Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Can we have another Vaporstat discussion?...

Options

Tim_64

Member Posts: 76

I have a one pipe steam system, Weil McLain SGO-4, Beckett AFG which is oversized (SGO=450 EDR, rads in my house= 375 EDR)

I have recently installed a Vaporstat 408J1009, I have low pressure gauges installed... (one on the boiler, one on a radiator at the end of a main)

Monitoring calls for heat for a cold system (radiators cold to touch 60 on thermostat) I get steam in all radiators in 25 minutes..

At 35 minutes.... all radiators are hot... and indicated pressure is between 3-5 oz/in. sq.

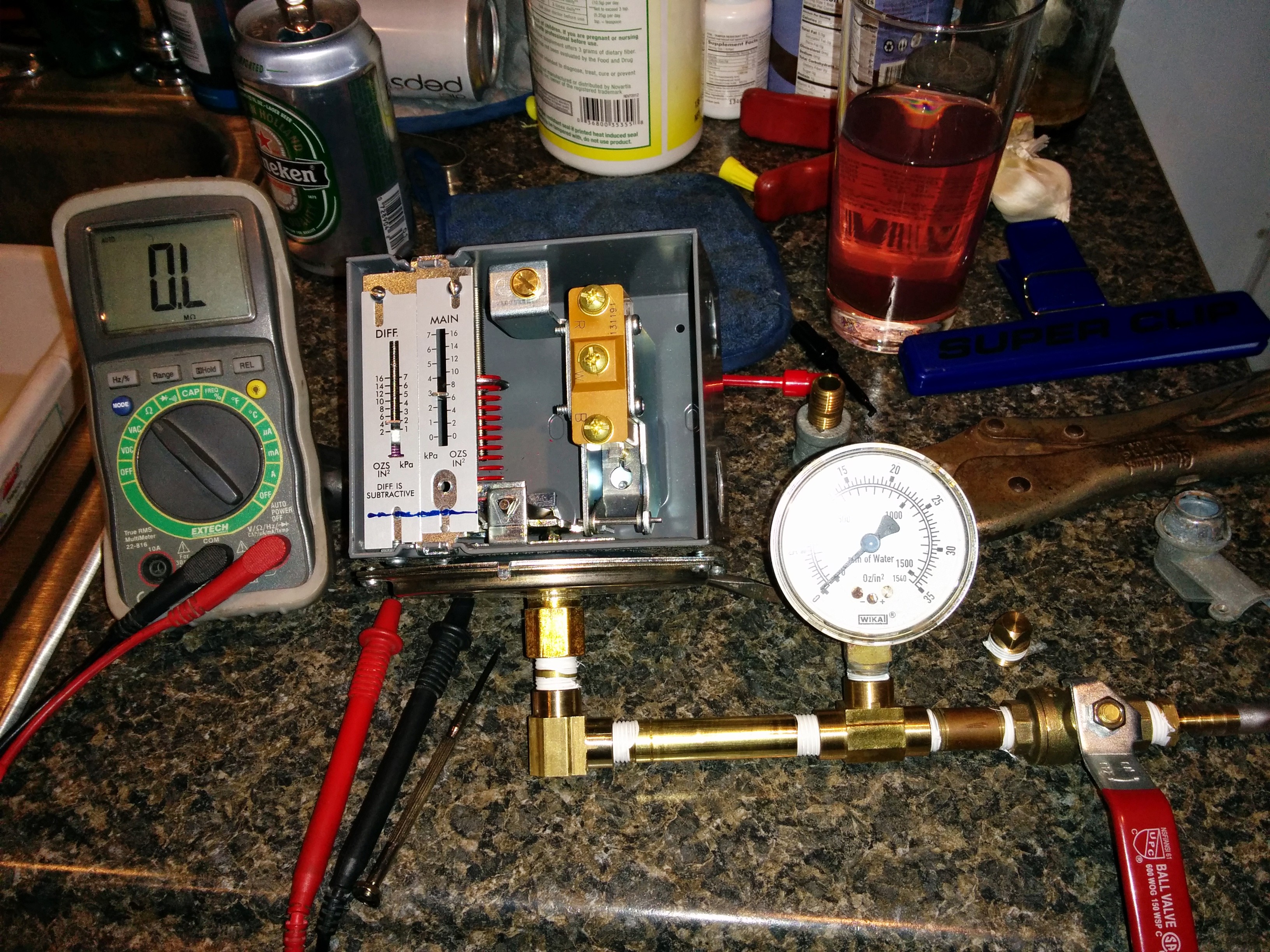

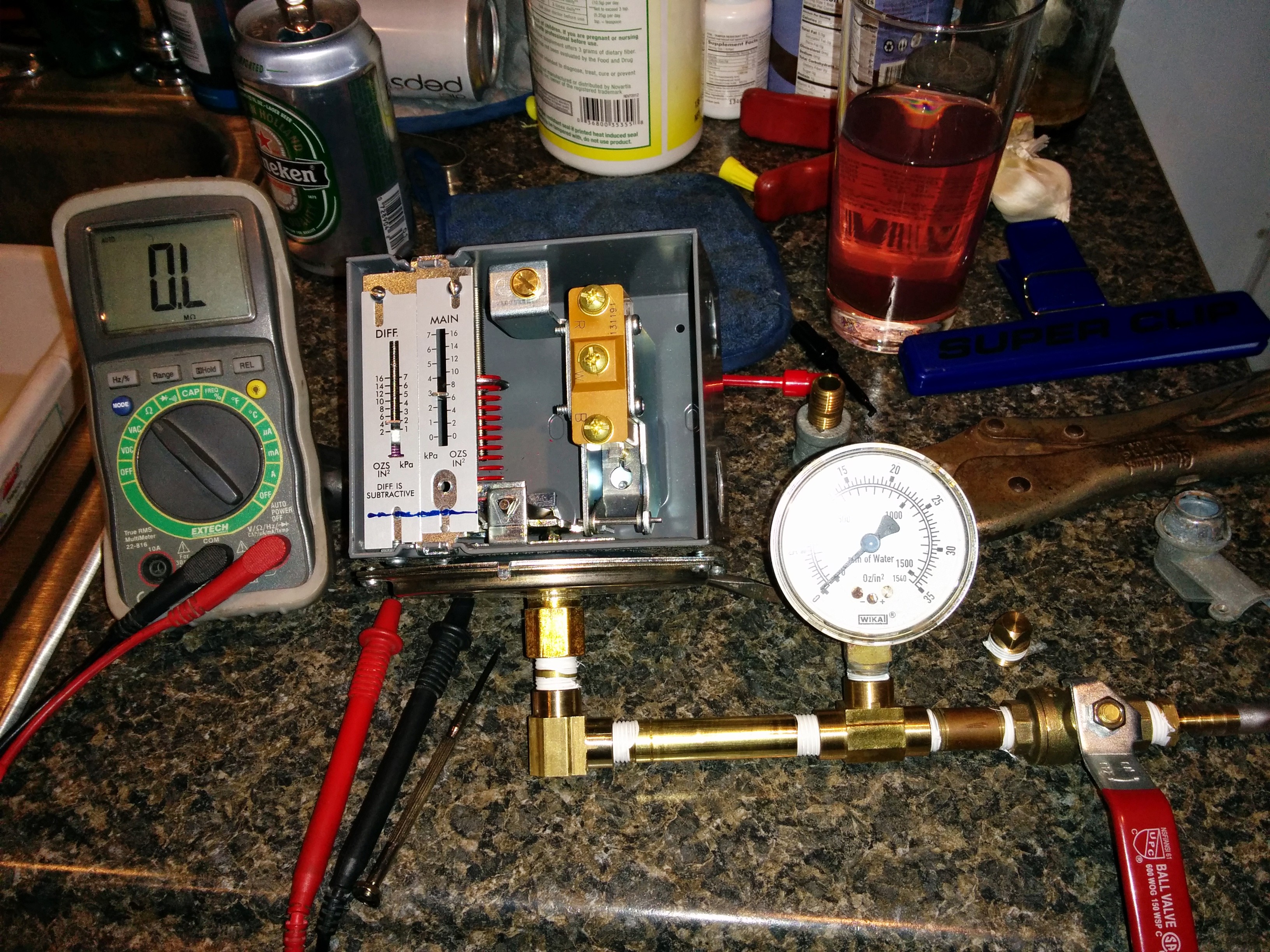

I built a test rig for my Vaporstat as seen on this site....

The unit I have is only reliable to 6 oz/in, sq. The differential no matter where it is set cuts in at 1oz/in. sq.

I want to have this Vaporstat cut out at 4-5 and cut in at 2-3

What mods or hacks do I need to do?

I see on the bottom of the Diff screw there is a stop.. I think If I remove that the diff might be more effective...

I have recently installed a Vaporstat 408J1009, I have low pressure gauges installed... (one on the boiler, one on a radiator at the end of a main)

Monitoring calls for heat for a cold system (radiators cold to touch 60 on thermostat) I get steam in all radiators in 25 minutes..

At 35 minutes.... all radiators are hot... and indicated pressure is between 3-5 oz/in. sq.

I built a test rig for my Vaporstat as seen on this site....

The unit I have is only reliable to 6 oz/in, sq. The differential no matter where it is set cuts in at 1oz/in. sq.

I want to have this Vaporstat cut out at 4-5 and cut in at 2-3

What mods or hacks do I need to do?

I see on the bottom of the Diff screw there is a stop.. I think If I remove that the diff might be more effective...

0

Comments

-

Also when the Vaporstat is on my test rig... when I bleed pressure.... the diaphragm at some point.. ( around 5 oz/in sq) "pops" like it is preloaded and does not inspire much confidence in me in the unit0

-

What exactly are you trying to achieve? With a Cut -in of 2-3 Oz. and a Cut-out of 4-5 Oz your boiler would short cycle, burner off, burner on within about 2 to 3 seconds. Not enough time to really let the steam in the radiators condense enough to refill with much steam and your boiler would just cycle on and off almost constantly until the Thermostat was satisfied (if it could be satisfied).

The Vaporstat should normally be set from Cut-Out around 12 OZ. and Differential of around 8 OZ for a Cut-In around 4 oz. that gives the steam a minute or two to condense before the boiler kicks back on to fill the system with steam again.

How much venting do you have on the Mains? Venting on the Mains is the best way to reduce pressure.

As far as the boiler being over sized, it is not too bad but you certainly can have the burner down fired a little and that should put you right where you need to be.

The Vaporstat and/or Pressuretrol should really be viewed as a "Safety" switch to shut the boiler down should pressures get too high and it is a "Control" device only when it is extremely cold outside (Around 0) or when you are trying to recover from a deep setback (which, normally, isn't something you really want to do unless you will be gone for several days) 2 to 3 degree setback is the most you typically want on a steam system, if you insist on a setback.0 -

It takes my system 40-50 seconds seconds to refire from a pressure cut out... That is with the Vaporstat in its current state... It breaks at around 5 oz/in.sq.

I want it to make at 3 oz/in. Instead of 1, or a slight vacuum...

I don't want to allow the steam to collapse..

The mains on my system all have 1/2 in tappings...and each is vented with one Gorton #2 and three Gorton #1's (which just fall short of an open 1/2 tapping),

My current Vaporstat setting is it breaks at 5oz... and the diff is 2 oz.....

Im trying to find that sweet spot...

Since I know the radiators in my house are all hot with 3-5 oz/in.sq. I want the vaporstat to make at 2 oz...

The adjustments available on the unit dont allow this

0 -

The steam has to collapse or the boiler can't load anymore in the system. besides that, It's not until the steam collapses that it gives up its heat.0

-

The steam collapses very quickly, after the burner cuts off. You want to have enough venting so that the boiler does not short-cycle while pushing the air in the boiler+supplies+dry returns out through the main vents. Inadequate venting can add a few minutes to each cycle, which causes more fuel to be used over a winter.

Even though the Gorton 2's are expensive, so is extra fuel burnt to force the air out of the constipated little openings of inadequate main vents!

In regard to an over-sized boiler, some down-firing can be done, but for best and safest results, a qualified burner tech should check the flue gasses with his analyser to make sure all is well.--NBC

0 -

The purpose of my post was to find out how to get my Vaporstat to play well when set at the bottom of the scale... I offered the configuration of my steam system because I knew if I did not It would be asked of me...

Main Vents:

I have a one pipe steam system, with three mains... at the end of each main is an 90 deg elbow with a 1/2 in tapping...

I have at the end of each main, 1 (one) Gorton #2, and 3 (three) Gorton #1 vents...

According to all references, this vents slightly slower than an open 1/2 in tapping.

The radiators are vented appropriately..

Can anyone share a tip or trick to get the Diff on a 1009 Vaporstat to work at pressures less than 5 oz/in.sq.?

0 -

You say you are trying to find "that sweet spot", but what method are you using to try to determine that? I'm assuming you want to heat all the rooms to the desired temp with the minimum amount of fuel. What I would suggest would be to put an hourmeter on the boiler and start keeping track of your results for a week vs the degree days for each day. Then make a change to your vaporstat settings to the settings Fred recommends and collect data for another week and see where you are at.0

-

You might get more consistent results with one of the older mercury switch type of vaporstats. I have heard it said by some on this site that they were better. You're lucky that you have a vaporstat at least. I have a pressuretrol and I observe a cut-out that varies by about 0.3 psi (1.7 to 2 psi) when I have it set at 1.5 psi on the dial. I believe my boiler is oversized relative to the EDR (which I haven't calculated yet) and my main vents are way undersized so I know I have lots of room for improvements. It only really ever cuts out on the pressuretrol when recovering from a deep overnight setback. Other times it doesn't really even show any pressure on the gauge (0-3 psi). Maybe it will if this winter ever gets really cold. Been a pretty wimpy winter so far.0

-

Third try is the charm I hope...

I have set the cutout threshold to a much lower pressure than Fred mentioned.... It is now set at 5 oz/in sq.

All radiators are hot after 25 mins at this low pressure..

Observing the gauge during a call for heat from a 5 deg setback.... The system is cutting on pressure at 4 oz/in sq observed.. and cutting in at a slight vacuum.. appears to be -1/2 oz/in sq.

The Vaporstat I have seems accurate in the high and middle settings, the diff works then.... when you turn it down things get hinky..

Does anyone have any tips or trick to get the differential setting to work at the low end of the scale?

I would be sweet to get the differential to work... cut out at 4 oz.. cut in at 1 or 2.....

I bet if i refine my rad venting.... I could get my system to work at 2-3 oz/in sq (as it was designed)

I'm going to dissect the Vaportstat over the holidays....Hopefully I have something constructive to report... instead of asking for tips tricks and hints..

0 -

How old is the vaporstat? You might want to report your results to the Engineering Dept. at Honeywell and see what they say. If you get in contact with an actual engineer there you could get some very useful advice. Maybe a good clean and lube will get it to act properly at the bottom of its range.

I guess I understand what you're trying to do, but I'm not sure there is a real need to keep the pressure THAT low, and I believe that you will just be wearing out your gas valve with all that short cycling, and perhaps wasting fuel to boot, since there is some milliseconds of incomplete combustion every time the boiler fires up.

Having said that, perhaps for the degree of fine control you are trying to achieve, it might be best to locate the vaporstat at the end of your largest main, instead of on the boiler.0 -

How often is your burner cycling set up like this during a normal heating cycle?

If I didn't have the EcoSteam to do the 10 minute delay @ 4 ounces I would use no less than a 8 ounce cut out and probably cut back in at around 1 ounce or less. Personally, I don't care if steam pressure drops off, the main vents likely won't even have time to open and the system would end up in a vacuum rather than pulling air in.

If I found my burner cycled a lot (even once during a normal cycle) at 8 ounces I would take other measured to stop this like more venting, less burner, modulating burner etc. Being you have an oil burner, can't that bad boy be downfired big time fairly easy?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Like he said, He hopes the third time is a charm. He's not addressing anything on this post other than his Vaporstat is not accurate at the low end of the scale and he wants to make it accurate to as close to 100% as is humanly possible. Did I get that right Tim?0

-

Ah I'm sorry, I missed the point.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

That is pretty much it... Looking for tricks, tips, hacks... to get the Vaporstat to work within its design range... Heaven forbid I want to run my system at 3-4 oz... and have a control that will turn on the boiler at a 1-2 oz differential...Fred said:Like he said, He hopes the third time is a charm. He's not addressing anything on this post other than his Vaporstat is not accurate at the low end of the scale and he wants to make it accurate to as close to 100% as is humanly possible. Did I get that right Tim?

I'm very interested in the Dwyer-stat mentioned in another thread....

0 -

Many boilers run at 3 to 4 oz of pressure and even less. Your boiler is slightly oversized for your system. The size of the boiler, the size of the pipes, the total EDR, and the amount of venting determine what pressure the system will operate at. All a vaporstat will do is determine at what pressure the boiler will turn off at and then turn back on at. Also your trying to set the cut out where the cut in is supposed to be set. The cut out should be set at the upper end of the scale and the cut in at the lower.0

-

Today's vapor stats and pressuretrols suck..that's about all there is to that..if I were a controls company I would smell opportunity all over that.gwgillplumbingandheating.com

Serving Cleveland's eastern suburbs from Cleveland Heights down to Cuyahoga Falls.1 -

"Today's vapor stats and pressuretrols suck..that's about all there is to that..if I were a controls company I would smell opportunity all over that. "

That's why I ask why somebody hasn't made controls to work by temperature?

0 -

It is, of course, perfectly possible to design and build a control with almost any cutout and differential you want. You might even be able to afford it once it was built. But... why? Other than pure fanaticism, perhaps.

Several reasons why I say that. First, if the differential is small, then there is a possibility that the differential will be satisfied before some other parameter is -- in the system I care for, for instance, the vapourstat is set for a six ounce differential. No point in anything less, as the off time at that setting is less than the post purge cycle time of the boiler's burner. Setting the differential any smaller would make no difference in cycle off time. Second, the steam pressure isn't constant -- even with the vapourstat on the drop header and protected by a snubber, it varies by an ounce or two. Setting the differential within that variation would give very unstable control. Third, as someone has pointed out, the vapourstat doesn't control the pressure; the relationship between the boiler capacity and the radiation capacity does. All the vapourstat does is prevent the pressure from rising higher than desired, and then turning the system back on when there is a demand for more steam.

As to the quality... like all control devices, there is a compromise between build and design quality in areas such as precision and accuracy and longevity -- and cost. I tend to agree that the older mercury switch design was somewhat superior in terms of precision, but was accurate only so long as it was levelled properly (a lot of them weren't) and, of course, the environmentalists put paid to the mercury switch anyway.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 428 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 114 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements