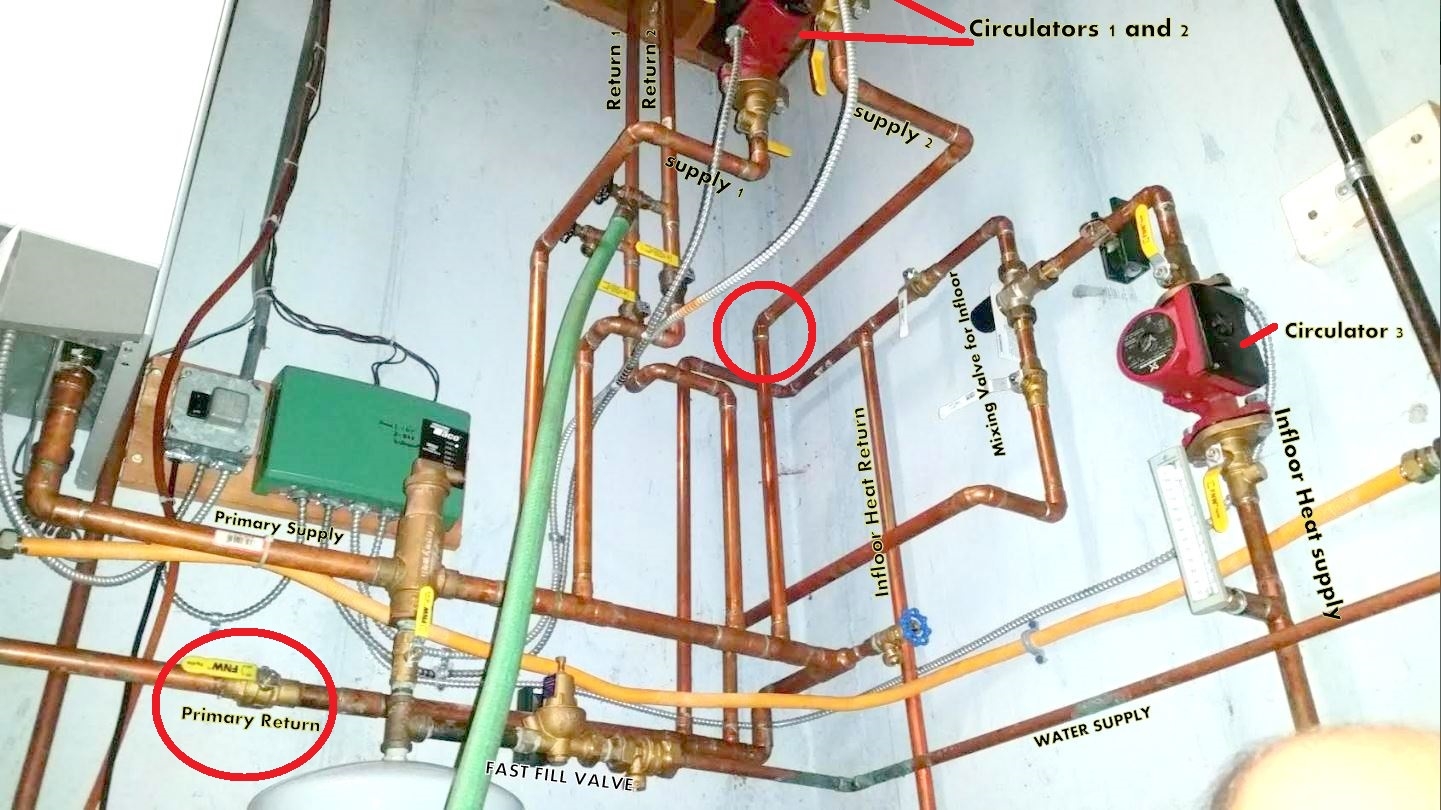

No Heat in 1 of 3 Zones. Air locked?

Also, I want to purge it right now but the Triangle Tube is still at 130 degrees. I hear it's bad to introduce cold water into a hot system so my next question is if I shut off that ball valve, circled in the bottom left, if that's enough to isolate the boiler from the system or not?

Also, is there a chance my air problem is in my primary loop, and not my secondary loops? If so is there a way and is it appropriate to purge just the primary loop and if so how would I go about doing that?

Additional details.

1 story home with basement. 2 upstairs zones are baseboard, downstairs is infloor heat. System pressure about 15 PSI when running.

Thanks in advance for your help!!

Comments

-

how do you know circulator is running fine? try purging your loop again, regardless of temp....i doubt its an air problem in your primary loop....other zones heat fine.....how high is the zone that doesnt heat from the fill valve.....15 psi should be fine (about 35 ft from fill valve)....what is the static pressure without pumps running?....system looks piped correctly....ASM Mechanical Company

Located in Staten Island NY

Servicing all 5 boroughs of NYC.

347-692-4777

ASMMECHANICALCORP@GMAIL.COM

ASMHVACNYC.COM

https://heatinghelp.com/find-a-contractor/detail/asm-mechanical-company0 -

Same distance as the other zone that is heating fine as both are on the same floor. 1 is bedroom zones the other is living areas. I'm going purging it again right now. The pressure at cold is always above 12 psi. As for the circulator, I just put my ear up against it and it's running through it on both sides of the pipe. I don't know if there's something else I can do to test the ciculator is functional?Paul S said:how do you know circulator is running fine? try purging your loop again, regardless of temp....i doubt its an air problem in your primary loop....other zones heat fine.....how high is the zone that doesnt heat from the fill valve.....15 psi should be fine (about 35 ft from fill valve)....what is the static pressure without pumps running?....system looks piped correctly....

0 -

if you have a electrical meter, you can check the amp draw that sometimes helps....those pumps are funny ive seen them pull the rated amp draw when they were bad.....listening to the pump is definitely not accurate you could be hearing the boiler pump etc.....I would purge the zone really good ....turn on all the other zones if it still doesn't heat and the other zones do I would replace the pump......shut the bottom isolation flange on the pump, shut the return valve and open the return boiler drain in that zone....just knock the pressure down it should not be a lot of water...try not to let air get sucked in once the pressure is down....then shut the 2nd isolation flange on the pump and replace the pump with the gaskets.....but without an electrical meter this is just a guess....that Taco circulator control relay could be bad as wellASM Mechanical Company

Located in Staten Island NY

Servicing all 5 boroughs of NYC.

347-692-4777

ASMMECHANICALCORP@GMAIL.COM

ASMHVACNYC.COM

https://heatinghelp.com/find-a-contractor/detail/asm-mechanical-company0 -

The purge fixed it, was totally air locked. Still mad because in that zone I still get this "dribble" sound from the rads. No matter how hard I try I can't get a silent baseboard on that zone, but at least now it's heating properly. You can only purge so many times!0

-

Why are those valves closed in the photo?0

-

Now my dang condensate pump is running non-stop. Usually runs for a few seconds and shuts off, what could that be about?0

-

I can't visualize how that low temp zone works. I'm use to seeing it in diagrams from TMV manufacturers.0

-

Is it only accepting condensate? is the relief valve or backflow draining into it as well? Could just be the float is stuck. Most of those, the top just lifts off and you can get to the float and un stick it if that's the problem. If the relief valve is draining into it then you might have too much pressure, or you your relief valve may be shot. Hard to say exactly without seeing it.smithfan said:Now my dang condensate pump is running non-stop. Usually runs for a few seconds and shuts off, what could that be about?

1 -

Just replaced the whole thing, including the tubing. The pump literally had never been cleaned so it was probably a combination of mucked up impellers and clogged tubing. New ones working flawlesslydelta T said:

Is it only accepting condensate? is the relief valve or backflow draining into it as well? Could just be the float is stuck. Most of those, the top just lifts off and you can get to the float and un stick it if that's the problem. If the relief valve is draining into it then you might have too much pressure, or you your relief valve may be shot. Hard to say exactly without seeing it.smithfan said:Now my dang condensate pump is running non-stop. Usually runs for a few seconds and shuts off, what could that be about?

0

0 -

What is the pressure without any pumps running? You want 12-15 psi static to assure the system is filled.

I assume you have a pump on the primary loop pumping into the boiler? if so the gauge on the boiler will read the fill plus the delta P the circulator adds, since you are correctly pumping away from the expansion tank..

Sometimes adding a few psi on the fill will help remove the last small bubbles. Adjust the expansion tank pressure if you add pressure and leave it elevated.

Is the air purger at the boiler working? Sometimes getting all the air out of primary secondary piped systems takes a few days. A second air purger on the secondary loop sometimes is needed.

Any high point float vents on the system?Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

The supply and return for that secondary loop are reversed. Look a how they are on the other loop.

The way it is now, the secondary pump for that loop is "pumping towards" the primary which is the PONPC. This will cause the pressure differential that the circulator creates to be DEDUCTED from the static fill pressure. If it was reversed, and "pumping away" from the primary, the delta p of the circ would be ADDED to the static fill pressure.

In other words, reverse the piping coming out of those two tees.

If you have 20' of elevation that takes about 9 psi from your 12 psi static fill pressure. That leaves 3 psi at your highest point. The circulator can produce about 5 psi pressure differential (delta p). That 5 psi is DEDUCTED from the 3 psi that your have at the highest point leaving it in a vacuum, which in turn lowers the boiling point. If the circulator was "pumping away" like it should, the 5 psi would be ADDED to the 3 psi static = 8 psi.

Raising the static fill pressure to 18 psi may alleviate the issue, but then you run the risk of the system over-pressurizing when it reaches 180* because the expansion tank may not be able to accept the volume.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

I think supply to pump 2 is wrong, pump 1 and the mixed are correct? Hard to tell exactly from the camera angle. The mix valve has the hot port facing down, return ties in into an odd place but should work. Often the mixed return is into a tee at the cold port of the mixer.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks for the replies. Didn't see them until today. As of now the is system working. I think the mistake I made was purging it and then not running it. Definitely air locked on that second zone. So I purged the problem zone and its pushing water again fine. The system seems quieter now as well. I can still hear a bit of air in the baseboards, but it's not that bad. So I think it's working it's way out. On my way to reply to your other comments:)hot rod said:What is the pressure without any pumps running? You want 12-15 psi static to assure the system is filled.

I assume you have a pump on the primary loop pumping into the boiler? if so the gauge on the boiler will read the fill plus the delta P the circulator adds, since you are correctly pumping away from the expansion tank..

Sometimes adding a few psi on the fill will help remove the last small bubbles. Adjust the expansion tank pressure if you add pressure and leave it elevated.

Is the air purger at the boiler working? Sometimes getting all the air out of primary secondary piped systems takes a few days. A second air purger on the secondary loop sometimes is needed.

Any high point float vents on the system?0 -

It's not a great pic of the boiler piping. The piping itself was completely redone to meet the primary/secondary specifications as the original homeowners had it installed wrong. I've had a small amount of air in the system since the job was done.Ironman said:The supply and return for that secondary loop are reversed. Look a how they are on the other loop.

The way it is now, the secondary pump for that loop is "pumping towards" the primary which is the PONPC. This will cause the pressure differential that the circulator creates to be DEDUCTED from the static fill pressure. If it was reversed, and "pumping away" from the primary, the delta p of the circ would be ADDED to the static fill pressure.

In other words, reverse the piping coming out of those two tees.

If you have 20' of elevation that takes about 9 psi from your 12 psi static fill pressure. That leaves 3 psi at your highest point. The circulator can produce about 5 psi pressure differential (delta p). That 5 psi is DEDUCTED from the 3 psi that your have at the highest point leaving it in a vacuum, which in turn lowers the boiling point. If the circulator was "pumping away" like it should, the 5 psi would be ADDED to the 3 psi static = 8 psi.

Raising the static fill pressure to 18 psi may alleviate the issue, but then you run the risk of the system over-pressurizing when it reaches 180* because the expansion tank may not be able to accept the volume.

The piping is a little messy because they didn't want to have to re-do the pex on the ceiling just to get everything fitted on the wall, so there's a few more elbows than normal.

Just to clarify, as of now it's working and I'm at between 12-15 psi on the boiler. Are you basically saying my tees on the secondary loop are backwards? Or the supply side should be in front of the return tee on both loops?

0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 427 Carbon Monoxide Awareness

- 119 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 114 Geothermal

- 165 Indoor-Air Quality

- 3.7K Oil Heating

- 76 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.6K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements