soldering vs brazing of ac unit

Comments

-

As far as I know, all joints should be silver soldered while flowing dry nitrogen which some refer to as brazing.

You say the joints were soldered, do you mean soft soldered?

Are the joints silver in color? Silver colored joints suggest soft solder. Brazed / silver soldered joints will be copper colored.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Here's some pictures.

First, is a proper joint.

This picture shows soft solder used for plumbing.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

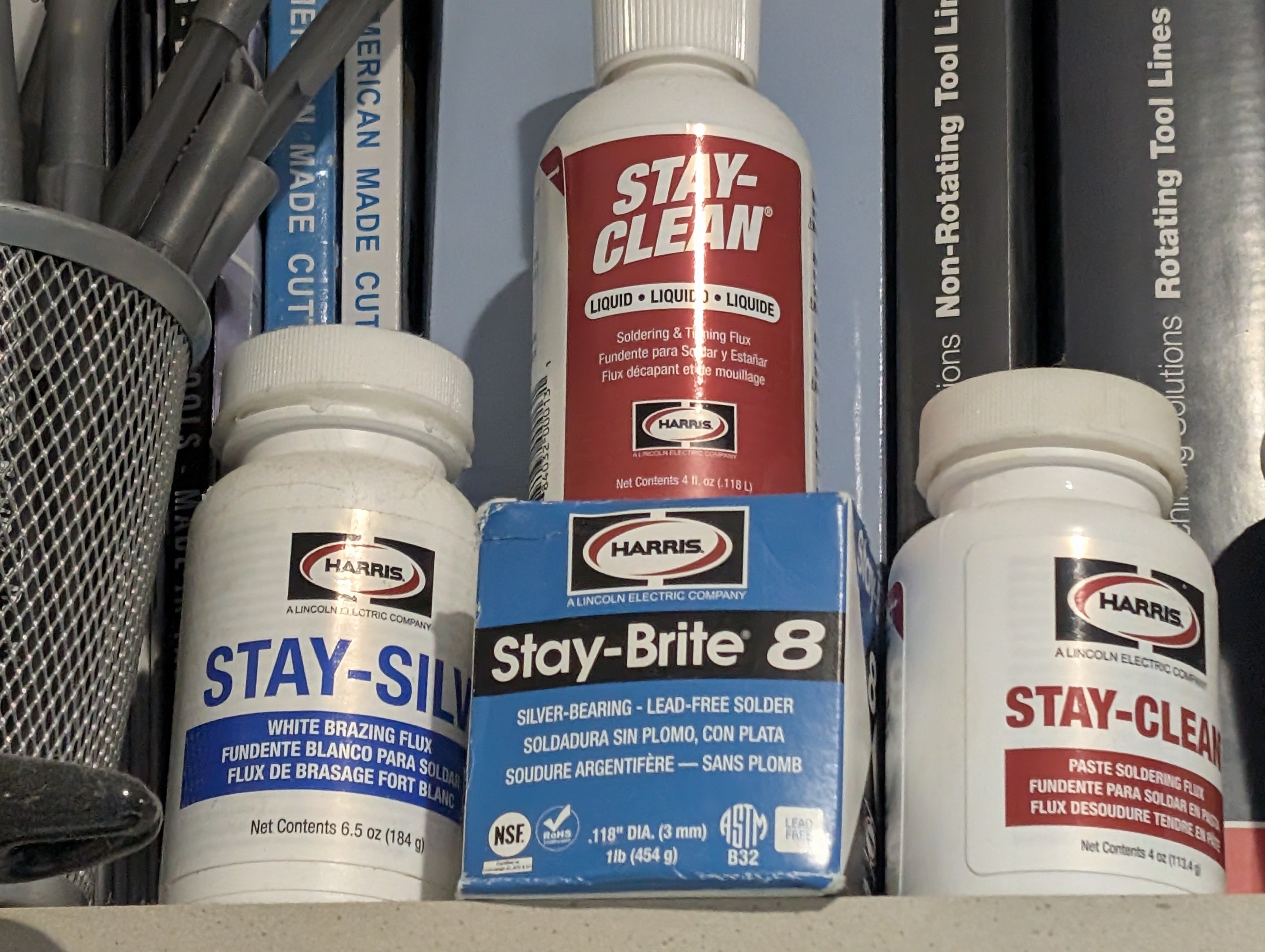

As ChrisJ said must be brazed with nitrogen flowed through to prevent flaking ....the pic below are brazed refrigeration connections...some guys use stabrite 8 which i believe is silver solder....i use 15% brazing rodsASM Mechanical Company

Located in Staten Island NY

Servicing all 5 boroughs of NYC.

347-692-4777

ASMMECHANICALCORP@GMAIL.COM

ASMHVACNYC.COM

https://heatinghelp.com/find-a-contractor/detail/asm-mechanical-company1 -

I thought I remembered something like Staybrite 8.Paul S said:As ChrisJ said must be brazed with nitrogen flowed through to prevent flaking ....the pic below are brazed refrigeration connections...some guys use stabrite 8 which i believe is silver solder....i use 15% brazing rods

I remember one of our monitor top guys using something like it.

So far, I'm a stay-silv 15 guy which I believe is a 15% silphos rod.

80% copper, 5% silver, 15% phosphor I think?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

80 cu

5 phosphorus

15 silverASM Mechanical Company

Located in Staten Island NY

Servicing all 5 boroughs of NYC.

347-692-4777

ASMMECHANICALCORP@GMAIL.COM

ASMHVACNYC.COM

https://heatinghelp.com/find-a-contractor/detail/asm-mechanical-company1 -

I was close.

Ok, not really.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Thanks. mine are silver in color indicating soft solder0

-

In the past Staybrite 8 and some other soft solders were allowed to be used to solder suction lines, liquid lines, driers, and txv,s. . Any thing on the discharge side of system, hot gas line , oil separators and service valves required sil-floss (stay silv 15 ) or a high rated silver solder, partly due to the excessive vibration on the discharge side, Staybrite 8 has a shear strength of 11,000 lbs. With the new refrigerants like 410a which operate at higher pressures, solder requirements have changed These all depend on the equip you are working on, type of refrig. and local plumbing/mechanical codes. You can also check with Harris solder Co. This is of course what I learned over the years, others may have different insights.

There was an error rendering this rich post.

0 -

The reason for brazing and nitrogen is to keep the inside of the AC system clean and free from acidic . Flux is an acid base and the nitrogen displaces the oxygen out of the system so it would not burn with the torch and leave carbon ... Which I understand turns acidic as well .. Rod you don't need flux and with the higher pressures 15% rod should be used .

There was an error rendering this rich post.

0 -

In general, most mfrg's say to Braze(Hard Solder) in R410A systems.Some places like NYC require the systems be brazed( I was told). If using a silphos 15 braze rod (SILver PHOSphous- w/ 15% Silver) the phos is a flux. .In ChrisJ photo all of that darker colored copper is where "oxidation" took place, the oxidation was all of that "powdery,flaky stuff" . You can blow lots of it away, or wipe it away. So ,where it is on the outside of the pipe it is also on the inside of the pipe, so a Nitrogen sweep is used to prevent that contamination from happening.

On service I Soft Solder( StayBrite#8 w/6% Silver) most all LL&SL stuff, and braze all Discharge Line and Cond unit coil stuff.0 -

Staybright 8 supposedly creates a stronger joint, but doesnt handle vibration very well. I braze all my refer joints.DL Mechanical LLC Heating, Cooling and Plumbing 732-266-5386

NJ Master HVACR Lic# 4630

Specializing in Steam Heating, Serving the residents of New Jersey

https://heatinghelp.com/find-a-contractor/detail/dl-mechanical-llc

https://m.facebook.com/DL-Mechanical-LLC-315309995326627/?ref=content_filter

I cannot force people to spend money, I can only suggest how to spend it wisely.......0 -

I was very close to using it, but the flux, and having to clean every connection is what stopped me.

Dang it @Kaos this thread's a bit old………and stale.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

Wow, @pecmsg , I thought I was the only "weirdo" who does SB8 on most ref joints! I am not quite at 40 yrs yet tho! The beauty is you do not have to flow nitrogen and less heat around components. And yes, I do compressors with it too. A Harris rep once said, "If I could only carry one Solder/flux product on a work van it would be SB 8". I do not recall ever having a joint break due to vibration/movement except for one outdoor unit that got slammed with something, and in that case the Brazed joint/fittings may have failed also. SB-8 gives a stronger overall joint because the copper is not softened with high heat.

0 -

I use Stay Brite 8 on my linesets as well. I was taught the same thing as @pecmsg, flux the pole not the hole. I never had any problems with Stay Brite, it's a great product. Quick, easy and much less chance of burning anything.

I wouldn't use it on a replacement compressor. I have seen a leak develop on the connection to the discharge line once. I believe the condenser fan motor failed and the compressor continued to try to run, the heat of the discharge line and vibration caused the solder joint to fail.

0 -

Do you guys do the same when fluxing water pipe for soft soldering?

I personally have absolutely no doubt SB8 8s plenty strong.

The flux was my main concern.The next would be cleaning all of the joints and dust getting into things.

Sitting above my desk as we speak

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I treat it like soft solder.

If you flux the hole when you insert the pole it pushes the flux into the pipe itself and away from the joint. By fluxing the pole only all the excess is on the outside of the pipe, easily wiped off if needed.

and yes, I've used Nokorode flux in emergencies.

0 -

liquid vs paste thoughts?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Paste

Liquid is too messy

0 -

I used to only flux the pipe but I went to fluxing pipe and fitting but with less flux overall than when I only did the pipe. Especially with ACR piping, I basically just wet the pipe & fitting with the paste. To do so you must have it warm enough and NOT have gobs on the brush. When lead free brass plumbing fittings came around I found it difficult, so I tried other fluxes, having used nokorode for years. I finally settled on Nokorode tinning flux which worked much better.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements