Navien NHB-110 Boiler For Hot Water Hydronic BaseBoard Heating Howling

Hi All!

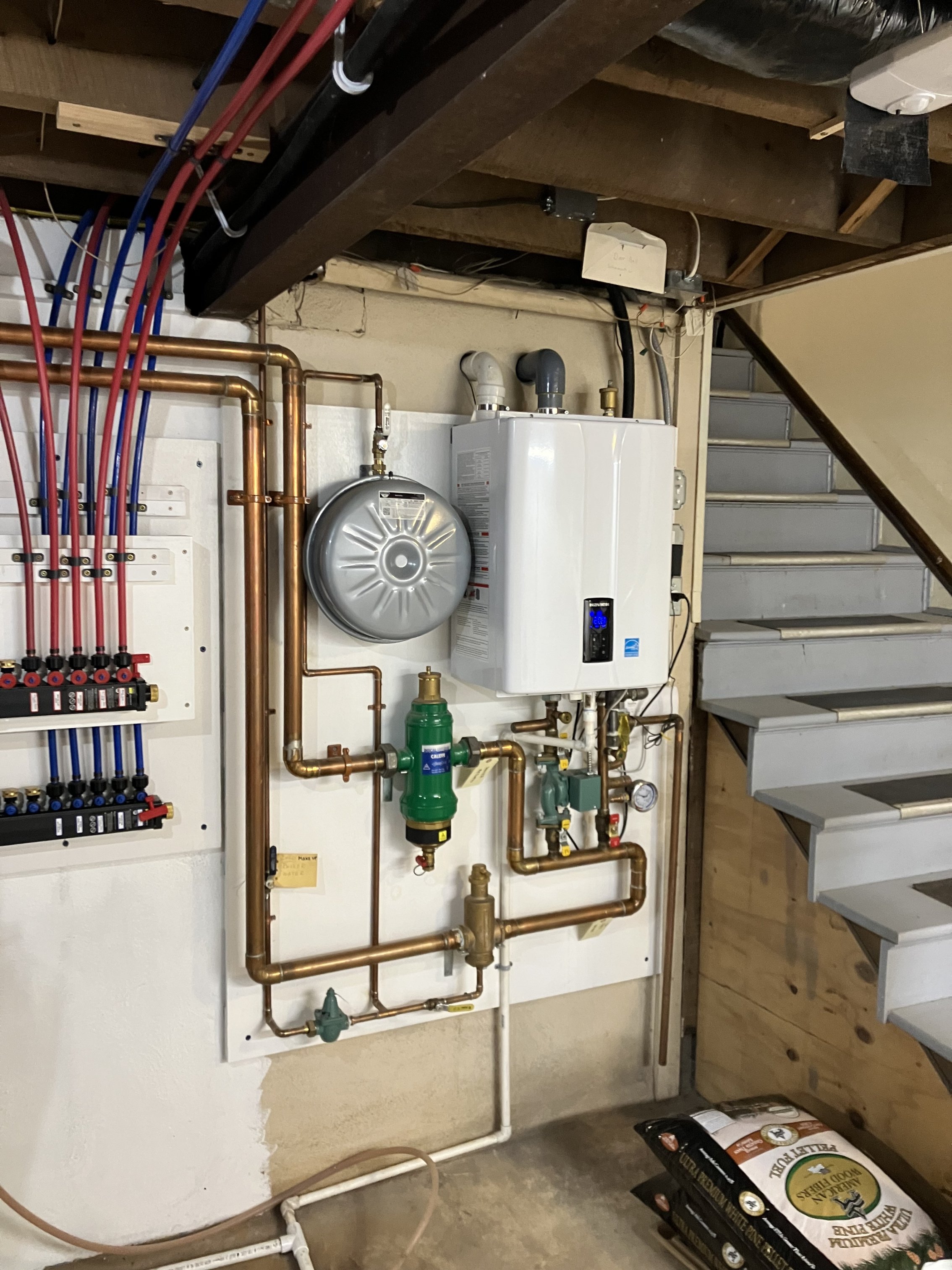

I am attempting to troubleshoot why my Navien NHB-110 boiler howls during higher demand calls for heat from multiple zones at the same time. The 2800 sqft house has 3 floors and 5 different heating zones. The unit pulls air intake from outside and exhausts outside. The unit also has an outside ambient temperature sensor. The circulating pump that sucks water into the boiler is a 3 speed taco 0015-msf3-ifc set to the middle speed. the noise exists at both middle speed and high speed. The boiler uses propane gas that is regulated down to 7-11 inches water column. The cold boiler pressure is around 12 psi and the hot boiler pressure is around 18-20 psi @ 180 degrees F .

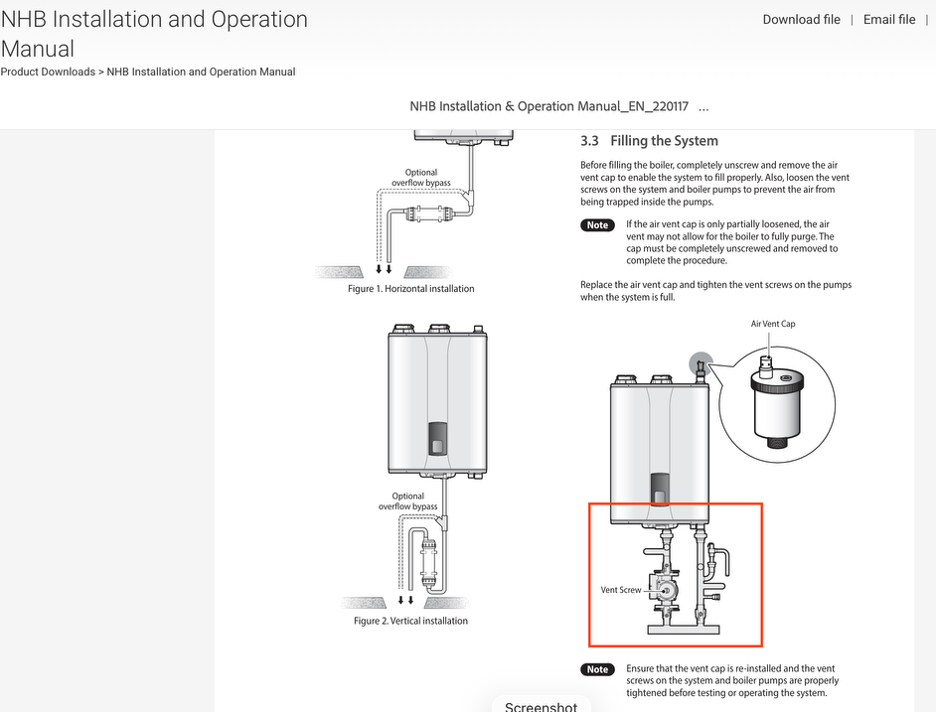

I have purged the air out of all 5 zones. I have performed the annual maintenance on the boiler such as cleaning fresh air intake mesh screen, drained/cleaned the condensate trap, cleaned the in-line water strainer, and descaled the unit for 60 minutes using nucalgon vital flo descaler.

The boiler is located in the basement and the howling is loud enough that it can sometimes be heard on the second floor.

I have attached videos of the howling and pictures of the boiler and 5 zone manifold.

I do believe the noise is purely related to the boiler as the noise is definitely coming from within its appliance shell. The noise is there whether the front cover is on or off which makes me think it is not a air intake question or a faulty front housing cover gasket.

I appreciate any thoughts on what I could try…

Thanks!

Comments

-

I don't have speakers to hear the howling, typically when a condensing boiler howls like that its coming from the venting, and typically the first step is to get out the combustion analyzer and make sure your combustion is dialed in correctly to spec, the venturi is in good condition (smooth, with no soot, not rough, check backside of venturi for perforation) Some brands actually install a "muffler" of sorts in the vent to mitigate the issue, if navien doesn't recommend that I would avoid it!.

I have also seen with some brands where they will limit the max firing rate, or fan speed to eliminate the howling sounds when all else fails.

Some things you can easily inspect. The outdoor venting! If your two vents are really close together the flue exhaust can get sucked back into the intake, when this happens there are various not great things that can happen, but one common symptom is the deterioration of the venturi in the boiler. The venturi is responsible for bringing the air in to the burner to complete combustion, when it deteriorates or becomes perforated, you will hear a howling sound almost like blowing over a partially full glass coke bottle, but different pitch and louder.

0 -

Could be the gas pipe. It appears to be CSST feeding that boiler but I can't be sure. I have experienced this with CSST gas pipe making the howling sound when the burner is at maximum input. The fix is to go the the next size larger CSST pipe, or run the proper size gas pipe using iron / steel pipe and fittings.

How long is the black covered steel gas pipe? If it is more than about 6 feet, then it is probably too small, looks like 3/4" in the photos. You need at least 1" for any distance and you may need 1-1/4" if the run is over 30 feet.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

@EdTheHeaterMan

You are correct that the propane line connected to the boiler is about 6-8 feet of 3/4" CSST which connects to 50 feet of 1" black steel pipe that is connected to low pressure regulator providing 7-11 inches of water column regulator which is outside of the house.

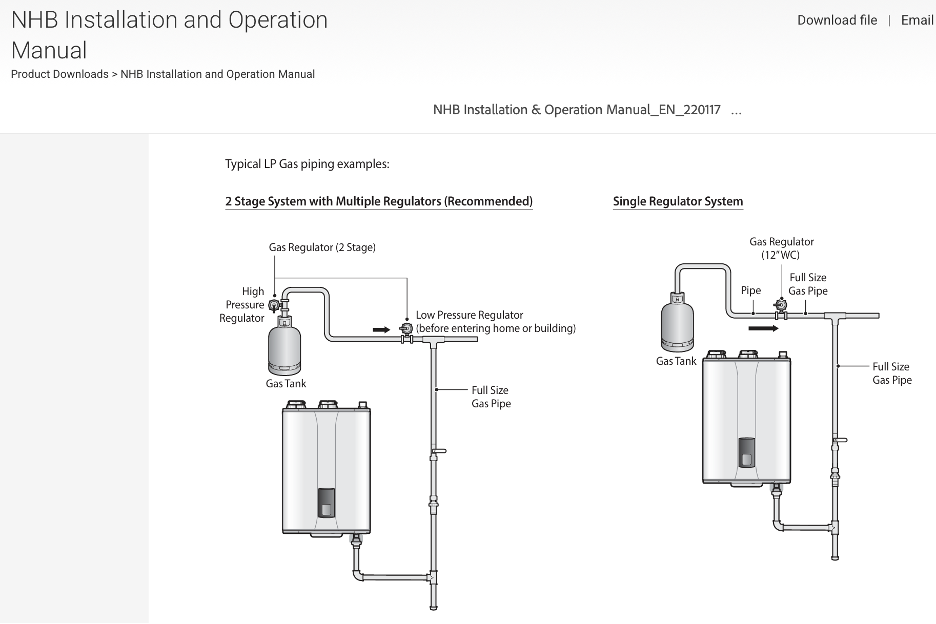

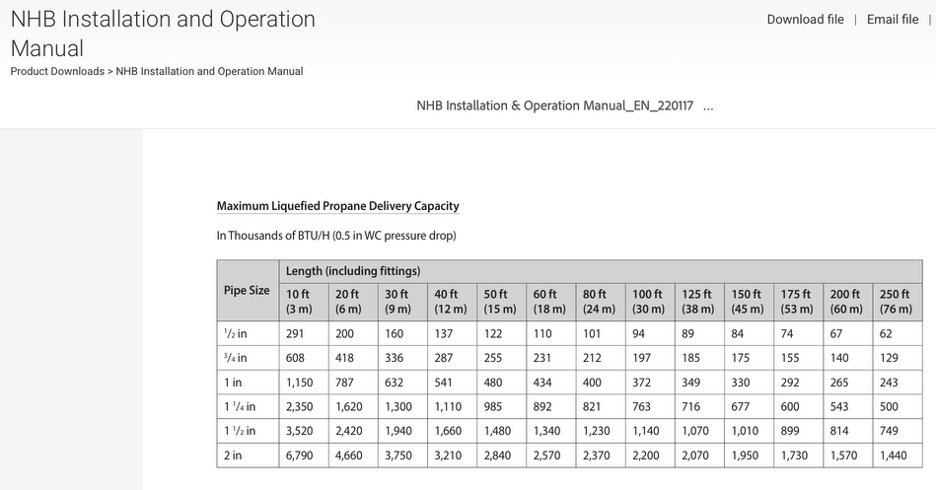

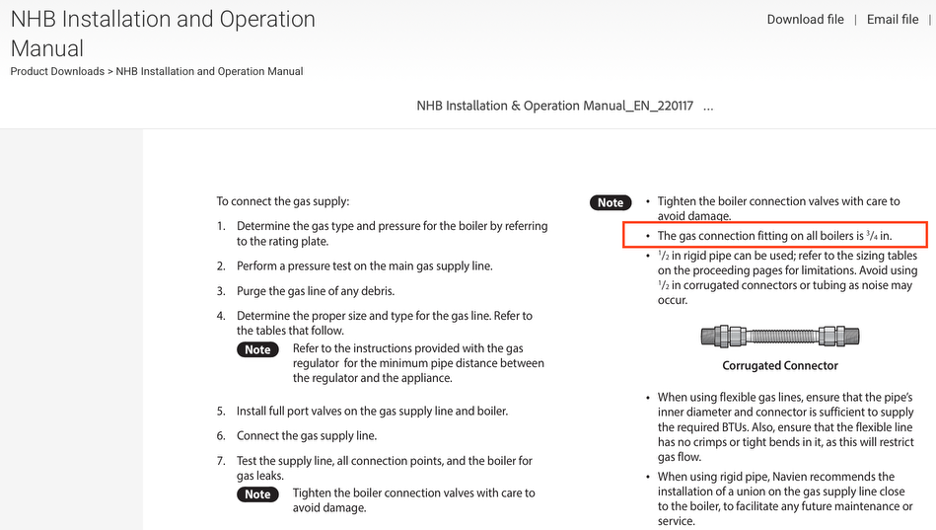

I was looking at the install manual (linked below) and pages 39-44 define the requirements for connecting the gas supply. Page 41 has the figure for the propane gas install option. It states "full size gas pipe" should be used. Page 40 states that "The gas connection fitting on all boilers is 3/4 in.". Therefore, would 3/4" back steel pipe be considered full size gas pipe? Can 3/4" CSST be considered full size gas pipe?

Per the Maximum Liquefied Propane Delivery Capacity table on page 43, it appears that the combination of 50 feet of 1" black steel pipe and 6-8 feet of 3/4" CSST pipe should be capable of supplying the boilers required 110,000 BTUs.

It is noted that the boiler is the first appliance located on the main manifold line.

It is also noted and shown in pictures that the 3/4" CSST does not appear to be kinked.

Should I recommend to the installer to replace the 6-8 feet of 3/4" CSST with 1" black steel pipe that reduces down the 3/4" black steel pipe right before the boiler?

Thank you so much for your time and assistance!0 -

It seems like CSST was heavily discussed here as well.

Id say mine is more of a tea kettle/ how instead of a fog horn though…0 -

-

@hot_rod

I recently purchased this house in the summer of 2025.

However as I still stay in touch with the previous home owners, they confirmed that this boiler made the howling noise at higher demands for heat since it was originally installed in 2021.

If just one zone calls for heat in the middle of the day with a mild outside temperature of say 45F, the howling is either non-existent or so soft it's not noticeabale.

However, at colder outside temperatures and with more demand on the boiler, the howling intensifies.

I don't see how they could have "learned to live with" this howling as now that we are in the middle of a cold snap it howls for nearly every call for heat.Thanks again for your time and assistance!

0 -

With the detail you presented on the gas line size, I agree with @hot_rod, the gas pipe in probably not the source of the "tea kettle" noise. I think that you can rule that one out by a factor of 89%. The only way to be 100% ruled out is to replace all the CSST with hard pipe. But I would look elsewhere before doing that gas pipe redesign.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I listened to the video again and that does not sound like the "Fog Horn" noise that I have experienced that results from undersized CSST. So now I’m up to 92% sure it’s not the gas pipe.

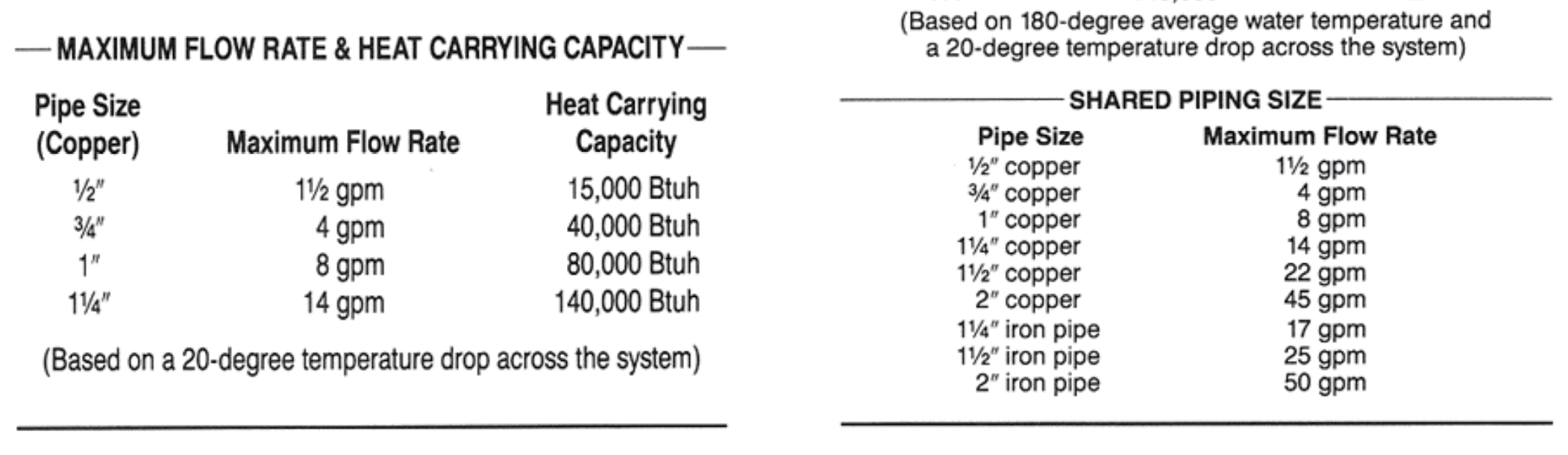

I did notice that you have 5 circulator pumps and I am thinking there might be too much water flow thru the common pipe. Just using a rule of thumb for pipe sizes and the fact that the Taco 007 pumps can move over 20 GPM in certain conditions, let's look at what might be going on in that neat boiler piping.

Using this rule of thumb for pipe size and recommended GPM needed to reduce noise, we can add up all the pump’s possible flow rates to see what the total might be. Remember this is not the actual GPM flow rate, that can only be measured with some calculations. I am just pointing out a possibility. That’s all.

Four of your five pumps are connected to ¾” copper that can move up to 4 GPM under ideal operating conditions. That can be a total of 16 GPM for those 4 pumps. The fifth pump is connected to a larger pipe. At least 1-¼” but it may be 1-½” copper pipe. If it is 1-¼” pipe that has a capacity of 14 GPM for a total of 30 GPM thru the shared piping. Looking at the near boiler piping, the primary loop appears to be 1-¼” copper close to the boiler, then increases to 1-½” copper when it turns up to the ceiling to then go over to the circulator pump manifold. Since you have the possibility of moving 30 GPM thru the shared piping and you have only 1-¼” of shared piping near the boiler, I might look at repiping the section of pipe indicated in this photo in Blue highlight from 1-¼” copper to 1-½” copper

A test to prove this “too much water flow” theory would be to adjust all 5 circulator zones to a lesser flow by closing each zone about 80 to 85%** with the ball valve on the discharge side of the pump. This will reduce the GPM in each zone and still provide sufficient heat for the building. When the reduced flow makes the noise dissipate, you will know that the noise is from the 1-¼” shared pipe near the boiler.

** adjusting flow with a ball valve does not do very much with the first 70% of the valve throw. You only actually start getting a measurable restriction after that amount of closure.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

are all the zones radiant? If so about .50 gpm per loop, add them up.

While it is possible to have a 30 gpm flow potential, you only have a 110 boiler.

, so all the distribution should be sized to that?

Excessive velocity is typically a hissing noise.

I’m back to a combustion noise.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Your flue & fresh air pipe looks to me to be 2" PVC pipe. For that length, I think it should be 3" pipe. A pic of the termination outside would be helpful. When the howling is going, I would have someone outside placing their palm over the exhaust outlet and see what the sound is at the boiler. That may tell you if it is a exhaust problem.

I just hate it when I see cast iron mixed with copper. A retro fit from steam to hot water, I can see it. But, that's me, whata I know.

Your piping of the boiler violates some hydronic principles. It is more convoluted than necessary. The inlet to the boiler pump should be at least 10 diameters of straight pipe and the outlet should be 5 diameters of straight pipe before any change of direction. Running pipe like it was a domestic water sys with higher pressures let one get away with simple errors. But, a hydronic sys with low pressures can create problems if one doesn't minimize pressure losses in the piping arrangement.

I know that you just want to get rid of the howling. I would look at the exhaust and air intake sys.

A mechanic's stethoscope that you can get at an auto parts store or Harbor Freight may help you pinpoint the origin of the sound.

0 -

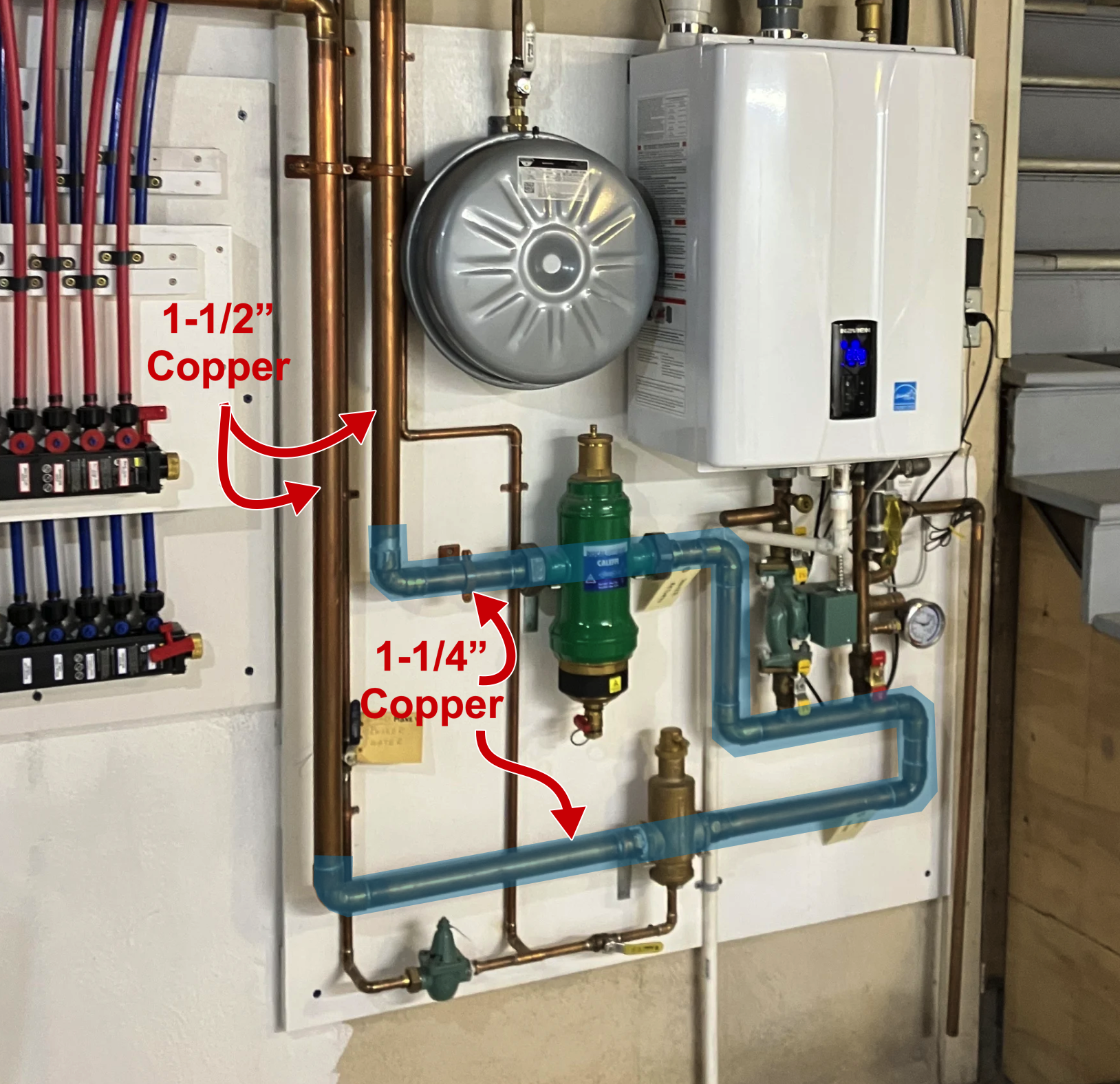

@EdTheHeaterMan

I measured the copper pipe OD in the area you have highlighted blue beneath the boiler. The pipe OD measures as 1.675" which would probably measure 1-5/8" if it wasn't thermally expanded. Therefore I believe all of the pipe is 1-1/2" pipe not 1-1/4" pipe.

Now knowing that the shared copper piping is all 1-1/2", should I still slightly close the ball valves underneath the (5) taco circulating pumps to 85% in an attempt to reduce flow still?

Thanks again for your help!0 -

@hot_rod

4 out of the 5 zones go to radiant baseboards located throughout the house.

The fifth hot water zone goes to an addition that has its own forced air handler for AC. Above the AC A-coil in the air handler is an aqua coil for heat.

I tend to agree that the noise is combustion as the noise definitely comes from the boiler and not associated piping.

Thank you for your help!0 -

The steel Caleffi DiscalDirtMag is the tip off that it is 1-1/2” tube size

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Take a close look at the pipes in the photo. I believe that the installer used a reducing 90° elbow here. Check the outer diameter of the vertical pipe and compare it to the horizontal pipe.

Is it possible that you have 2” copper between the near boiler piping and the risers that go to the circulator pump area?

Since it does not cost anything to adjust a valve, it can't hurt to try the adjustment. I also agree with @hot_rod that you are probably not pumping the maximum in each zone, but since it is free to adjust, you can certainly start at about 70% then75% then 80% but I don't believe that I would go much past 85% or you may reduce the actual heating capacity of the zone(s)

OMG. I just looked at the optical illusion created by the 1/2" water feed pipe next to the vertical pipe when I put the red arrows on that photo

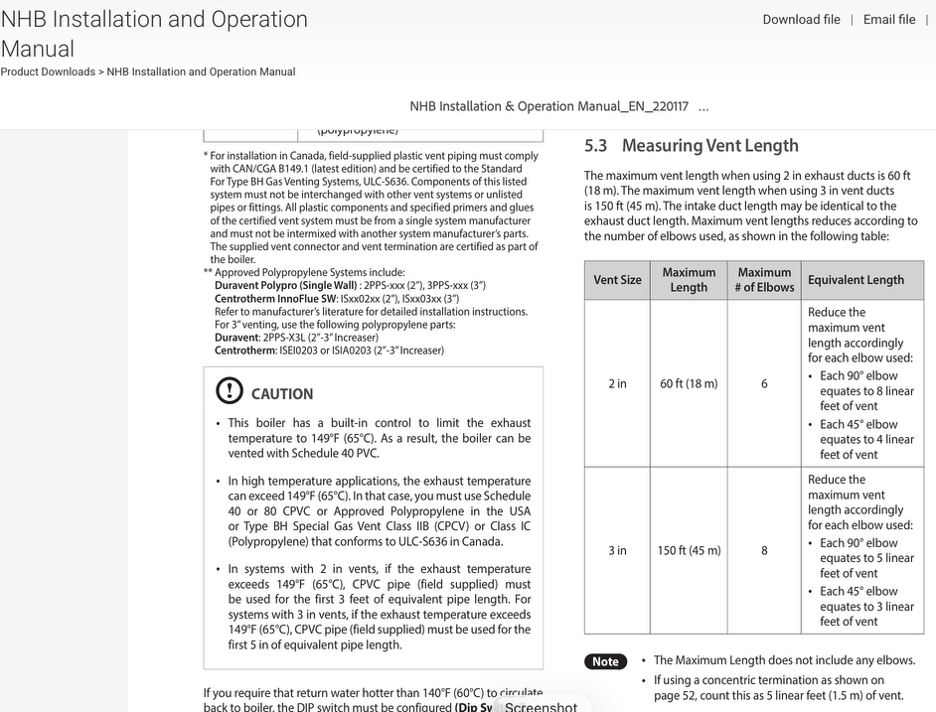

Also combustion noise is a possibility. If you look at the manual there should be a maximum vent length for different vent diameters. Make sure you are not exceeding the total equivalent length (EL) of the vent pipe. Sometimes each 90° elbow will add 5 to 10 feet of EL of strait pipe. so 20 feeet of pipe with 4 elbows might actually be 60 feet total equivalent length.Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

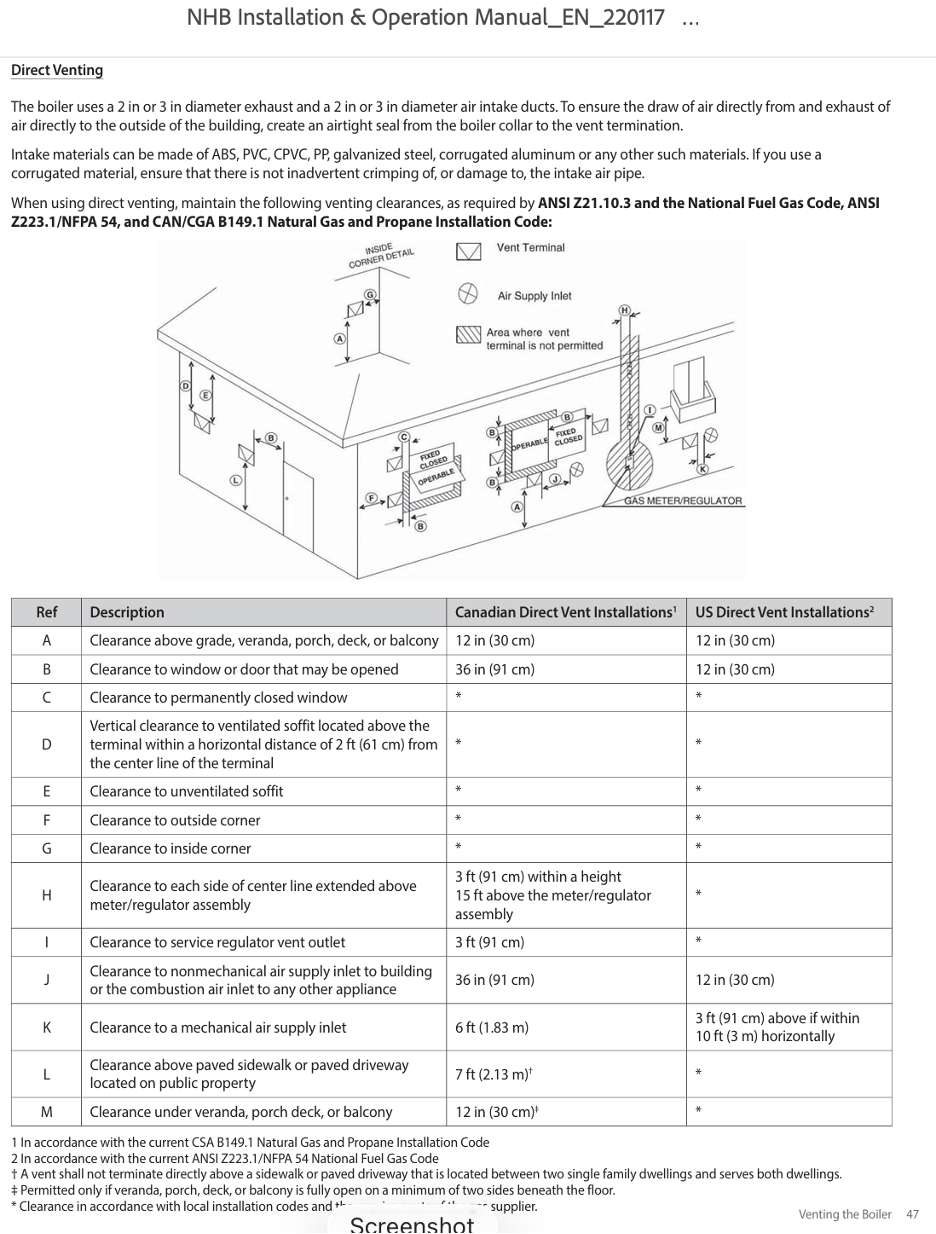

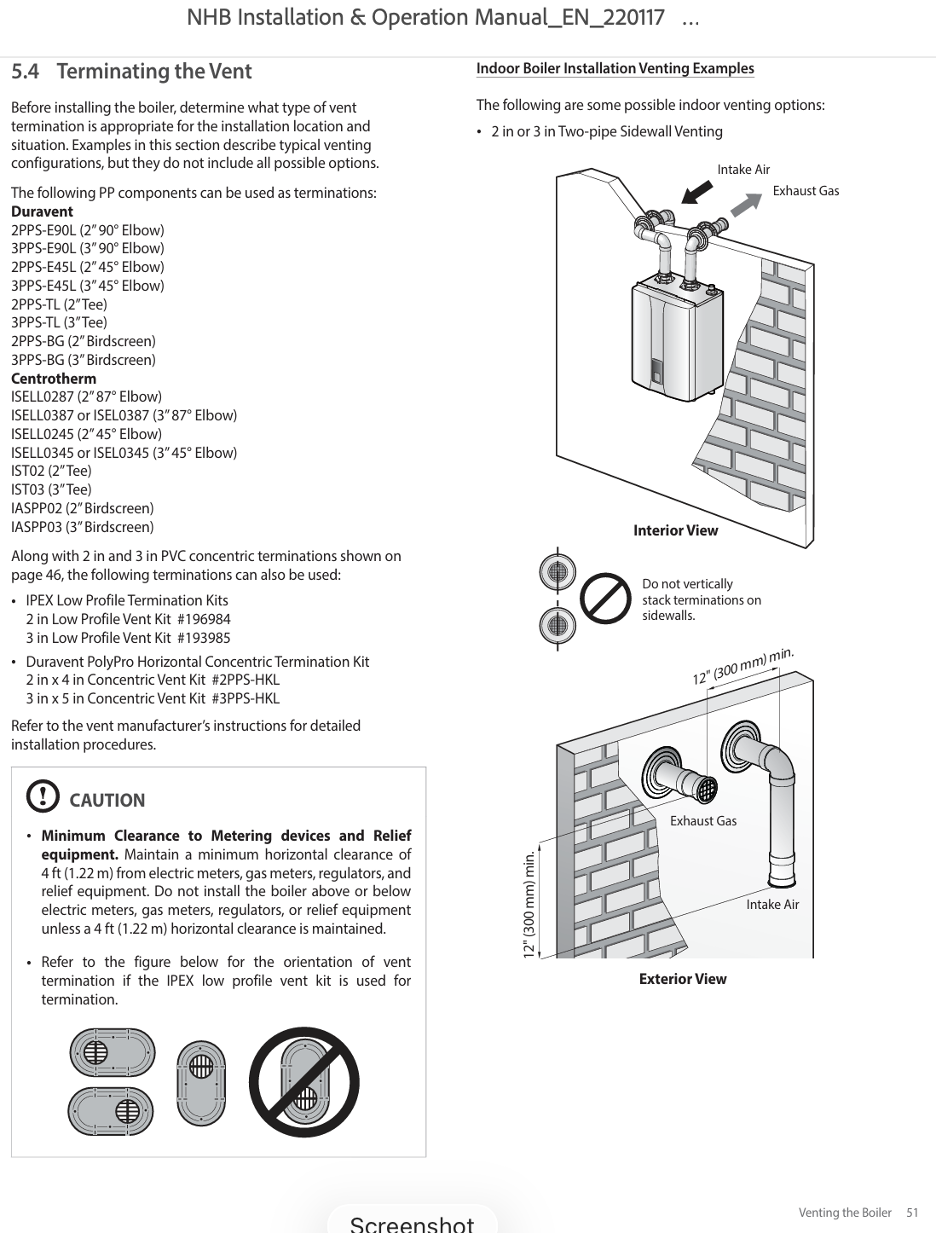

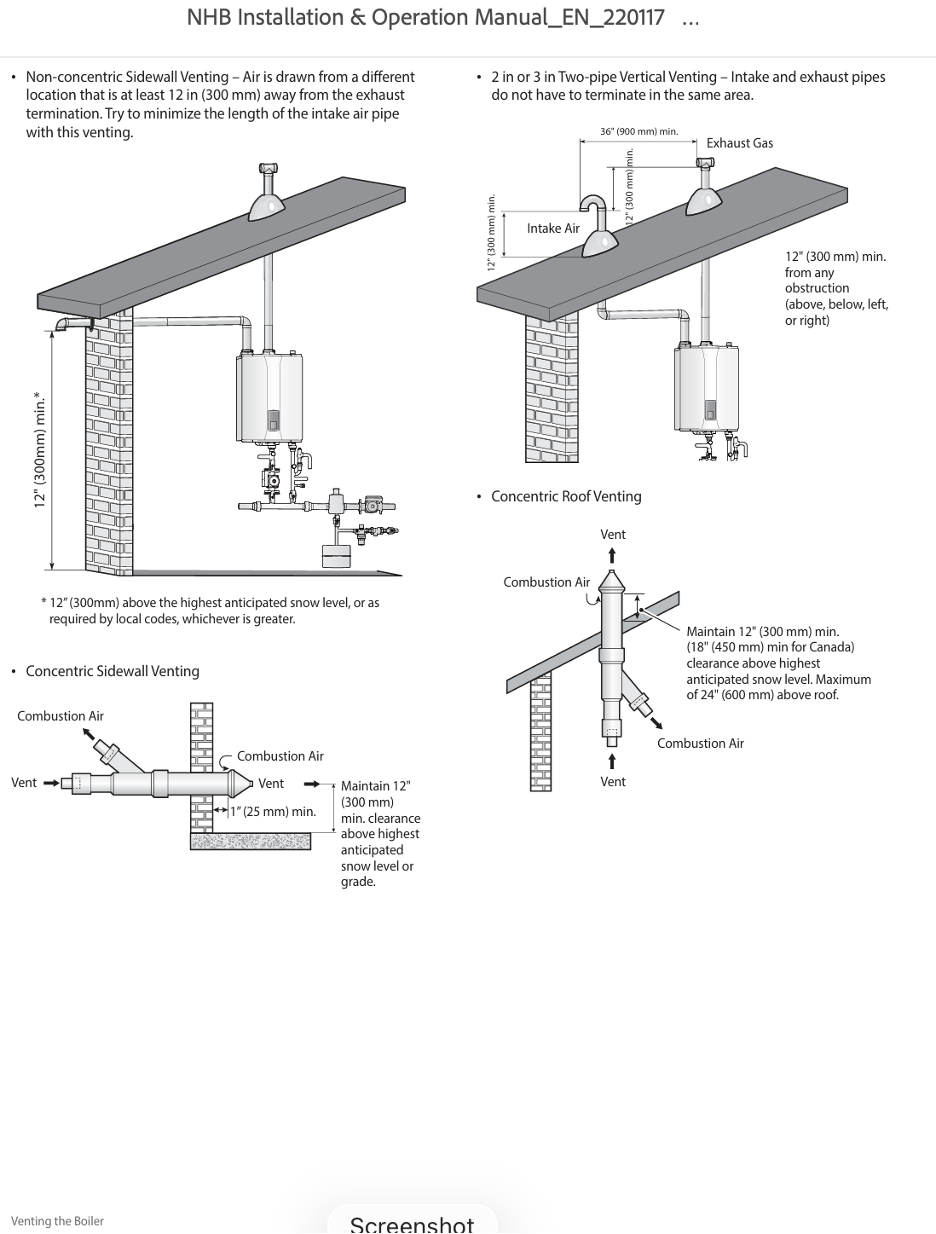

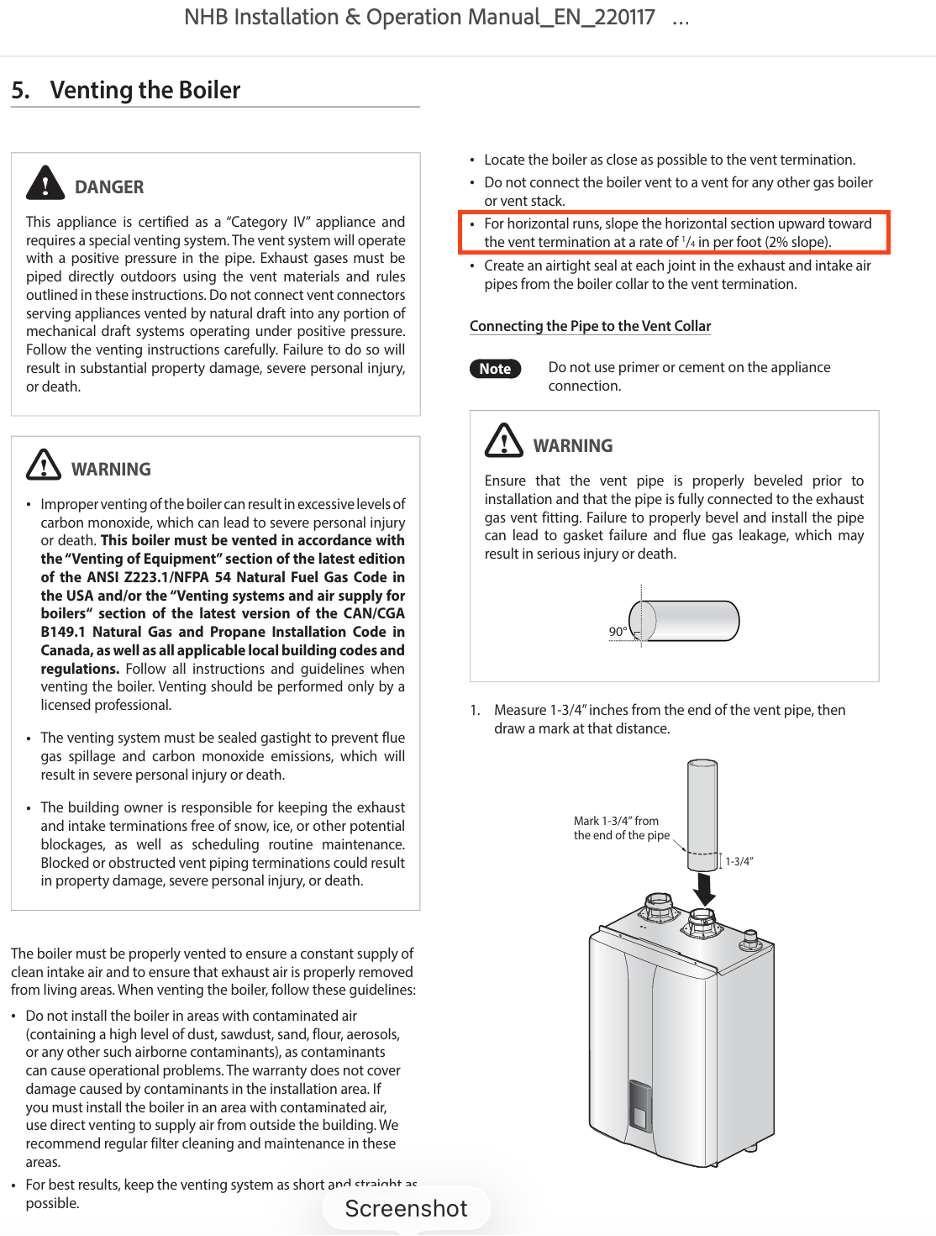

@HomerJSmith

You are correct that the intake and exhaust vents are 2" PVC pipe. According to the Navien install manual snippet below, the max length for a 2" vent is 60 feet. This max length is then reduced by the number of elbows in the system. A 90 degree elbow subtracts 8 feet per elbow and a 45 degree elbow subtracts 4 feet per elbow. As shown in the vent pictures below, my exhaust vent would be the critical path as it has (2) 90 degree elbows and (2) 45 degree elbows. Subtracting these (4) elbows from the maximum length of 60 would net in a new maximum length allowed of 36 feet. I measured my linear feet of pipe resulting in 30 to 32 feet of pipe. I do note that this is right up against the maximum allowed pipe length of 36 feet after subtracting off elbow length.

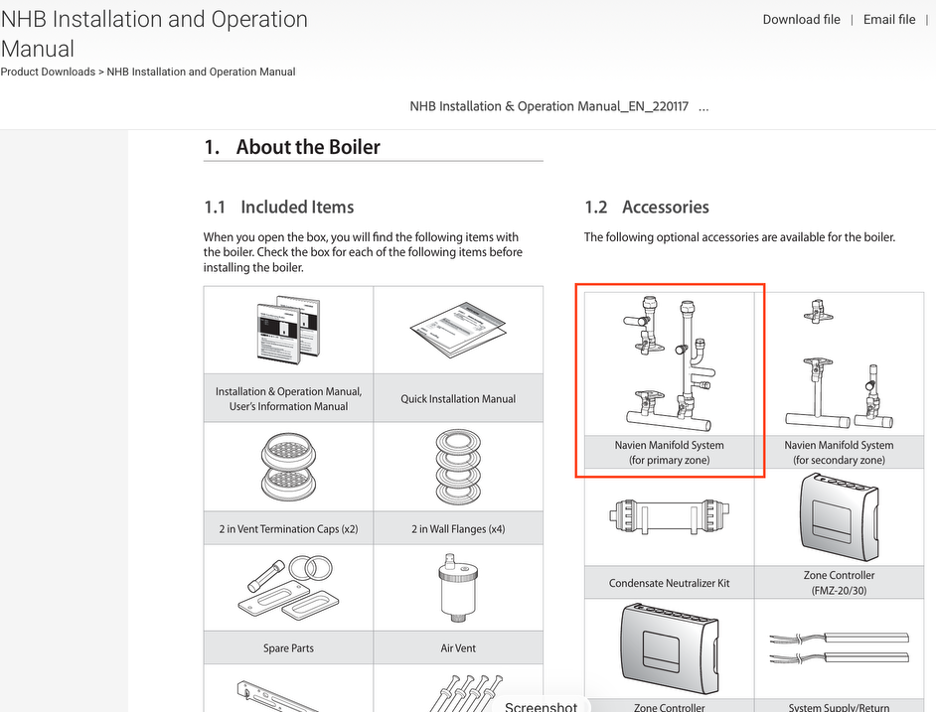

Regarding the core hydronic principles that you mention, the manifold beneath the boiler is a Navien supplied part (shown in pictures below) that gets solder sweated to the 1-1/2" shared piping. The install manual doesn't mention adding additional pipe length between the 1-1/2" shared piping and the Navien manifold.

I do intend on getting a mechanics stethoscope and pop off the cover during howling noise to see if I can pin point any specific components within the boiler as being the culprit. Some forums were indicating it could be a 3-way valve within the boiler shell.

Anyways as I have said to others, I appreciate all of your help and suggestions!0 -

If the noise varies with the load the boiler is under it isn't a water flow issue unless you have variable speed circulators.

My guess is combustion related/venting.

One thing you could try is limit the boiler input and see if the noise diminishes when all zones are calling.

0 -

@GGross

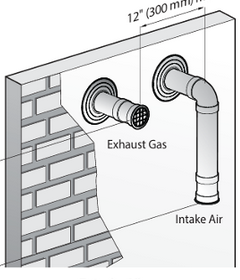

I have added pictures of the venting to show that the intake and exhaust openings are not terminated within 6-8 feet of each other.

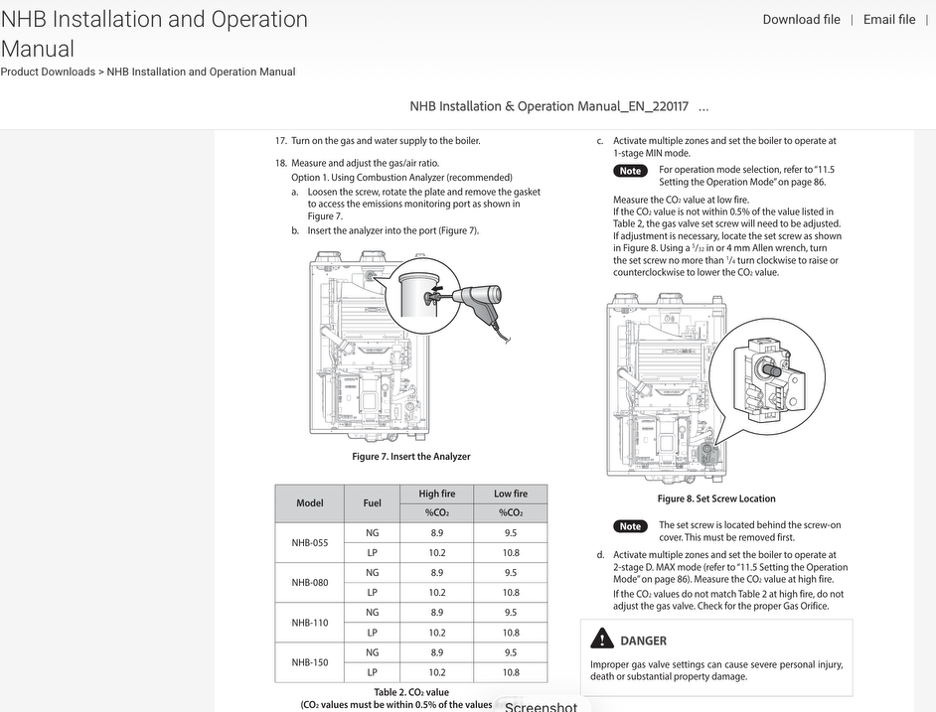

I can look into a combustion analyzer however even the residential ones (Testo 310) are kinda pricey at around $800. The image below shows how to ensure combustion is dialed in after completing the natural gas to propane conversion. I wonder if the original installer who installed and converted the unit to propane performed a combustion analysis… Linked below is a YouTube video of a tech performing an analysis and adjusting the gas vale set screw to make micro adjustments to pressure until Co2 percentage is within spec.

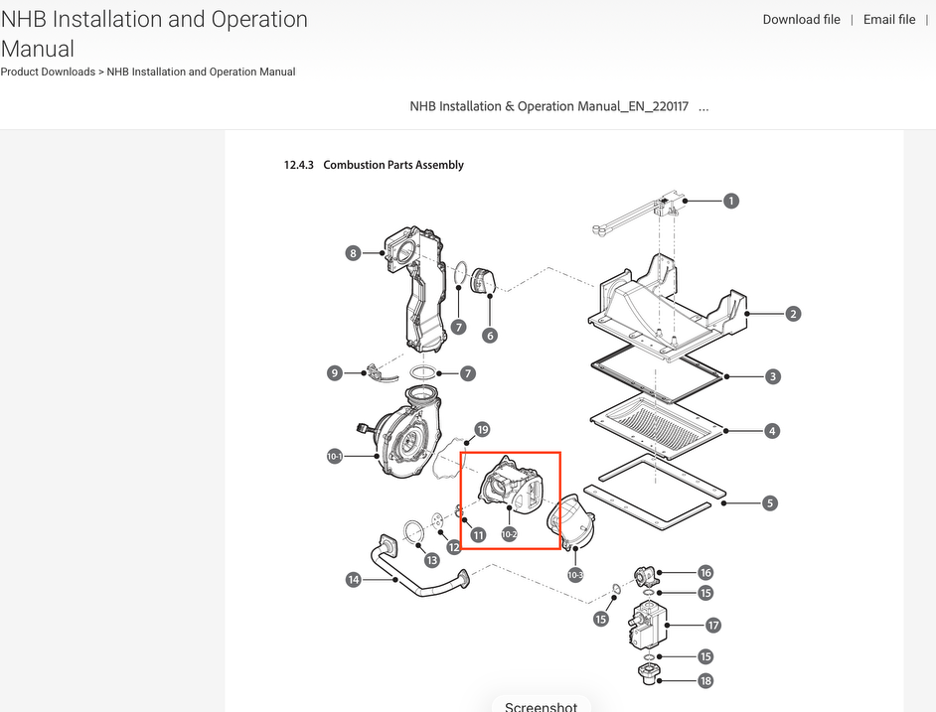

To visually inspect the Venturi (shown as item 10-2 in the picture below), I assume it would need to be unbolted from the Fan Assembly (shown as item 10-1 below) to check that the internal surfaces are smooth and soot free? I assume I could see perforations without unbolting it as there would be holes in it, right?

I can try to get some close up pictures of the Venturi.

Thanks for your help as well!0 -

@EdTheHeaterMan

Doooh! I see the optical allusion now that was fooling you. Yes the 1/2" cold water make up pipe is running slightly offset behind the 1-1/2" shared pipe, making the shared pipe look to be larger in diameter from that angle.

If you look at my reply to @HomerJSmith above, you can see once you reduce the 2" maximum 60 ft vent length to account for elbows my maximum allowed vent length is 36 ft. My linear length of pipe is around 30-32 feet putting the actual length right up against the maximum length of 36 feet.

I guess one experiment could be to hack off some of the exhaust vent and if that doesn't make the howling stop, I could use a straight pvc coupling union and put the exhaust back to where it originally was…0 -

@EBEBRATT-Ed

The noise definitely varies with load. With a single zone call with mild outside temperatures, the howling is almost non existent. With a multiple zone call and an outside temperature of 0 degrees, the howling is significant.

All of the (6) circulators are single speed, with (2) of them having option to set or select one of three speeds, low, medium, or high. One of selectable speed circulators is located on the third floor loop and is set to high to ensure water makes it to third floor elevation. The other selectable speed circulator is directly under the boiler and is set to medium per the navien manual.

When you say I could try to limit the boiler input, do you mean slightly close the propane line ball valve to decrease flow or to use the navien gas set screw to decrease gas pressure?

Thanks for your time!0 -

Try partially closing the supply valves maybe 1/4 and see if the sound changes.

0 -

@pecmsg

When you say "try partially closing the supply valves", which valve are you referring to:

1. The water ball valves above or below each of the (5) zone's respective circulator.

OR

2. The water ball valve below the boiler's (1) circulator.

OR

3. The propane gas supply line ball valve.

Thanks for your help!0 -

The zones

0 -

@ScagDriver1037, venting length is delineated two ways. Combined length, both intake and exhaust added together giving an overall length and separate length for both intake and exhaust, which would be the same.

I had to call Lochinvar tech , once, to find out which it was because it wasn't clear in their installation instructions. It turned out to be separate for a 3" pipe. Otherwise I would have to go to 4".

0 -

Removing the air intake pipe will tell you if the inlet pipe is too long for the diameter you are using. As long as there is enough combustion air in the boiler room by leaving doors open and perhaps a window open to allow for outside air to get to the boiler location. When the howling stops as soon as you disconnect the intake, you have found your problem. The fix is a larger diameter vent pipe

Lets say it does not completely stop the howling, then cut the vent pipe just before the first elbow (with room to add a coupling) and see it that makes the problem stop. If it does, then the fix is a larger diameter exhaust pipe. Put the pipe back together with a coupling to heat your home then order to larger diameter intake and exhaust piping to get the job done.

Good luck with getting rid of your werewolf.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Show me in the install manual where it can be vented like that.

0 -

I would say that vent is suspect to say the least.. If we ignore that the manufacturer almost definitely doesn't approve that much venting being outside, if a little wind hits the exhaust it will just swirl around under that overhang and get sucked right back in the intake. Not to mention the mini split being a little bit in the line of fire as well.

0 -

@HomerJSmith

I spoke with Navien. They informed me that 60 ft maximum vent length stated within the install manual was for each individual vent leg. Therefore the intake vent can be 60ft long and the exhaust vent can be 60 ft long.1 -

@EdTheHeaterMan

I have not removed the air intake pipe, however where the air inlet pipe connects to the boiler housing it terminates and has a screen strainer filter. Therefore, the inlet pipe just feeds the general boiler housing. Taking the front panel of housing off and let the boiler run would be the same as disconnecting the air intake pipe. I have done this and it still howls.

I will try making the exhaust vent shorter and see if that eliminates the howl next.

Whether we are calling it a werewolf or a tea kettle, I want to get rid if the noise asap.Thanks again for your time!

0 -

Agree that removing the cover and removing the pipe with the cover intact is the same.

You can start with removing the exhaust pipe while operating at high fire and see if that does anything before you cut the pipe and need to repair the cut with a coupling. Just don't breathe during that test.

Of course if the connection to the boiler is not mechanical (Glued) then that may not be an option.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@ScagDriver1037, I also use this sound detector. I originally bought it for my car. but works great for the boiler, too.

0 -

@yellowdog

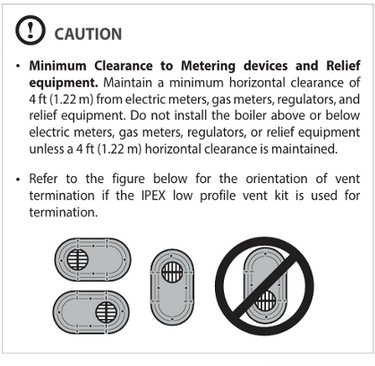

I mean this in the politest way possible but the install manual is very vague on venting requirements other than maximum pipe length and venting clearances. I have included snippets of the manual below. When referring to the manual, it seems that as long as the clearances are maintained and the maximum length is not exceeded, it doesn't seem to matter how much piping located on the exterior wall side. It does seem that my exterior piping system does meet that of the manual, with the most notable concern is exhaust length is within 6 feet of max allowed length.

I do appreciate your insight!0 -

@GGross

As I stated above to @yellowdog , I can't seem to find anything in the install manual that limits the amount of venting located outside.

I included another angle of the outside venting to show the intake and exhaust meet the 12" min separation requirement defined by the install manual.

I'd note that the mini split condenser is about 3-4 feet away from the exhaust outlet.

Thanks again for all your suggestions!0 -

I spoke with Navien today and tried to pull as much information out of them as possible without me being an "installer".

They stated that the howling is most likely due to the 6 possible reasons:

1. Low Gas Pressure

2. Offset Pressure Error

3. Defective Air Pressure Sensor

4. Exhaust Gas Recirculation

5. Damaged Air Pressure Hose

6. Improper Install of Unit

I am going to inform the installer of these possible reasons whenever they get availability to support a service call.

Reasons 1 and 2 - Need a combustion analyzer and digital manometer to check which I don't have access to.

Reason 3 - Im not sure where the air pressure sensor is located or what metering needs to be done to determine if it is faulty.

Reason 4 - Im not sure how this is would be possible if my venting is more than the 12" minimum apart required. Current vent terminations are approximately 6 feet apart.

Reason 5 - Im not sure where the air pressure hose is in order to perform a visual inspection of it.

Reason 6 - I think this one is outside my pay grade to even discuss.Let me know if anyone has any thoughts on the above.

Thanks in advance!

0 -

@ScagDriver1037 , I never use this, ever. Did I say ever? I do not trust this venting. I have seen it on the windward side of the building, which can be a big problem with gas reversion.

I do a variation of this.

0 -

The manufacturers minimum distance will not ever guarantee that you have no flue recirc. it is a MINIMUM separation. I can definitely see how your install can recirc, its definitely possible. I do not think thats what is making the howling though. as far as recirc goes, I would just pay attention to it, if the wind often blows in such a way it goes under that overhang, or blows back into the mini split ODU, then I might be concerned enough to look for an alternate route. You would start to see staining on the underside of the deck I would think if it happened often. There is also a reason you will not see your venting termination in the install manual, they almost certainly do not approve it, that being said these types of installs do occasionally happen in the field. Confirm the exhaust venting maintains the proper pitch that the book recommends, the entire distance of the vent length including that portion outside the building envelope, as an easy enough thing you can do yourself without getting too deep into technical stuff

I do think step one for a tech is to make sure the unit is dialed in correctly for combustion (using an analyzer)

I would also add that on a few occasions, with different brand equipment and working with tech support, I have had to change a boards programming when a fan RPM results in harmonic resonance and everything else was confirmed within spec.

0 -

@ScagDriver1037 , sorry I din't see your outside termination pic. Looks ok. I like the way you brought the exhaust outside of the decking. Lot of moisture in the exhaust. I have done that, too, but in my area the winters are really cold, so I insulated the pvc to prevent freezing of moisture in the exposed pipe.

1 -

Yes I usually like to see it insulated as well. I would hope the condensate wouldn't collect enough to freeze with the warm flue gas right there, but it definitely can happen in my neck of the woods.

0 -

@GGross and @HomerJSmith

I will definitely buy some insulation to wrap the exterior exposed portion of the exhaust vent pipe. I do note that after running for a considerable period of days, immeadlty under the exhaust vent termination a reverse icicle forms from the ground as the condensation drips from the pipe to the ground.

The install manual states that exhaust vent should slope upwards the termination point at a 2% slope or 1/4" rise per foot of linear horizontal length. I will verify the slope is correct as currently installed and potentially adjust hangers if need be.

With that slope and the termination point being the highest point, wouldn't the majority of condensate run back towards the boiler and drain out the condensate drain line?

Thanks again for everyone's support!0 -

-

It should run back to the boiler yes. Sometimes I have observed where the pipe sort of creates a "belly" sometimes its just improper hanger height or not enough support. When the condensate pools a little in a spot it can cause all sorts of issues.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements