Prefab boiler panel for phased hydronic upgrade

Hi all,

I’m planning a phased upgrade to my home’s hydronic heating system and would appreciate some feedback from the pros here.

Current system

- Older cast iron boiler (Peerless WBV series) with a Carlin EZ-Gas conversion burner

- Two zones today:

- “Main House” (mixed cast iron radiators + cast iron baseboard)

- “Addition” (cast iron baseboard)

- Each zone has its own circulator (currently Taco 007s) and both zones are pumped on the return

- Near-boiler piping is functional but messy/maze-like from years of modifications (pipe size changes, some dead-end runs, etc.)

- Boiler is basically on/off, 180°F type operation (no mod-con yet)

Phased plan

Eventually I’d like to convert the whole house to radiant floor, but I’m doing this in phases and want to build a clean “backbone” now.

What I want to do now is

- Repipe the near-boiler area cleanly

- Convert the current 2-zone setup into 3 zones (split Main House into Upstairs/Downstairs) while I’m already cutting/repiping

- Keep everything as high-temp water for now (180°F-ish), since I’m not installing radiant yet

- Use copper for the near-boiler “panel” and oxygen-barrier PEX for the distribution runs

- Install a hydraulic separator (I was looking at the Caleffi SEP4) mainly for:

- hydraulic separation / decoupling boiler flow from system flow

- air elimination

- dirt/magnetite separation (I’m sure there’s plenty in the system)

- Stub/valve future ports for radiant so it’s easy to add later

Wiring constraint

Upstairs is tricky to wire for a new thermostat. I currently have central AC with a wired thermostat upstairs (attic air handler). I’m considering using a thermostat setup that can run wired AC in summer and provide a wireless heat call to the basement zone relay in winter.

Prefab panel question

I’m considering buying a prefab “boiler panel” (pumps + control relay, etc.) such as the RHT Trident Boiler Panel type products, and then using a hydraulic separator between the boiler and the panel.

My thinking is:

- prefab panel = clean, tested, professional layout with 3 zone pumps + relay

- separator upstream = hydraulic separation + air/dirt separation + future-proofing

- I can connect my three high-temp radiator zones now and add radiant/mixing later

Questions

- Is it appropriate to use a prefab “radiant boiler panel” even if I’m NOT installing radiant yet (just high-temp radiator/baseboard zones)?

- Is it reasonable to place a hydraulic separator (air/dirt) between the boiler and the prefab panel, or is that redundant / incorrect?

- For a cast iron boiler, anything I should be careful about regarding low return temps / condensation if I add hydraulic separation?

- Would you recommend pump-per-zone for now (3 ECM pumps), or go straight to one system pump + zone valves?

- Any “gotchas” with these prefab panels that I should be aware of (pipe sizing, flow limits, serviceability, etc.)?

My father-in-law is a licensed pipefitter, so I will have him help out, but I want to learn what I want before bringing him in.

Thanks in advance — I really appreciate any guidance.

Comments

-

what type of experience do you have or are you relying on your FIL ? Not to blow anybodies candles out just wondering ,being there alot of mistake that can be made even by those who are in the business . None of those here would want you to get in over our head and end up w a work of pooh and issues . Just from what question your asking you most likely will spend more then you should . Unless your willing to possibly at some point pay some one if there issues it may be harder to get some body to lay there hands on it . I say this not to be mean spirited but as a word of advice being i ve seen more then my share of work by those who thought it was so easy and some who thought it was so easy and lived w the results for years . Just some food for thought .Possible do some more reading before leaping . Some of your concerns are not even warranted .

peace and good luck clammy

R.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating0 -

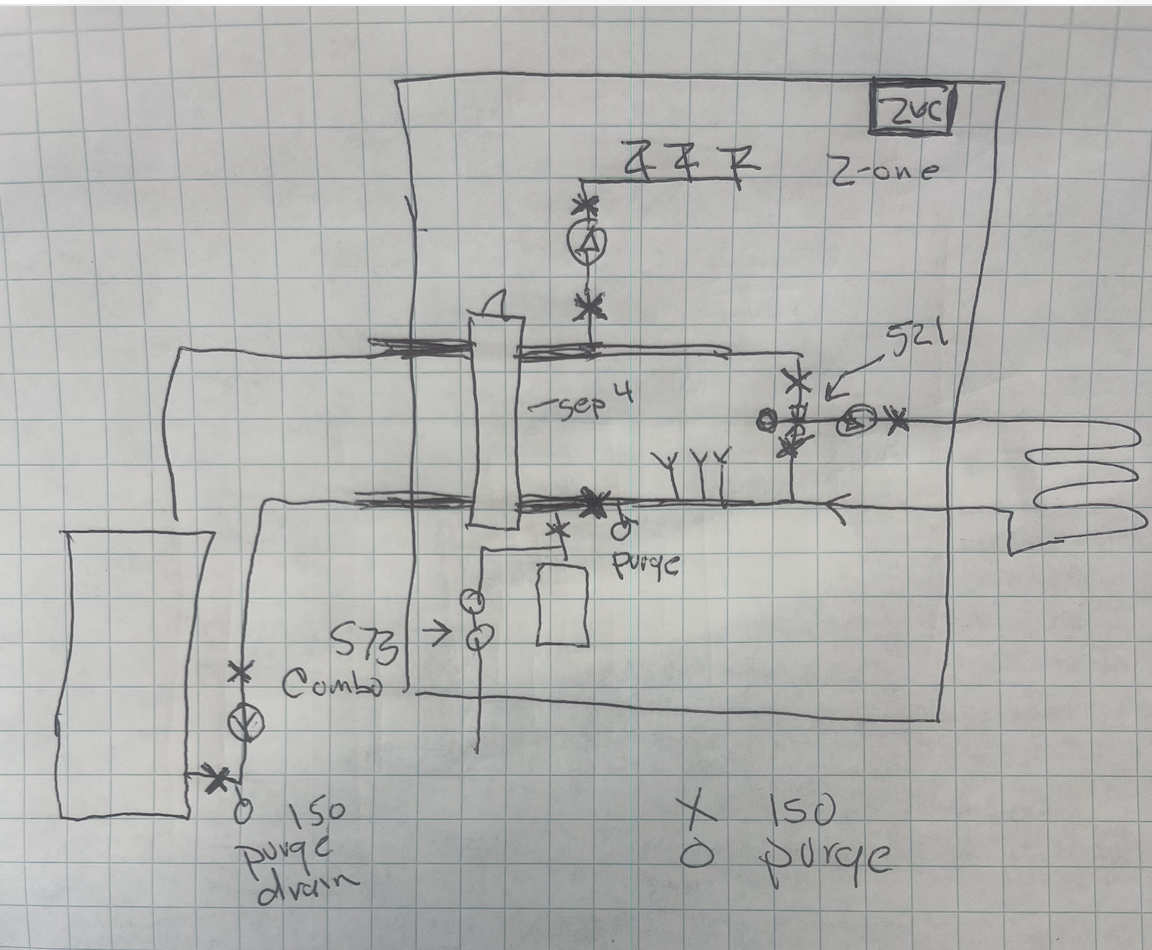

If you have access to an experienced pipefitter, build your own. Build it on a bench and pressure test so it is ready to hang and connect.

Probably fit all those components on a 4x4 sheet of plywood, maybe smaller if you are squeezed for space?

Relay box in upper right above all the piping

Sep 4, a 1" if the boiler is 100,000 btu/hr or smaller

Z-one zone valves

573 combo fill backflow

#30 expansion tank

521 mix valve

2- Alpha 15-58 circs 1 high temperature, one after mix valve

ZVC relay box 4 zone so you have a spare

2- 1" Webstone purge iso valves at sep and at boiler return

misc iso valves

3 fin tube zones would not need a boiler protection device

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

No offense take. I'm happy to have honest feedback. I don't have much direct experience but have some good resources to pull in in case of emergency. I would probably start in April and have until October before it becomes and emergency.

But you said "Some of your concerns aren't even warranted". Can you be more specific about what you mean?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements