Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Microbubble Air Eliminator

Options

Alan (California Radiant) Forbes

Member Posts: 4,699

in Gas Heating

Does anyone make an air eliminator with a union connection like they do for fill valves or mixing valves. It sure would make servicing/replacement a lot easier, no?

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab

Two btu per sq ft for degree difference for a slab

0

Comments

-

The Caleffi hydro seps with microbubble and dirt separator have unions on them, can't think of any others off the top of my head.

Totally agree though, would love unions on them....0 -

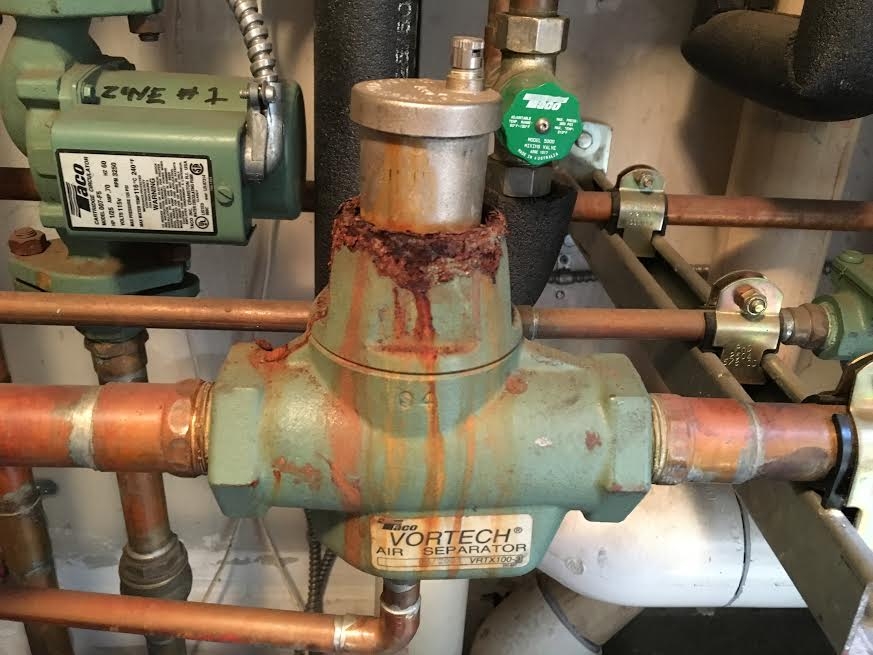

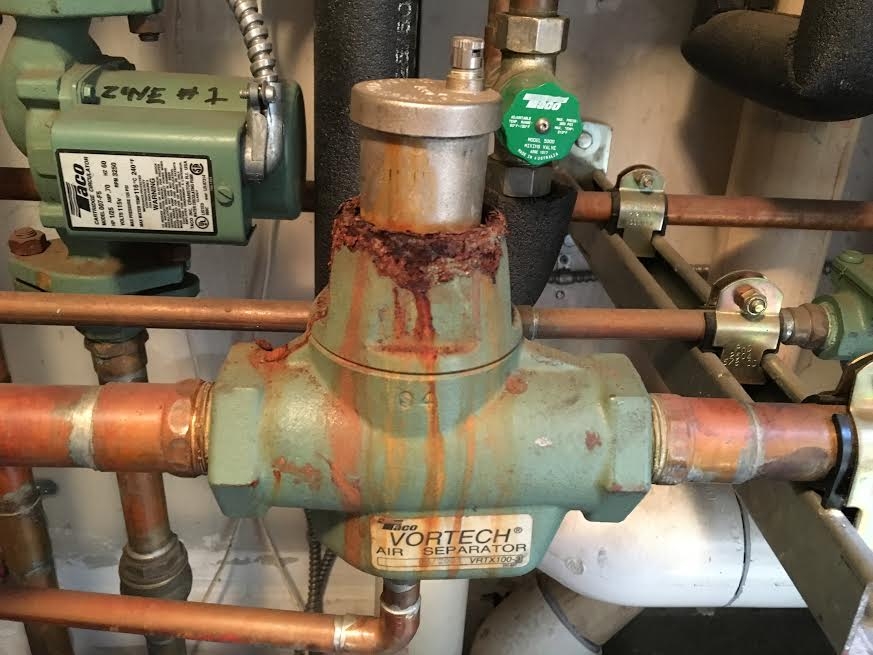

Replacing this leaking Vortex would be a snap with a union connection.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

quick and simple would b a press version, 1 or 1-1/4". Or a threaded version could be assembled with any union tailpiece, sweat, MIP, or press.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The Caleffi, SpiroVent, and SuperVent can all be disassembled in place and the guts replaced.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Ugh. I hate those ones where you don't have room to do anything. One thing I was always taught was that when you install something, think about how you would replace it. Is there enough room to cut the pipe and solder a coupling? no? well you might be kicking yourself in ten years when you have to replace the thing!!Replacing this leaking Vortex would be a snap with a union connection.

Hope it went well.... 2

2 -

-

Check out Viega copper press x MIP unions.

79740 1" P x 1" MIP

79745 1 1/4" P x 1 1/4" MIP

79750 1 1/2" P x 1 1/2" MIP

79755 2" P x 2" MIP0 -

-

Don't, don't, don't try to pull the entire vent out, you'll crush it along with using some very foul language at the same time. That vent is Loc-Tited in.

If its leaking from the top, simply replace the float mechanism and cap from a standard 400 style vent assembly, then discard the leftover body.

Dave HDave Holdorf

Technical Training Manager - East

Taco, Inc

1 -

Agreed Dave0

-

-

®

SPIROVENT VJR,VJS and VJV

Junior Series Air Eliminator

Had one of these pieces of garbage blow off uncontrollably while purging new zone on 10 year old system. Yes, it is installed as per man specs and there is no glycol in system and boiler pressure is normal... Got it to stop by lighting tapping on it and the before our eyes, about 5 min later it blew off uncontrollably again.... Good thing we stayed to watch boiler reach temp and check circulation of new zone, otherwise it would have flooded the basement. I had to cap it off with a 1/2" cap....... it just wouldn't stop. BEWARE IF YOU DONT WANT A LIABILITY INSURANCE INCREASE!!0 -

There was room enough for a union on the left side and we unbolted the pump flange on the right side and replaced it with a Caleffi (sweat connection) air eliminator.

Yes, I've tried removing that vent as well. The Loc-Tite would not yield and I ended up destroying the vent.8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements