Using an indirect water heater as a buffer tank.

So I have a situation that I need to improve. I recently built my forever home and did much of the construction and design myself. This has resulted in some wonderful things about the home and some problems.

So a bit about the home its 1800 sqft. a modern home which is well insulated but has lots of windows and cathedral ceilings. When I say modern what I am trying to convey is a lot of exterior wall relative to the square footage

So for the heating I hired a contractor to install a combi boiler that would be appropriate for radiant heat with me doing all the rest of the install work. He chose a Bosch Greenstar 151p.

I went to another company for all my radiant supplies and they did a complete design for the system. It was going to be 4 zones. During the install I split 1 of the smallish zone into 2 micro zones, worried a bedroom and a main bathroom would need different temps for comfort. The install is thin staple up aluminum plates over plex. I did a very through install of reflexive radiant barrier 2 inches below, and its well insulated underneath.

Current system has primary/secondary piping with a circ pump feeding each zone.

Sorry the to back story was too long.

I have 3 problems with the system.

- The system at minimum output short cycles even when multiple zones are calling for heat clearly the boiler installed was not a good match for how the rest of the system was designed.

- The noise created by the expansion and contraction of the pex is really at an unacceptable level.

- The living room which we spend most of our time in has real difficulty getting up to the temp we want. We are getting old 72 degrees is nice.

So to try and resolve problems 1 & 2 I just picked up a used 50 gallon stainless indirect water heater, with the intention of using it as a buffer tank. All 4 connections are 1 inch and it has a 3/4 in t&p high up on the side of the tank. Hot water out is on the top.

My plan is to do a major reconfiguration of the system. Install the water heater as a buffer tank and replace all the circ pumps feeding the zones with a single auto adjusting Alpha 15-58f ECM pump with zone valves on each zone. My intention here is to tightly control the temperature of the tank and have the temperature as low as possible. I am hoping the water temperature in the pex could be much more stable hence less noise.

If you have any thoughts on this please point them out.

So on to specifics about connecting the water heater as a buffer. Given the connections to the tank I can either connect it as a 2 pipe or as an upside down 3 pipe buffer. So as 3 pipe what I'm thinking is the system return and boiler in teed together as close as possible at the bottom port. System supply comes out of the top of the tank, and boiler out is connected to the 3/4 in t&p port. I know this will cause some mixing in the tank but maybe that a good in that I want to tightly control the temp to the zones to avoid large swings. The coil ports will be left open as they are not needed.

Does this sound like a good plan?

Do you have any suggestions?

For the control end of things I have installed an outside thermistor for the boiler. Not that I think I get any benefit from it in the current configuration but I do have a Bosch FW200 that I could install and believe I could use it to maintain the buffer tank at a variable temp based upon the outside temp. I am not sure if it would tightly control it the way I would like it to be though

Any thoughts here? I do have a bit of a controls background (not in the HVAC world) so I could build my on system but maybe using off the shelf components (aquastats ect) would be best when I cannot be the one fixing things in the future.

Again please any suggestions.

Comments

-

So the indirect will be for DHW also? Or DHW pre-heat? Or will you use it as just a supersized heat exchanger for the boiler/ radiant?

Did you try all the available boiler settings. Derate the firing to the high load? Perhaps it has "anti cycling" function? This basically locks the boiler off for a period after a cycle. If the radiant has some mass, that may be an option.

If you know the load of the smallest zone and the lowest turndown you can calculate some run time improvements.

But if you have the tank already, may as well maximize it.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hot Rod thanks for your thoughts. Yes I have thought about how could I configure the indirect coil to benefit on the DHW side too as that also is problem as temps in the shower can bounce around a bit but I have been more concerned about the heating at this point. Project 2… will probably be a DHW recirc addition to the system that may help

It has occurred to me that maybe I could get some benefit out of the coil of the DHW side but that would be a bonus to getting the heating working better.

Yes I have adjusted the internal settings of the boiler to minimum output to see how that would improve the short cycling and it did. I also tried different flow rates of the boilers internal circ pump I found the slowest setting increased cycle times. When the boiler's max was set to 100% I was seeing cycle times of 2 minutes max. often more like 1 minute. I changed it so its max output is its minimum (this boiler has a very poor turn down ratio, clearly a very poor choice). Under this scenario I am seeing cycle times commonly around 4-5 minutes I have seen a couple times where it was 9 minutes. Im sure most all zones were calling for heat at the same time then. We have had some pretty cold temps here so those longer cycle times are probably not very common otherwise.

To my understanding with an outside reset thermistor connected to this boiler it optimizes its burner ramp rate and anti-short cycling. So if I am to believe that I would think disconnecting the outside thermistor would have only made cycle times worse. I could disconnect the outside thermistor and try to increase cycle times manually but it seems to me that is likely to only worsen my second problem with noise from the pipes.

As for buffer tank sizing I did the calculation a long time ago when I realized that was probably a big issue. in came somewhere around 50 ga.

Does the 3 pipe setup I described sound reasonable?

0 -

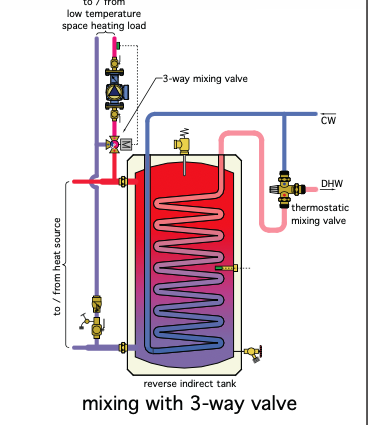

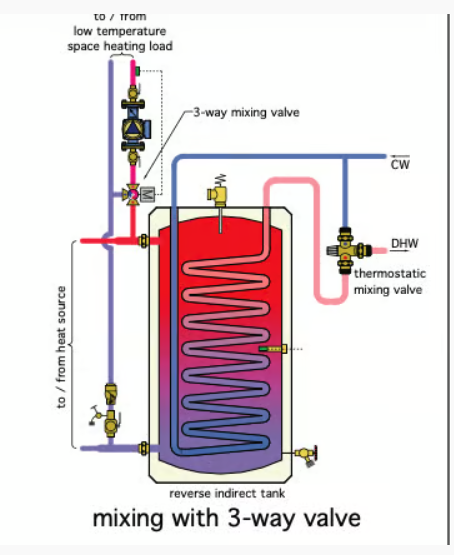

So to maximize a buffer to length cycle time, the best use is to run the tank hot, then mix down to the radiant via an ODR control. That give you the most energy drawdown.

However the mod con looses efficiency at temperatures above 140 or so. If running the tank at system temperature buys you enough extra cycle time it is the simplier approach.

We had Bock Water Heater run some test years ago regarding pulling heat out of an indirect via the upper coil. Solar in the lower coil. unless the tank is somehow being circulated the performance was dismal. The coil ends up in a pool of cool water if the tank is not mixing. Same with the middle drawing here, the coil at bottom.

To best use the tank you might connect the radiant to the tank itself, the 50 gallons. Then heat the tank with the boiler. You would not have a DHW function from the tank however.

A reverse indirect works well, as the entire tank top to bottom has coils.

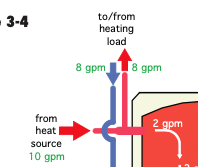

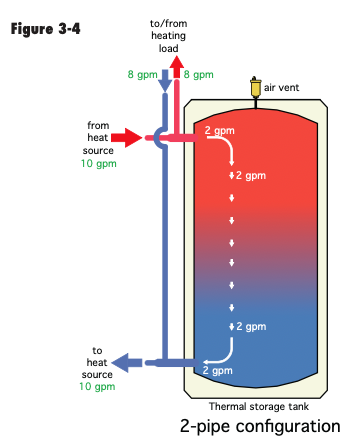

Caleffi has buffer tanks in the European market, this is a drawing they use showing various piping options.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks hot_rod you have given me a good direction to pursue. Using a hotter tank with odr/omr injection sounds like the best approach to try and solve all the competing facets of the problem.

I'll comeback to ask a bit more when I have a better handle on a design.

Thanks again.

0 -

Hi hot_rod

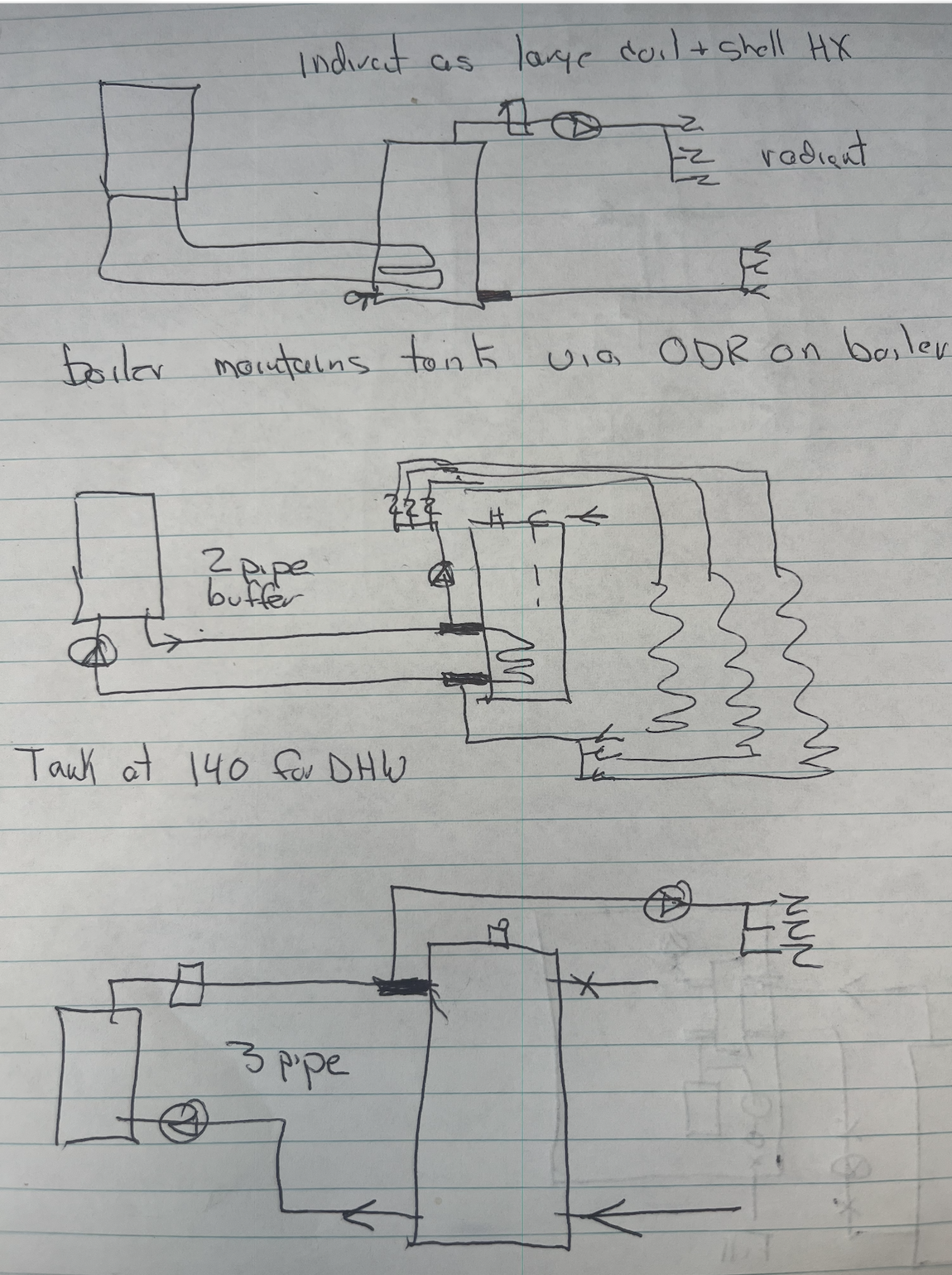

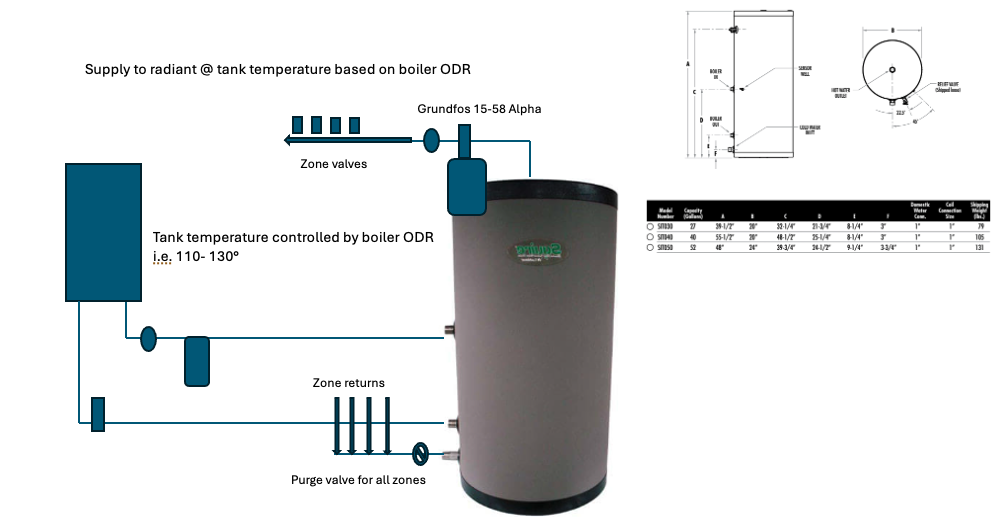

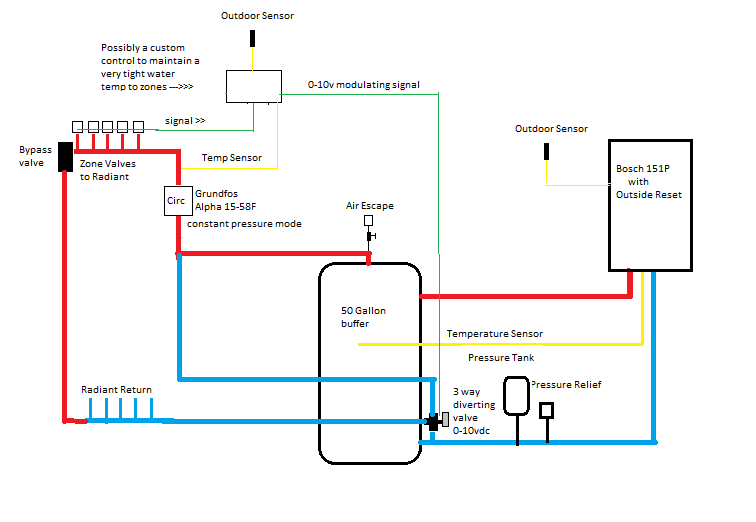

The attached image is what I came up with using variable speed injection. For simplicity I have left off a lot of shutoff valves ect. At this point I am totally ignoring the fact that I have an unused coil which I may in the future us to my benefit for DHW.

Do you see anything in my plan that stands out as a bad idea?

The Tekmar design essay e021 said I need closely spaced tees on both ends of the injection circuit. I did not think that was needed on my tank side of the circuit, but I do show the 1/2In Dia ( size from their design doc) injection pipes dropping down for a heat trap. Any thoughts about that?

The components I chose are pretty much the first ones I came across that seemed reasonably priced. If you think there are better choices that I should be looking for please let me know.

Again thanks for all your help.

0 -

I suppose the cold water to the DHW side of the combi could run through the coils and pick up some heat.

I would connect that the supply from the tank off the side port like you have the return. It is probably a 1'"?

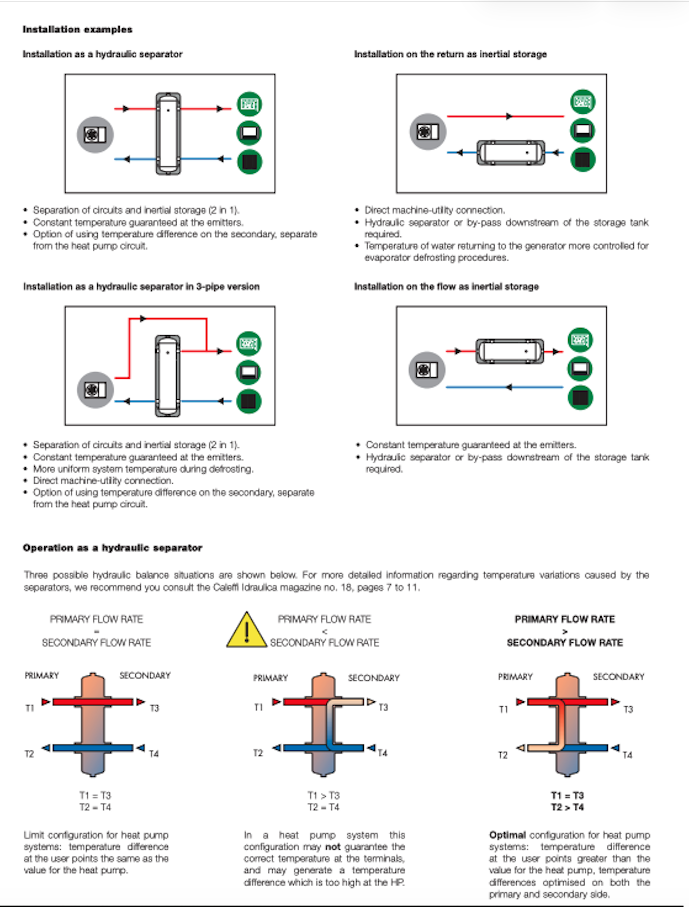

The piping at the tank is the hydraulic separation function. You have more of a 2 pipe method.

The 3 pipe concept is more about the return piping. It brings the coldest water back to the HP or boiler and also engages some of the the tank without top to bottom mixing.

We have done injection mixing from boiler loops to a tank, or tank to load without close tees at both ends.

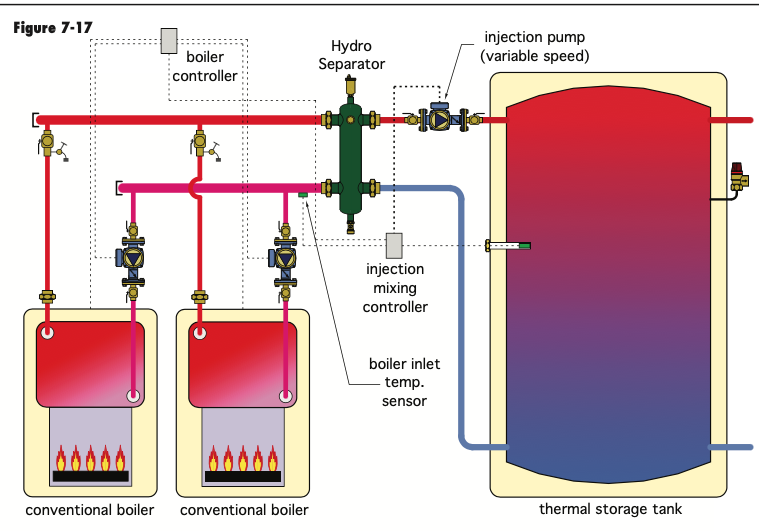

7-17 runs the tank temperature and offers boiler return temperature protection.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hi hot_rod,

That side port up high is 3/4inch it was for the T&p. Does that change your opinion that I should connect the feed to the injection pump there as well as the hot water from the boiler? I kind of feel the 3/4port with 1inch pipe coming to it from the boiler probably does not really function well as a sort of closely spaced tee configuration.

I do wonder if it makes sense for me to be running 1in from the boiler to the buffer tank and back considering the injection circuit will be only plumbed with 1/2inch. Do you think 3/4 would be adequate? That would save quite a bit of money but might look wrong.

I realize I cannot do a proper 3 pipe as my ports don't allow it

0 -

The size of the injection loop depends a bit on the temperature of the tank. The hotter the tank, the less flow it needs, the smaller the pipe.

So if you know the required temperature for the radiant and what the tank will be, you see the pipe size. I suspect 3/4 would be plenty.

If your tank has two 1" connections up top, one must be the cold with a dip tube? The coil connections are on the side?

Or is it a HeatFlo, they have all 4 connections on the top, coil and tank?

You already have ODR built into the boiler. It may be simplest to just let the tank temperature be controlled by the boiler. It limits the tanks "buffer" capacity a bit, but much less $$ and simple piping.

You are basically building a 50 gallon boiler.

Maybe a pic or link to the tank info would help see the best option. Is the Greenstar a combi, or how do you make DHW?

Your 3 goals that a buffer will help with

1-reduce cycling

2-reduce pex expansion noise, the ODR will handle that with near constant circulation.

3-As long as the main room has enought tube it should heat. Getting the high temperature setting on the ODR should cover that.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Yes my intention is the boiler will manage the tank temperature on its own with the tekmar managing the temperature of the heating circuit.

The tank is a Lochinvar Squire 50ga SIT050 here's a link https://s3.amazonaws.com/s3.supplyhouse.com/product_files/Lochinvar-SIT050-Brochure.pdf

For the design of the injection circuit and pipe sizing I used this Tekmar document https://www.watts.com/dfsmedia/0533dbba17714b1ab581ab07a4cbb521/35980-source/638705598180000000/e0021-06

From the design docs the radiant supply house did for my entire house it came up as needing 43,710 btus. My gut feels like that might be a little low but maybe not I used 50K in the calculations. Here is a spreadsheet I made up of a few scenarios.

Buffer tank DegF

System DegF

Buffer to Sytem Delta T

Sytem Delta T

Btus Required

flow rate GPM

Flow Ratio

Injection flow rate

pipe dia

pump

Tb

Ts

Calced Value

from table

calced value

from table

from table

135

110

25

10

50000

10

0.28

2.8

0.5

Taco 007

140

110

30

10

50000

10

0.25

2.5

0.5

Taco 007

120

105

15

10

50000

10

0.4

4

0.5

taco 007

I do worry that the flow needed through the injection circuit might be very low at times such that the injection pump might not be able to be metered down enough. Which might lead to a sort of pulsing on and off of the injection pump and I would end up with bouncy temps feeding into the heating zones. I have really no idea of how tightly the Tekmar control will be able to manage this feedback loop.

For the living room which is hard to get up to temperature (it has 3 exterior walls, tons of glass and a cathedral ceiling) I am thinking of adding another loops to its circuit that feeds a 24in x 48in European style radiator at the coldest corner of the room. I am assuming I can get some sort of non electric thermostat to manage that.

The Greenstar is a combi and that is how I make dhw.

0 -

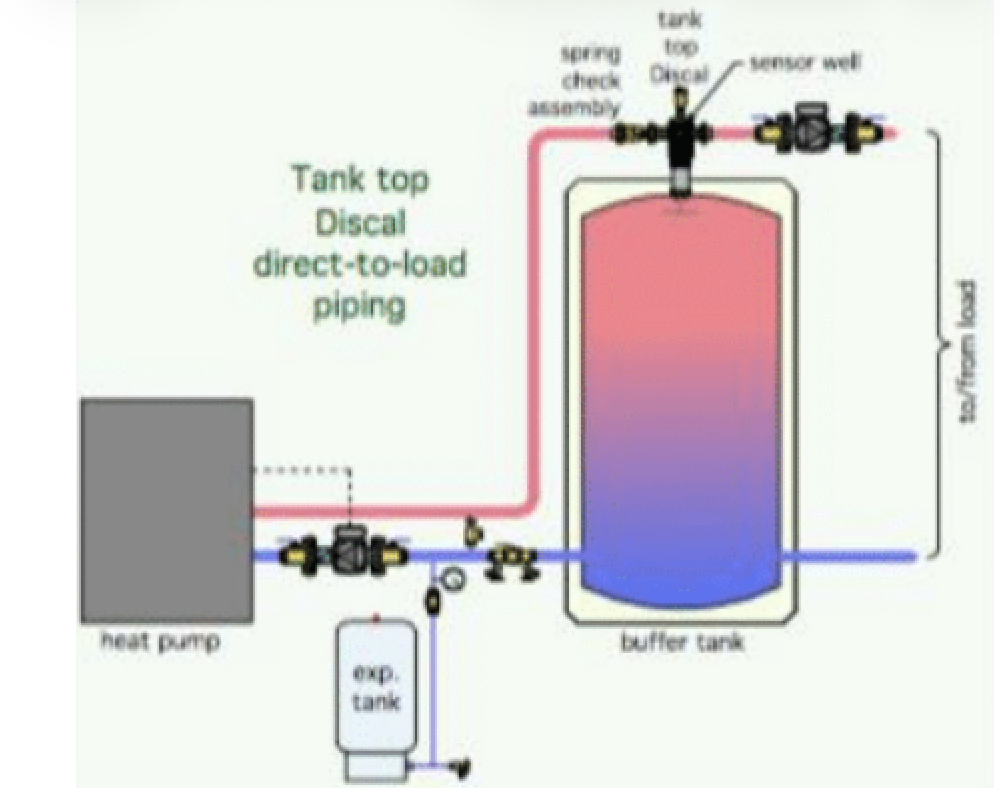

Skip the injection control and additional ODR control. For a 50K load the injection flow would be well below and small circulator as you mentioned.

This uses the buffer as a heat exchanger/ buffer. It's temperature varies based on the boilers ODR

It does require two air purgers, expansion tanks and fill valves.

You want to add heat emitters to that great room so all zones can heat adequately with the same supply temperature.

Boiler supply to the bottom coil connection, radiant return to bottom tank conection for counterflow direction.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Sometimes you lose the advantage of stratification when one uses an indirect tank instead of a real buffer tank.

You may have to resize the Expansion tank for the increase in water quantity.

0 -

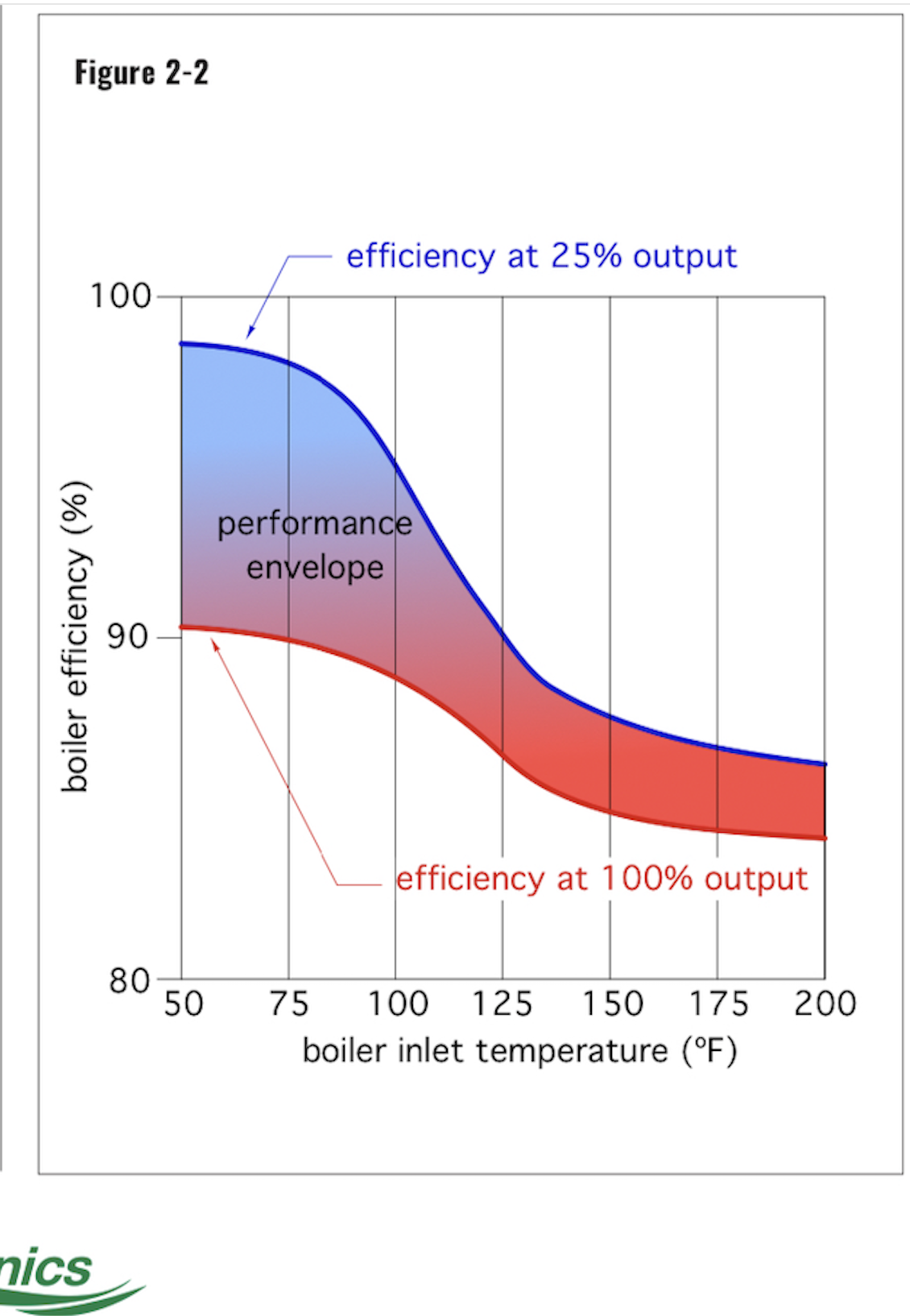

This graph shows how efficiency changes as you run the boiler hotter.

Notice a couple things, as the return drops below 130 the curve goes up quickly. 130 and below return is about where you start condensing.

Also as the boiler modulates down its firing rate efficiency goes up also.

That is why you want to use the boiler ODR and I would also limit the firing rate to that 40- 50,000 btu/hr rate. If that is the heat loss number?

Using the upper blue curve there will be many days where you run below design temperature. If you get to a point where the boiler has modulated down to it's lowest firing rate, maybe ODR targets 100 or so, now you are running mid 90% efficiency.

If you lock the boiler at a higher SWT to make injection mixing numbers work, you are sliding down the efficiency curve.

These point gets overlooked a lot with mod cons. The lower the SWT, more importantly the RWT, the more efficient. The lower the firing rate the more efficient.

Even IF the boiler was running 200°F, lowering the firing rate gets you a few % better efficiency. The blue curve vs the red curve.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hi Bob hot_rob, thanks so much for your suggested design with the isolation of the boiler water from the radiant circulation water. I like the simplicity of it, but I'm finding the creaking of the pipes in my system is driving me crazy. I'm not confident that the temperature swings of this design will be tight enough to alleviate this creaking. To that end I did remove some insulation under an accessible area under my floor to remove some blocking that I used to retain the ends of the loops at the end of the joist bays. I had put them in when I installed the piping. I was worried the the ends of the loops with constant flexing would eventually pull down the flimsy staple up plates. Anyways removing this blocking probably only fixed 25% of the noise problem.

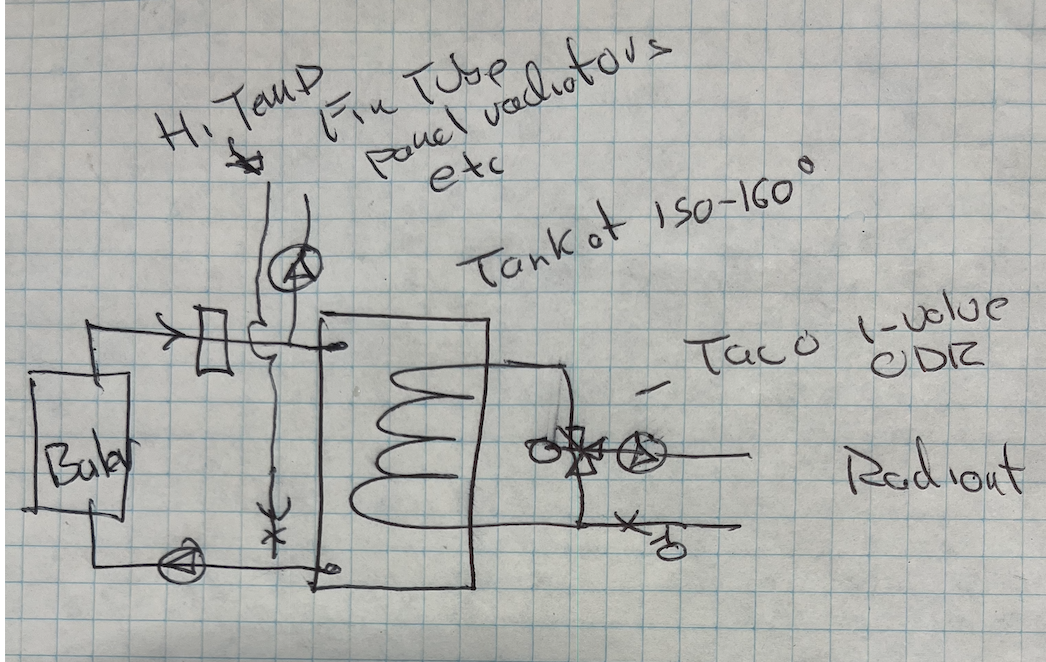

So given that an injection pump system would probably not work well on warmer days considering my small load I have been investigating modulating 3 way diverting valves. I'm thinking this way I could have a very tight control radiant water temperature and not have to worry about warmer weather as a problem. If I can find an off the self control to drive it I'll go that way or otherwise I will build my own (its within my skill set).

See the attached drawing of what I'm thinking.

I have been struggling with trying to make sure sizing of the valve and the circulation pump works for my design. I have gone through the effort of trying to figure out this sizing using demo versions of tools and online resources but have gotten bogged down in the weeds on this. My efforts to get a good handle on this have certainly given me an appreciation for the skills needed to do this right.

So the 3 way valve I'm thinking of is a 1in Siemens 248-00233 diverting valve. There might be better choices not sure, that's what I could find readily available. My worry is that I might be oversizing and will not get good resolution on the output. I am very confident the my coldest day load is somewhere between 7 and 10 gpm. Do you think dropping down to 3/4in would be better I'm thinking in that case it might still make sense to connect it up with 1in copper and reducers so as to not add additional resistance to the system.

For the circulation pump Grundfos Alpha 15-58F in constant pressure mode. I am thinking a bypass valve would protect the pump when there is very low heat demand but I am worried that the high end requirement might exceed what the pump can handle. My system has 11 circuits of 1/2in pex ranging from 250ft to 180ft runs. Not asking for an analysis but does your gut say the pump should be able to handle the high end demand?

For the great room that just does not have enough floor to heat the space I'm thinking the easiest solution is to add a small amount of electric baseboard using a setback thermostat set a bit lower than the radiant thermostat so it only kicks in if the radiant can't keep up. I did look into the European style large flat panel type radiators but they are very costly and was to sure they would do the job at low water temperatures. I did think about it being feed with its own circulation pump and the higher temperature water from the buffer tank, but that just adds more complexity to a system which it probably too complex already. The analysis I did suggests I only have a 2500 btu shortfall. We also like to use a woodstove in this room so that is another factor reducing my worry of heating cost of electric.

0 -

Meant "joist bay" not stud bay. I tried to edit but it did not seem to work

0 -

The outdoor reset fuction is your best bet to lessen thermal expansion/ contraction noise. Properly set up you get near constant circulation. This helps for comfort, efficiency as well as most noise problems.

You have two choices. Simplest is just run the boiler and tank on the ODR, so the tank temperature is always modulating to the heat load.

Or run the tank to a set temperature, maybe 150 or so and use a mixing valve off the tank on ODR.

This Taco 3 way valve is a crowd pleaser, it has the ODR function built in, comes with the various sensors.

If you wanted to run the tank at higher temperature for fin tube or panel radiators in those under radiated rooms. This option covers all the potentials

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Hot_rod thanks so much for your thoughts on this I'm going to look into that taco valve.

0 -

I took a detailed look at the taco I100U3R-1. It seems to be exactly what I was hoping to achieve with my own custom control paired with a 3 way valve.

Though I would love to build my own control, using a properly designed off the shelf product is a much better idea.

Do you think 1in is likely oversizing the valve?

0 -

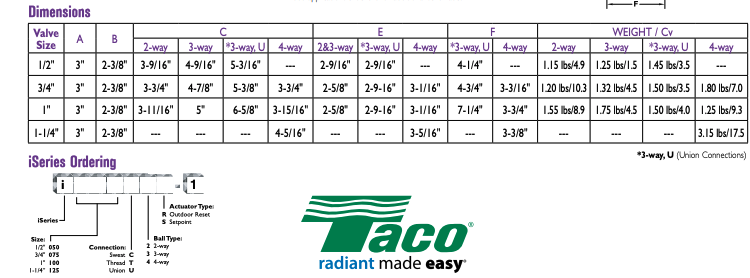

I took a further look at the charts for 1in and 3/4in taco valves with unions they seem to have the same specs. I think the difference is in the union adaptors.

0 -

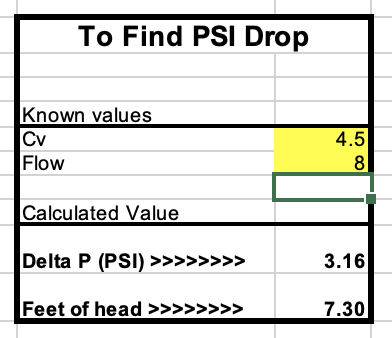

In a perfect hydronic world, you would size a control valve to the gpm you intend to run through it.

So if you are intending to run 4.5 gpm through the circuit, a valve with a 4.5 Cv is perfect.

Since valves do not come in 1 or 1/2 gpm increments you use a Cv calc sheet like this.

Suppose you need 8 gpm in the circuit and have a 4.5 Cv valve. Now you add 7.3' head to the circuit

The pricepoint of that I valve seems reasonable. I doubt you could build the 3 pieces for that $$.

It is somewhat limited on adjustability compared to a stand alone control like the tekmar

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Hi Bob hot_rod, I ran across a youtube video from HeatingHelp that discusses mixing valves versus diverting valves. The video makes me believe that I should be going with the use of a diverting valve in the configuration I drew versus the mixing valve you suggested. Do you agree? If I go forward with the diverting valve as I originally planned do you see a reason for a check valve? For that matter if the check valve was removed from the mixing valve design you showed wouldn't that satisfactorily resolve the cavitation concern pointed out in this video?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements