Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

URGENT HELP NEEDED: Gas Line Size out of meter to new furnace

Options

chadpils

Member Posts: 2

in Gas Heating

Hello all,

I just had a new Trane furnace and A/C installed to replace a heat pump. To do so, I had a new gas line run from the street to the house a couple of months ago. I had a gas service guy install the line about a month ago and the furnace installed a couple weeks ago. Delays in inspections /permits caused the meter to only go in this week. I just had the HVAC tech at my house to start up the system. He told me that the line is too small, but the gas service guy is claiming that they are screwing him b/c they didn't get the plumbing portion of the job. Here are the specs, please help me understand which is right.

Trane Furnace: 100,000 BTU's

Pipe: Black Iron Pipe

From the meter, there is 1" line out which is brought down to 3/4" at an elbow where you can check the pressure. there is about a foot of 3/4" which goes to a 90 degree elbow and reduced to 1/2", the 1/2" line then goes 30 feet up the side of my house and 90 degrees into my attic. There is about 20 feet or so of line inside the attic.

HVAC company claims it should be 3/4", and although the line passed inspection, the county is now saying it should be 3/4" all the way up. The guy that put the line is says 1/2" is plenty

so is 1/2" iron pipe big enough to handle enough natural gas for a 100,000 BTU furnace with a 30 foot rise and 50 total feet of pipe.

I just had a new Trane furnace and A/C installed to replace a heat pump. To do so, I had a new gas line run from the street to the house a couple of months ago. I had a gas service guy install the line about a month ago and the furnace installed a couple weeks ago. Delays in inspections /permits caused the meter to only go in this week. I just had the HVAC tech at my house to start up the system. He told me that the line is too small, but the gas service guy is claiming that they are screwing him b/c they didn't get the plumbing portion of the job. Here are the specs, please help me understand which is right.

Trane Furnace: 100,000 BTU's

Pipe: Black Iron Pipe

From the meter, there is 1" line out which is brought down to 3/4" at an elbow where you can check the pressure. there is about a foot of 3/4" which goes to a 90 degree elbow and reduced to 1/2", the 1/2" line then goes 30 feet up the side of my house and 90 degrees into my attic. There is about 20 feet or so of line inside the attic.

HVAC company claims it should be 3/4", and although the line passed inspection, the county is now saying it should be 3/4" all the way up. The guy that put the line is says 1/2" is plenty

so is 1/2" iron pipe big enough to handle enough natural gas for a 100,000 BTU furnace with a 30 foot rise and 50 total feet of pipe.

0

Comments

-

Engineering toolbox says for a 50 foot long run you need 3/4 inch pipe to supply the required 100 MBH.

http://www.engineeringtoolbox.com/natural-gas-pipe-sizing-d_826.htmlHydronics inspired homeowner with self-designed high efficiency low temperature baseboard system and professionally installed mod-con boiler with indirect DHW. My system design thread: http://forum.heatinghelp.com/discussion/154385

System Photo: https://us.v-cdn.net/5021738/uploads/FileUpload/79/451e1f19a1e5b345e0951fbe1ff6ca.jpg0 -

Many plumbers seem incapable of reading the tables to size gas lines properly any more. Even with the book open in front of them & a finger pointing out the proper size I've had them argue, or start talking about turning up the pressure.

Check the installation manual, it probably has a section on sizing the gas line. If it doesn't meet that, then you can tell the gas line installer that he owns the warranty on the unit. That sometimes gets their attention.

The problem is the difference between "best practices", which will result in good performance under all conditions, & "kinda works", which sometimes results in adequate operation for the first year.1 -

Thank you both for your help. The gas line installer is coming out tomorrow (Saturday) to replace the line to make "the HVAC and County Inspector happy"... As for me, the paying customer, I guess my happiness or satisfaction doesn't matter much.

Just one note, this is the guys business. He owns the company. It's his name, he's the one who did it and he specializes in gas only, he doesn't do any other plumbing. I thought by hiring a "specialist" I would get the highest quality work... go figure0 -

The guy specializes in gas work and does not know how to size a single appliance gas line? Wow.0

-

The real problem is there isn't a sharp line between "works" & "doesn't work". There's "should work", "outta work", & (my favorite) "can't understand why it didn't work".0

-

Assuming a starting water column of 8" and a specific gravity of .60 1/2 iron pipe has a .019" water column pressure drop per foot at 100K BTU's. Multiply 50 feet by .019=.95" WC drop across section. Take the starting 8" water column subtract .95 and you have 7.05"WC at the furnace. More than enough!LANGAN'S PLUMBING & HEATING LLC

Considerate People, Considerate Service, Consider It Done!

732-751-1560

email: langansph@yahoo.com

www.langansplumbing.com0 -

-

When I had my Smith G8 with a Carlin EZ-Gas installed they ran a 1" line from the meter to just above the boiler and a 7 ft 3/4" line 7 ft down to the EZ-Gas.

A manometer on he input side of the EZ-Gas shows a pressure drop of about 0.1" WC.

I should have added I'm in an area where the street pressure is pretty low so I'm more than willing to pay for the difference between 1/2 and 3/4" pipe.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

@4Johnpipe, that works out to about 2 in wc drop per 100'. It might be fine, but the tables I'm used to seeing are 0.3 in wc drop per 100. In this application, the 1/2" pipe is over five times more restrictive than what the old guys would have used.

I don't mean to dump on you, but I continually have trouble with undersized gas lines. Just today, I was on a job where the inlet pressure dropped to 3.7 in wc when all the appliances were operating at high fire. Too low. No reason for a 5 in drop on an 8 in line. They're going to have to rework it (again!) if they want us to warrant the units. Last week I fired two duct heaters, the gas line was sized with an 8in wc/100' pressure drop. No kidding. At most 50' equivalent length, 4 in drop. Too low.0 -

Yes the tables typically show a .3 or .5 water column pressure drop. We have been over-sizing gas pipe for years. The "allowable pressure drop is the designers choice". This is from the IFGC code book. Once we know the required minimum of the appliance and the starting delivery point. We can design the pipe size to deliver what we need as long as we do not drop below the appliance manufacturers recommended minimum gas pressure.

In this particalur example 1/2" will be 7.05" water column which is still 2" above the minimum.LANGAN'S PLUMBING & HEATING LLC

Considerate People, Considerate Service, Consider It Done!

732-751-1560

email: langansph@yahoo.com

www.langansplumbing.com0 -

Ratio ,

The problem you have described would indicate that some installer did not know quite how to use series summation method for sizing gas systems . I assure you that what 4johnpipe said is an approved sizing method in all gas codes . Not to suggest that the designer / installer should not be fully aware of supplied pressure at the meter , pressure drop through the meter and the fact that if the meter is not sized right and the load exceeds the rating that the Pd through the meter can increase from the customary 1/2" to 2" which could leave you in trouble .You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

-

-

-

-

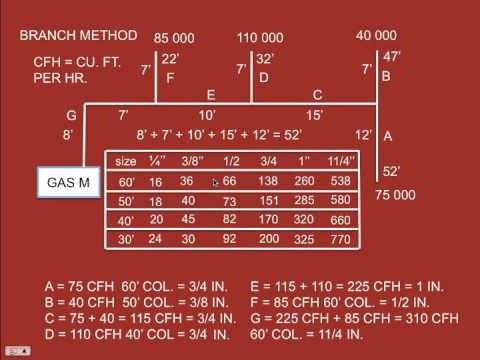

I just prepared this real quick guys . Paul, that is a rather nice presentation but is lacking some approved engineering methods of sizing gas pipe . Please remember to take into account your pressure at the meter and what each appliance requires .

The equations I have shown depict the exact same system the presenter used . You'll clearly see that the sizing could have even been smaller and the system would never suffer .

John and I happen to enjoy a rather generous 8" wc supply pressure with a .5" drop through the meter , if and when the home exceeds meter duty rating you can get in trouble .

Several years ago when rinnais and the like became popular we ran into a couple problems in homes with 415 k meters installed where the load was about 40k shy of 415 . In the winter when all were calling the Rinnais kept shutting down . That will happen when you tear out a 40k water heater and replace it with a 199 and exceed the meters duty rating . 750 Rockwells solved those ills , the gas company could not figure it out , geniuses .

Quite awhile before that I attended a CSST class and afterwards , I had questions . I called Brian Kraft , then at Gastite and asked him why I could use smaller CSSt when in fact it had a larger pressure drop than Iron ? Being an employee of the manufacturer he could not tell me why but did tell me to dig , it is allowed in all model codes .

So , I figured it out and brought it to Trenton , NJ and it is now recognized sizing for ALL gas piping applications , non building type dependent .

REMEMBER , DO THE MATH is not limited to hydronics and unless you live in a place where the laws of physics and Boyles and Charles laws cease to exist , this sizing will not get you in trouble .

Please look at the attached documents and then I'll show you how bad you are really oversizing your gas jobs . Also remember . The intent of the code is to minimize the hazards associated with the storage and distribution of flammable and/or explosive gases within the built environment .

at an average of 50.00 per house material and labor savings you'll probably enjoy the extra 12,500.00 a year that has been picked from your pockets .

You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

@Rich, 4Johnpipe, yah, I know, I was letting off steam a little. .3, .5, these are really low pressure drops & just about anything would be fine with only one appliance. What I run into a lot is like you said, series appliances sized ...optimistically, I'll call it. And this is complicated by the fact that I don't do the gas line, so the cost is inconsequential to me. But we do have to warrant the equipment & sometimes I have to recommed to my boss that we don't. That usually gets results.

But the 8 in wc pressure drop I mentioned was on an appliance regulator, no excuse for that. The mfgr even included the .5 in wc table in their installation manual - that got a note "not installed to mfgr's spec". Too many guys just run whatever is sticking out of the unit is without thought the volume that's needed.0 -

When all else fails go by the book. Lol...is your area high or low pressure...and did anyone contact the local gas supplier for the pressure and btu content in your area...its as it appears lately from other posters here to speak of local codes...so I won't...I taught gas pipe sizing to 11th graders in one day...it truly is not rocket science....and somone posted it was the plumber you said it was a gas specialist.... Was it a plumber a gas fitter or a want to be so called heating guy...who was to lazy or dumb to pass tests...0

-

Anyone ever ream out the inside of pipe after cut and threading it?

0 -

All of our pipe gets reamed .You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

Figured it did.How much of a difference to overall sizing will unreamed pipe make.Unreamed 1/2 in is scary and I bet you are in the minority that does it0

-

The way I see it , the ID ha sto be the same ID the manufacturer made the pipe . We even ream all of our copper . You're right , don't see many that do it . Maybe that's why pipe that is big enough still does not allow proper flow .

With all the money that is saved by doing the math there is money to spend 5 seconds per thread to ream it .You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38331 -

Rich.........The charts have the specifics, as to pressure, listed on top of them. There's no sense in trying to make a "Peanut into a phonograph needle", to quote Eddie Murphy. I'm not trying to be a smart-****, but it isn't and never was rocket-science. It requires care, because you are dealing with a flammable gas.1

-

One would think reaming is standard practice...but who knows some codes may not require it...so again local codes are not discussable on this site per some of Santa's helpers. Lol0

-

It does require care.Working with my former company we never saw how important sizing was.1/14 blk to boiler room for boiler and water heater.Waste was 4in and 2in.Easier to make your material list and the cost is really not that much more when buying in bulk.I have since on this site learned how important math is.If you use math properly you size properly this applies to gas ,dwv and lately more than ever I have found out how important it is in steam and hydronics.Take care.0

-

I agree Paul . It is not rocket science . Nothing I calculated requires more than simple 3rd or 4th grade math , just multiplication , addition , subtraction and division and a chart that tells one pd for Iron pipe . If heating is worth doing the math to get it right since people will be cold than so I say is doing the math to truly meet the intent of the model codes . i showed the math so others may see how piss poor the charts are . This also shows that in a building where some request 1# , 2# pressures due to building size or method that in fact it may not be required at all , it was only thought to be needed because the charts say so . Those buildings with that higher pressure within the built environment are certainly more hazardous . Good job , " Protecting the health of the Nation " , Master plumbers .

The charts contain nothing specific , I have shown that , can anyone argue the math ?

Again , history comes into play . When most of this sizing in the charts was figured out there were not very many homes with gas service , therefore the pipe had to be bigger to make sure folks at the end of the line had proper flow and pressure . I would also point out that gas valves have dropped in their minimum requirements significantly . A new or replacement heating system starts with a room by room heat loss calculation but a gas system differs I suppose ?

Jonny 88 . When buying in bulk this makes all that much more sense . Shipping takes into account weight . If that shop is buying that way due to a high volume of work , think about how many more jobs get done in a year . Real opportunity for massive profit increases .

You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

Can't argue with anything here...said....But let the book be your friend as it is in at least my area the law...You also have to know the area you work in and deal if you wish with what the gas company supplies you with...low pressure high pressure dirty gas wet gas...Up here but do not know about other places we as master plumbers,gas fitters and such can NOT touch anything in gas unless it's the inside fit...but we are also required by brains to find the answers about what is supplied....if the gas company keeps up there big **** BS...I can see a return to oil...No that would be as we say pissa....Then overpaid gas company workers would have massive layoffs and gas company goes private...they would then farm it out to all licened contractors and the gas world would be a better place...this comes from a former VPI will Never Ever deal with the lazy ones at the gas company0

-

-

Rich and I happen to work predominantly in an area with a fantastic natural gas supplier. In fact it was an engineer from this company that first endorsed the "summation method" which we began to employ roughly 15 years ago. Now we have been asked by inspectors to teach this sizing method. Usually it was the ones that also operated a plumbing company of their own as they saw the monetary advantages of doing so. To make it even simpler Gastite brand has free design software that allows rigid pipe as well as CSST tubing to be sized for speed and accuracy.

We also have the liberty of testing the pressure right at the meter with the blessing of the gas company. I agree the charts make it real simple unless as Rich mentioned you are involved with multiple pressure or hybrid installs. The math really counts and certainly doesn't lie. We have areas that have extremely low pressure to the point of no regulators required at the meter. This is perhaps an even more important area to size this way.

Had a customer recently who wanted a tankless. Well he couldn't get it without re piping to a larger size from the meter to the tankless due to the low pressure. He didn't believe me so hired another contractor. Yup it didn't work! I was called back to "fix" it. He has just under 6" water column with 1-1/2" pipe with a .05" WC pressure drop now. Just makes it and the manufacturer wasn't too happy.LANGAN'S PLUMBING & HEATING LLC

Considerate People, Considerate Service, Consider It Done!

732-751-1560

email: langansph@yahoo.com

www.langansplumbing.com0 -

Thanks for the tip re the Gastite app - very nice to use. I wish more people used something like that - it'd make my job a lot easier!0

-

anyone know if the gad problem was fixed, or ?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements

https://www.youtube.com/watch?v=mPjEllrv0Bs

https://www.youtube.com/watch?v=mPjEllrv0Bs