Should I direct pump this boiler...radiant floor with one zone.

Comments

-

Mark, the fact that it is one zone with a very load head was the exact reason I was second guessing the P/S setup.

It is a farm shop that we repair equipment in as well as store machinery that must run when it's cold outside. I don't leave the house without long underwear Dec-March so a 60 degree temp and uneven floor temps don't really bother me. It is very comfortable to work in with a sweatshirt. If we were to start from scratch, yes I would put more pipe in, but I was in diaper's when the concrete trucks were there.

There are 9 of each, just a little hard to see.

It is not a bypass, but rather the top and bottom supply ports are connected as well as the top and bottom return ports. the point I was making was in reference to why I came out the top and back in the bottom. It was simply a matter of using less pipe to connect it and space concerns.

I second the gauges are cheap. I was more interested in the thermometer's on them then the pressure side.

I have a condensate pump ordered with a higher cut out because I have to pump it across the ceiling of the building to the drain on the other side of the building. It is currently draining into a 30 gallon drum that I have been emptying daily. It is producing 7-8 gallons a day. I smile when I see that water and when it was 35 degree's outside you couldn't see the exhaust coming out of the vent pipe.0 -

@Mark Eatherton

That was a general statement regarding direct pumping. Again.....With everything being proper, it will always be the most efficient way.

I stand corrected regarding the tube spacing. It was based on the OP's complaint of not enough heat.0 -

nickh1 said:

No it is not cycling. The ignition counter counts 10x and it still reads 0. The unit has been running for 3 days. It is currently modulating at 52%.

There is a backup modine heater in the building, so it wasn't completely cold in here, but the floor definitely wasn't warm.nickh1 said:Mark, the fact that it is one zone with a very load head was the exact reason I was second guessing the P/S setup.

It is a farm shop that we repair equipment in as well as store machinery that must run when it's cold outside. I don't leave the house without long underwear Dec-March so a 60 degree temp and uneven floor temps don't really bother me. It is very comfortable to work in with a sweatshirt. If we were to start from scratch, yes I would put more pipe in, but I was in diaper's when the concrete trucks were there.

There are 9 of each, just a little hard to see.

It is not a bypass, but rather the top and bottom supply ports are connected as well as the top and bottom return ports. the point I was making was in reference to why I came out the top and back in the bottom. It was simply a matter of using less pipe to connect it and space concerns.

I second the gauges are cheap. I was more interested in the thermometer's on them then the pressure side.

I have a condensate pump ordered with a higher cut out because I have to pump it across the ceiling of the building to the drain on the other side of the building. It is currently draining into a 30 gallon drum that I have been emptying daily. It is producing 7-8 gallons a day. I smile when I see that water and when it was 35 degree's outside you couldn't see the exhaust coming out of the vent pipe.

Sounds to me it's purring like a kitten.

I still see 10, and 9 as Mark pointed out.

1 -

This post has been an interesting exploration into the nuances of hydronic design. There have been some good points made all the way around.

I am curious how many of the folks commenting would actually bother to change this system if it was installed in a shop they own? I for one would not. I don't see a significant savings and am reluctant to go around fixing things that are not broken."If you can't explain it simply, you don't understand it well enough"

Albert Einstein2 -

-

-

One last thing though. Htp recommends pumping into the boiler on P/S piped setup. With the PONPC on the system side.

They also show direct piped setup pumping out of the boiler.

So I find it hard to believe that this schematic was just left behind from the more restrictive hxers. There is a reason. Thoughts?0 -

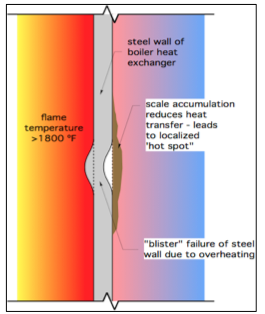

I think that is a big reason the "pumping into" became the requirement on the first, small tube type HXers. You have a very high temperature from the burner flame, very close to the wall of the tube, and a very thin walled HX. The additional ∆P provided by pumping into the boiler buys you more "wiggle" room, to prevent flashing.Hatterasguy said:

You pickup about 15F margin on the boiling point (presuming a DP of 4 psi across the circ).Gordy said:

So I find it hard to believe that this schematic was just left behind from the more restrictive hxers. There is a reason. Thoughts?

Not meaningful IMHO, but you never quite know what goes on inside the HX in localized areas.

This shows the relationship and how small deposits on the HX from minerals cause the pin holing of HX.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

With the highly restrictive heat exchangers, I always heard they wanted you to pump towards, to avoid pump cavitation.0

-

Time will tell.Hatterasguy said:You would think the traditional approach with relatively high flow rates will protect the boiler without issue.

However, the newest group of 1 GPM mod-cons really give you some pause when you look at those sketches. If a 5 GPM mod-con needs additional margin.........what does it say about a 1 GPM mod-con?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Makes one wonder what the Reynolds numbers would be like in this scenario too...hot rod said:

Time will tell.Hatterasguy said:You would think the traditional approach with relatively high flow rates will protect the boiler without issue.

However, the newest group of 1 GPM mod-cons really give you some pause when you look at those sketches. If a 5 GPM mod-con needs additional margin.........what does it say about a 1 GPM mod-con?

As it pertains to absorbing concentrated radiant energy, that design of HXer doesn't have nearly the exposure that the Gianonni's do. There is a potential, but I think it's smaller than the alternative helical heat exchangers. Still makes one wonder...

ME0 -

The question still remains why on P/S ,and why not on direct piped? Would there not be more potential for a higher delta p in a direct piped scenerio verses P/S where in the latter the delta p would be minimal in the primary(boiler loop) due to shorter, and larger less restrictive piping.

Edit: to compare to the loch KHN 10:1 all drawings show pumping into the boiler direct piped, or p/s all though HX designs are different.0

Categories

- All Categories

- 87.4K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 168 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 56 Water Quality

- 52 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements