Atmospheric barometric conversion

With help and material from @JStar I'm converting my EG-40 to a barometric damper. After I install everything and it cools down outside Jstar will be coming to set everything up.

I've attached pictures of my progress so far, though I'm not sure if the barometric is too close to the chimney or not. I did this as I wanted it pulling air away from the hot boiler. I always hated the drafthood pulling air right next to the boiler, seemed silly to me.

Once everything is figured out I need to swap in the modified drafthood, screw everything together and wire the new spill switch.

This is my first time doing anything like this so go easy on me.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

Comments

-

Nice @ChrisJ . It looks just like the ones on my power-based boilers, although the spill switch looks different. Hats off to you with the "fancy" ducting. I just ditched the housing that came with mine and used a "T". However, I was a little rushed to get it done.Two-pipe Trane vaporvacuum system; 1466 edr

Twinned, staged Slantfin TR50s piped into 4" header with Riello G400 burners; 240K lead, 200K lag Btus. Controlled by Taco Relay and Honeywell RTH6580WF1 -

-

Tim McElwain said:

Did you take any combustion readings before converting over? It is nice to do that and see if there is any change when going to a barometric. Nice looking vent work and conversion.

Hi Tim,

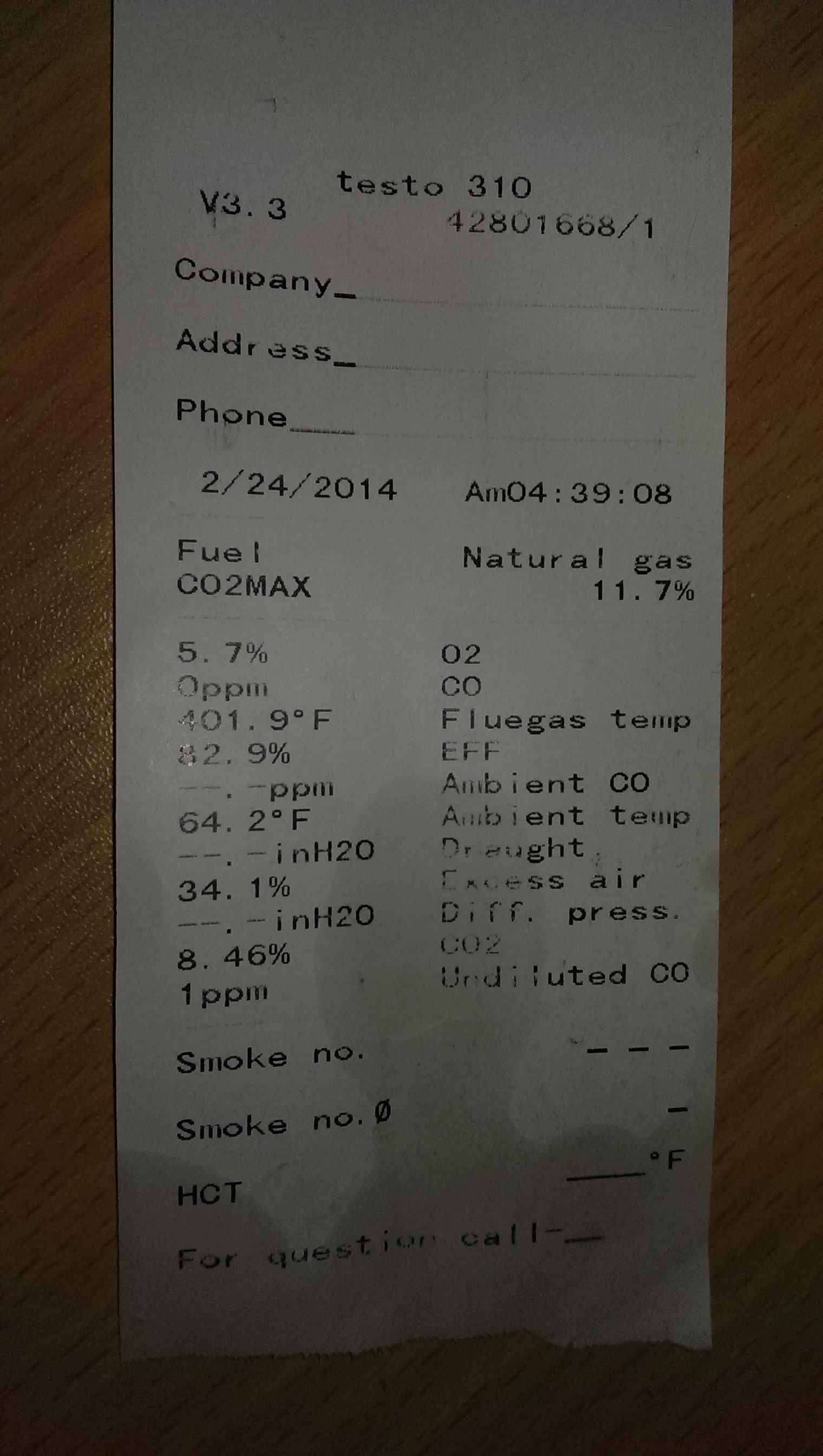

I had one done back before I converted it from an EG-45 to an EG-40. The only difference being one less burner.

I know it's not going to be an exact apples to apples comparison but it's the best I've got.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Pictures of the bottom of the block I took while I had the burner out.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

With that CO2 reading with an O2 of 5.7% it should have been about 78% efficiency with a 400 degree stack. Does that sound about right to you?

I would be interested to see what you come up with now that you have changed over to an automatic draft control.0 -

I could, but it will throw the damper a hair out of plumb then. I don't know how perfect it has but I tried to make it perfectly plumb.RobG said:Chris, the only thing that I would do is try to tweak the fittings a little to get the spigots a little more into the hubs on the horizontal sections. Elsewise it all looks good.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Ouch, 78%?Tim McElwain said:With that CO2 reading with an O2 of 5.7% it should have been about 78% efficiency with a 400 degree stack. Does that sound about right to you?

I would be interested to see what you come up with now that you have changed over to an automatic draft control.

If you look at the print out it says "EFF 82.9%". But your temp number does match up as it says 401.9F flue temp.

Were those results bad?Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I think the flue temp listed is the gross temperature not the net temperature. That would work out to be around the 82.9% If we go with a net temperature of 337.8 degrees F.

Cost is what you spend , value is what you get.

cell # 413-841-6726

https://heatinghelp.com/find-a-contractor/detail/charles-garrity-plumbing-and-heating1 -

So, how do you get the O2 reading lower and the CO2 higher?

Just by lowering the draft?Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

One thing I'm not understanding is how the drafthood pulls a draft through the appliance? I'm sorry for the childish drawing, but it's the best I could do. Why would the flue ever pull air through the boiler rather than direct from the hood and room?JStar said:Control air - control efficiency.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

VenturiChrisJ said:

One thing I'm not understanding is how the drafthood pulls a draft through the appliance? I'm sorry for the childish drawing, but it's the best I could do. Why would the flue ever pull air through the boiler rather than direct from the hood and room?JStar said:Control air - control efficiency.

0

0 -

With an atmospheric burner which gets its air for combustion from within the room it is located within it needs much more excess air than say a power burner (such as oil or a gas conversion burner). In fact it will run sometimes as high as 50% excess air. This tends to make for a larger package passing through the heat exchanger which tends to also increase the velocity of flow which would pull all the heat from the heat exchanger (higher stack temperature). The draft hood will allow dilution air (room air temp) to mix with those hot flue gases in affect slowing them down. The three "T's" of combustion Time, Temperature and Turbulence come into play. Time how long the flue gases are allowed to remain in the heat exchanger and accomplish heat transfer. Temperature what temp they are and hopefully not cooled by excessive excess air. The last is turbulence accomplished by the design of the heat exchanger and the products of combustion combined with air. The draft hood does three things,

!. It neutralizes the affect of stack action

2. It allows for a down draft or back pressure to spill into the room rather than back into the chamber.

3 Provides for the ready escape of the flue gases in the event of no draft, back draft or stoppage beyond the draft hood..

4 -

To continue on all of this is predicated on there being sufficient air in the combustion zone to allow for air for combustion. In the case of natural gas 10 cubic feet of air for every 1000 BTU's plus 4 cubic feet of excess air and then finally at the draft hood roughly 15 cubic feet of dilution air mixing with the products of combustion to accomplish safe and efficient operation as efficient as can be expected with atmospheric burners.

Speaking about efficiency I rarely use the efficiency readings that I get with testers as that as Charlie wrote is a calculated number as is CO2 with most testers. The important figures are O2, Stack Temp, draft and Air free CO . I also actually use a draft gauge as I do not always trust the analyzer draft.

I do have my own charts and tables which I had compared with very expensive analyzers years ago and my charts are accurate to within + or - .3 of a percent, pretty accurate for what it is worth.

There is obviously a lot more to this and I have covered it in depth with my Fundamentals of Gas Volume I and then also my three volumes on Combustion Testing.3 -

A little more on this if you will. Back in 1990's testing was done by AGA in conjunction with Field Controls on design gas equipment and removing or blocking the draft hood (if it was built into the equipment).

The addition of a barometric damper was very effective in eliminating some drafting problems and actually increased efficiency of the equipment.

It was not cost effective for gas boiler and furnace manufacturers to retool (there were other reasons also) and change using draft hoods so they continued right up until more modern and efficient equipment came into being.

The reason oil heating equipment was always more efficient than atmospheric gas equipment was because the oil burner used a power burner which needs less excess air to operate so it is therefore more efficient. The atmospheric gas burner had the need for more air in order to burner safely (low CO).

I hope this has helped. Maybe my friend Jim Davis will chime in and add to this discussion.3 -

Tim,Tim McElwain said:A little more on this if you will. Back in 1990's testing was done by AGA in conjunction with Field Controls on design gas equipment and removing or blocking the draft hood (if it was built into the equipment).

The addition of a barometric damper was very effective in eliminating some drafting problems and actually increased efficiency of the equipment.

It was not cost effective for gas boiler and furnace manufacturers to retool (there were other reasons also) and change using draft hoods so they continued right up until more modern and efficient equipment came into being.

The reason oil heating equipment was always more efficient than atmospheric gas equipment was because the oil burner used a power burner which needs less excess air to operate so it is therefore more efficient. The atmospheric gas burner had the need for more air in order to burner safely (low CO).

I hope this has helped. Maybe my friend Jim Davis will chime in and add to this discussion.

Thank you for the detailed reply!

Do you have any educated guesses on what kind of efficiency increase if any I may see with this conversion?

It is also my understanding that this setup should prove safer as well?

A few pictures of the wire I ran for the spill switch. Not sure how happy I am with it, but I wanted it away from anything hot.

It goes across the ceiling and then back down following my thermostat wire into the vestibule on the boiler. I pulled the factory 2 wires for spill switch into jacket and coupled to that rather than modify the harness (red connectors off on the left side).

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Would also love to hear from Jim Davis on the subject as I had read some of his older stuff on the forum.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

I guess I'm not seeing how this will increase any kind of efficiency. On a power burner, intake air to the boiler is controlled by dampers on the burner. On an atmospheric, you have no damper control on the air. What is to prevent chimney draft sucking air thru the sections now that you've closed off the draft hood. You might get a bit of air "leaking" thru the barometric damper, but there will still be a ton flowing thru your sections when burner is off.0

-

@Abracadabra if you look at the horizontal section of pipe above the barometric damper you'll see the 24V electric damper that came with the boiler. This had to be moved as this way if it ever fails to open and some how the burner still lights the spill switch will shut it down.Abracadabra said:I guess I'm not seeing how this will increase any kind of efficiency. On a power burner, intake air to the boiler is controlled by dampers on the burner. On an atmospheric, you have no damper control on the air. What is to prevent chimney draft sucking air thru the sections now that you've closed off the draft hood. You might get a bit of air "leaking" thru the barometric damper, but there will still be a ton flowing thru your sections when burner is off.

This location will also allow to stop the flue from sucking air out of the basement while the boiler is off.

Same as this, except mine has the hole plugged because I have EI ignition.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Ok... missed the electric damper. Wouldn't you want to add that between the barometric and the boiler tho? Instead of between the barometric and the boiler?

What is your plan for adjusting the barometric? are you just going to do a combustion analysis or pressure check?0 -

I don't think so as that would allow the flue to suck air through the damper pulling warm air out of my basement. The basement isn't hot, but 50-60F is warmer than -8F.Abracadabra said:Ok... missed the electric damper. Wouldn't you want to add that between the barometric and the boiler tho? Instead of between the barometric and the boiler?

What is your plan for adjusting the barometric? are you just going to do a combustion analysis or pressure check?

Also, @JStar wanted it after the barometric as this way if the damper doesn't open and somehow the burner lights anyway the spill switch on the barometric will shut it down.

@Jstar will be setting it up for me. As far as I know he's going to do an analysis. He's the brains when it comes to this stuff I'm just putting the stuff together.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Is there a trick to leveling one of these dampers? I've got it perfectly plumb, but what do I set the level against to level it?

I know this is going to end up being a really dumb question but I'm clueless right now.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

We usually put the level vertically against the front of the barometric to level it in that plane. To level it horizontally, use a very short level- hold the damper wide open and set the level on top of the wide-open damper.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

Thanks Steamhead that worked. I've got it perfectly level and plumb, at least according to my torpedo level. I'll be swapping the drafthood this weekend and then all we need is some cold weather.Steamhead said:We usually put the level vertically against the front of the barometric to level it in that plane. To level it horizontally, use a very short level- hold the damper wide open and set the level on top of the wide-open damper.

C'mon fall!Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

I believe the AGA report assumed that because the appliances were making a considerably lower amount of carbon monoxide they were more efficient. During the test we were not allowed to change anything else to improve efficiency.

My rules of combustion are fuel, air and heat. Gas pressure controls fuel. What controls air? That would be draft. For draft to control combustion air the flue would have to be connected to the appliance not disconnected. Then because draft changes with the weather and conditions it would have to be controlled, thus a barometric. I helped contractors modify drafthood appliances starting in 1980 for energy programs. It was then that I discovered how unsafe drafthoods were if you measured continuously and watch the readings. The first time it took 20 minutes to see an appliance turn totally deadly but then I realized what to start looking for. Without a digital combustion analyzer this could not be done.

The barometric can only be set up with a combustion analyzer on gas appliances. On oil you do use a draft gauge and set for a specific draft. The farther the barometric is from the equipment the more likely weights might have to be added to set it correct, Again that is up to the combustion readings to determine.

Safety and equipment wear and tear are the first two reasons to use a barometric and get rid of the drafthood(single most dangerous device ever invented). Efficiency is not always improved with this modification. Knowing how to interpret the combustion readings and then taking the necessary action will do that if possible.

Efficiency = Non-condensing minus 14% = 86%

Oxygen 6% minus 6% = 80%

Net Flue Temperature divided

by 30 degrees 330 divided by 30 minus 11%

Actually efficiency is 69% maximum

That's better than some of these new furnaces!!1 -

Thank you for responding Jim!

So I have to ask.

How is AFUE calculated? Isn't it combustion efficiency with jacket losses included and if so, how can a combustion efficiency of 69-78% possibly give an AFUE of 82.9% as Weil-Mclain advertises?

Is this similar to the 7HP shop vacuums that could never produce more than 1HP on a good day?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

I'll drag this somewhat less off-track by saying it looks like I'm finally going make it to one of Jim's CO classes this winter. Looking forward to it!0

-

Jim Davis?SWEI said:I'll drag this somewhat less off-track by saying it looks like I'm finally going make it to one of Jim's CO classes this winter. Looking forward to it!

That's awesome! I'm planning on buying one of Tim's manuals.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Modifications to a certified gas apliance are not permited in Canada. Such a modification would need a field aproval. There is also the problem of liability in case of a problem with the apliance. I am sure that the insurance company would go after the outfit that modified the apliance even if the modification did not cause the problem.0

-

Hi Henry, thanks for responding.Henry said:Modifications to a certified gas apliance are not permited in Canada. Such a modification would need a field aproval. There is also the problem of liability in case of a problem with the apliance. I am sure that the insurance company would go after the outfit that modified the apliance even if the modification did not cause the problem.

Good thing I'm not in Canada and I'm the owner of the appliance eh?

NFPA 54 12.13.4

12.13.4* Additional Devices. Appliances (except incinerators)

requiring controlled chimney draft shall be permitted to be

equipped with listed double-acting barometric draft regulators

installed and adjusted in accordance with the manufacturers'instructions.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

And Tim.SWEI said:

I understand Jim has some experience in this areaHenry said:I am sure that the insurance company would go after the outfit that modified the apliance even if the modification did not cause the problem.

They're both very seasoned in this area. More than most.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements