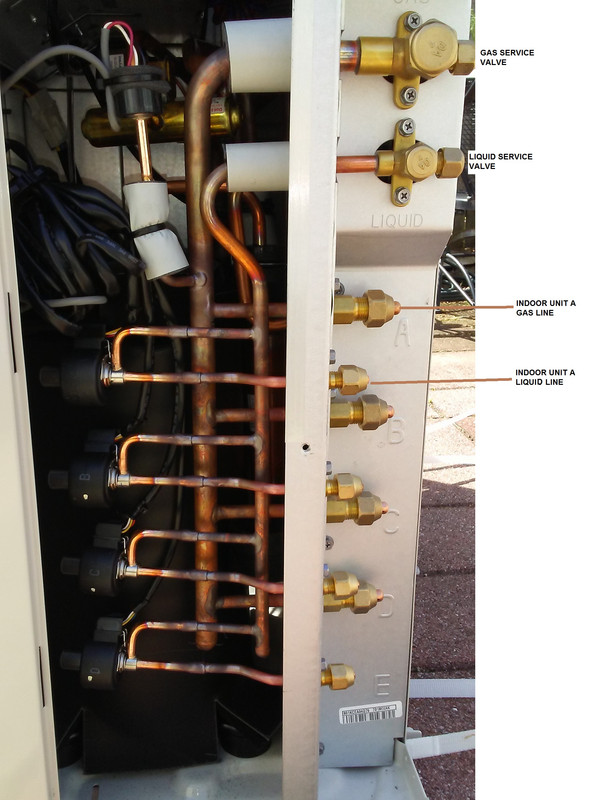

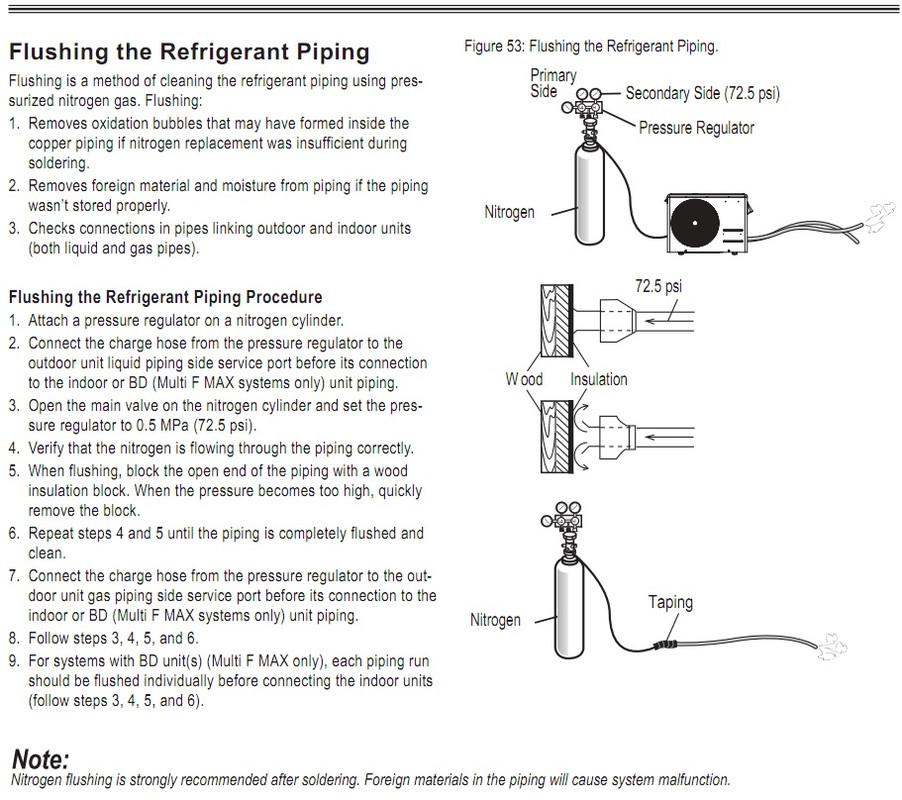

When going over the Nitrogen purge procedure it seems I will have to connect the nitrogen regulator to the Gas service valve then crack the individual liquid connections at the outdoor unit for each zone to purge the air out of the lines with nitrogen.

Looking at the photo of the interior piping it seems that the electric solenoids close off each individual liquid port to the liquid manifold so with the zones pressurized with 75PSI nitrogen- pressing the schrader valve in the liquid port will not let the pressure escape. It looks like I have to crack each liquid connection (for the three zones) at the outdoor unit.

Does this make sense since each zone doesn't have it's own service port?

Next step is to mount the lineset cover bases then mount the three indoor units and connect the linesets.

When going over the Nitrogen purge procedure it seems I will have to connect the nitrogen regulator to the Gas service valve then crack the individual liquid connections at the outdoor unit for each zone to purge the air out of the lines with nitrogen.

Looking at the photo of the interior piping it seems that the electric solenoids close off each individual liquid port to the liquid manifold so with the zones pressurized with 75PSI nitrogen- pressing the schrader valve in the liquid port will not let the pressure escape. It looks like I have to crack each liquid connection (for the three zones) at the outdoor unit.

Does this make sense since each zone doesn't have it's own service port?

0

Comments

-

The indoor unit valves should be open until they are powered. I'm just guessing that the indoor unit connections are flared so you should be able to gently sweep one line or line set at a time. You just need to flow enough to keep the atmosphere from entering the tube , you can use male flare adaptors or service stubs and tape for that matter to introduce the nitrogen for braze purge.hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

0 -

-

If I misunderstood and you are referring to pressure testing I would finish all of the piping and pump it up. Or like mentioned above you could pull a vacuum before introducing the nitrogen.hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

-1 -

-

Thanks guys....

No brazing going on... will be cutting linesets to length, making flare and connecting to outdoor and indoor units.

The LG install manual recommend nitro flushing linesets to remove any foreign objects and moisture prior to 3-step 550psi/nitro pressure test and triple evac w/nitrogen.

I was assuming the electric valves on the liquid lines on the outdoor unit were normally closed when unpowered. If they are actually normally open, then that makes everything easier.

So what I'm getting from this is the nitro lineset purge isn't really necessary before pressure test and triple evac?

0 -

They are saying to blow through from outdoor unit to each indoor before they are connected. If the tubing was kept free from debris when installing I wouldn't think this would be necessary , but if there is any doubt now would be the time to get it out.hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

-1 -

mini splits are one system with multiple zones, they work independently but are in fact a single system, so yes you can vac the system down from any of the service ports, just make sure you leak lock the flares, as they are pron to leak, and pull a good vacuum below 500 and you should be fine"The bitter taste of a poor install lasts far longer than the JOY of the lowest price"0

-

Thanks guys!

I have to rent the nitrogen tank and it's the same $$ if I return it 3/4 full or empty... so I might as well blow out/purge the three linesets prior to final connect to the indoor units.0 -

Here's the outdoor unit (36K BTU) on the 18" stand- did this on Sat.

0 -

On an unrelated topic....

The outdoor unit is pre-charged for up to 98ft of lineset.

My three zones add up to roughly 113ft. I'll need to have my HVAC buddy come over and add refrigerant once the install is done and I accurately measure the linesets.

Is there problem starting/testing the system (for a short period) with the factory pre-charge with my 113ft total length?

Thanks... Rob0 -

You are going to want to pressure test to somewhere around 500 psi ( refer to the manual ). Soap all the flares and let it stand at that pressure for a day. You may find that you need to release the nitrogen test pressure to correct an imperfect flare ( meaning you may need all of the nitrogen you can get your hands on ).hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

0 -

Thanks @hvacfreak2

Here's my notes that I have collected on the pressure test and triple evac procedure....

*********************************************************

Make sure to use fresh oil, once the vacuum pump oil becomes milky it has absorbed too much moisture.

The moisture is absorbed into the oil so use fresh oil!!!

*********************************************************

Leak Testing in 3 easy steps:

Step 1- 45 PSI (N2) - Test for a minimum of 3 minutes

Step 2- 220 PSI (N2) - Test for a minimum of 3 minutes

Step 3- 550 PSI (N2) - Test for 24 hours (if using R410A)

*********************************************************

*********************************************************

Triple evacuation in 6 steps:

Step 1- Evacuate the system to 1000 microns from service valves.

Step 2- Break the vacuum with N2 to 14 PSIG

Step 3- Evacuate to 500 microns

Step 4- Break the vacuum with N2 to 14 PSIG

Step 5- Evacuate to the lowest pressure that the pump will achieve (200 microns for a minimum of 1 hour)

Step 6- The rise test (Stay Under 500microns for 30 min) must then be carried out for a minimum of 30 minutes.

*********************************************************0 -

15' of pipe will be close to negligible difference. I am sure your being careful running and terminating the lines as far as contamination and debris. The factory is overcautious considering all the hacks in this business, they have to cover their a--. I wouldn't worry about the purge0

-

Thanks Ed!

Wanted to be sure I wouldn't damage anything if I was 15' over and wanted to test run the system.

I may be closer the the 98' figure once trimming is done, the 113' is kind of a rough measurement.

I may have to have the HVAC tech over soon anyway after relocating one of the indoor units of the existing Panasonic minisplit. Would be a goo opportunity to add refrigerant to the new system if it turns out it needs a few ounces.

Thanks again for the advice!

Rob0 -

Too bad this system only has just a set of master service valves/ports vs. my 2013 Panasonic minisplit that has valves/ports for each individual zone.

With the Panasonic I was able to use the system as I completed each of the four zones over different days. With this system I have to completely finish all three zones before using the system.

I guess that's how the manufacturer keep costs down... cut out the expensive parts like individual zone valves, etc...

The new 36K BTU outdoor unit (with heat and cool) only cost $120 more than the 2013 Panasonic 24K BTU outdoor unit (cool only) did.

1 -

> @newagedawn said:

> just make sure you leak lock the flares, as they are pron to leak, and pull a good vacuum below 500 and you should be fine

You should never put pipe compound on a flare fitting.

If it needs dope, there's a bad flare.1 -

I agree with @HVACNUT , no leak lock, no dope. a drop of refrigeration oil if anything. I don't know, I just never have problems with flares but I guess some people do. I just have trouble with everything else LOL0

-

-

That's what I use too. Actually, I just picked up the new flavor the last time I got a bottle, before I used the refrigerant-oil specific ones. Technically, IDK how well this one works; but the other ones worked just fine so I expect no issues with this one either.NY_Rob said:This is what I picked up for the threads....

0 -

In addition to the threads, some ppl suggest lightly coating the face of the flare with Nylog?0

-

Thanks @SuperTech!

I had no issues installing my 4-head Panasonic minisplit 5yrs ago, but as a last step I had a HVAC tech come over and evac the lines for me. FWIW- he didn't nitro purge or triple evac, he did a single drawdown over a half hour or so... and the system has been perfect for 5yrs so far.

This time I'm going to try to do it all myself so I want to go full-in and do it all "by the book" whenever possible.

Thankfully everyone here is super generous with help, so that gives me the confidence to tackle a job like this.-1 -

The project is progressing.. admittedly at a slower than expected pace due to the fact that it has rained for both days of the past three weekends in a row making outdoor work slow going.

I have all three indoor units now mounted.

Two of them (the 18K BTU and 7K BTU) are complete with linesets flared and connected to the outdoor unit. The electrical 240v work is done/inspected for the outdoor unit and the tray cables for two of the indoor units are connected. The lineset covers for two of the indoor units are installed/completed.

Rented the nitrogen tank yesterday... 60cu/ft tank for $19.

Plan to complete the lineset, electric and lineset covers for the 3rd (and final) indoor unit Sat (rain forecast for after 5pm Sat), rain forecast for Sun and Mon too, but I'll at least try to get in the 500psi nitrogen testing.... will make bubble testing easy at least

The poor weather has been killing me! If I could get in a full day or even two without rain... I'd be done already.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements