2nd Half of vented Main slow to get steam.

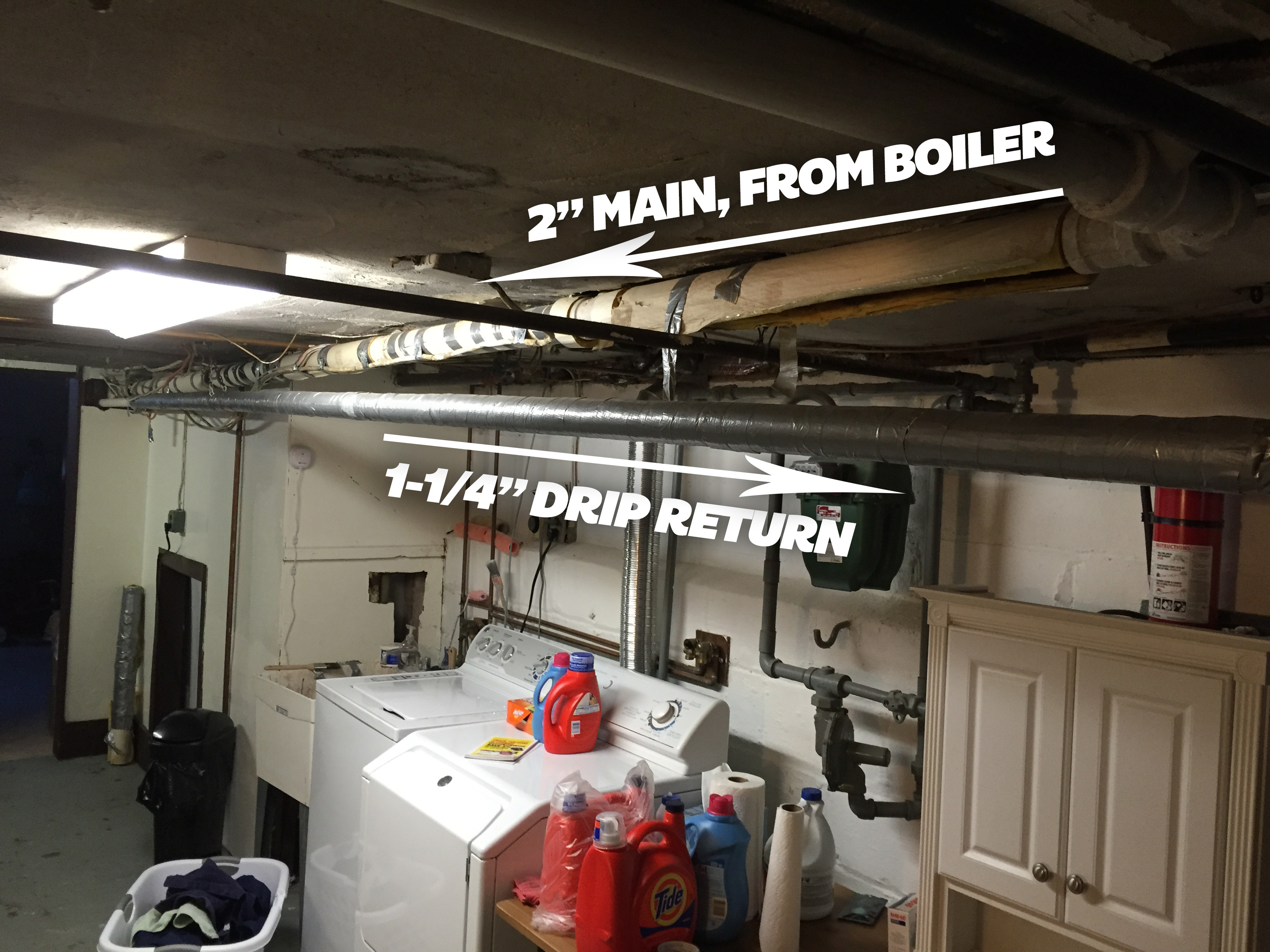

I'm a new owner of this house. I have a 1-pipe steam system, with 109' of 2" main.

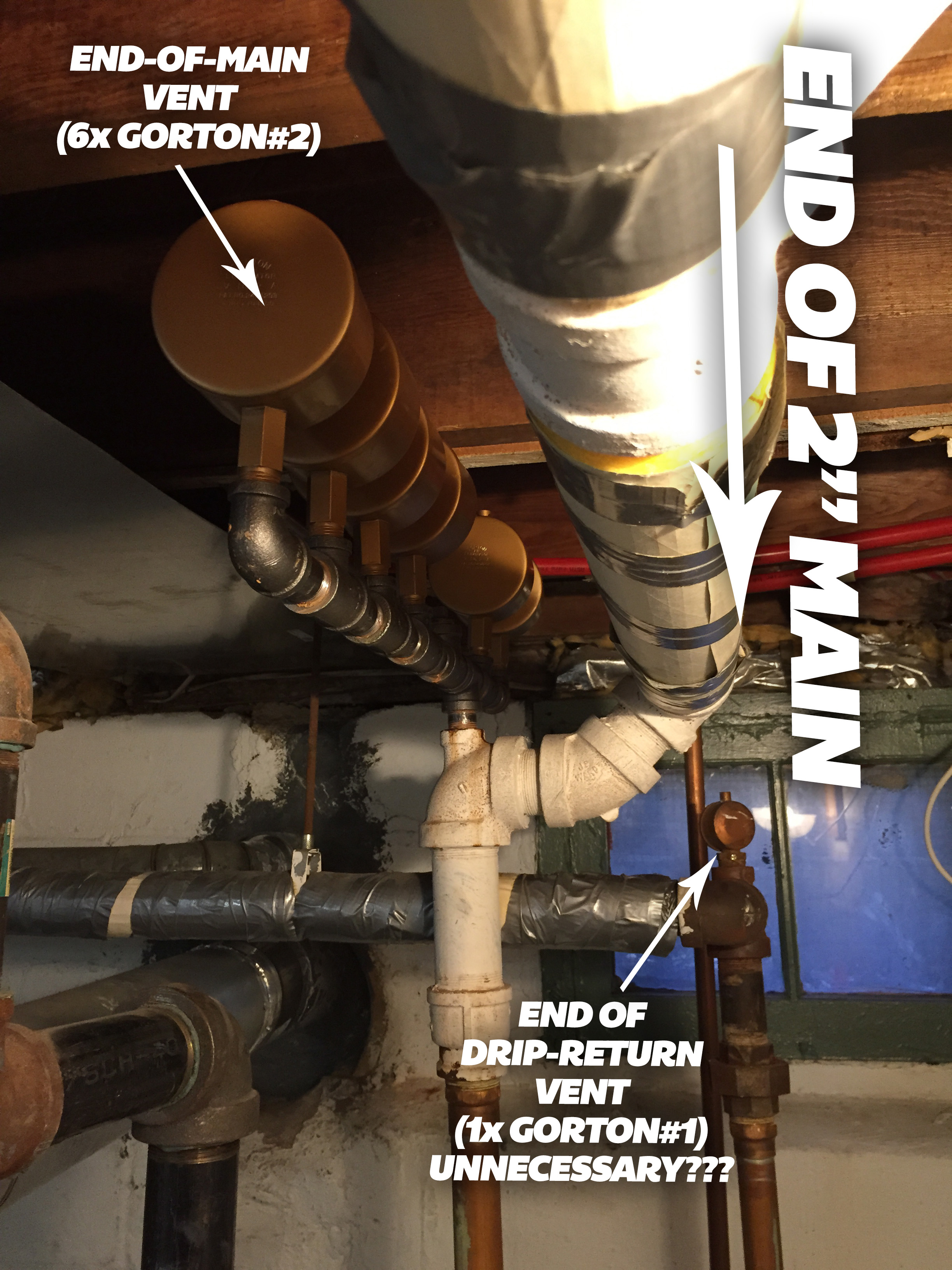

Some of you may have seen in a previous discussion, I just replaced the 1 Gorton #1 at the end of this main with SIX Gorton 2s.

The bummer is, I saw no improvement in speed of steam getting through the main.

The first half of the system seems to get heat very quickly. The second half does not. It takes around 9 minutes for the second half to become heated at all... and then not fully for much longer after that.

I have made a couple observations that may be the cause of the problem. Take a look:

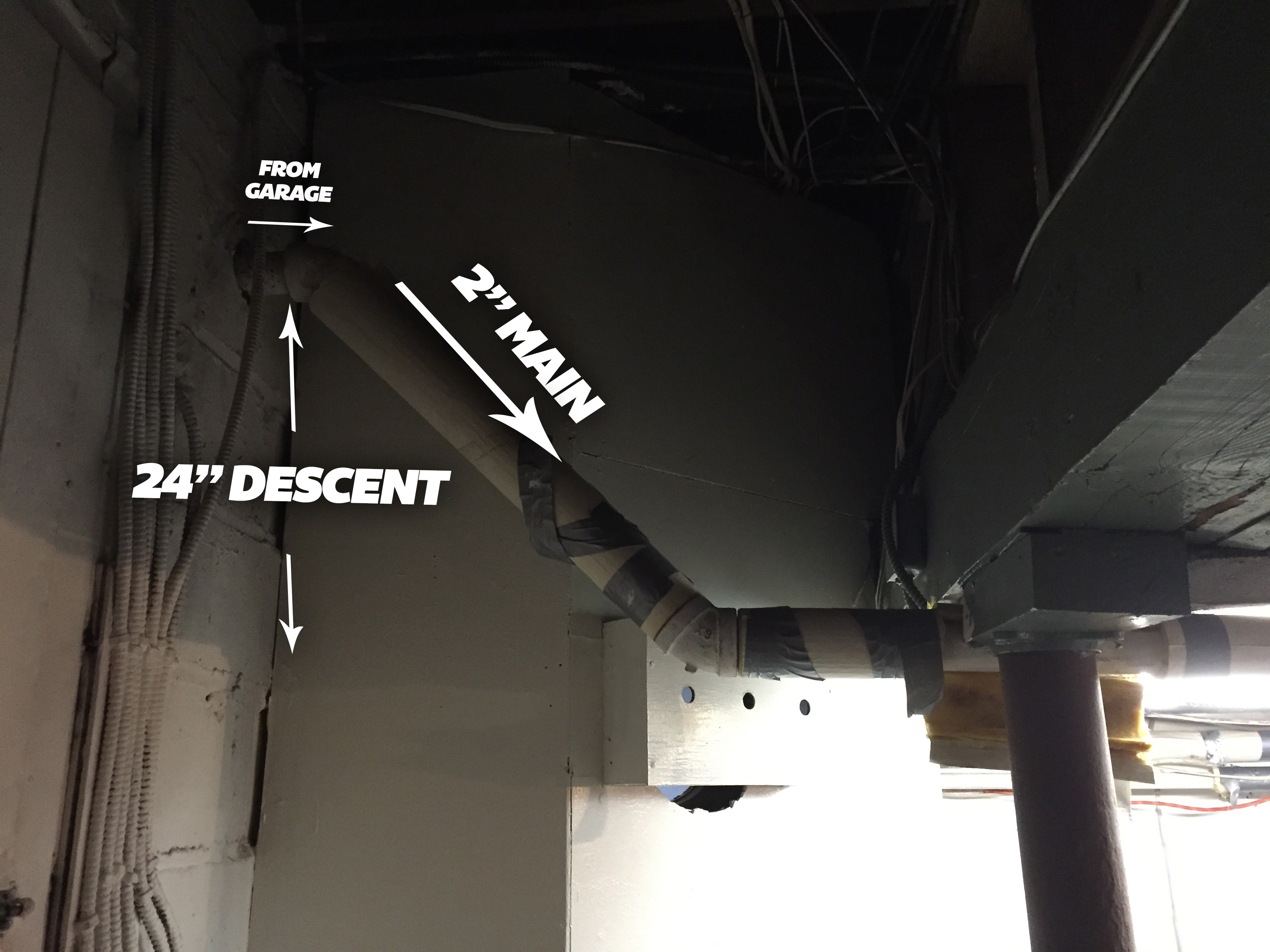

- 33.5 feet along the main, it elevates UP by 28", loops around a large basement room feeding several radiators, then passes through an otherwise UNHEATED garage for 10 FEET before coming back into the basement, immediately descending 24" DOWN to continue the loop another 20 feet , feeding some more radiators, and back to the boiler.

The heat seems to stop at the garage or this point of descent.

With the exception of one very minor spot, everything seems pitched properly back toward the boiler. There is the occasional small ping as the system is heating up, but nothing major.

My question: Is it possible the 24" descent slows the steam down from reaching the 2nd half of the loop?

OR

is the cold of the 10' uninsulated pipe running through the garage (I'm assuming in a pitiful attempt to heat the garage) KILLING the momentum of the steam until the boiler can generate enough to overcome the temperature difference?

I'd gladly give up a slightly-warmer-than-outside-garage, if it would mean my kitchen and other kid's bedroom would heat up before the rest of the house got so hot.

I appreciate any thoughts or observations.

Thanks,

Chris.

Comments

-

Part of the problem could be the garage, but if I am understanding what you are saying all that elevation change is most likely the bigger problem. Pictures would help a lot. Steam mains can change elevation, but it isn't as simple as just doing it. There are drips and other things to consider. Take some pics to clear up what you are talking about...a diagram wouldn't hurt either.0

-

Will post pics w/i the hour, and a rudimentary diagram as well. Thanks.0

-

Here are photos, in order, of the whole loop. Appreciate any feedback.

Thanks!

0

0 -

You don't need a vent on that drip return.

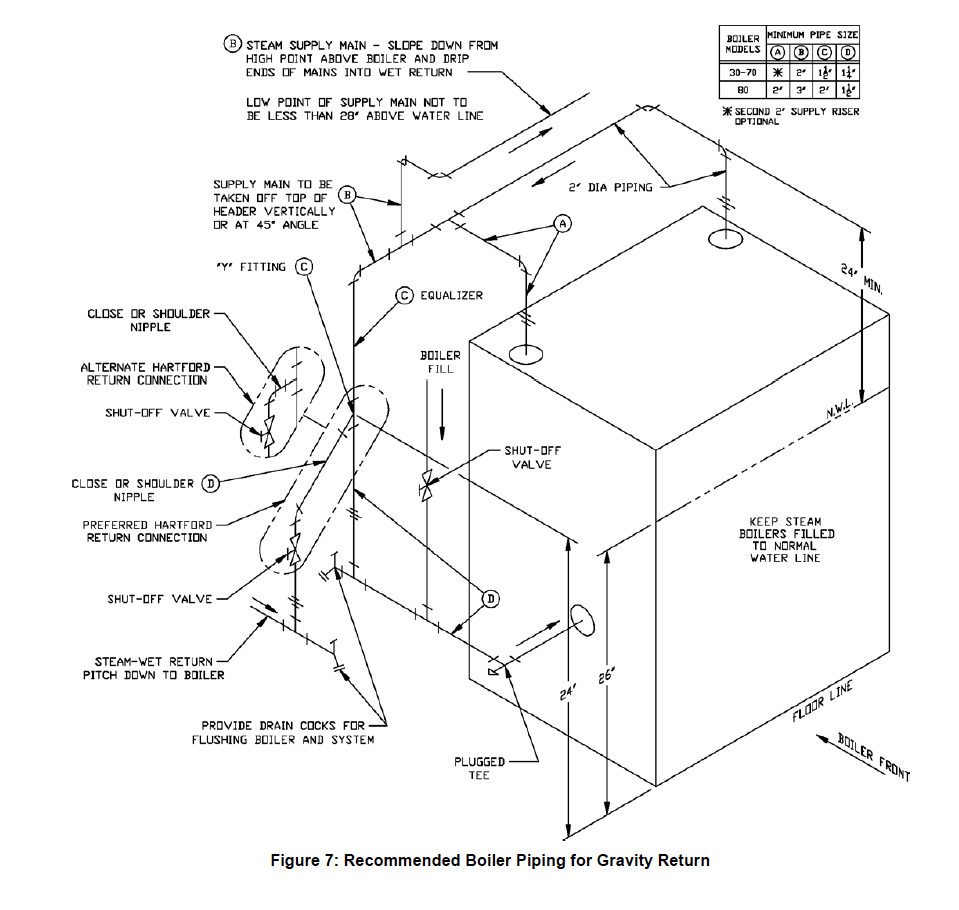

You DO need to repipe that boiler. My guess is you have "wet steam" which dies out way too soon. Proper piping at the boiler will separate the steam from any water that gets up that far, leaving the steam dry when it heads down the main.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

That 10 foot length of uninsulated pipe in an otherwise unheated space is killing you -- in two ways. First, steam trying to get through there is going to condense, big time, until that pipe is fully up to temperature -- and that's going to take a while. Second, both where it starts to rise and where it bottoms out after dipping back down you need a drip to a cold return -- not to the dry return if at all possible. You are getting condensate in there, and that's not helping you either.

So... insulate that pipe and get some drips in place. That will help. Actually, 10 minutes for 100 feet of pipe isn't that bad, but by then it should be fully steam hot, not just sort of kind of thinking about it.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

@ Steamhead: is it that vertical tee in the header that's the biggest problem with the near-boiler arrangement? I've been looking at Dan's diagrams of Hartford loops and that seems to be the biggest difference.

@ Jamie Hall: thanks for the feedback. went out and got some 1" insulation and took care of the garage today, as well as the near-boiler piping (which clearly has its own issues, but at least now it will be still hot).

I'm also attaching a rough diagram of the system, in case it helps anyone.

Thanks! 0

0 -

What kind of vents are on the radiators in the basement? I assume the basement radiators are ceiling hung?0

-

There are no radiators in the basement... just the mains and take-offs to the radiators on the 1st, 2nd, and 3rd floors.0

-

Another symptom: Although there aren't widespread hammering noises, etc, after the system has been cooling for a while, when it kicks back in and starts generating steam, there is often one large THUMP that sounds like it's coming from just down the main from the boiler.

By what I've described above, what of my many issues might be the cause of this?

I'm assuming it's steam building up pressure and finally forcing its way past something.

Just got past this point in a heating cycle now, and checked the pressure on the boiler and it says 2lb.

Any thoughts?

Thanks again.0 -

Try lowering the pressuretrol setting. You don't need 2 lbs.0

-

Six Gorton #2's are all hooked up to that 1 elbow. What is the size of that elbow? It might not be big enough to handle all those Gorton#2's. Also your main piping is a remnant from the coal heating days. One main running around the perimeter of the basement. Two mains would be much more efficient. That way the steam is distributing in 2 directions at the same time. Instead of all the way around. The near boiler piping is wrong and inefficient and needs to be fixed. Where are you located? Maybe there is a pro nearby that can fix your problems.1

-

Thanks, Mark.

I just discovered this morning by some research and talking with my contractor that, at most, 4 #2s can be useful on a 3/4" tapping. So I've removed 2 of them. (serves me right for not taking time to do that math before I bought them).

The header layout has been bothering me... I'm also wondering if the dual returns (the copper in the photos) could be less complicated.

I'm in West Orange, NJ, if you have any recommendations for nearby pros. I will also check the search page here on the site.

Thanks!0 -

Abracadabra, I've also lowered my Pressuretrol back to .5 lbs. I had set it to 2 because at .5 it was shutting off before heat reached the 2nd half of the house.

I have to keep reminding myself "less is more with steam" and "fix the problem, not the symptoms".

thanks everyone!0 -

Looking at my boiler install instrux.

Is it possible for the return loop to be piped into either side of the boiler?

It looks like my install was done on the opposite side from the instructions, with the fill side being installed where the return is indicated in the diagram.

Does this matter?

Just trying to understand this all as much as I can before someone potentially comes in, so I can make good decisions.

0

0 -

Gateway Plumbing and Heating is right in Orange, NJ. They do 1st rate work. That bullheaded T right in the supply is probably killing your steam.0

-

I figured.

Is it possible for the equalizer leg to not be completely vertical? For example, would the drawing attached here be a possible solution?

Just curious if it could be fixed with a minor rework, or if it's more complicated than that. (just gearing up the ol' savings account for what might be coming).

Thanks! 0

0 -

Your fix is much better. Also do yourself a favor and buy some of Dan's books. Get We've Got Steam Heat and The Lost Art of Steam Heat.0

-

Absolutely!cnjamros said:I figured.

Is it possible for the equalizer leg to not be completely vertical? For example, would the drawing attached here be a possible solution?

Just curious if it could be fixed with a minor rework, or if it's more complicated than that. (just gearing up the ol' savings account for what might be coming).

Thanks! 1

1 -

Already have the former. Am threatening to get the latter.

This system saw it's fair share of uninformed neglect, so his book has been crucial on getting at least a layman's understanding on what's going on.

Thanks much!

C.0 -

KC_Jones said:

Well lookee there wouldja.cnjamros said:I figured.

Is it possible for the equalizer leg to not be completely vertical? For example, would the drawing attached here be a possible solution?

Just curious if it could be fixed with a minor rework, or if it's more complicated than that. (just gearing up the ol' savings account for what might be coming).

Thanks!

Absolutely!

@KC Jones:

Thanks!

and sexy setup, too!

C.0 -

just wondering...that vent antler..is it sloped properly so water drainw...the first vent should be at least 15 inches back and it doesn't appear to be...

i want to try one alot more than 15..like a few feet...it should keep the pipe colder and let more air out...will experiment with that...who knows if it will work...but i like trying stuff...did you do all the basic tests with no vents on timing the air getting out of pipes...did you figure how much air is in the pipes.

just curious how you figured out all these vents..? .also...the nipple going into the steam main is too short...should be at least 6 inches...is there a union to hold this all on...don't see that..not sure or not..makes it easier.

i see you used street elbows here..since it's a gorton 2 it's 1/2 inch anyway...don't use those on 3/4's..the hole looks like its 3/4..i learned alot on this site about flow restriction.

i guess they made that vent with a half inch since it's really big..it would have been nice if they made it with 3/4's...better flow i guess and you'd need less of them...i guess the engineers had their reasons to do that...just curious..does anyone know?0 -

a 1/2" pipe can vent 4x the amount a gorton #2 can. Why use 3/4 when 1/2" will do. What I don't understand is why Gorton provides 3/4" and 1/2" on the #1. Seems silly to me. Probably reusing some old design..

@cnjamros the return and fill should be on the same side as the LWCO. The feed water should feed into the bottom of the return manifold/header.0 -

i see...great point...i saw the 3/4 amount on the vent chart and looked at the 1/2 inch venting rate...now i see why they made the 1/2 inch because it must be cost effective and makes sense due to the venting rate..at least up to 3 oz...and besides it supersedes the vent and won't restrict flow.

but at higher rates probably the air would already be eliminated in most cases so it would be a moot point. I guess then it's fine to use a street elbow for steam applications in these type of cases.

maybe gorton does that with the number one so if the main thread is a half inch thread you can just put a nipple in and be done rather than a reducing fitting?0 -

My personal favorites from Dan for steam are The Lost Art of Steam Heating and Greening Steam. I highly recommend both and I feel Greening Steam is a must read.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Hello folks.

After. Long time away from this thread, I thought I'd post an update.

I have posted ad nauseum details in some other threads, but the upshot is that I called Gateway Plumbing and they evaluated and redid my near-boiler piping with a beautiful new drop header.

Now we've got nice dry steam.

Added a vaporstat and a low pressure gauge. Currently running at 4.5oz with a 4oz differential.

Have nearly balanced all of my mismatched radiators and the entire house is constant, within 2 degrees in every room.

Have one problem-child radiator that is howling, but getting a vent-rite #1 tomorrow to hopefully slow its venting down and take care of that.

I want to thank everyone here (and Dan's books... And Gill and Pajek) for the insight and advice. It really set me on the right path to stop treating the symptoms and bite the bullet to fix the cause of the problem.

Now I can see the finish line... A quiet, comfortable, low pressure steam system. It can be done.2 -

You can, with an offset, put two of those gortons #2 vents where that on # 1 vent is.Cost is what you spend , value is what you get.

cell # 413-841-6726

https://heatinghelp.com/find-a-contractor/detail/charles-garrity-plumbing-and-heating0 -

@Charlie: would there be a benefit in relocating the 2 #2s to the end of the main, considering it's only a 3/4" tapping (equal to 4 #2s and one #1)?

Honestly don't know if they're better there, or at the end of the drip return where I have them now.

I put them at the end of the return because in theory the end-of-main tapping is maxed out on ventilation... but perhaps, although they won't all vent simultaneously, it would still be better to have them all at the end of the main... it will just vent slightly slower than if the tapping were larger.

Right now, with the 2 vents at the end of the drip return, that drip return is filling with steam as the vents do their thing... am I wasting that steam by letting it into that 35' or so of pipe that goes nowhere but back to the boiler?

A diagram of my system is attached. I appreciate any thoughts.

Thanks!<img src="https://us.v-cdn.net/5021738/uploads/FileUpload/26/e2ea40744607cb331c82c06b491222.jpg" />0 -

You are pretty much maxed out on venting. I think you need to address your heat issues by way of your radiator vents. Typical answer by me is by a nice new Vent Rite #1 for each radiator. You are wasting heat heating the drip return. The idea is to get steam around faster and unless you cut in a 1" port on the main you have no where else to vent the air. Try this. Plug the tee on the drip return and see , aside from time, if the system works more evenly.Cost is what you spend , value is what you get.

cell # 413-841-6726

https://heatinghelp.com/find-a-contractor/detail/charles-garrity-plumbing-and-heating0 -

@Charlie... I disabled those drip return vents, and it seems like the only effect was the steam got to the other end of the main one minute FASTER. So the only assist they were giving in venting was allowing that drip return to unnecessarily fill.

I put Vent Rite #1s on the problem radiator in the master bath, as well as the larger rad in the bedroom that hisses occasionally. I sat with them for a heating cycle and adjusted just below where they started to make noise.

My system seems to run at about 2.4 oz for most of its cycle. When it starts to go above that, it continues to rise well past 8oz, or until the VaporStat shuts it down. So, I adjusted my Stat for 3oz with a 2oz differential.

With those changes, I'm now finally running a nice, quiet system with even heating in all my rooms. Finally. What a thrill!

Thanks again for all the assistance.

C.1 -

I called Gateway Plumbing and they evaluated and redid my near-boiler piping with a beautiful new drop header.

Now we've got nice dry steam.

A proud papa is supposed to show off his new baby with pics. Lets see them.

0 -

That's great! Now you can enjoy the pleasures of Steam heat!0

-

-

What model is the boiler?0

-

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 427 Carbon Monoxide Awareness

- 119 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 114 Geothermal

- 165 Indoor-Air Quality

- 3.7K Oil Heating

- 76 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.6K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements