Radiant floor does not feel warm

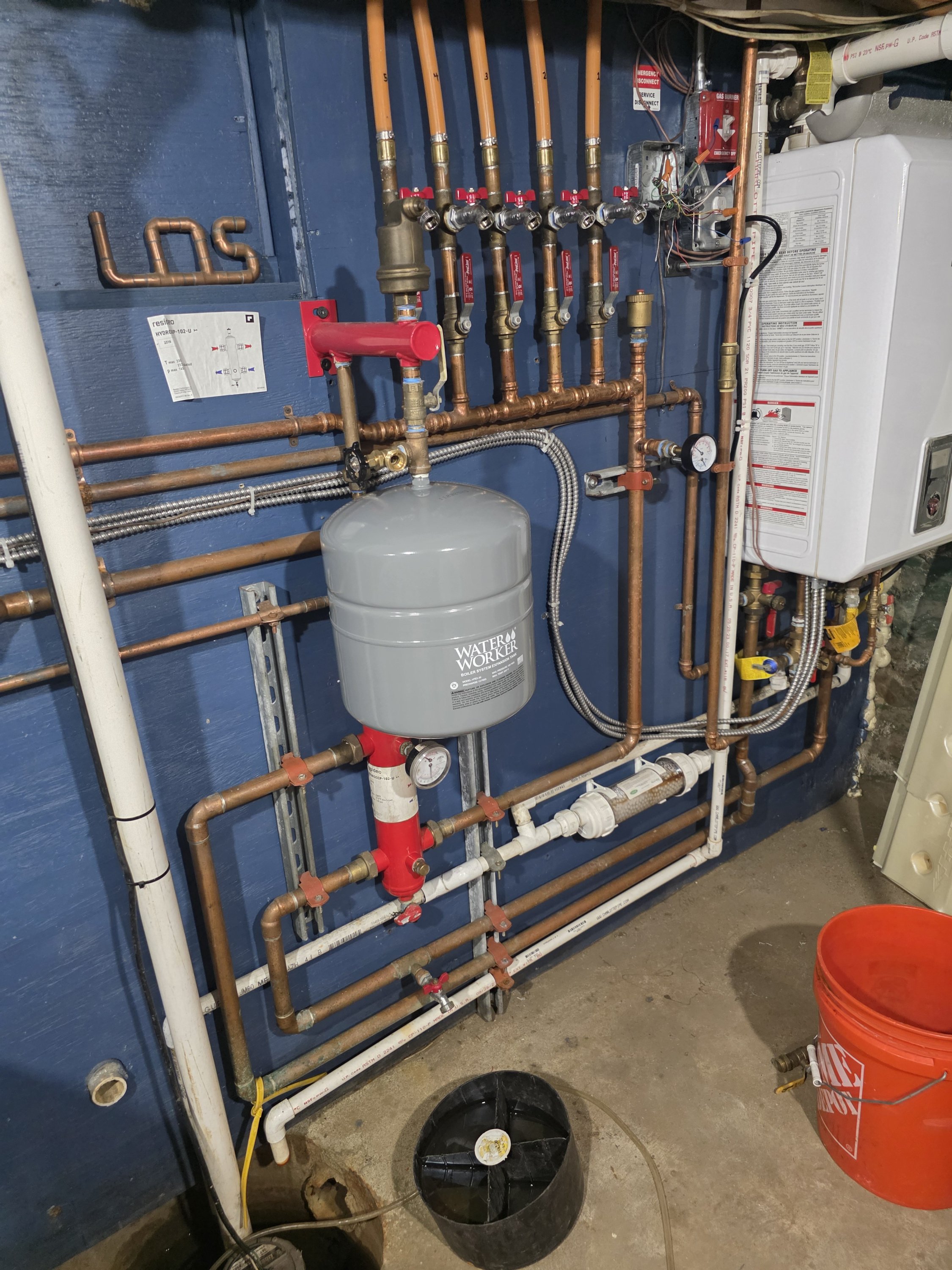

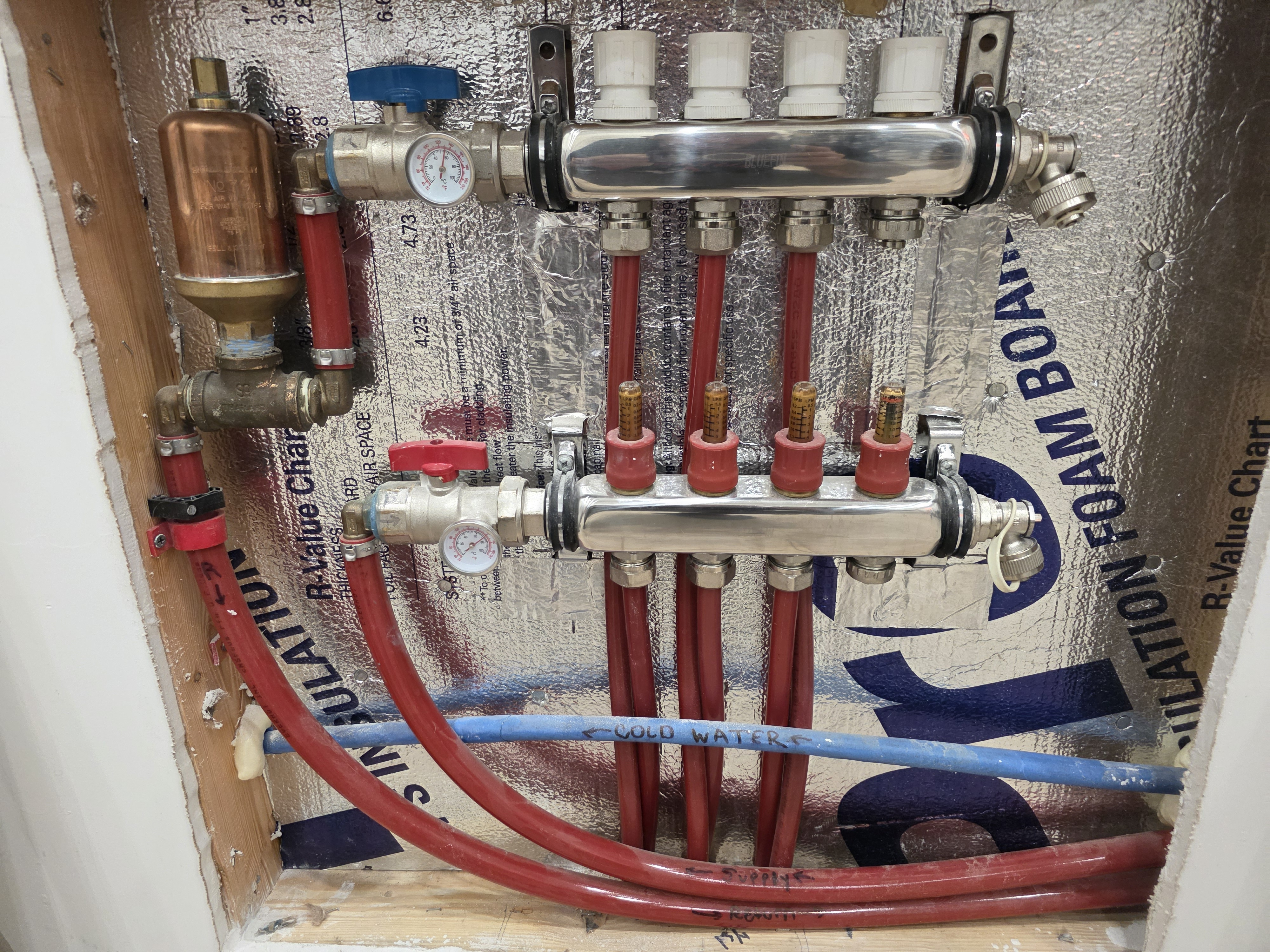

We have enclosed our deck and completed an extension to our home. The lattice around the base of the deck was removed, and we framed, sheathed, and stuccoed the area to create a foundation-like appearance. For insulation, R30 was placed between the floor joists, and then 1-inch foam board was nailed to the underside of the joists. The existing pressure-treated decking was retained. An aluminum vapor barrier was installed over the decking, and 2x4s were placed 16 inches on center on top of the decking. This provided the necessary height to align with the level of our home's entrance. The extension measures 16 feet by 32 feet. We utilized aluminum heat transfer plates securely fastened to the decking. There are three loops in total, each constructed with 1/2" PEX tubing, and no single loop exceeds 300 feet in length. A manifold is situated within the wall of the extension, with 3/4" PEX main trunk lines (for supply and return) feeding from the boiler into this manifold. This zone is equipped with a Taco 5004 mixing valve and a three-speed circulator pump. We installed 3/4" plywood over the 2x4 framing. While the room's thermostat indicates that the heat is functioning and the temperature does increase when activated, the floor itself does not feel warm to the touch. I have observed other radiant heating installations where the floor temperature registered between 70 and 80 degrees and felt noticeably warm. Currently, my mixing valve is set to approximately 140 degrees, and the return piping registers around 110 degrees, resulting in a delta T of 30 degrees. I am considering whether increasing the water temperature or even removing the mixing valve might help the floor feel warmer.

Any suggestions or assistance would be greatly appreciated. Thank you.

Comments

-

-

The drywall and plywood sheathing are all done. The whole area is about 550 square feet and is being turned into a bedroom and a master bathroom. We're using marble tile in the bathroom, but I'm not sure what kind of flooring to go with in the bedroom. Any recommendations, looking for something that work best transfering the heat? Hoping to be able to get the floor temperature up to at least 70 to 80 degrees

0 -

hard surfaces are best, concrete, stone, tile, for radiant . Hardwood works well. I like a thin engineered wood for good stability and good heat transfer.

The floor surface temperature needs to be above the room ambient temperature. So if you want the room at 70, the floor surface will need to be above that to warm the space.

The control for the system. A basic wall thermostat?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

-

-

-

the tube and plates will heat those channels and transfer heat upward. It may take a high temperature supply like suspended tube methods.

How you get the surface to 80 degrees does matter as much as if you can get the floor that warm. Lots of glass on the one end is the biggest load.

How well it heats depends on the heatload of the spaces, I suppose.

Looks like no going back at this point. Anxious to know how well it heats.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I'd drill a small hole in the plywood and measure the air temperature on the underside with a probe thermometer. The floor assembly is probably about R1.75, to get a surface temperature of 80F with the room at 70F the air under the plywood has to be at 105F.

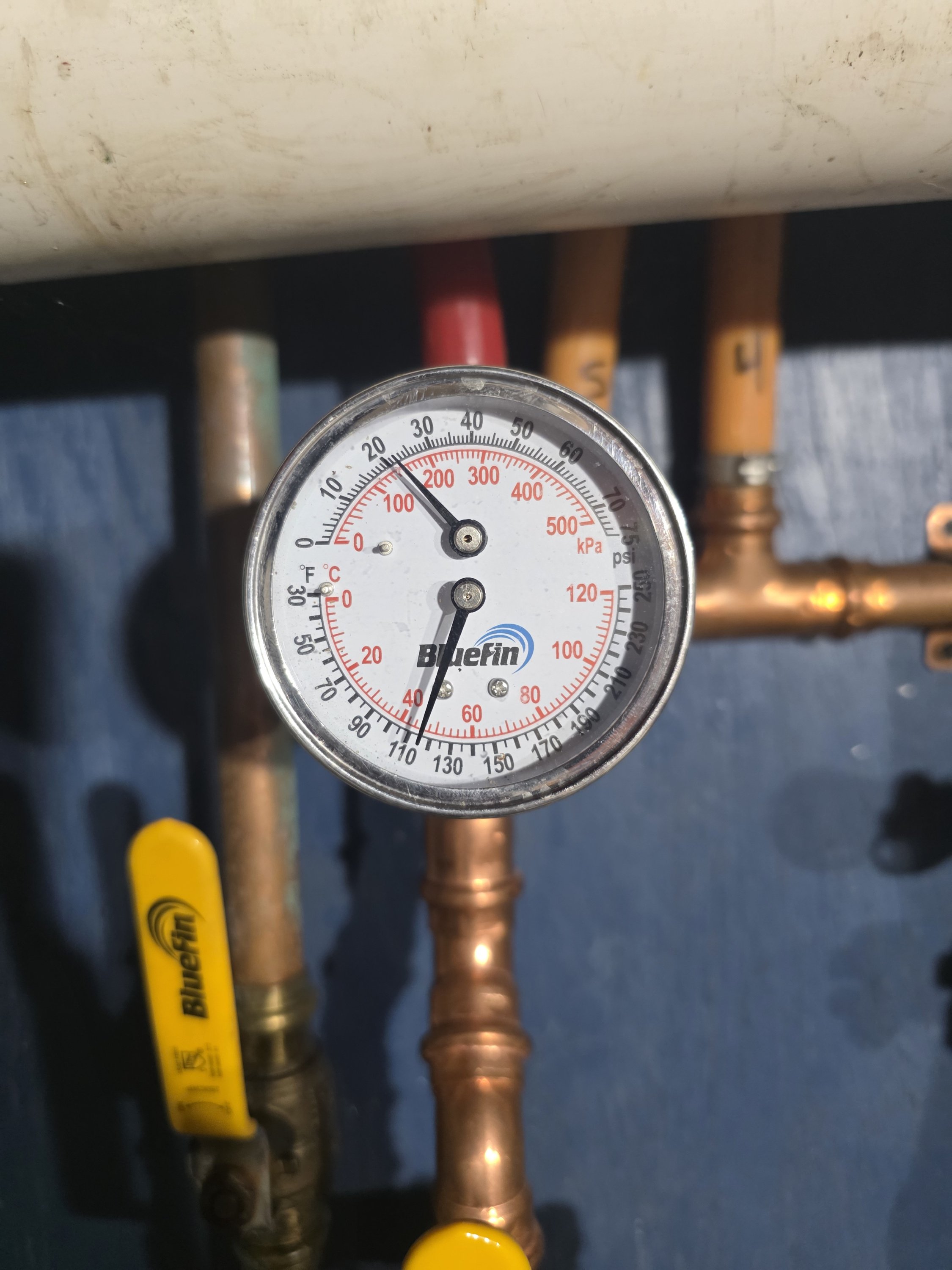

The water temperature is dropping a lot — 130F to 110F — so either a lot of heat is being delivered, or the water flow is very low. Measuring at both ends of the loop might give an idea. If you have good heat at the hot end of the tubing it might just be you need to increase the flow.

2 -

RFH does not always mean a warm floor. If the desired ambient air temp is 70 and the heat load is 15 BTU per square foot, a 77.5 degree floor is going to meet the load. A warmer floor is going to overheat the space so the only way to have that cake and eat it too, is raising the heat load (I.e. opening windows or similar). This is a regular complaint with high efficiency homes

3 -

What you have is a little like a joist bay heating application. The flooring doesn't actually contact the tubing in this install so what you are relying on is to heat the air space between the tube and the floor, and that hot air is what will heat the floor. It will work but is more a medium or high temp application than a low temp radiant floor. With a 30 degree delta T that does show us you heating something, if that heat doesn't end up in the room I might look at where it is going. The good news is that you can definitely make it work, it will just be a slightly higher temperature supply that you need.

1 -

Hello, and thank you all for your contributions. The room is equipped with its own thermostat, a Nest 4th generation.

The room does eventually reach the thermostat's set temperature, however, it takes a considerable amount of time to do so. Given that the heat transfer plates are not directly affixed to the subfloor and I am relying on hot air to heat the area beneath the floor, I am considering whether I should remove the mixing valve and operate it at 180 degrees?

0 -

-

-

-

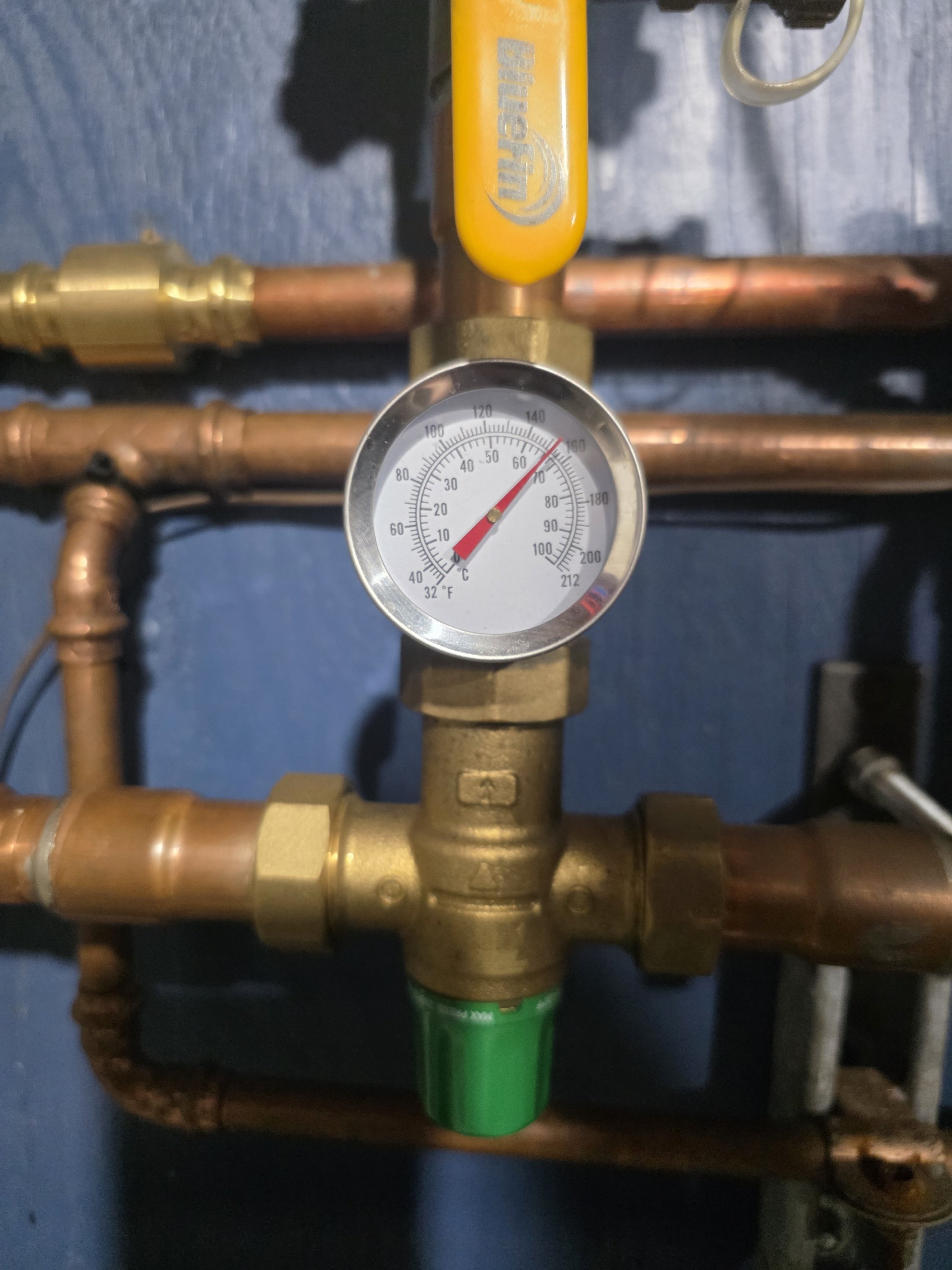

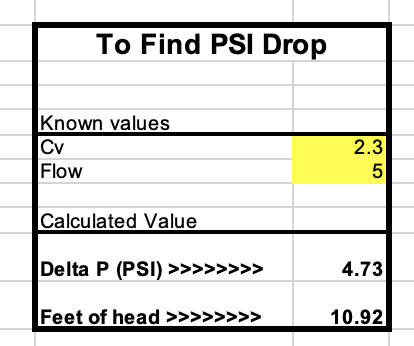

Hey, thanks for getting back to me so quickly. I actually cranked the mixing valve temp to max. I've got the Taco 5120 union and temp gauge on the mixing valve, but I'm not seeing the water hit that 175 degrees. It only gets up to about 150, I'll have to check it again this weekend when I'm back by the system. And yes, the mixing valve is a 2.3 cv valve.

0 -

what is the temperature going to the mix valve? H port?

Do you know if that valve has strainers on H and C?

I typically discard them when using a mix valve on hydronic system.

A lack of flow reduces heat output, just as a lack of adequate temperature does.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

The water temp on the H port of the mixing valve is set to 180 degrees. I don't think there's a strainer in the mixing valve, but I'll open it up to check, I think there might be a check valve inside. I also know the circulator pump has a check valve. I'll be back by the boiler this weekend to double check everything. Again, thanks for your help ☺️

0 -

remove the checks. Usually if there are checks, there are also strainers. The strainers may be built into the union washers.

Measure the temperature at the H port, it needs to be a bit higher than the mix outlet you are trying to get. You cannot get to 175 if the hot is only 180. It varies from valve to valve, usually the hot needs to be at least 10 degrees hotter than the mix that you want

But I’m not convinced you need to go to 180. Ultrafin, suspended tube (joist bay heating) those can run 140- 160 temperatures

if in fact you do need over 160, get rid of the mix valve. You get higher temperatures and much higher flow potentialBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

-

-

I have a Navien boiler, and I believe the temperature for that zone is set at 180 degrees. I will measure the temperature entering port H. Additionally, I will inspect the mixing valve for any strainers or a check valve by opening it. I may also consider removing the mixing valve. I will provide an update over the weekend. Thank you for your assistance.

0 -

I have installed several types of radiant systems; one like yours with soft aluminum pans but stapled-under-floor using 7/8 PEX with R-19 below in the joist space, foil up. That house has 1/2 subfloor, 5/8 underlayment and commercial vinyl tile. Has worked well since 1991.

Another very recent house has Uponor extruded aluminum double channel pans per bay with 1/2" PEX screwed up under the floor. R-19 below, no foil. I'm struggling to get this house to temperature but think it's more of an infiltration problem (old house). In this house I'm seeing mid to high 130's feed temps and 90-100F return temps. I've been shooting the floor surface with a hand-held IR gun and getting 72-80F surface temps. The 80F surface temp is probably too high from what I've read (feet sweat) but like you, I am trying everything to get the room temp up.

I thought these numbers might help you but we have different problems. I don't like your air space and I know you don't want to hear this but I would have filled that space with gypcrete or something that would take the heat from your pans and transfer it to the floor surface. Your insulation under the system is great. Buy or borrow an IR gun and shoot around to see your surface temps. C.

1 -

Hey, quick update. I took out the mixing valve. It didn't have a strainer, but it does have built-in check valves on the C & H ports. Should I try taking out the check valves?

Also, the mixed water going to the zone temperature hit about 152°, and the return temperature was around 115°.

0 -

I would leave the checks out, no need for them in a hydronic loop.

You need to let a hydronic system run for a while to get an accurate operating delta. It typically starts wide when the distribution system is cold.

The higher the mass or under heavy heat load, the longer it will take to stabilize.

when the supply and return temperature stabilize, stop moving, then your are at hydraulic equilibrium. That will be actual operating delta. It will always move some as the load on the room changes.

Residential radiant designs are in the 10-15 delta window. The tighter the delta the more consistent the floor temperature will be.

The main motivation of any heating system tends to be to satisfy the wall thermostat setting. That may or may not = warm floors

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

Thanks Bob, I appreciate all the info. I had the heating system running for a while with the mixing valve and didn't see much change in the delta window.

Before your last message, I actually just took out the mixing valve. I just turned on the system, going to keep an eye on the return temp. The supply temp is set at 180.

0 -

You are sure the washers didn't have strainers in them? Are they black rubber or a hard fiber type?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

Hey Bob, no strainers in the washers. They were the black rubber type. Here's a picture

0 -

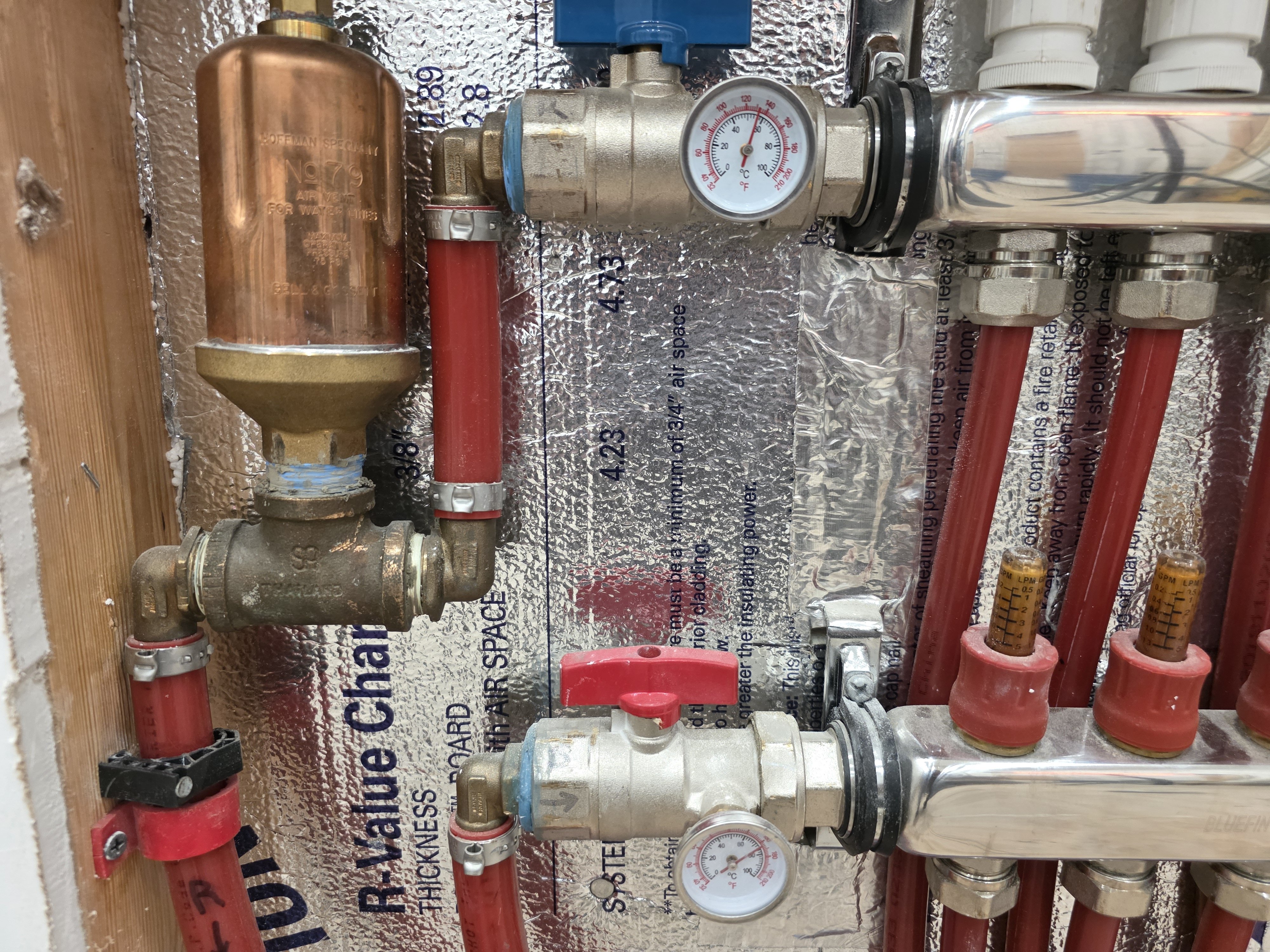

Here is a picture of the manifold, following the removal of the mixing valve. The water temperature is now considerably higher. The water actually reached 180 degrees Fahrenheit on the supply, with approximately 150 degrees Fahrenheit on the return. However, I have not yet observed a significant increase in the floor temperature. I have ordered a thermal imaging camera and am awaiting its arrival so I can obtain some readings of the floor temperature.

0 -

An interesting law of physics may be at work here. 140F temp on radiant floor, could be good or maybe too much. When floor temps go up so does the room air current speed up which in essence drops the floor surface temp a few degrees. This has been documented. Now there are many factors at play, but many different factors can produce the same results or varied results. Lower temps may need more emitter surface, but less surface more temp. not to mention how this space interacts with its building spaces and uses. but is the goal here to have toasty feet, or a satisfied thermostat, or both. Its all in the design and choices we make between staple up, in floor, surface of floor or between joist spaces with sheet fins. All in all there must be dozens of choices that go into building a heated floor or space. Remember the old floor furnace in the center of the foyer running on gas or kerosene without electricity? It was a very cost efficient device when you consider all we do today to a heat system. I'm still a fan of a Fireplace and Wood stove. Always works when the power is out.

0 -

-

^^What DC said above…..^^

I went through this years ago with my slab.

I was sold the "warm floors" pitch and all that. When we fired the system up, and set the thermostat to 68, The floor slowly warmed up to 69 degrees or so, the thermostat kicked off and it was done. 21 years later guess what? As I am typing this the room temp is 68 and the floor is 69 degrees lol. And it is cold to the touch. In the beginning, I thought the same thing as the OP. Somethings wrong. Nothing is wrong. If I run my floor above 70 degrees for any amount of time the floor will get warm, but guess what? It will run you completely out of the basement. The heat load for my basement doesn't dictate the floor needing to be above 68 degrees. If the OPs thermostat is being satisfied in a reasonable amount of time, its working correctly.

1 -

well yes…. If the floors are your source of heat, and you like the air temp at 68, and its kept at 68, if you were to get the floors warmer than they already were it would raise the air temperature. warm floors are a heat emitter, the hotter the floor the hotter the temp in the space. I have run into this on a couple occasions but its pretty rare, when a customer wants the floors kept at 85 all year but the air temp to be 68… If you want hot floors install a floor sensor and run the stat based on the floor temp not air temp, fair warning the space will probably be hotter than you want it.

1 -

-

-

I understand. Do you believe a larger circulator pump might be necessary due to the head pressure? I have approximately 900 linear feet of piping in total. Is it possible that the pump is undersized, which could be contributing to the significant difference in Delta-T?

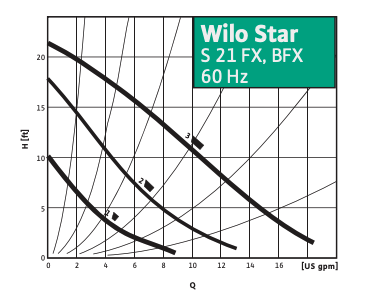

The circulator pump I am currently utilizing for this radiant loop is a Wilo Star 21. My boiler is a Navien model NCB-250/150H.

I have been conducting some research and have gained some understanding regarding GPM and head pressure. I am considering whether it would be more beneficial to keep the mixing valve and operate the system at a lower temperature. I'm guessing a good pump size will give me the right Delta-T. I suppose I'll just have to deal with the system as it is, instead of having warm floors.

0 -

What size loops and how long are they. How many loops?

Typically around 1/2 gpm per 1/2" loop 250 -300' max length.

So the number of loops X 1/2 gpm = the total gpm the radiant needs.

Lets assume 10 loops, so a 5 gpm total gpm

With a 2.3 Cv valve flowing 5 gpm, the pressure drop is around 11' head. That is about the high side of flow through that mixer

Here is the Star 21 pump curve. Enter the bottom at 5 gpm, run up to see about 17' head. So you should have plenty of pump for 5 gpm or so. If there is more restriction in the piping, that drives head up, gpm down.

You want to measure the delta after an hour or two of continuous running. The delta will start out wide on a cold system, cold rooms, cold fluid. As the room warms the delta will close up, the load is dropping down. Somewhere in the 10- 15 delta is a common residential design delta. The system may never get to an exact ∆ number you calculate. It's the room load that drives the delta.

Here is the math if you have some accurate numbers looks like this 500 X flow X delta T

So if you are moving 5 gpm 500 X 5 X 30°= 75,000 btu/ hr being transfered to the zones.

As the room warms, delta decreases to say 10° 500 X 5 X 10= 25,000 btu/hr being delivered. Delta dropped due to the room warming, the load decreasing, see the bold printed sentence above.

But really the goal is to satisify that on/ off switch on the wall, the thermostat. If you set it to 70° and the room gets to 70° the job is done. The floors may or may not "feel" warm during this process.

If you have some stable actual data plug it into the formula.

Do you know the heat load of the system in BTU/hr?

Do you know how many gpm is needed to cover the load?

Do you know system head, based on piping loops and mix valve?

Do you have some actual ° readings after running to steady state condition.

Without a few actual pieces of data there is really know way to know if your system is operating properly, satisfactorly?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Repost: If the room is reaching the thermostat set point, the thermostat is cutting off the flow of water. That means the floor is putting out enough heat to meet the heating load, that's as warm as the floor is ever going to get.

Everything else is a distraction.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements