Two boiler repipe for primary/secondary

When this heating season ends in a few months I'm going to try to implement @EdTheHeaterMan 's good suggestion to repipe our 4-unit condo building's two WGO-5 hot water boilers as primary/secondary. The existing setup has one boiler heating the #7 side of the building, and the other heating the #11 side. Both boilers are massively oversized, and either one could heat the entire building by itself. On a design day, the entire building could be heated with an input of 0.7 gph, and they both now run at 1.2 gph each.

Repiping as primary/secondary would allow us to run just one boiler and leave the other idle. We could switch over annually to alternate the boilers and thereby extend their lives. They're already 30+ years old but still could have another 10 years in them. Then if one boiler fails, the other boiler is available as backup. Eventually one or both boilers would be replaced, and the primary/secondary piping would already be in place.

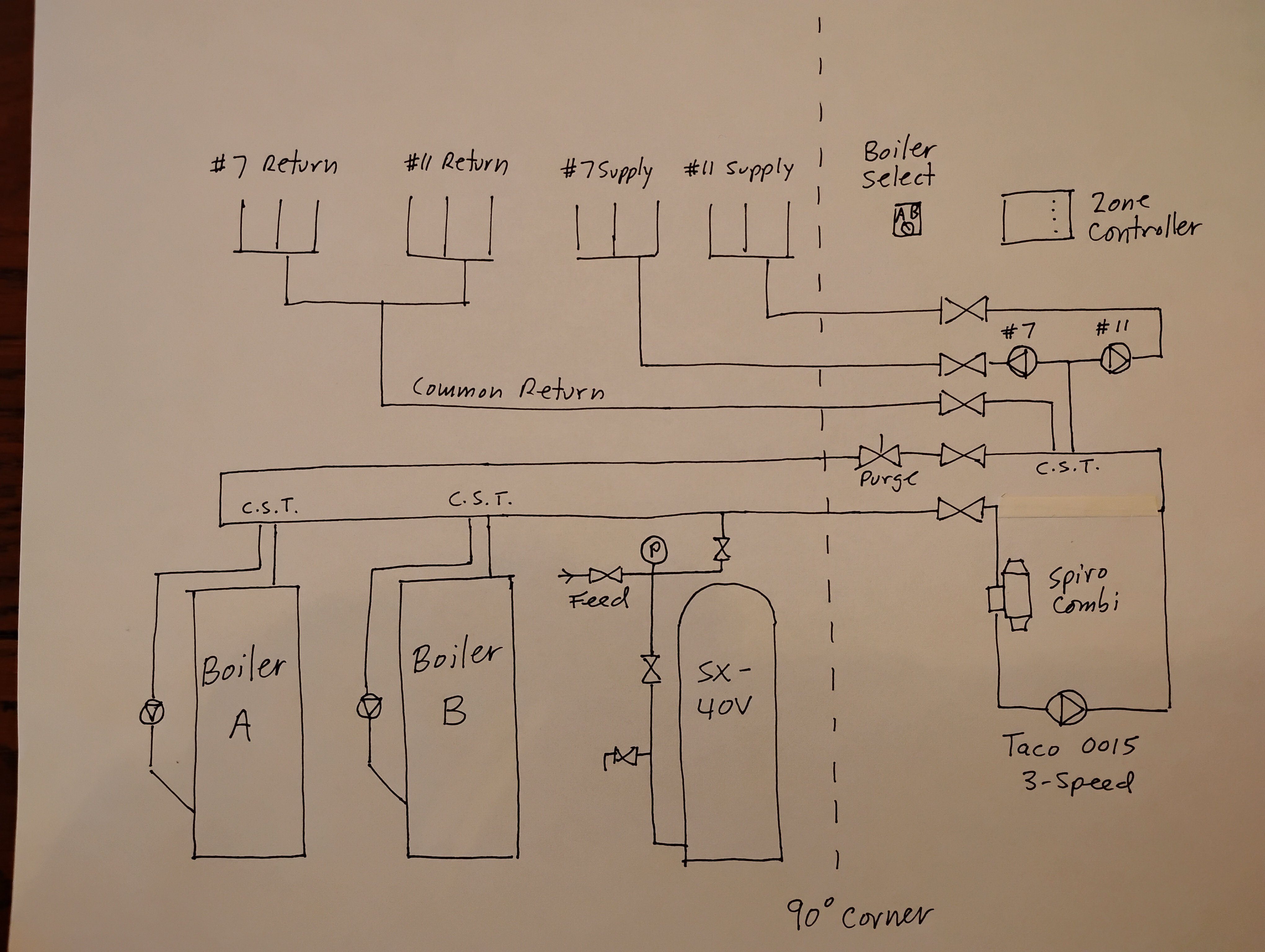

Following is a proposed diagram based on what Ed drew for me a few years ago. There's not enough room above the boilers to fit all the primary/secondary piping, so I would run the primary loop around a 90 degree corner beside the boilers and put a plywood mounting panel there with more room for all the pumps, etc.

If this looks reasonable, I will start planning and trying to convince the other owners to spend the $$ to implement. I already tried once and they balked, but I'm going to try harder this time and sell the benefits of not having to replace a boiler when one conks out because we'll have a spare capable of heating the entire building.

The zone controller would run the primary and secondary circulators. The boiler aquastats would run the boiler circs, as is the case now. A selector switch would direct the zone control output to the desired boiler, and the following year we'd switch to the other boiler.

Comments

-

-

In that scenario it wouldn’t matter, but what about down the road when they could be cascaded with two properly sized boilers?

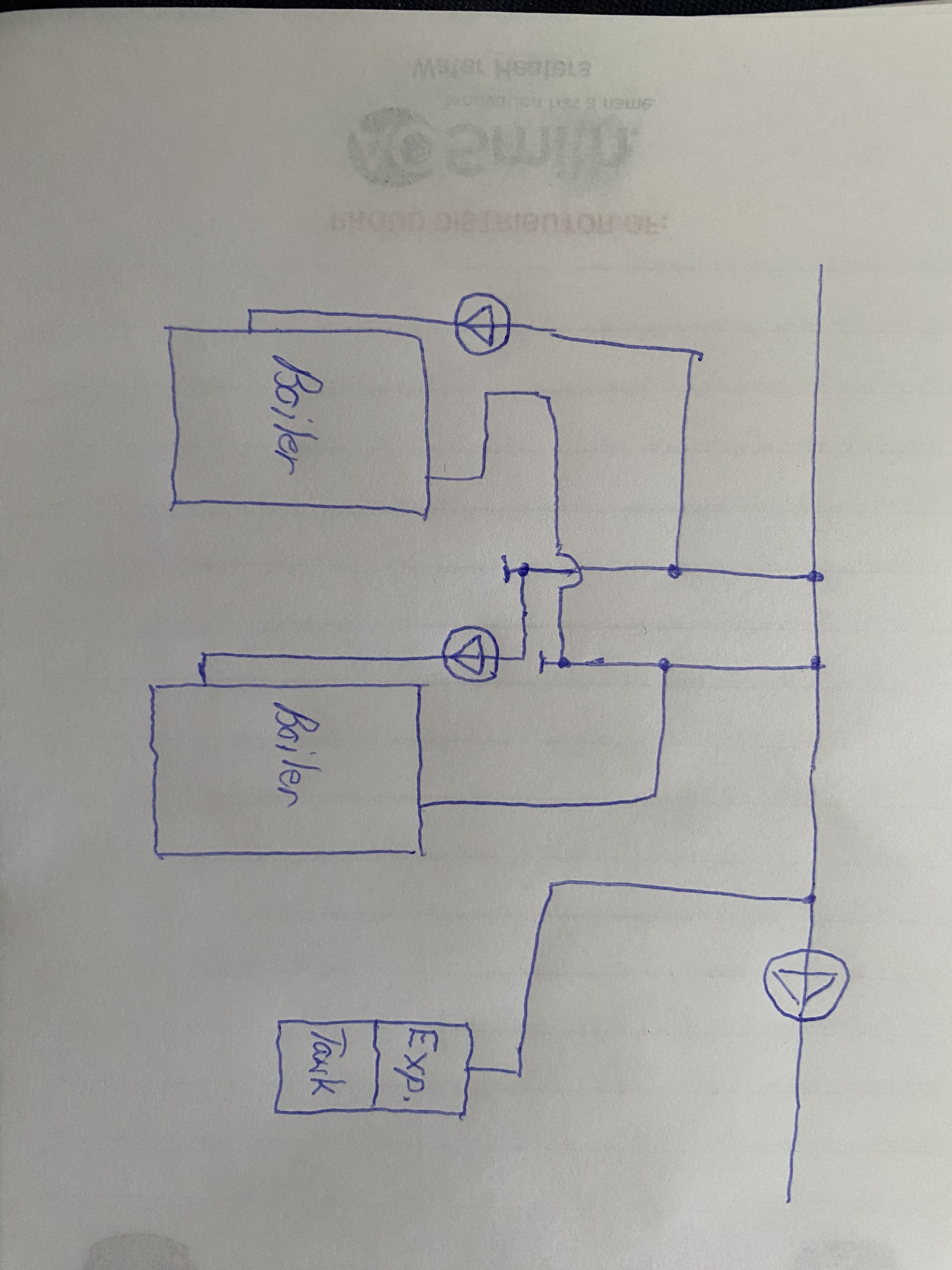

There’s really not much different in what’s involved to do them p/s parallel .

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

I thought of that also @109A_5, However in the future, you may want to replace a failed boiler with one that can handle only 60% to 70% of the load. Then you can save even more on 85% of the winter months. Only when the “new smaller boiler” can't handle the load will the original boiler be turned on, and the new one turned off. Eventually you will have two boilers that can only do 60% of the job when the second original WGO fails, and you have two smaller boilers that only need to operate together for 15% of the heating season. Now that will be a more cost saving system that you can plan for. And the P/S piping for two boilers operating at the same time will already be in place.

Try to plan ahead with options. And you don't lose anything in the process. You are doing the same thing on the system side of the loops. Why not on the source side?

Eventually you may get the other 3 unit owners to seporate the first from the sedond floors so each owner hat their own thermostat. That can be done easily when you do the repipe this summer as part of the boiler repipe job.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

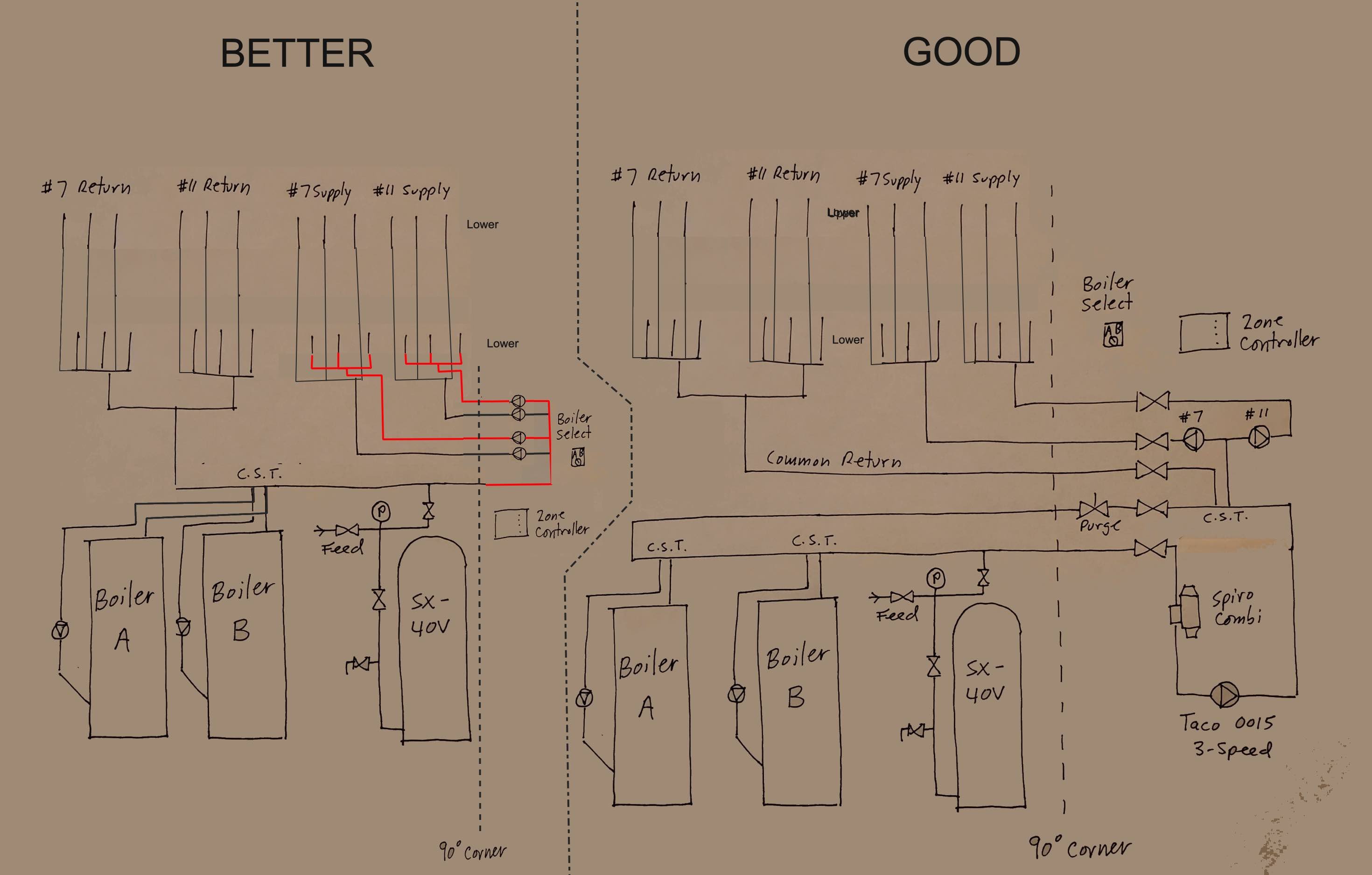

@EdTheHeaterMan OK thanks. So I see the logic of piping the boilers together as @Ironman showed. We can do that.

I also understand your proposed repiping to separate all 4 units, but that's not going to happen because all the large-diameter gravity piping has takeoffs for both upper and lower units all around the basement. We'd need to rip out and repipe all the large diameter piping, and that would cost mucho dinero. With ecobee thermostats in the lower units and remote wireless sensors in the upper units, our temperature control is surprisingly good and everyone is happy with their units temps.

So I think the plan going forward will be to repipe the existing boilers P/S as planned with Bob's improvement, and then that gives us the flexibility to run either or both boilers in future.

0 -

Two high temperature boilers for a zoned system?

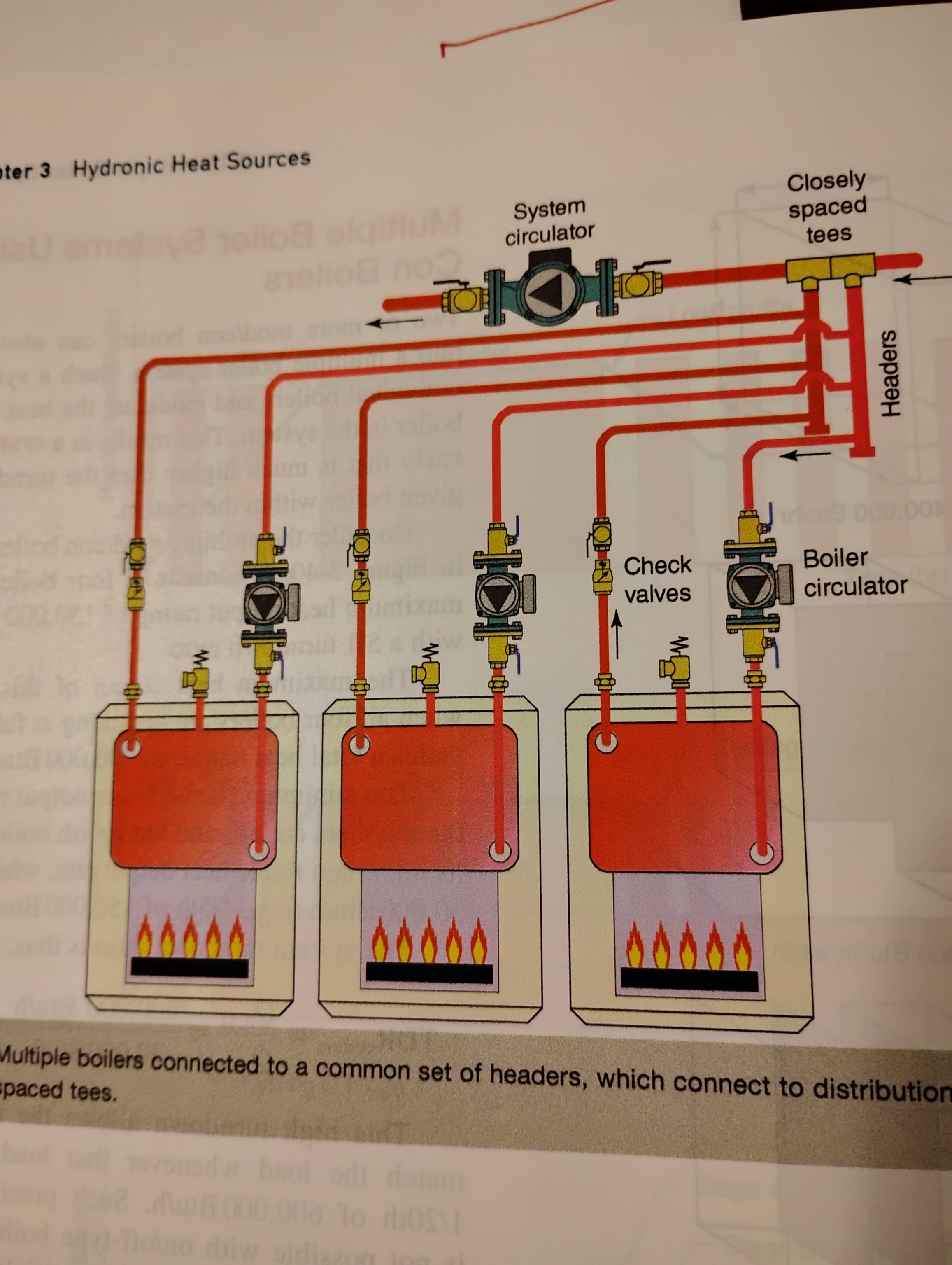

Here are other options. Really no need to P/S as you will get temperature blending at the closely spaced. So you will be blending down the 180 boiler temperature to the zones depending on the various and changing flow rates.

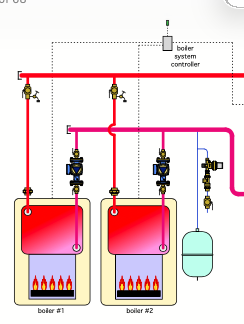

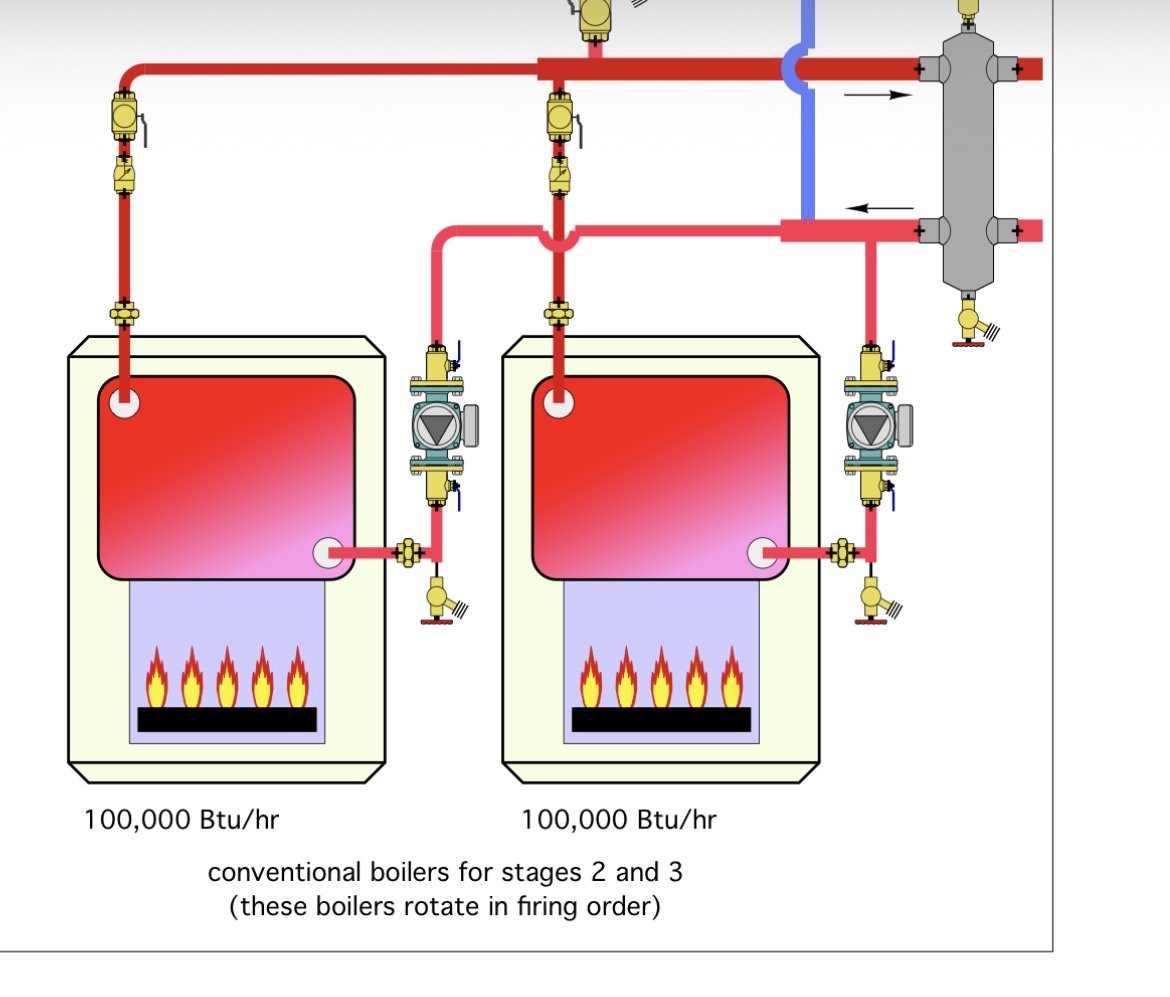

Parallel boilers, the first drawing, is a common option for two like boilers. Very simple piping. You could add a boiler stage control and chose lead/ lag, equal run, or alternating functions, and ODR.

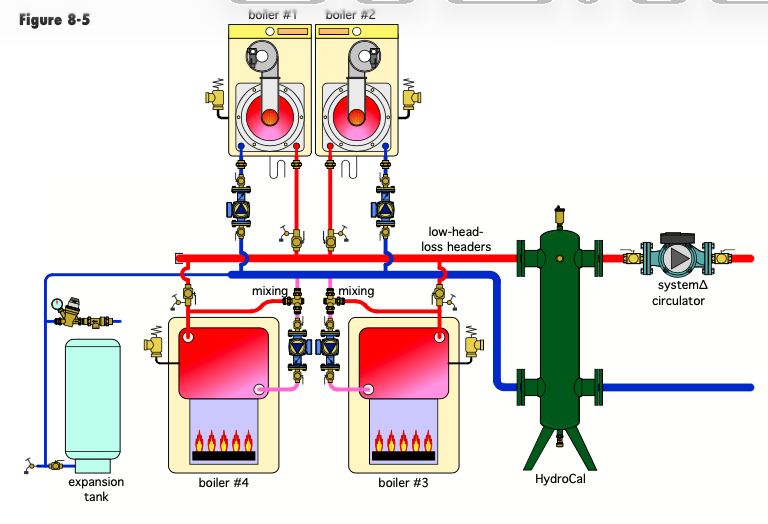

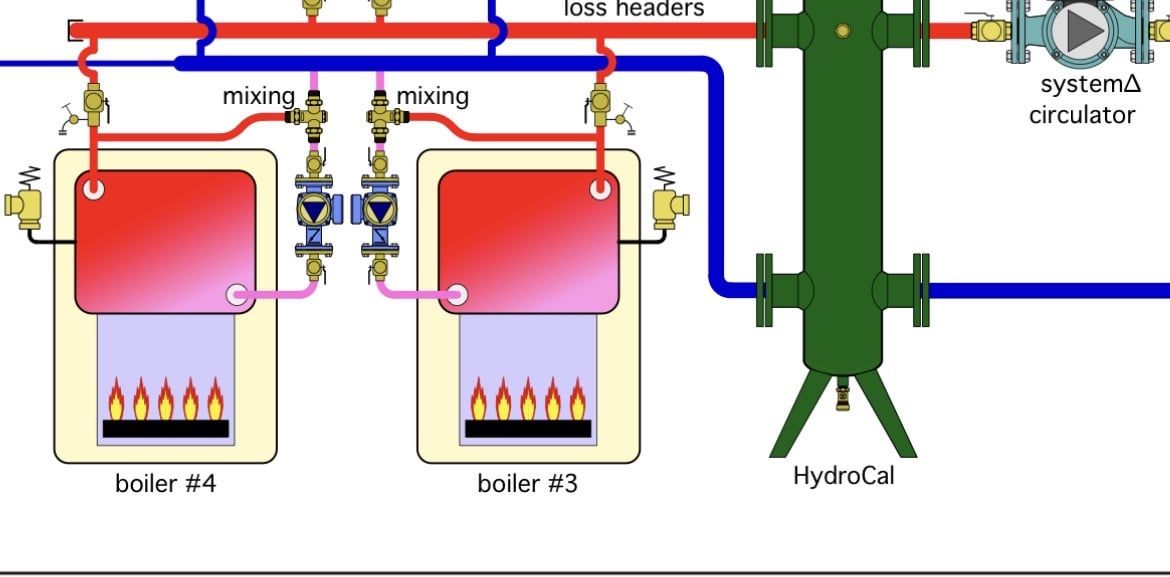

If you want p/s, a hydraulic sep, fig 8-5 makes a lot of sense for air, dirt, magnetic and hydraulic separation in one device. But you still get temperature blending in the sep.

Separators are ideal with different types of boiler, hybrid piping, with different or variable flow rates. Or if you need multiple temperatures.

The example in 8-5 shows a variable speed circ for the distribution. It modulates based on zones calling, keeping flow rates consistent with the loads. That would provide the best distribution efficiency, never over=pumping the system side.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

@jesmed1 said: We'd need to rip out and repipe all the large diameter piping, and that would cost mucho dinero.

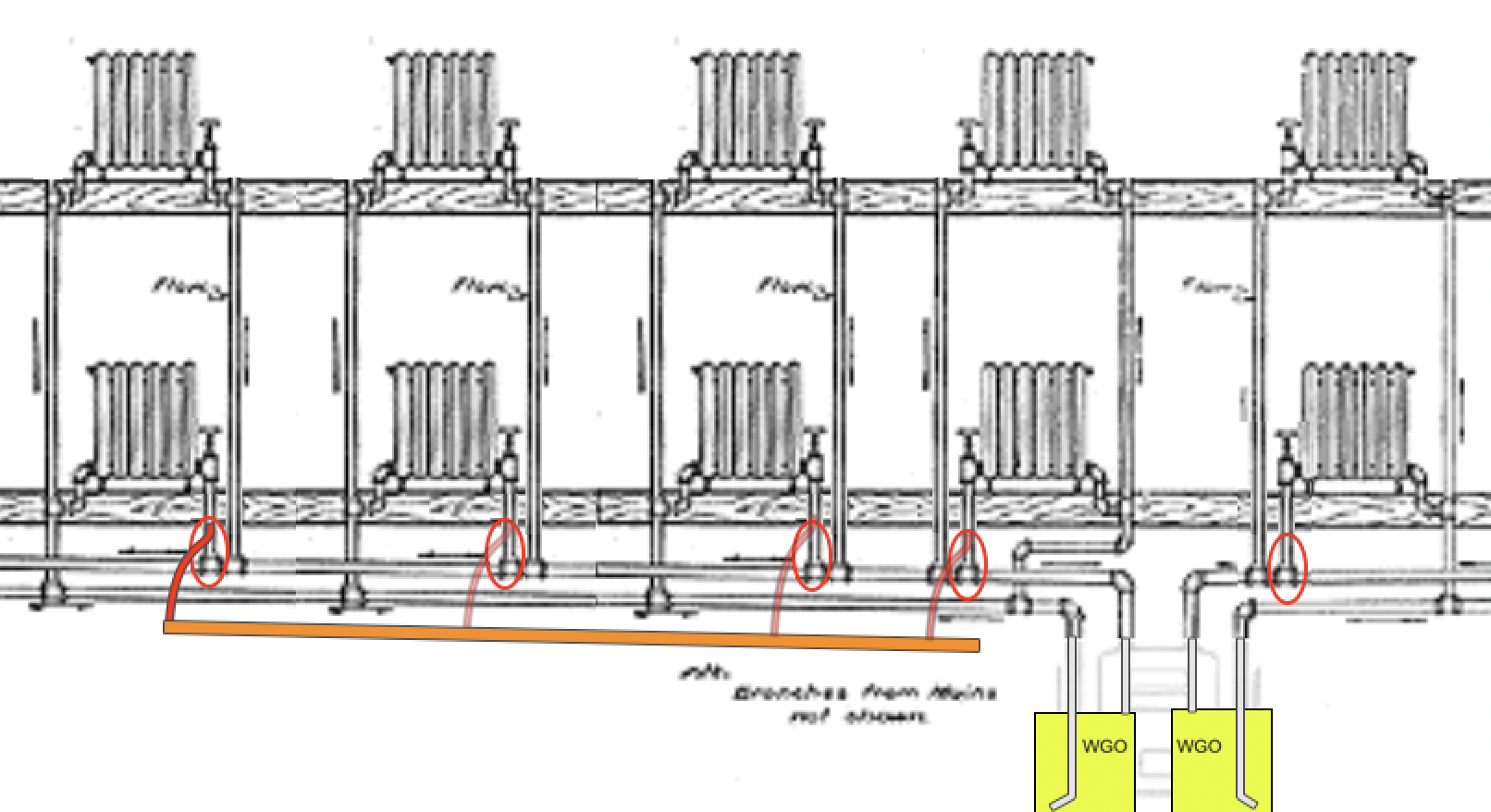

and that is not necessarily true. If you look closely at the diagram, you will see the red piping is all that needs to be changed to zone the first from the second floor.

You leave ALL the old pipes from the return and All the pipes from the supply. All you need to do is to disconnect the first floor radiator supply pipes from the large supply main. Plug those openings. Run a 1” copper supply from the 90° corner to the radiators that you disconnected. Connect those radiators with ¾” PEX to that copper main.

How many radiators are we talking about? 5 or so from each side? Not such a big piping job at all.

That is a lot less piping than the project you are talking about.

Ono of my first jobs when I went into business for myself was for the owner of a 4 unit building just like you have. Two upstairs and two downstairs long before wireless thermostats and sensors were available. He had one oil fired boiler and one thermostat in one of the hallways. Always got complaints from tenants about too hot or too cold.

I purchased 3 gas boilers, 4 gas water heaters and a ton of copper pipe and fittings from my local supply house and all of that was able to fit into this one service van.

The guys at the supply house couldn't believe it all fit. I drove less that a mile to the job and took 2 days to complete the job.

You might be thinking, “Only three boilers?!”

Yes. My original proposal was to install four new gas boilers, but the owner wanted to save money and asked, “What if we install only three and leave the old oil boiler serving one apartment?” So that’s what I did.

The system was laid out much like yours: all the radiators on the left side were on one main, and all the radiators on the right side were on another. To separate things, I removed the first-floor radiators from each main and connected them to a new gas boiler. On the left and the right sides. The second-floor radiators remained connected to the existing mains on the left . On the right side, the old oil boiler continued to serve the remaining second-floor system.

As you might expect, that oversized oil boiler burned significantly more fuel than the three gas boilers so the tenant complained in a big way. The following summer, I went back and replaced it with a fourth gas boiler.

That experience showed me this can be done with very little new piping. In your case, you only need to modify the supply side. The returns can all remain as they are, since they’re still returning to the same boiler.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

-

@EdTheHeaterMan Ah, I see about the piping. Yes possible, but at this point the others don't feel the need and wouldn't pay for it. Love the Scooby Doo van! Classic.

@hot_rod Thanks you for those other options. The first would be easiest. Would we then use zone valves?

Also, these are cold start boilers with low temps, rarely exceeding 140-150 SWT. I am wondering what happens when one zone satisfies, then the other zone that's been cooling off for 3 hours calls, and 100+ gal of cold (65-70 F) water hits the boiler that just ran 45 minutes and finished at 140? Does that then require a bypass with a mixing valve?

0 -

I agree with @Ironman 's method.

You want both boilers to get the same return water temp. I know you say they will never run together but you never know.

Also I would not switch boilers yearly. One sits idle all the time and when the other one fails you need the spare boiler.

If it was me I would alternate weekly or monthly, mnot yearly.

2 -

@hot_rod that was not my exact van. I had one just like it though. I started my first self employed HVAC business in a van like that.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

-

if the goal us to separate the boiler circulation from the system circulator , then I prefer a hydraulic sep to close tees

You need air separation, with old steel systems a dirt and mag separator is wise. The srp

Includes all the functions

Yes if there is potential to dump a lot if room temperature water to a hit boiler, I would add a return protection function

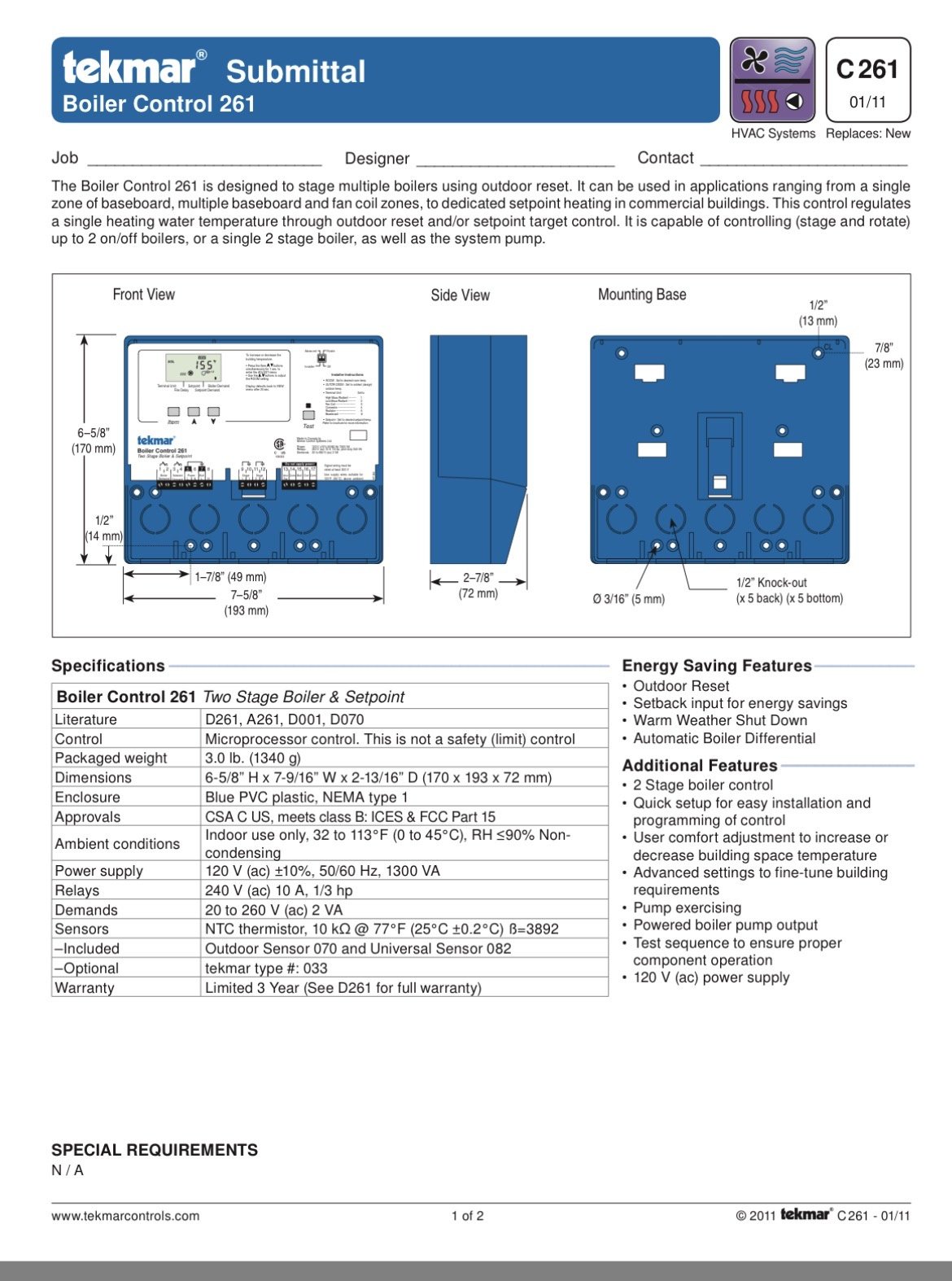

A stage control like this would manage rotation and ODR

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements