Taco Cartridge Circulator installed backwards (water hammer on Honeywell zone valves)

First, I spent a lot of time on forums like these and this is a very common thread and problem that has a lot of good data. If I ask questions that are addressed on other threads, I apologize. It's a lot of data and I'd like to get focus here on this thread with my specific problem to this common dilemma.

The new boiler is a Slant Fin Sentry Gas Fired Boiler (model S-120 EDP) with 2 zones. The new zone valves are Honeywell V8043E1012. The cartridge circulator is a Taco 007-F5.

The problem is that the installer mounted the Taco pump with the water flow backwards. I'll prove that with a bunch of photos below. So of course this is causing water hammer on the Honeywell zone valves because they were mounted in the correct intended direction. So the valve stamped arrows and the pump are pointing at each other which I understand is an issue.

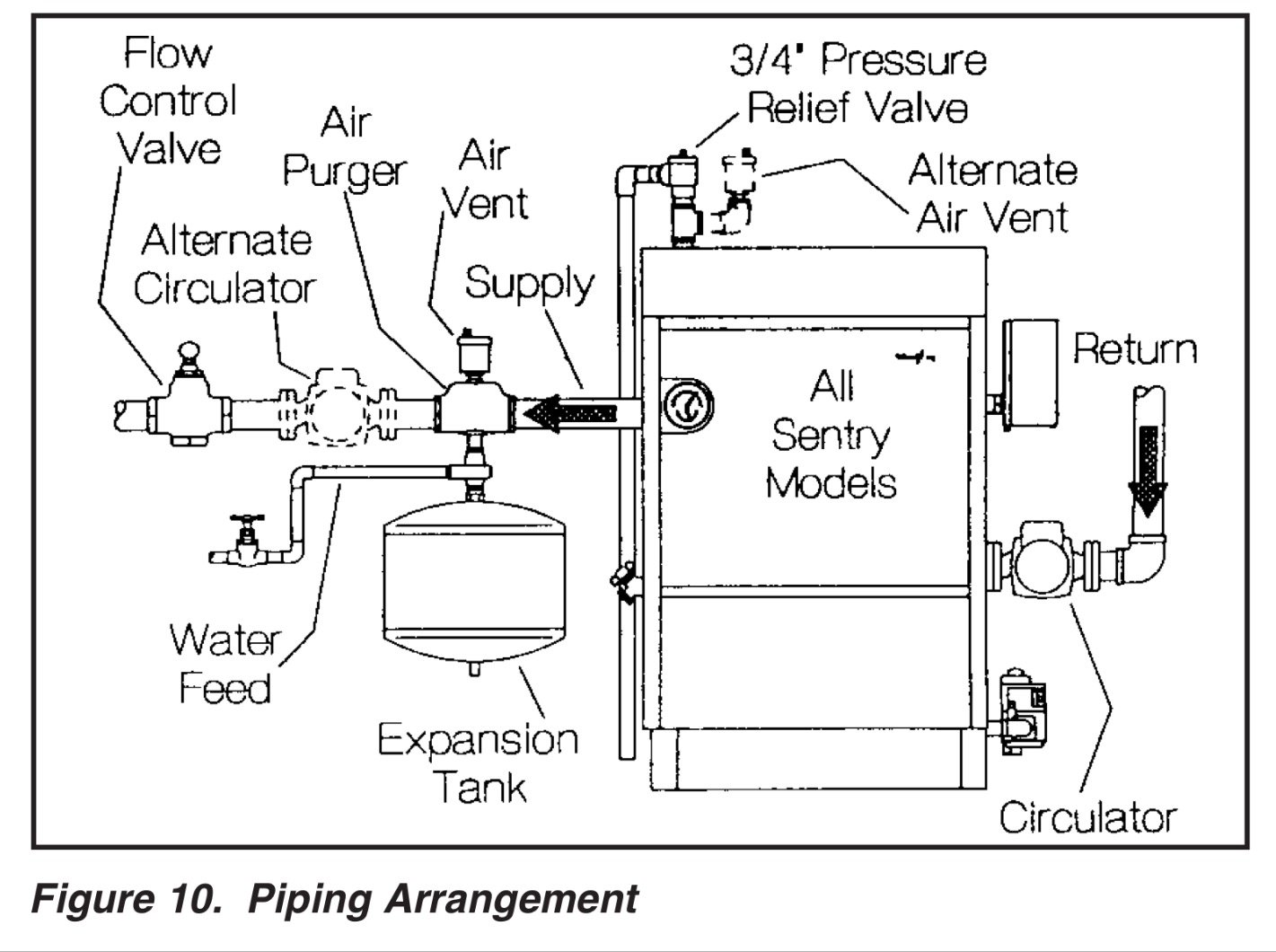

This is the intended piping arrangement on all Sentry models according to the installation guide.

This is what most people know about the Honeywell valves and why water hammer happens.

This is the new boiler install with the green arrows being the intended setup, but the red arrows are the current flow because of the pump being installed incorrectly.

This is the proof that the circulator was installed incorrectly.

Front view of the circulator. The wiring control box should be on top (not bottom)

Top view of the circulator. For those of you familiar with the Taco circulator pumps, you can also tell from this image that the water flow is going in the unintended direction.

Ok, that's my story. Here are my quesitons:

1) Do I have to worry about damage to my new boiler since the waterflow is backwards? If there are serious concerns, I'll get someone to reorient that pump ASAP. If not, I'd like to wait until it gets warmer (about 2 more months)

2) The water hammer is obnoxious, no doubt, but I've seen other forums where people have had this problem for years and then addressed it. So I'm hoping I don't have to worry about damage to the baseboards, piping in general, the Honeywell vavles, or the boiler itself with the water hammering.

I welcome any other suggestions or professional opinions. Thanks everyone for your time and attention!

Comments

-

Have you called the installer and what does he say? How long ago was this installed?0

-

Those zone valves could still make noise even after the circulator flip. Have the original installer back & have him(or her) fix it. Either that or have someone else fix it. You know that at least one of your problems are fixed...

Robert O'Connor/NJ0 -

I'll call them eventually. It was kindof a nightmare experience and the house is heated just fine with the water in reverse. I don't want them to give me yet another night without heat in the winter. That's why I asked if it's damaging to the boiler to be in reverse. If not, I want to wait for warmer weather. The warranty is for a long time and they'll cover that repair. It's fully installed with the warranty in place. So that's what makes it so difficult to just fire these guys and go with someone else.

I had 4 nights of no heat because of issues that happened with this new install. Not all were the installers fault. I had electricity issues with the cut off switch that caused 4 issues. Luckily it was mild in NJ and they provided us with free space heaters for our inconvenience.

But the installer wasn't good enough to figure out all the complex electrical issues. I had to escalate to the owner and he was sharp and figured everything out.0 -

-

I would just go ahead and get it fixed right away. It should be very easy and shouldn't take long.0

-

Less Than that if they would have used isolation flanges. Just makes sense anymore.Ironman said:A night without heat? It should take less than an hour to valve off the boiler, drain it, flip the pump 180*, refill and purge the boiler.

Your "installer" doesn't know which way water flows through the boiler???

1 -

I assume it's an easy job. But my reservation is that when he installed the boiler, he admitted the pump looked slightly bent from shipping. But he "took it apart and put it back together again and it's operating fine now". So that's probably how it got reversed. But I'm afraid that maybe it doesn't fit correctly the normal way because of potential damage and he tried to pull a fast one on me. Part of the reason I don't like or trust him.

But I know guys, he and his company are responsible for the warranty repair and making this right. I can no doubt call him and ask about the original damage concern and if we need to replace that pump under warranty to get it oriented the right way.

My desire to delay is because I've missed a bunch of work staying home to babysit this install over 4 business days of several issues. So I just want a break before a 5th day of yet another repair which is why I'm inquiring if I'm causing damage to the system by it having reverse water flow.

So, sure, in a perfect world, I'd like to get this repaired right this instant. But I'm just asking if I can wait or if I'm damaging my system. It's winter in NJ and the heat runs pretty frequently.

Are there any licensed HVAC pros reading this that know if a water reversal is a serious issue that needs to be resolved instantly? I've read a lot of forums of people who have water hammer and realize after years they had a pump installed the wrong direction. Most of those people reverse the zone valves (but if their pump is in the wrong direction, there's still the boiler health concern).

The Slant Fin documentation has no warnings about water reversal. Maybe it's less common than I think because they're shipped with the pump installed correctly from the factory. But in this case, he had to remove it and reinstall it for some reason which I have to find out from him once I call him out on this error.

Thanks for your understanding guys.0 -

The circulator is easy enough to flip.

You will then be pumping into rather than away from the poorly supported expansion tank. That should be fixed as well.

Then we have an air vent attached to a tee rather than a true air eliminator.

The boilers instructions are horrible. Pumping into the expansion tank and dumping the sediment from the air eliminator into the expansion tank.

Bad instructions and your installer somehow managed to make it worse.

"If you can't explain it simply, you don't understand it well enough"

Albert Einstein2 -

Robert, I do see an inordinate amount of people with Honeywell V8043 zone valves complain of water hammer upon closing on a zone where the pump is still on for another zone.Robert O'Connor said:Those zone valves could still make noise even after the circulator flip. Have the original installer back & have him(or her) fix it. Either that or have someone else fix it. You know that at least one of your problems are fixed...

Robert O'Connor/NJ

Everyone is having great success with removing the smaller return spring on the NC motors.

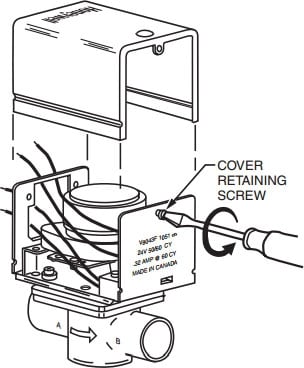

For the DIYers who want to remove that spring, here's some illustration.

First remove the cover

This is how the spring tension closes the valve when the motor releases it.

This is where the springs hook. Everyone is recommending to remove the smaller spring. That will leave the larger spring as the only return spring which will slow the valve down when closing which helps out with water hammer.

Everyone seems quite pleased with that simple fix.0 -

That is one of the craziest modifications I've ever seen, removing a spring

Why do they have two springs if one will do?

Removing one will change the close off rating of the valve, with enough circ, you will experience bleed by. There is a reason the two springs are designed into the valve.

But if any zone valve bangs, it's an indication that it is trying to shut off excessive flow, beyond what it was designed for.

A PAB or delta P circ, or flat curve circ would be a much better solution. And check to see if the circ you have is sized correctly.

Part of the reason ZV bounce or bang on closing is the spring tension winds up in that gear train and motor. If you watch that valve close with a slo-motion camera you will see the valve mechanism bounce 4 or 5 times before the spring inertia winds out. that bounce is what can start the bang, bang, bang.

Some ZVs eliminate that bang potential with a lost motion gear train and a coil spring with better dynamics that is set on every valve with a torque meter.

The lost motion allows the motor to disconnect from the spring tension when the valve powers off. And when the motor powers up the spring tension is disengaged from the motor and gear train until it winds through the lost motion slot.

Think of trying to stop your truck at a red light without pushing in the clutch petal. The lost motion range essentially gives you a clutch to disconnect that spring inertia from the motor, which becomes a flywheel when the spring pulls off.

A "screen door" type spring has a lot of tension when fully extended, but lessens as it retracts. A coil spring with many more wraps allows a more consistent tension from one extreme to the other.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

It's not my idea.

Search online forums. Many people are doing it. Someone even said they got Honeywell to support it. Hammering is a common complaint about Honeywell zone valves. The thought is that they close too fast.

Thanks for your over detailed explanation of physics. I'm not arguing it.0 -

Squidstro said:

It's not my idea.

Search online forums. Many people are doing it. Someone even said they got Honeywell to support it. Hammering is a common complaint about Honeywell zone valves. The thought is that they close too fast.

Thanks for your over detailed explanation of physics. I'm not arguing it.

Oh I know it is a "fix" that has been around for years, I'm not hammering you, sorry if it came across that way.

I'd like to hear the explanation from Honeywell engineering some day

5 fps velocity, when shut of quickly, seems to be the velocity that causes problems. I can't recall the banging problem back in the days of the B&G 100 circs.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

You want the great and powerful OZ to explain?

Next you will want them to change the design>

Blasphemy!

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

The only one who can answer your question about hurting the boiler is SlantFin. Short term I don't think you will hurt the zone valves. The pump is cast iron I doubt it's bent. I have installed hundreds of MH zone valves with no problems .

There was an error rendering this rich post.

0 -

I'll contact Slant Fin and see if I can get an answer, thanks.

On the same token, does anyone know why the documentation states the return line is where the primary pump is? That's probably not even a slant fin specific thing. I see most other boilers seem to have the pump into the boiler on the return side.

Just wondering why it's a thing in general if it's a loop. Why would direction matter.0 -

The piping diagram you show has the "alternate" location for the pump. That would have you pumping away from the tank (which is not supported and will eventually be problems) and the air purger (which you don't have and will be an air elimination challenge for the rest of your life). IMHO

Don't know about the hammer issue?0 -

"I see most other boilers seem to have the pump into the boiler on the return side." That's old school you don't see it anymore.

There was an error rendering this rich post.

0 -

He may have looked at some ModCon piping diagrams where they want the boiler pump to keep the HX pressurized by pumping into the inlet of the boiler.0

-

There's a technical reason that has very practical ramifications as to where the circulator should be located. It should "pump away" from the Point Of No Pressure Change, i.e.: where the expansion connects to the system.

The short version is this: a small wet rotor circ like the Taco 007 can produce about 5 psi pressure differential in the average hydronic system. If the circ is "pumping away" from the PONPC, its pressure differential is ADDED to the systems static pressure. If it's pumping towards the PONPC (like yours), then its pressure differential is DEDUCTED from the systems static fill pressure.

What this translates to practically is this: 1 psi of pressure will lift a column of water 2.31'. The system fill valve comes pre-set at 12 psi. If your house is two stories with your boiler in the basement, then the column of water will have to be lifted 22 - 24' once everything is factored in. We want to keep at least 5 psi positive pressure at the top of the system at all times. So that would mean that you woul need about 10.4 psi to lift the column of water + 5 psi = 15.4 psi static fill. Remember, the fill valve is pre-set to 12 psi and most installers don't know to adjust them for system height. Now your circ kicks on with a call for heat and DEDUCTS 5 psi from your system which had 12 psi on it, leaving 7 psi. That's only enough to lift the water in your system 16'. What happens? The upper portion of the system gets air bound and flow stops or is hindered depending upon the lack of pressure. The boiling point of the water in the upper portion of the system is also lowered accordingly and boiling may actually occur also.

Had the circ been installed properly, "pumping away" from the PONPC, the the circ's 5 psi pressure differential would have been ADDED to the 12 psi static fill pressure = 17 psi. This would be more than enough for a two story house.

So, it's not so much a question of placing it on the supply or return, but its relation to the PONPC which is generally in the supply line.

The reason the circs came from the factory on the return for so long is that it made it easier to crate the boiler. That decision was made by the shipping department, not engineering. They knew better.

Dan has written a book on this entitled "Pumping Away". It's available in the book store on this site.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.3 -

Wow. Badass post Ironman.

Slant Fin called me back but I missed the call. I'll let you know their 2 cents too when I talk to them.

Let me ask this, when I eventually get the circulator installed in the right direction, I know obviously you have to drain to remove the pump and refill and bleed after the reinstall, but is the pressure regulator going to have to be adjusted?

It's holding just under 20 PSI right now. When he installed the initial regulator, it was going up to 50 and the relief was overflowing water. He replaced the regulator and it went down to normal levels which he said is between 10-20 PSI. He claimed the supply company for the valve has given him a few faulty regulators that are rated at 10-20 but producing higher pressures. He said they're factory set to their rating. I didn't know you could adjust them.

Thanks again everyone!0 -

It should be set for .434 psi per foot of elevation + 5 psi, with the system cold.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Don't forget to pressurize the expansion tank (with air) to the same pressure before you re-fill the system.0

-

Slant Fin called me and confirmed from this thread that the pump needs to be reversed. They said that waiting a few weeks isn't going to be a big deal, given my personal issues that are preventing me from having an emergency repair. But it no doubt has to be resolved.

So here's where you guys are going to get mad. I call my installer and let him know what's up. He gives me attitude saying this new boiler install was setup exactly the way my old one was. So if the old one worked for 20 years, this one should too. I had to put him in his place with the facts I presented you guys here about the pump being upside down. He asked that I send the pics to him to prove it.

I sent him all this data - you can't argue with it. I even told him I spoke to Slant Fin. I also asked him to stop throwing attitude at me since this isn't my fault and I'm just trying to get a warranty fix. So I don't have a response from him just yet (this is all hot off the press).

I haven't told you guys about the full experience with this installer, but he's an **** no doubt. He gets flustered with troubleshooting and then acts like an even bigger ****. The owner of the company is very nice and reasonable (and has been in business for over 40 years). I know you guys are going to hammer me to either fire this guy or talk to the owner. Don't worry - the problem is that this is a warranty fix so I have to deal with the same company to get it resolved at no cost. I already called the owner to make things right when he had other issues. The owner came onsite personally and resolved those. But at the time, none of us were aware that the pump was backwards. So this is just round 2. I'll get it resolved, don't you worry. The point is, the installer has some personality issues, so that makes everything extra difficult.

Ok, fire away guys. Be gentle...0 -

Sounds like you've got a handle on it. I would recommend that you tell the owner about the installer's bad attitude and rudeness. You'll be doing him a favor because this guy is costing him business treating his customers like that.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Funny enough, the last plumber he employed he had to fire because customers complained consistently about his shadiness and over charging.

He replaced him with this new plumber who's also an ****. Makes me question the judgement of the owner. He was assuring me that he's one of his best guys and does all this electrical work on top of plumbing and does massive commercial jobs. But again, that was round 1 when I was still figuring out that his plumber has personality flaws that are worth mentioning for customer service sake like you said, Ironman.

So this is 24 hours since I sent the plumber the pics proving the pump is backwards since he argued with me. Still not a peep. So I'm forced to call the owner now and tell him everything. He could've just made this right, but now I hope he gets what he deserves.

Sigh...0 -

Just out of curiosity , where in Jersey are you ?You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

The idea of pump placement on the return was a pump manufacturers "work around" for the trouble they had with hot supply water destroying the pumps. The return water is cooler and therefore solved the pump problem. The pump should, as was mentioned pump away from the "point of no pressure change".LANGAN'S PLUMBING & HEATING LLC

Considerate People, Considerate Service, Consider It Done!

732-751-1560

email: langansph@yahoo.com

www.langansplumbing.com0 -

It still works, as long as the boiler HX has little to no restriction. We've done it on probably 50% of our TT installs with no problems.4Johnpipe said:pump placement on the return was a pump manufacturers "work around" for the trouble they had with hot supply water destroying the pumps. The return water is cooler and therefore solved the pump problem.

0 -

Woo hoo!

I got him back to flip it and sure enough the hammer is gone. First thing he did when he got here was look at the arrow stamp on the back of the pump and go "God damn it, why the #$%! did I do that!" So that was glorious. On his way out he said he's sorry too.

A few follow up questions. Here's my finally normal operation furnace:

1) He didn't hose bleed the zones after refilling. He said that Taco Hy-Vent will take care of it. When he left, the zone water was very slushy and loud from having air bubbles, but that Taco Hy-Vent was hissing away releasing air from the return pipe. It's been about 1 hour and the slushing is completely gone! Are those Taco Hy-Vents supposed to be used for a full bleeding? I'm very impressed.

2) Zman mentioned the poorly supported expansion tank. I hate that it's sideways too. I see a bunch online sideways and people say it's fine even though it's not the most common way to install it. He leveraged a lot of my old furnace piping which gets in the way of installing that tank down or up. The last furnace actually had it diagonal. Since people say it's fine sideways, but yes, doesn't have anything supporting it, can I just put some Styrofoam between it an the boiler to keep it supported? Do those fill to the point where they get so heavy they'll bend towards gravity?

3) Regarding Zman's comments about the air eliminator attached to a tee as incorrect, why did it properly bleed both zones then? Sounds like it did the job to me!

Thanks gentlemen! I'm so relieved that everything is resolved. For the people with hammer issues, know that this resolution completely fixed my hammer issue.0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 167 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements