Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Change the pressure on this Burnham/Megasteam Beckett/Honeywell Burner combo? Someone did.

Options

Jack M

Member Posts: 239

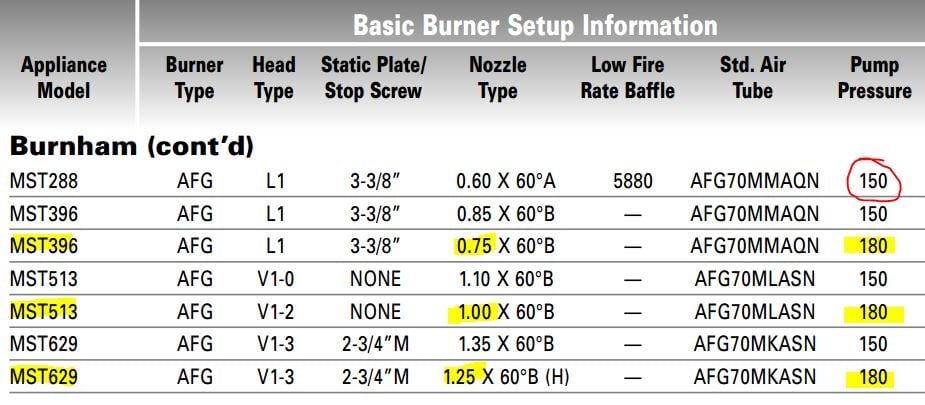

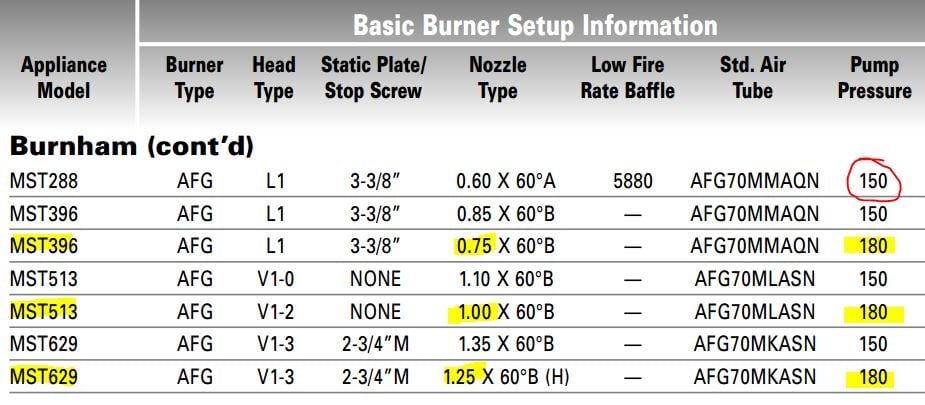

Why did Burnham change the oil pressure/nozzle spec for the Becket/Megasteam burners halfway through 2013? And should the pre-2013 installations follow suit?

Oil pressure was increased from 150 to 180 and the nozel gph decreased by 12%. The change was for all the boilers except the smallest (MST288) in the Megasteam lineup. Why did Burnham change the spec and would a pre-2013 boiler benefit by moving to the higher pressure? Nothing else on the boiler seems to have changed in 2103.

Oil pressure was increased from 150 to 180 and the nozel gph decreased by 12%. The change was for all the boilers except the smallest (MST288) in the Megasteam lineup. Why did Burnham change the spec and would a pre-2013 boiler benefit by moving to the higher pressure? Nothing else on the boiler seems to have changed in 2103.

0

Comments

-

They probably changed it as the result of firing in the laboratory. It's not uncommon. Higher pressure atomizes the fuel better and gives better combustion. Keep in mind the angle and hollow/solid (A or 'B') may have changed too.

There are charts to show higher pressure/lower nozzle gph adjustments.

You can change it. But you have to do 2 things.

-Mark on the burner that you changed the pump pressure (confirm with pressure gauge) & nozzle, so anyone else who works on the burner doesn't change back to the bigger nozzle with the higher pressure.

-Do a complete combustion analysis after you change the nozzle. Draft first, then a smoke test. Most likely the air band will need to be adjusted (via a smoke test).

If you combustion results are the same or better, you can leave it.

Also note the different head sizes for the higher pressures.There was an error rendering this rich post.

1 -

I would have hoped they worked out these issues in the laboratory before they released the boiler. Still, this does make sense. (Note: the angle/hollow/solid nozzle spec remained the same)0

-

Its not that. The megasteam has been out for quite some time. I'm just guessing, but they probably do continuous testing or did another round of testing and found this worked better. Or maybe they had to solve some problem and stumbled across this setup and found it worked a little better. It's not unusual.

Look at Riello, they put out a spec book, but many times you'll see a label on the burner with different specs-nozzle, head, air. They bench fired it and determined those settings work better on that combination.

Upping the pressure and lowering the gph to get the same firing rate is pretty common.

Is there a problem you encountered, or did you just notice this and was curious?You can give tech support a call at US Boiler (don't have the number).There was an error rendering this rich post.

0 -

I have been doing this for over 40 years. MAYBE the boiler/burner manufacturers test RESIDENTIAL boilers the way they should but I can assure you that testing on the commercial burners in many cases does not happen.

Just think of this:

A particular commercial cast iron boiler may be made from say 4-18 sections. To test that with (1) make of oil burner would require 14 test set ups.

Now test it with a gas burner

Now test it with a combination gas/oil burner

Now your complete with maybe (1) burner manufacturer.

what about Riello, Weishaupt, PowerFlame, Carlin, Webster etc.etc.etc.

The # of combinations is mind boggeling

Some test, some don't (let the guys in the field figure it out), some do minimal testing

When you have trouble and call the factory and ask questions and you get the "deer in the headlights" answer then you will know they didn't test.

I always set things up according to the mfg. specs, you have to start somewhere. Then the fun begins.0 -

Actually I just looked up my MPO, there are before/after settings for March 2013, bumping up the fuel pressure to 180, and dropping the nozzle a little, and switching it to a W. Now I'm curious too. I'll give them a call and post back tomorrow.

There was an error rendering this rich post.

0 -

Yes. I was interested in the difference between the MST288 and the MST386 (they share identical boilers). The smaller MST288 uses a low fire baffle in the beckett burner and I was curious to know why the pressure (150 psi) in the MST288 was not increased to 180 (in 2013) as it was in the MST386. And why the MST386 does not use the same low fire baffle when spec'd with a .75 nozzle (vs .65 in the 288). Must be a lot of work to reach 86 AFLUE.STEVEusaPA said:did you just notice this and was curious?

The rationale "it runs better that way" certainly make sense but may not be a complete answer. I was looking for that.

0 -

This is why I've moved to Riello again and again. Simply the best burner. 3 basic models, 2 different air tube lengths, super easy to work on and troubleshoot (unless you have to replace the burner motor)

Talked to both Burnham, who said call Beckett, and Beckett. Beckett basically said another round of testing with the higher pump pressure, lower nozzle. If the old spec works for you leave it, if you're having issues with light off, flame stabilization, smoke, etc, try the newer spec.There was an error rendering this rich post.

0 -

Thanks for clearing that up. Goes back to "EBEBRATT-Ed" comment and where the fun begins .

Wish they would spec Riello for the MST-288.0 -

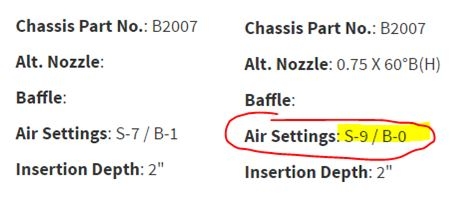

Note: as the pressure and nozzle changed so did the

Beckett recommended air setting:

0 -

If you want a Riello, call their tech support. You may be surprised to find that they have a recommendation.

I found this out at a Riello class when I asked them why a certain boiler on just one size didn't have a spec'd Riello.

They want their burner in every piece of equipment, so they will test it.

It turns out in this specific case, the manufacturer wanted an F5 spec'd for all 3 of their firing rates. Riello could only get the F5 on their 2 higher fired boilers, but the F3 worked perfectly on the lowest fired appliance. The manufacturer only wanted one size Riello, so they didn't offer it. But I bet that Riello has tested it on your megasteam. Give them a call

BTW, I hate that 9/0 setting. It only gives you one number to go up, then you have to bump the band to 1, lower the shutter and start over with your smoke tests.

Another side note, I did ask Beckett why the shutter and the air band? I couldn't get an answer that I liked, but to me it's like a 10 or 15 speed bike, where different combinations kind of lead to the same result-thru trial and terror.There was an error rendering this rich post.

0 -

great analogy.STEVEusaPA said:it's like a 10 or 15 speed bike, where different combinations kind of lead to the same result-thru trial and terror.

What's the best number to reach Riello. I never get an email response from their online contact email.

0 -

1 800-474-3556 is the only number I have.

There was an error rendering this rich post.

0 -

That # worked. The tech said Riello has no specs for a Riello on the Burnham Megasteam. Meaning that they have never tested one. Burnham may have tested a Riello however none of that information was shared.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements