Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Do headers ever loop or "U?"

Options

SteamedInWharton

Member Posts: 62

We've all seen the basic setup of a header: boiler riser, boiler riser, system riser, system riser, equalizer. Every pic I've seen here has that done in a straight line.

I'm hoping to have my near boiler piping redone soon. My boiler has side tappings (Utica) but an earlier boiler was likely "headerless" with two large three inch mains now located behind and in between the boiler risers. The hartford loop's on the right so that means the boiler risers should connect on the left side of the header. There's a wall on that side, so things can get a little tight. Can you maintain the prescribed order but do it in a U or L shaped configuration?

I'm hoping to have my near boiler piping redone soon. My boiler has side tappings (Utica) but an earlier boiler was likely "headerless" with two large three inch mains now located behind and in between the boiler risers. The hartford loop's on the right so that means the boiler risers should connect on the left side of the header. There's a wall on that side, so things can get a little tight. Can you maintain the prescribed order but do it in a U or L shaped configuration?

Steaming along slowly in Wharton, Morris County, NJ.

0

Comments

-

Many have done headers in an L shape. That isn't a problem as long as you keep the risers out of the boiler at one end of the Header, followed by the risers to the main, followed by the equalizer at the other end. I can't say I've ever seen a U shaped Header, I'm not sure why that would be necessary even.

0 -

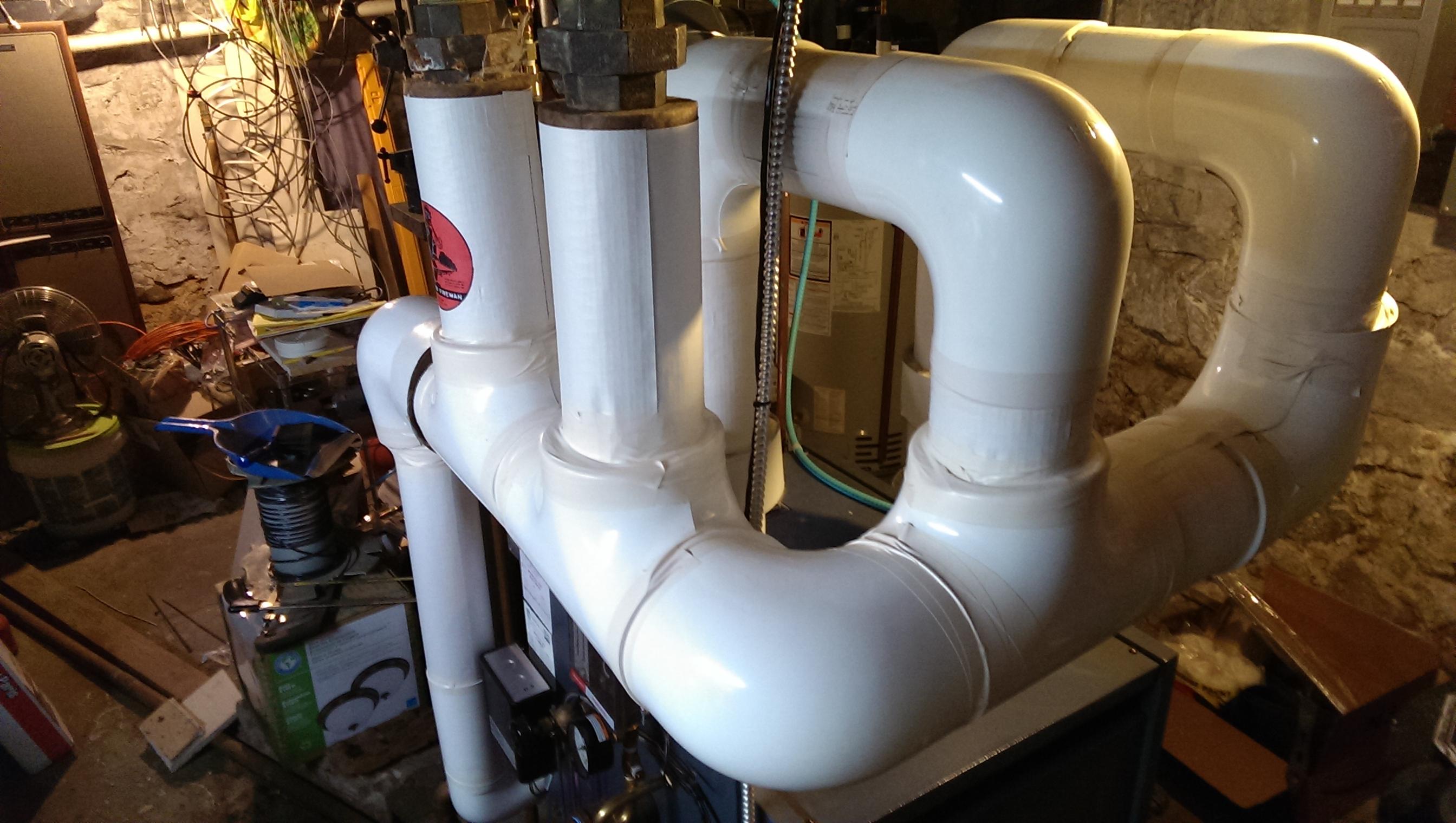

Is mine in what you're referring to as "L" shaped?

If so then yes, that works fine. A U shape may work too as long as it's pitched continuously towards the equalizer.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

-

I think it's a matter of preference and field conditions that can dictate header design. I don't think many will argue straight is the most straight forward design. Chris and I both did an L shape and if you look it was mainly a function of existing conditions and matching up with piping. Mine was the same way. I can't think of a reason a U shaped header wouldn't work as long as the pitch is correct. I think in that situation though I would try something else first. I can't quite get my brain around having 2 parallel pipes in the header and not being able to work it out with just a single pipe.0

-

As folks are saying -- keep the pitches good. However, if you can... just sayin', here... it might be better to go up one pipe size, at least for the U configuration, as there is bound to be some loss and turbulence in the bends.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Here's one with a U-shaped header:

http://forum.heatinghelp.com/discussion/141630/weil-mclain-sgo-8-with-carlin-201gasAll Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

-

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 428 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 114 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements