Efficient and dependable cast iron boiler recommendation

Now that Buderus is no longer selling its cast iron boilers in the US market, what cast iron boiler would the experts on here recommend? I'm considering replacing my 50+ year old Weil-McLain Gas boiler (245,000 input/196,000 output) with a newer unit. I'm considering two smaller boilers instead of one large one. In your experience, what brands have good efficiency and are dependable? Thank you!

Comments

-

Buderus still sells oil-fired cast iron boilers in the US, so are you asking about natural gas boilers? We have two Weil Mclain WGO-5 oil boilers that I plan to replace with Buderus G115WS's when the time comes.

Have you done a heat loss calculation for your application? Most existing cast iron boilers are 2x or 3x oversized. Our WGO-5's are 4x oversized. You may be able to heat your whole house with one G115WS/3 depending on how much your existing boiler is oversized. We could replace both WGO-5's with a single G115WS/3.

1 -

-

It's a gas boiler. The house is around 5,000 sq feet. I think I might have the smallest boiler in the neighborhood! When someone looked at the house a few years ago, the heat loss calculation they gave me was much higher than my boiler rating. And honestly, I don't even think my boiler is putting out as much heat as the boiler tag claims. When I looked at my gas meter at 0 degrees outside with just the boiler running continuously and the house at 70 degrees, the meter showed that the boiler was consuming only 210,000 BTU of gas per hour, and at 80% efficiency, must have been putting out 168,000 btu per hour. So I think for the size of the house, my boiler is nowhere as oversized as my neighbors' homes!

I am thinking about two small cast iron boilers which should be more efficient than one large one and also offer some redundancy. Are brands like Burnham, US-Boiler, Weil McLain, Dunkirk, etc, all comparable or is one superior to the others when it comes to cast iron gas boilers?

0 -

3 pass boilers with a power burner will be more efficient than an atmospheric boiler. a mod con could make sense if you have a lot of heat loss. they have a shorter life and require more maintenance but the cost of the maintenance could be wort it on a structure that needs a lot of heat if your emitters can be run at condensing temps most of the time.

the additional labor and materials to install and control 2 boilers instead of one likely isn't worth it unless the redundancy is very important. repairs to a single boiler unless the hx has cracked are usually pretty simple.

this is assuming hot water. your options for steam are much more limited and the cost of twining steam boilers is even more than for hot water.

0 -

Thank you! Yes it's a hot water system that runs on gas, and even with sub-zero temps, the radiators never get hotter than 130 degrees and the house stays at 70 degrees. I had thought about a condensing boiler (Vitocrossal 300 CU3A was my choice) but I don't really want to vent through the side of the house and prefer to keep using my chimney. It seems that through most of the winter, the house could stay comfortable with a small boiler and when it's very cold, both boilers would work, which seems more efficient.

I wish someone had a cast iron boiler that would modulate by firing all or just some of the burners.

0 -

Cast iron boilers need to stay above 140 f or so most of the time to prevent condensation so they generally can't be downfired much. Sometimes you get lucky and the boiler doesn't soot or rot out if it doesn't have protection to keep the return water temps high enough to prevent condensation, but if your system is running at such a low temp the new boiler should be installed with return water temp protection. I think energy kinetics does some stuff to deal with lower temps but in general conventional boilers aren't the right technology if you want modulating or low system temps. large commercial boilers modulate to match varying loads but that is more to keep a constant supply temp on a system with many zone valves in individual rooms or apartments.

your chimney may need to be lined when a new boiler is installed if it isn't already lined.

1 -

For a sanity check on your heat loss, you say you clocked 210,000 BTU/hr input on your meter at 0 degrees outside air temp. In a 5,000 sq ft house, that's an input of 42 BTU/hr/sq ft. Your nominal 80% efficient gas boiler is actually less than 65% efficient, because it's losing an additional 15% latent heat of vapor in the exhaust vapor which is not being condensed, and therefore the latent heat is not recovered. So in reality, your 42 BTU/hr/sq ft input is being converted to about 27 BTU/hr/sq ft output at 65% efficiency (or possibly less depending on how your system us set up).

But remember, that assumes your boiler is running continuously, 24/7, at 0 degrees outside air temp. If your boiler was only running, say, half the time (like 30 minutes on, 30 minutes off), that means the average heat loss of your house at 0 degrees was actually half of the above.

But let's say your boiler was running continuously. Then the 27 BTU/hr/sq ft heat loss suggests you live in a cold northern climate and/or have a fairly old leaky house. Depending on where you live and your house age & construction details, 27 BTU/hr/sq ft is in the realm of reasonable. As a point of reference, I maintain a 4-unit 100-year-old condo building in the Boston area, and our heat loss at 0 degrees outside air temp is about 15 BTU/hr/sq ft. So you are either north of us, or you have an older, leakier house, or both.

Back to your boiler options, something like a Burnham 208E has an input rate of 241,000 BTU/hr, so that would match your existing input rate fairly well (again, that assumes your existing boiler was running 24/7 to keep up with the heat loss at 0 degrees).

I am not a heating pro, just a home/owner/mechanical engineer, so I do not have experience with Burnhams. Some older Burnham steam boilers had high failure rates, but you don't have steam, and Burnham seems to have fixed that problem anyway, so I don't think it should concern you. My sister's house has a smaller Burnham atmospheric gas boiler, probably 20-30 years old, and it's still running fine. Heating pros here will be able to give you more advice on brand options and reliability.

1 -

Thank you! The house is an almost 130-year-old masonry house with the original windows and added storm windows in Missouri. The man who owned the house in the 1970s installed the new boiler himself with his buddies, and it doesn't have a water return loop to prevent condensation. Even in subzero temps, I have never measured temps higher 132, and the return was 10-12 degrees cooler. I have never noticed any condensation dripping onto the flame tubes, even when the water is lukewarm, and it has never sooted up either. I do vacuum up some rust powder when I clean the boiler each year, but it's just a thin layer. Honestly, I'm surprised that it hasn't rusted through or ever pooled condensation under the burners. But since it's over 50 years old already, I think it might be a matter of time before a leak. Some of the insulation inside the boiler has occasionally broken off an fallen onto the flame tubes, which worries me. The chimney is lined with a 7 inch diameter liner.

Even when the temp is in the 20s, the boiler cycles off and on, and I only notice it running continuously when the temps are in the single digits or below zero, and the house is always comfortable. So the numbers I'm reading off the boiler label (245,000 input) and the amount of gas I see being consumed by the boiler according to the meter just don't match up. The meter shows a gas consumption of 10 cubic feet in 2 min 54 seconds, which with a heat content of 1023 BTU/cubic foot according to the gas company adds up to 211,000 BTU/hr.

I have had friends and neighbors install Lochinvar condensing boilers, and they complain about the noise of the boiler itself as well as the noise outside close to the exhaust. So I think I'd rather stick to an old-fashioned, quiet, atmospheric cast iron boiler and use my lined chimney and try to achieve better efficiency with two smaller boilers rather than one larger one, though I'm not opposed to a single larger boiler (as I have now) either.

0 -

OK, so a 130-year-old masonry house with little/no insulation and original windows explains your probably 27 BTU/hr/sq ft heat loss at 0 F outside air temp. You may be able to improve that with a blower door test that shows where your air leaks are. Sealing air leaks is the first step in improving the envelope of old houses.

Don't get too hung up on your boiler rating. You measured an input rate of 211,000 BTU/hr vs. a rated 245,000 BTU/hr, or 86% of rated input. That's not far off, and the boiler gas pressure regulator may be set slightly lower than max, which would reduce your input rate.

My sister had a Lochinvar Knight condensing boiler in the basement of her last house, and it was quieter than our Weil-McLain oil boilers with Beckett burners. Apples to oranges, of course, but I slept in a guest room next to the Lochinvar, and the (to me) fairly quiet whine of the Lochinvar wasn't bothersome.

You should also consider that you have an ideal setup for a condensing boiler: probably big old cast iron radiators and low water temperatures. So if you could find a condensing boiler whose noise signature didn't bother you, your low water temps mean your boiler run run in condensing mode for nearly 100% of the heating season, using outdoor reset, with probably significant efficiency gains.

1 -

have an energy audit done and see how you can lower that load, first. 40 btu / ft is crazy high

If in fact the current boiler short cycles that further indicates the load is lower than you calculated How many days have you been at design?

Reduce boiler size and operating cost for the life of the building.

A mod con, even at high operating temperatures will be in the high 80% efficiency. The modulation is worth as much or more than condensing in a climate like yours

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Bob and I disagree on this but if you have room in the basement you should think seriously about a large hot water buffer tank to create more usable thermal mass. It will save you a great deal of fuel.

You would not have to insulate it as the radiant from the tank will add to the heat in the home and the boilers could be run less often.

0 -

A small mod con and CI boiler in a hybrid application. Mod con runs, possibly in condensing mode for some of them season, CI kicks in for second stage

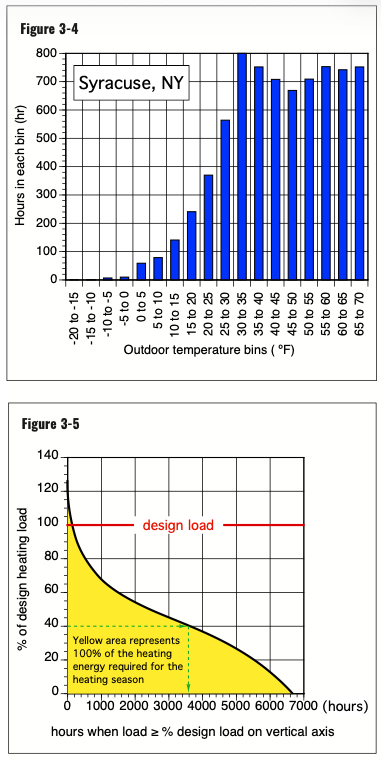

There must be a way to use AI to generate a BIN temperature for your location. Get an idea of low temperatures over the past 10 years or so.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Great idea hot_rod. Mod. con. + cast iron. C.I. would then last a "life-time" and always be on stand-by for mod. con. break-down/service/extreme cold.

0 -

if they say it runs at 130(not clear if that is supply or return) when it is 0f out my bet is that it would run on the mod con all the time.

maybe add a mod con and set up the current boiler so it can run backup.

0 -

At zero degrees outside, the outgoing temp is 132 and the return is 120 or so. 10 to 12 Delta T. I don't want a mod con, because I don't want to vent through a side wall. I just wanna use my chimney!

0 -

if there is nothing else using the flue in the chimney you can usually run the pvc vent up it and out the top of the chimney.

the difference in efficiency between 2 small ci boilers and 1 medium sized ci boiler will be very small and hard to measure. the difference between a conventional boiler and mod con may be big enough that you can measure it. either a conventional or mod con boiler will work here if installed with the proper controls but this is a great application for a mod con.

0 -

-

You clocked the meter at zero degrees—-you’re saying the boiler didn’t shut off for the entire hour? The boiler temperature didn’t budge? That’s very rare in our world unless you have a modulating burner (it will actually “stay running”)

I hear what you’re saying, your neighbors boilers are huge.

Seems like you have giant (I like!) rads.

Also, mod con venting out the side of the house: fear not. You could have the polypropylene pipe kit installed up the chimney shaft.1 -

-

Ed if he nailed the gas meter Clock, the heat loss report has been done, and it’s the most accurate heat loss report of all. Real time losses are zero

0 -

Yes, my radiators are large. I decided to measure the gas consumption on the meter because when one of the most reputable heating companies went around the house and measured rooms and windows, etc, the heat loss calculation was more than my current boiler's rating. So I decided to check and see how much it was consuming per hour, which is why recorded how much gas comsuption the meter showed (0 degrees outside/perfect 70 degrees inside/boiler running continuously with 132 degree output and 120 degree return). And I got far lower numbers than the heat loss calculation as well as the boiler rating. I thought I could get by with a smaller boiler than what they were proposing, and at the time, I didn't proceed further.

Yes, I would love to reduce my gas consumption, which is why I am thinking about two smaller boilers rather than one larger one. I love the idea of a Mod Con, but I am wondering if whatever I save on gas I end up spending on more maintenance. And I do not like the look of vents on the side of the house, especially since they'll have to go through thick walls and solid limestone (I hate vents going through windows even more).

Thank you for the advice of scratching Burnham cast iron boilers off my list. And I guess US Boiler and Burnham are really the same company. Is Weil-McLain still good?

0 -

ok not sure if I missed your answer on a different post: that boiler ran for a full hour and more, nonstop? You say you clocked but but didn’t specify the duration

also- run the new plastic vent up the chimney flue0 -

wm and peerless seems to be what most here like the best. buderus and ek are also very good. dunkirk and utica are ok too, especially for hot water. dunkirk is sold under a lot of house brands, i think there are some house branded WMs out there too.

burnham is really the only one we see a lot of people posting about lots of premature failures. certain wm models that have resilient gaskets that are field assembled can have problems if they aren't careful about getting the gaskets seated right.

1 -

Gary, when temps were close to zero or below, the boiler never stopped running. Outgoing water was 132 and return was 120 degrees. House stayed at 70 degrees. Once temp came up to the teens and higher, the boiler began to cycle on and off.

0 -

If you really want a cast iron heat exchanger, take a look at the GV90 boilers offered by Weil-McLain:

This boiler is a bit unusual b/c it has a cast iron heat exchanger, but it can also handle low water temperatures. It can also be vented up through your chimney. Based on your gas consumption test, with a little work on the house the largest GV90 looks like a good match.

1 -

Has anyone had any issues with Dunkirk DXL-K series boilers? One of the installers uses this brand and speaks very highly of it. Weil McLain seems to be more common in my area.

0 -

-

The fail point is not so much the blocks or heat exchanger of boilers, regardless of cast or stainless mod cons.

Its the electronics: computers, mother boards, ignitors, electronic aquastats, inducer fans, gas valves, relays, flame rods, display boards, etc.

You get all those "breakables" on mod cons of cast boilers these days.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thanks hot-rod! So going with CI boilers, you don't think Dunkirk DXL-K boiler is any better or worse than say Weil-McLain? I suspect they all have similar electronics. The Dunkirk is what one of the installers usually does, and they have a good reputation, and the smaller size of the DXL matches my needs a bit better than the slightly larger WM, though the difference isn't that great. I'm sure they could install WM as well, but they see to do more Dunkirks.

0 -

I wouldn't scratch Burnham off this list. Their problematic gas boiler was the Independence steam unit, and you don't have steam. I like the Burnham Series 2, ES2 and Series 3 hot-water units- the basic cast-iron block in these units has been in production for decades and seems to last a long time.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

Thank you. WM seems to be popular in my area, and one installer who has a good reputation installs the Dunkirk DXL-K series. I haven't heard anyone around here mention Burnham, but I'll inquire. The 120K BTU Dunkirk is the perfect size, while the WM and Burnham are a bit oversized for me, but not by a huge margin.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements