American Standard Acroliner - varying hot water temp

Hi,

Hoping the community can provide some insight on this old Acroliner tankless water system. The last couple of days, the hot water in the shower and sink would start off with the normal hot temp, then few minutes later, the temperature cools.

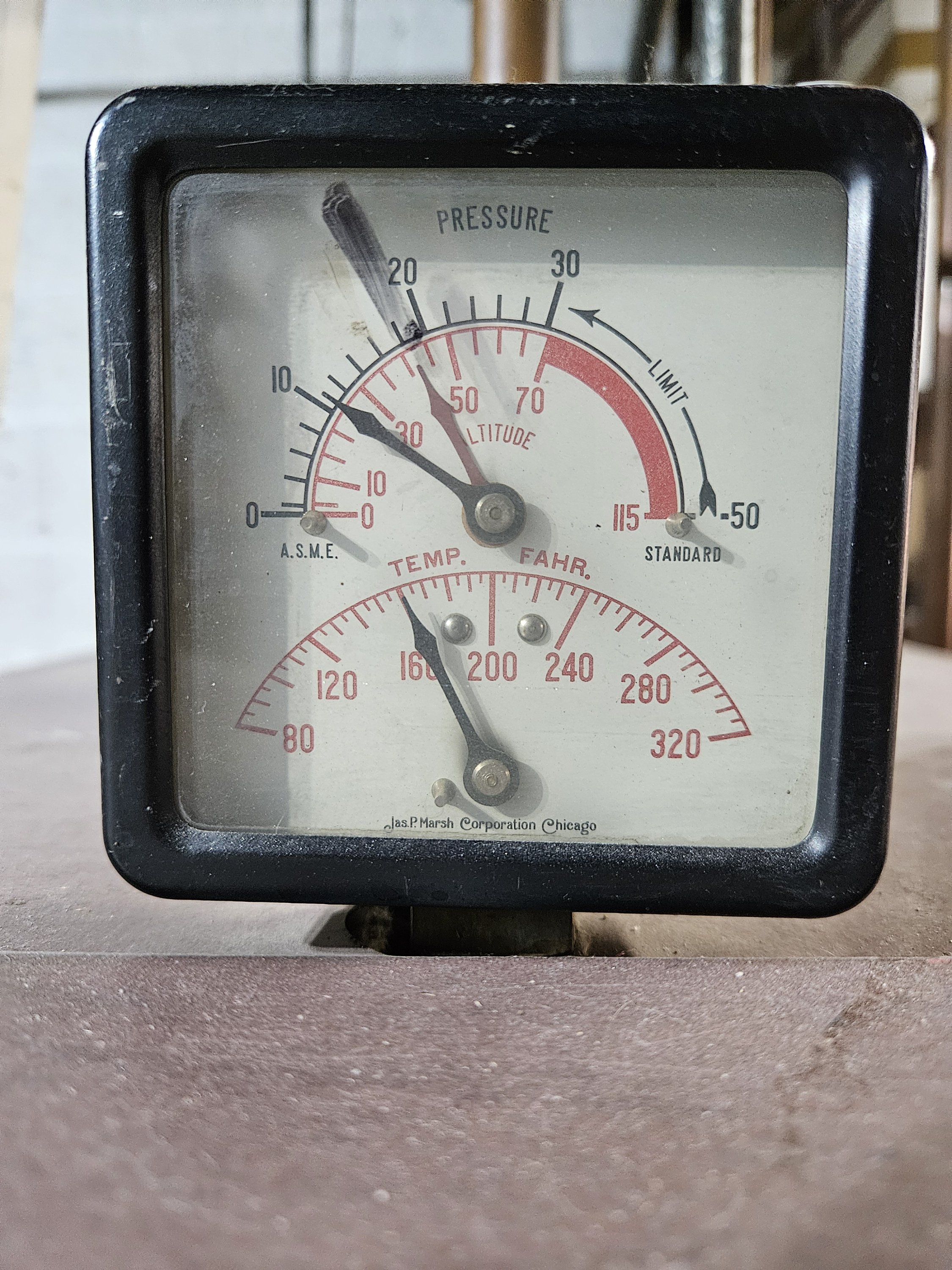

The pipes feel warm. 1/4 tank oil. Burner has fire, gauge needles havent changed. What could it be? I was thinking its the water sitting in the pipes but for how long its run, it should have already removed it all.

Any ideas?

Could it need a cleaning? Descaling? Also if anyone has any info on how to maintain this boiler, any info is appreciated!

Also, the water hasnt been turned on since 8am-6pm, but this has been a pretty normal routine.

Thanks

Comments

-

is the boiler set up as hot water or steam? i'm thinking the boiler is low on water so the coil isn't fully submerged.

or the low setting on the aquastat isn't working right. or the heat call keeping the boiler at the heating temp was making more hot water

0 -

thanks for chiming in Mattmia2. It looks to be setup for hot water. It has an expansion tank.

my googling did bring up the aquastat but have not read up on it yet.

I am mechanically experience and logical so anything I can do, I will. Anything you guys explain and say leave it for the pros, I will, most likely. An explanation of the dangers and consequences is appreciated. It is really for my understanding.

Thanks

0 -

0

-

There may be two things going on here. The first problem may be that the mixing valve is no longer operating properly. The second may be that the coil may have some scale build up on the potable water side of the coil. That will need to be cleaned. It does not appear to have the necessary fittings and valves in order to do the cleaning, so I would wager that the cleaning has never been done.

I also believe that the tankless coil is not the original. Since it may be only a few years old. I would tighten up on the flange nuts in order to prevent the gasket from leaking. They should be snugged up after 500 hours of operation and again after 1000 hours of operation. I hope that is is not too late to get that done.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

Thanks For the info guys. The thermostatic mixing valve - if thats the black knob on the bottom left, then yes, not turning. Im afraid of breaking it. It wont budge.

<Edit> - yes that's the Thermostatic valve according to Google. Any suggestions on unsticking it? My first thought is heat but given the solder, I dont know, and don't think that'll work for scale build up <end edit>

Any good way to test the aquastat? When I was talking to our oil guy, he said they made a line at black line and the current used mark. He said one was set for hot weather and one for cold?

The potable water side coil cleaning. Whats the process? Like flushing a heater core/radiator with cleaning solution in one and out the other, or unbolting those7 bolts and taking out the unit?

0 -

If you look at the controls just above the burner (sometimes inside an extended metal jacket with a metal front door), you should see three separate controls:

- High limit control

- Reverse (circulator) control

- Circulator relay (also operates the burner on a call for heat) Sometimes on the wall near the boiler.

Another control is attached to the coil flange plate

- Operator control is installed in the coil flange plast as you have pictured may not be inside the boiler jacket

High Limit Control

The high limit shuts off the burner if the boiler water temperature gets too high.

This is usually set at 180°F or 190°F.If the boiler temperature reaches that setting, the burner shuts off regardless of other demands.

Reverse Control

The reverse control is so named because it makes on temperature rise and breaks on temperature fall — the reverse of a high limit.

It is commonly set around 140°F.

Its purpose is to give domestic hot water priority. If the boiler temperature drops below its setting, it shuts off the circulator pump to prevent sending heat to the radiators. This keeps enough heat in the boiler to maintain adequate hot water for the tankless coil.

Circulator Realy

The thermostat is usually connected to this control. The burner is also connected to this control and the circulator pump is connected to this control

On a call for heat the burner will operate as long as the water temperature in the boiler is belos the high limit setting

On a call for heat the circulator pump may operate as long as the boiler water temperature is not below the minimum reverse temperature control setting

Operating Control (Tankless Coil Control)

The operating control is usually installed in the tankless coil flange plate.

It operates the burner in a similar way to a thermostat, but it only controls the burner — it does not operate the circulator.

It typically maintains boiler temperature between 150°F and 160°F:

- Burner cuts in around 150°F

- Burner cuts out around 160°F

This keeps the boiler hot enough year-round to provide domestic hot water.

Why You May Be Getting Colder Hot Water

Possible causes include:

- The coil may de scaled

- The mixing vave may be failing

- The reverse control set too low

- The operating control set too low

- The high limit set too low

- A combination of these

Summer Operation (No Call for Heat)

- The boiler maintains approximately 150°–160°F continuously.

- The tankless coil sits in the hot boiler water.

- The domestic water in the coil reaches boiler temperature (which is scalding hot).

- When you open a hot water tap, very hot water leaves the coil and reaches the mixing valve.

- The mixing valve blends in cold water to deliver about 120°F to the fixtures.

- As water flows through the coil, it has less time to absorb heat and may leave at a slightly lower temperature.

- The mixing valve senses this and reduces the amount of cold water it adds.

- As boiler temperature drops, the operating control turns the burner on to restore the boiler to 160°F.

- The burner may cycle several times during long hot water use.

Winter Operation (Call for Heat)

- A thermostat calls for heat.

- The circulator runs and sends hot water to the radiators.

- Cooler return water from the radiators lowers the boiler temperature.

- If the boiler temperature drops to the reverse control setting (around 140°F), the reverse control shuts off the circulator to protect domestic hot water production.

- The burner continues running to raise the boiler temperature.

- When the boiler temperature rises again, the reverse control allows the circulator to restart.

- This cycling can repeat several times during a long call for heat.

- If the boiler temperature rises to the high limit (around 180°F), the burner shuts off, but the circulator continues to run until the thermostat is satisfied.

During the entire call for heat, someone can take a shower without losing hot water because the reverse control prevents the system from sending all available heat to the radiators.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Hi, About that tempering or mixing valve… Have someone run water while you feel the cold supply to that valve. If it cools down when water is being run, you know it's cooling down the hot water. Also feel the outlet of that valve and see what sort of temperature you're getting. If it's too cool for showering, that's a problem to fix. Those valves can be taken apart with Channelock type pliers by grabbing the ribbed brass piece which is directly under that black knob. Inside on a spring, is a wax driven element which often sticks open. You can get by with a squeeze of the pliers to depress the rod some back into the copper body. Use a little teflon tape on the fine threads of the brass piece before putting it back together.

Yours, Larry

0 -

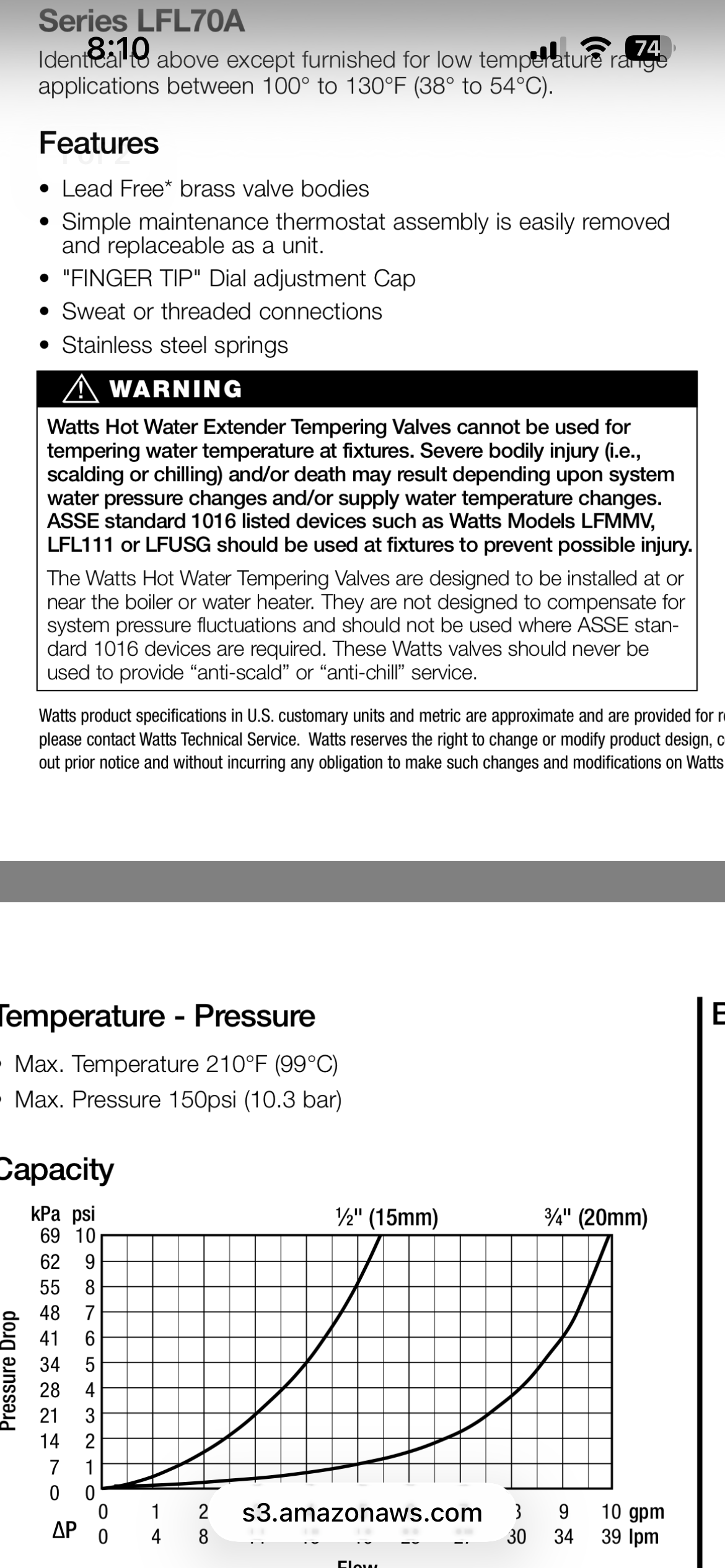

Thermostatic valve according to Google. Any suggestions on unsticking it? My first thought is heat but given the solder, I dont know, and don't think that'll work for scale build up

This is the install and maintenance instructions for that valve: Watts 70A valve and this is the replacement temperature sensor: Watts 70A Repair Kit.

Any good way to test the aquastat? When I was talking to our oil guy, he said they made a line at black line and the current used mark. He said one was set for hot weather and one for cold?

That was a thing that some people did to lower their fuel usage in the summer. You should be fine at 160° if the control is still accurate after 70 years. It probably is.

The potable water side coil cleaning. Whats the process? Like flushing a heater core/radiator with cleaning solution in one and out the other, or unbolting those7 bolts and taking out the unit?

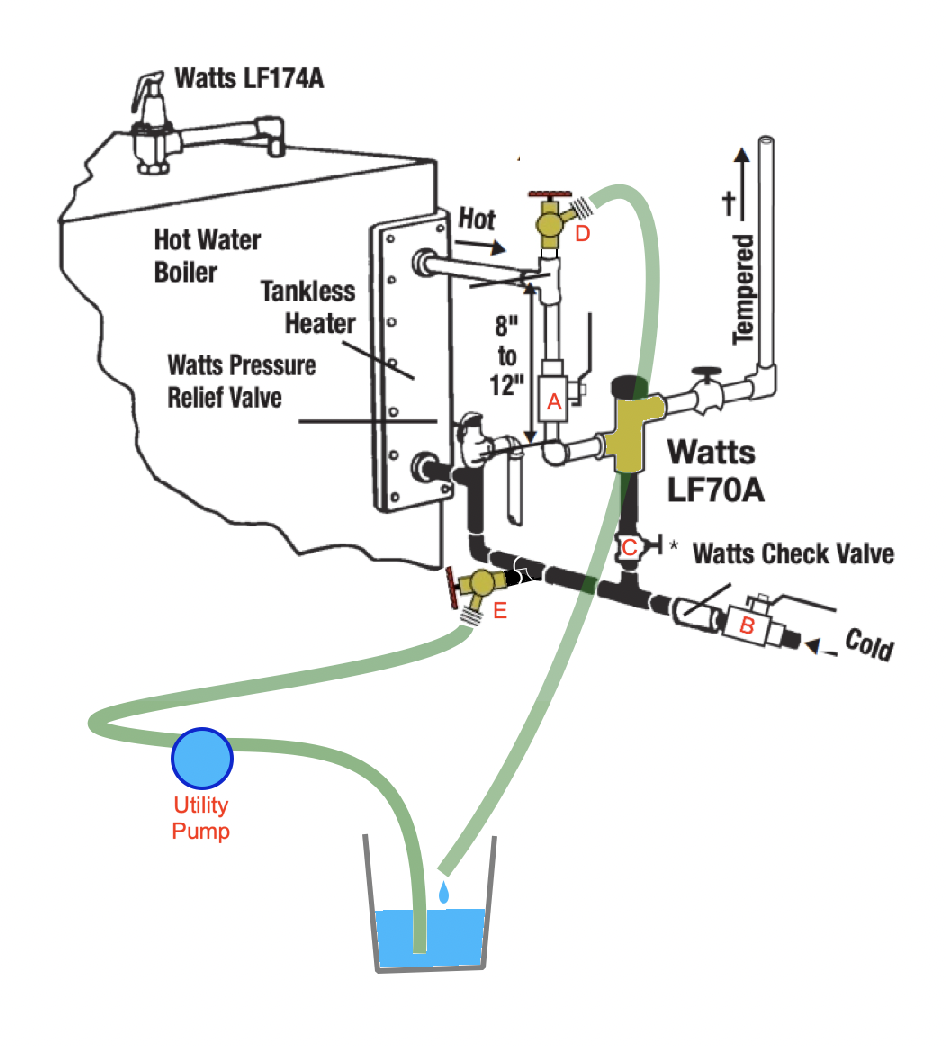

That will involve adding some valves to that coil so you can pump a cleaning chemical (mostly vinegar) thru the coil for about 30 minutes. That procedure is done with the coil in place on the boiler so you do not need to remove it.

Piping diagram to follow:

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

-

This is the piping arrangement you ahould be looking for. You should already have Valve B. You may need to add Valve A and C. Then you must add draw off valves (also called boileer drain valves) D and E and get an inexpensive utility pump. We used to use a really economical pump that you attach to an electric drill.

Close valve A B and C then attach hoses as shown to D and E and open those valves. Pump the cleaning chemical thru the coil for about 30 minutes. Then close E and open B to flush out the chemical. close D whan the water runs clear and open A and C. You should be good to go.

Agree with @hot_rod on upgrading to a ASME 1070 listed valve while repiping for the flushing valves

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

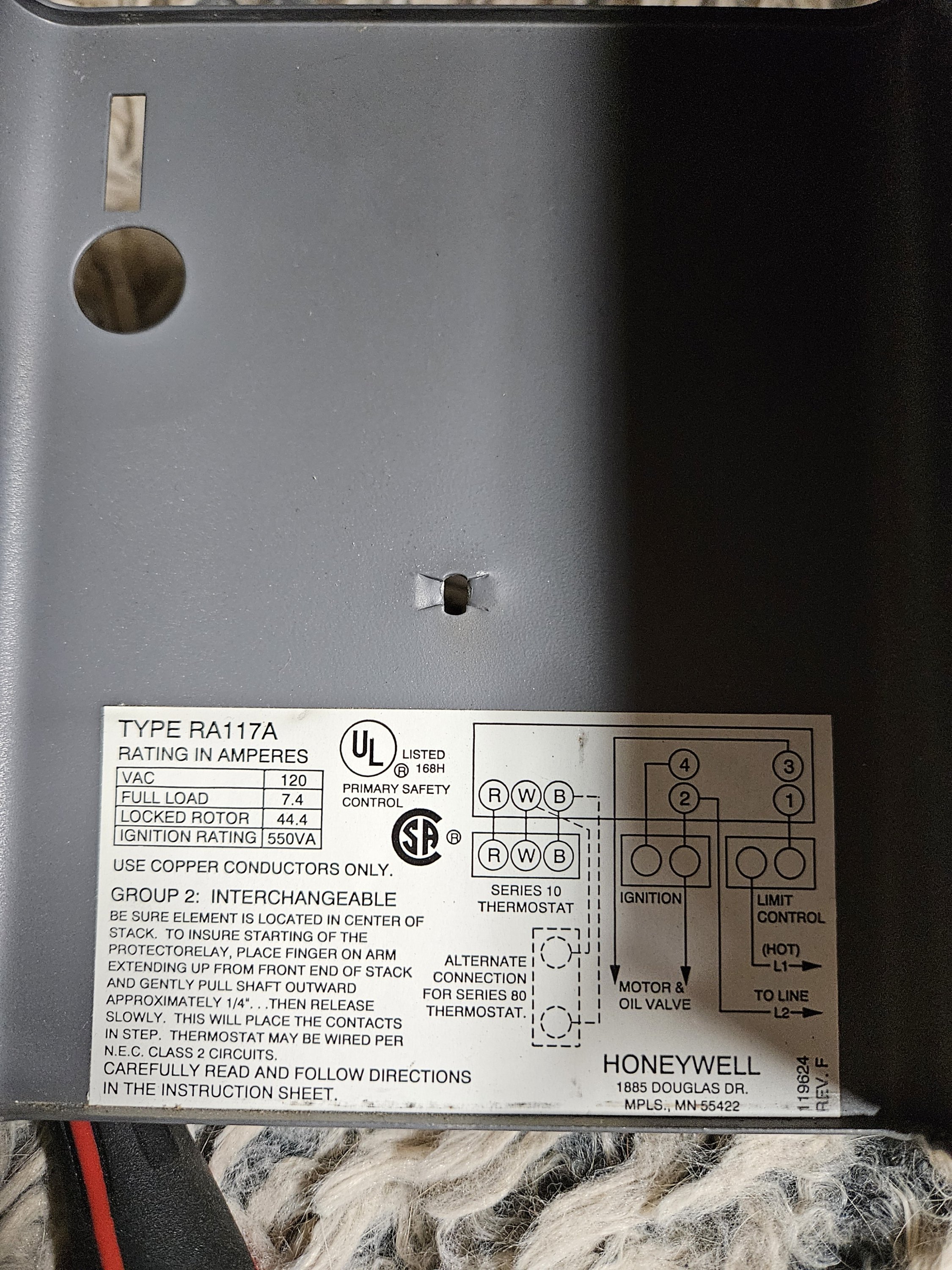

Thanks Ed for this information on how this all works! I think Ive located most of what you mentioned

High Limit ControlThe high limit shuts off the burner if the boiler water temperature gets too high.

This is usually set at180°F or 190°F.Looks like this may be it

Circulator Realy

Here is the cover and the diagram

Operating Control (Tankless Coil Control)

Havent found anything indicating another temp settings for reverse control. The other possibility is this

Thanks Larry for the advice and instructions. I went ahead and tested. Water has not run in a couple hours. I touched the output from the mixing valve and it was a light warm. Went to turn on the hot water and got hot and stayed hot. Going to be taking a shower later on to see what happens.

Thanks Ed for the link to the part and it's rebuild piece that will come in handy, and the diagram. going to have to practice my copper pipe solder skills and determine if is going to be my first copper pipe project. Got discouraged the last time I tried. It was up between the floor joists and next to a pvc radon pipe without all the proper tools so wasnt the most favorable setup.

Thanks Bob for the info on upgrade. Im in MA. I will add that to the list if it gets repiped for valves.

0 -

WOW… you still have an RA117A primary safety control? That is obsolete and has poor safety performance. You should think about removing that from the system completely if it is still connected. Replce it with a much safer primary safety control like the Carlin 70200 PRO. It is a much safer control for your oil heat system, and it should be installed by a professional.

The black covered box installed just below the vent connector (smoke pipe) is your circulator/burner relay. The thermostat wire connects tothat control and should turn on the circulator pump and also the oil burner by way of the RA117A primary safety control, Honeywell called the primary safety control a "Protectorelay®". I would strongly recommend upgrading that control. The Honeywell version of the Carlin 70200 is the model number R7184U protectorelay. But I would still recommend the Carlin control because it has the most safety and diagnostic features.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

these kits make it super simple to delime coils and water heaters

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements