Is it common to get air into Hydronic System?

I have owned my home for 3 years. It’s an oil fired hydronic boiler with 1 zone. The main house is copper fin baseboard. There is also a sunken in family room that is slab on grade with copper pipe directly into the slab from when the home was built in 1963.

The first year owning the home we had the autofill valve and expansion tank replaced (2023). It ran fine the past 2 heating seasons. Right before heating season this year (2025) my service company said they bled some air out of the system. He left the auto fill valved out because it was over-pressuring the system and causing the relief valve to open and he said it shouldn’t matter just keep an eye on your pressures.

It’s now been 3 months since he bled out the air and i can hear air in the pipes (sloshing) when the circulator kicks on. My cold pressure is 5psi and after the boiler is done firing pressure is 15psi. Before pressure was 10psi cold and 15psi after firing. The expansion tank sounds hollow on the bottom and it also has a blown diafram indicator that looks good.

I am worried I may have a leak in the slab that I am unaware of. Or is it common to have air in the system with the autofill valved out. I heard a neighbor say they had to abandon their in slab loop but not sure how they knew.

Comments

-

once filled and purged , a closed loop system should maintain

Does the system have an air purger?

Typical fill pressure with the system cold is 12-15 psi. It may drop a bit in summer if the boiler cools down more

It you do nit see any visible leaks it could be an underground small leak

Boost the pressure back to 12 psi and keep an eye on it

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

It has a spiro air scoop and a small Taco Vent on the top of the boiler.

When the heating season is over can a leak down test be performed?

0 -

Yes, but you're doing a long-term leak down test right now. The only way the system can lose pressure is by (1) an air leak, or (2) a water leak. You can check for air leaks by spraying soapy water on the Schrader (bicycle tire) air valve at the bottom of the expansion tank. If you see bubbles expanding, it's leaking air, and you can try to tighten the valve core with a tire valve core tool.

But if there's no air leak and the system pressure continues to drop slowly, the only remaining possibility is a water leak. You do have to check pressure at a consistent water temperature, obviously, as pressure will vary with water temp.

0 -

Based on the information provided so far, I would guess that you have a small water leak somewhere. Getting the Auto Feed Valve (Pressure Reducing Valve) to operate properly will keep the system at the proper pressure for the rest of the heating season. Where is the cold water feed located on your system? Someone did it correctly almost when the replacement boiler was installed by pumping away from the expansion tank, but I like to see the cold feed valve connected at the expansion tank. I don't see it in that picture you posted.

The fact that the auto feed valve overpressured the boiler and it is now losing pressure with the cold water feed valve closed, is a clear indication of a leak in the closed system. That leak can be one of the air vents if the boiler pressure drops below the atmospheric pressure on the suction side of the pump when the pump operates. With the circulator pump pushing away from the expansion tank, that is unlikely. I’m thinking it is a water leak in a 63 year old copper pipe in a concrete slab.

To test that theory, you will need to isolate that pipe at the beginning and the end of the pipe where both ends get connected to the rest of the system. That may involve adding some valves that you can use to isolate and pressure test the sections of the system.

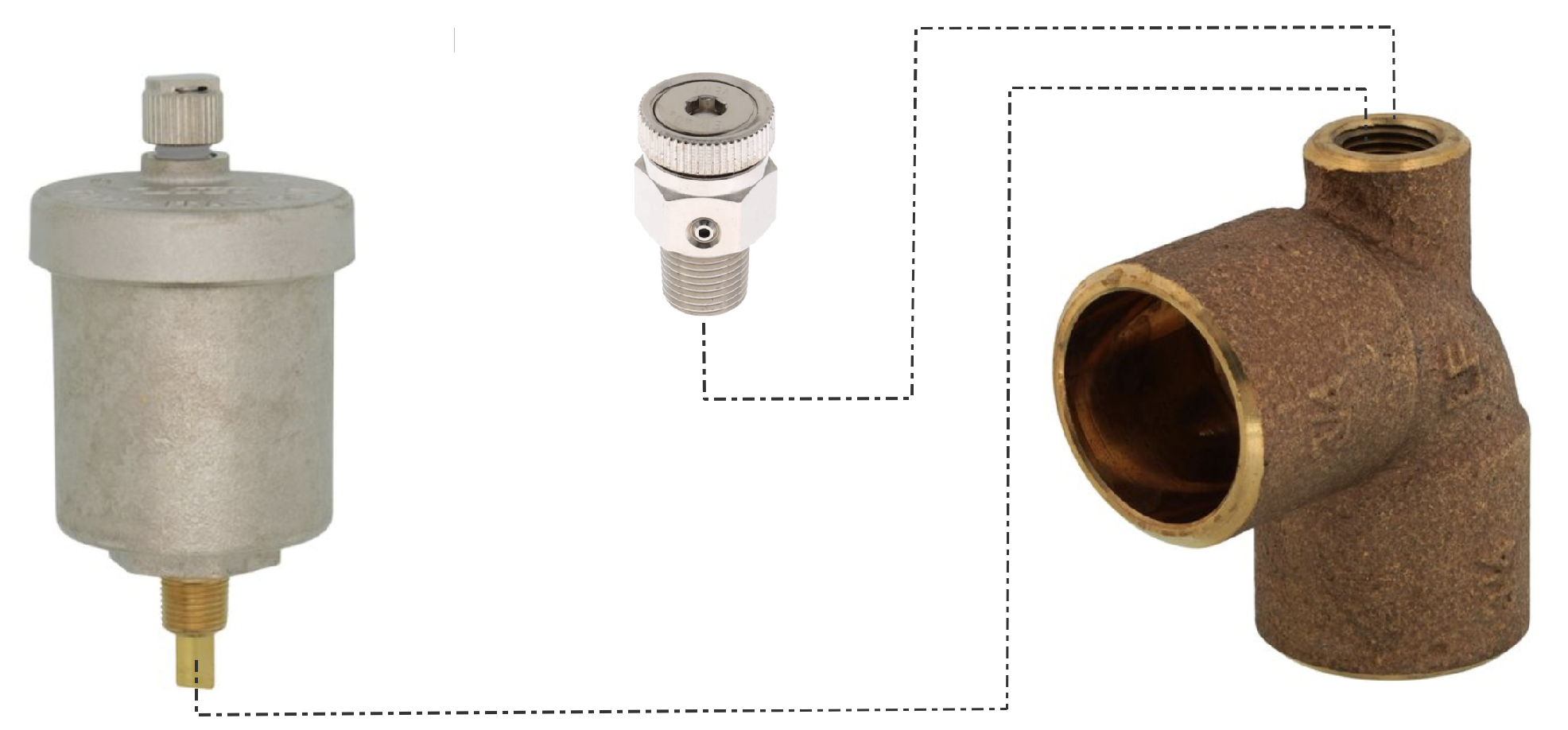

Another thing to check is to see if there are any automatic air vents, like the taco Hy-vent on the boiler, behind the baseboard covers. You may also have something called a Hydroscopic vent behind the radiator covers. They can certainly let air into the system even without an actual leaking pipe in the system. Look for this type of fitting on the ends of the baseboard radiators.

The fitting that can connect an auto-vent to the baseboard is on the right. The vent on the left is like the one on the boiler, the one in the center is called a coin air vent and some of them have a hygroscopic wafer under the cap. If it is dry, then it will let air in and out. When it gets wet, the wafer expands and stops the movement of air and no water will leak out. They can be a real problem when the pressure in the system is too low, constantly letting air enter the system on the upper floors of the building. You never know where the installer put them.

With the circulator Pumping Away from the expansion tank, you do not need any air vents on the upper floors of your system. If you have any air vents up there, I recommend that you remove them and put 1/8" pipe plugs in those openings. The you will never have air problems related to air vents on the upper floors after you do that.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

A soapy solution sprayed on the Schrader valve as @jesmed1 says above is a good idea, don't forget the one on top of your boiler, the hi-hat vent.

You might be correct about having a leak at the sunken living room. Back then (1963) copper tubing was used and concrete was poured on the tubing when the floor was put in. This would cause a chemical reaction and create leaks in the copper. It's surprising that it has lasted these sixty two years.

I would hazard a guess that the noise you are hearing sounds much like an old time piggy bank being shaken when the thermostat calls for heat. The air is getting in from the absents of water and/or the auto feed turning on adding air laden cold make up water. Cold water is oxygenated and will expand in the heating loops and there for adding the air.

Luckily you have a spirovent are separator on your system. They do a great job eliminating air. Turn the automatic water feeder on and allow for the pressure to be correct in the system. Better that then have the boiler go dry and cause more damage. Unless you are vigilant in your boiler monitoring.

If you can isolate that zone from the rest of the system with a valve on the feed and return, that will help to trouble shoot the zone in question.

Your neighbor might be right. You might need to abandon the old radiant and replace it with fin tube radiators.

0 -

If you do determine it has a small leak, in the tube you could try a hydronic leak sealent. It could buy you some time, maybe years if it is only one small leak.

A plan B as someday the system could develop more unsealable leaks, would be a good idea.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements