HELP!!Is It possible for a Boiler to Run with a Sealed Air Intake, and APS always closed

Comments

-

it's closed because that should be the normal position. it's what we call a "normally closed" device. it will open due to a blocked vent from what I could read. so until you have excess pressure in your exhaust vent it stays in the closed position.

0 -

if the APS was jumped you would see that at the connections on either end of the wire harness or wires cut and wire nuted together

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

oh my god... I’ve asked them millions of times where my commissioning report is... they never said anything... no report… no receipt….. that’s the origin of why this whole investigation started from the very beginning, not by a technician at all... just me …. because the air intake cap was never removed, I realized they could not possibly have a commissioning report with combustion analysis... and the supply and return water temperature difference right now is only a few degrees…

I just took some videos… Since now the intake cap is taken off and there’s no blockage in the condensate... when the boiler is completely off, no fan, no gas, no error codes, nothing, the APS status on the screen still says “ON”. it's not based off AI answers.. it's literally on the screen of the boiler… and I even got confirmation from the manufacture that this is not right…..

and the whole thing is now such a mystery, that’s why I doubt someone intentionally bypassed something when the intake cap was not taken off yet and the APS couldn't close properly… that's why they might "have done something"…

I sent some videos here, none of these are AI

Here are some crazy videos….

when boiler is ON, APS is ON

when boiler is ON, APS status is 1

when boiler is OFF, APS status is STILL 1

when boiler is OFF, APS is still ON

0 -

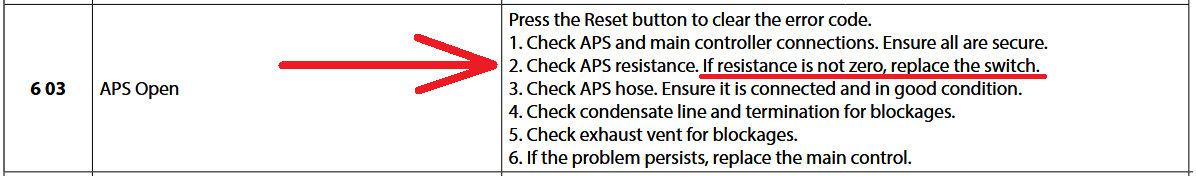

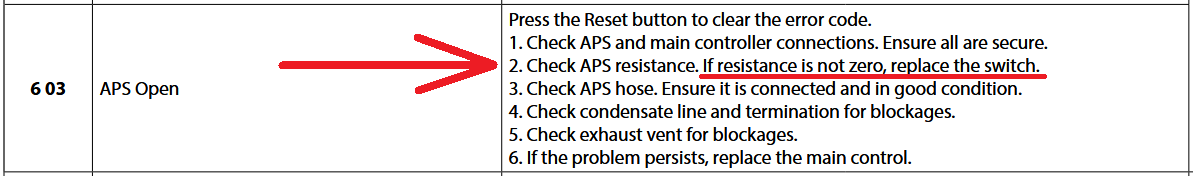

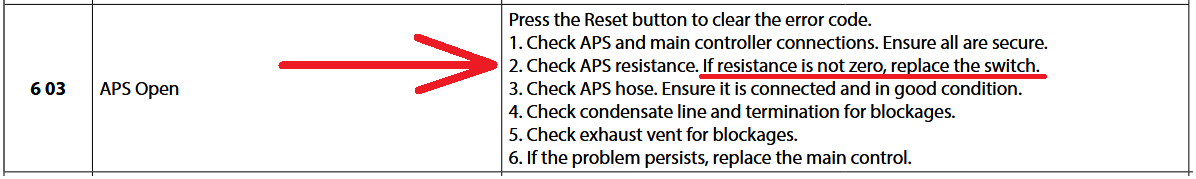

# 2 above expects the switch to be closed when the unit is not running. Resistance tests are not done with the unit operating. As near as I can tell from here the APS switch is normal.

Your links are password protected they need to be public or the videos posted on some other public host.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

That’s something I don’t know how to check, because I’m not a technician and I don’t want to “tamper” with anything. I’m reaching out to other authorities to come by and check very soon in a few days, so I thought I could post something here to see if anyone has any clue..

0 -

I just updated the links and everyone can see them now

Again, the boiler is still currently running like nothing happened, and there are no error codes currently displayed. The APS OPEN 603 error code is indeed in the error log, though it is not currently shown on the screen.0 -

I guess I just don't know how to explain it to you.

ON = APS switch is Closed = Good

1 = APS switch Closed = Good

0 = APS switch Open = Bad

APS switch Open would cause the boiler to shut down.

If the boiler is no longer malfunctioning it is good.

Although the combustion should be checked.

I would find another service company.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Currently, nothing is blocked. It has been running fine and providing heating. The air intake is not blocked, the exhaust is not blocked, and the condensate is not blocked. That’s why I think someone intentially bypassed something when the air intake was blocked for like six or seven weeks…

i shared more videos, check these:

when boiler is

ON, APS isONwhen boiler is

ON, APS status is1when boiler is

OFF, APS status isSTILL 1when boiler is

OFF, APS is stillON0 -

@109A_5 said "I would find another service company."

THIS!

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

If you convince the government there is a problem they may call the gas company, if you convince the gas company there is a problem they will shut your gas off and you will be living somewhere else if you want warmth.

I'd skip all that and just get another service company. I think you solved the problem by cutting the cap out.

If you disconnect the APS sensor connector you should get a APS error since now the circuit is open. That would at least verify the control logic.

I don't really recommend it but if you intentionally block the exhaust vent you may get a APS error.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

sorry if I’m being weird, I apologize again and I do not mean to challenge anyone here… I totally get what you’re saying, and everything you say makes sense. It’s just the logic of this status: “APS is ON = APS switch is closed.” The boiler should be running, right?

However, that’s the same status shown when the boiler is off… if you get what I mean.

It’s like the light is already on before you even plug it in… then there’s clearly something wrong with the light…

And yes, I do plan to call a certified technician this week to come and properly check everything. I’ve prepared all the documents and I’m here to see if anyone even has a clue about what I’m talking about.

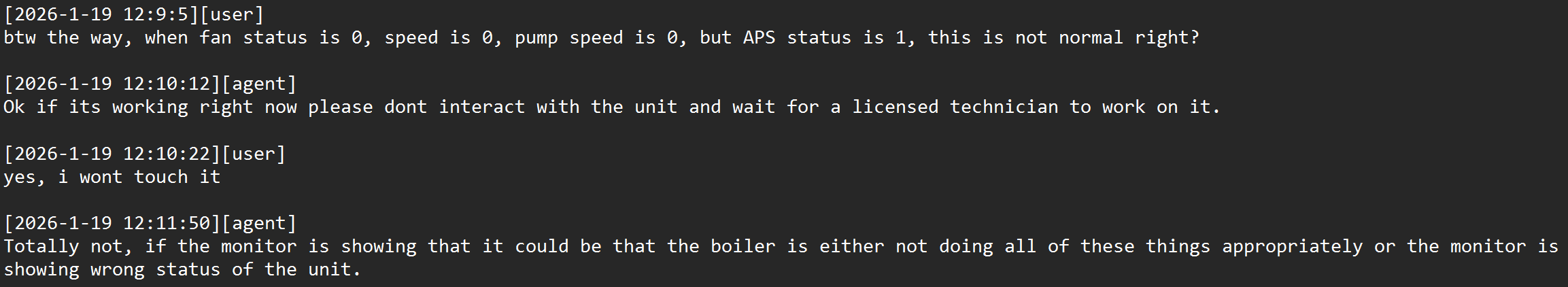

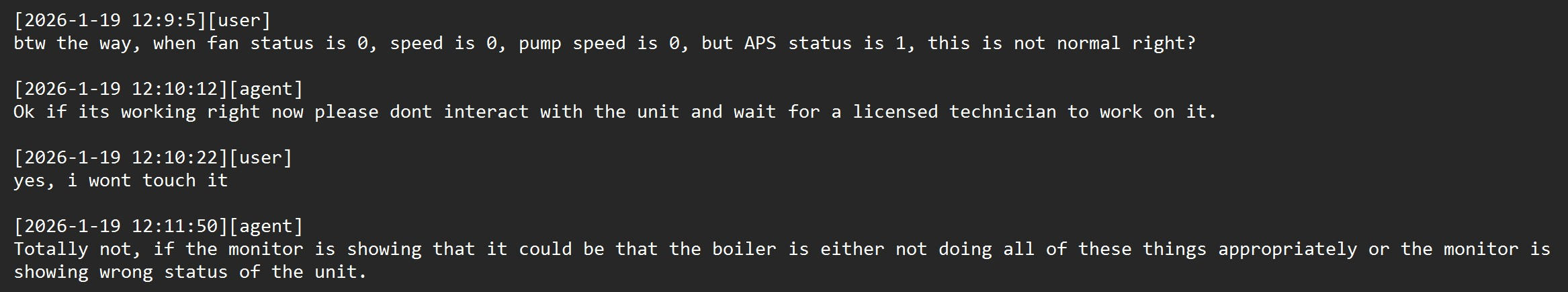

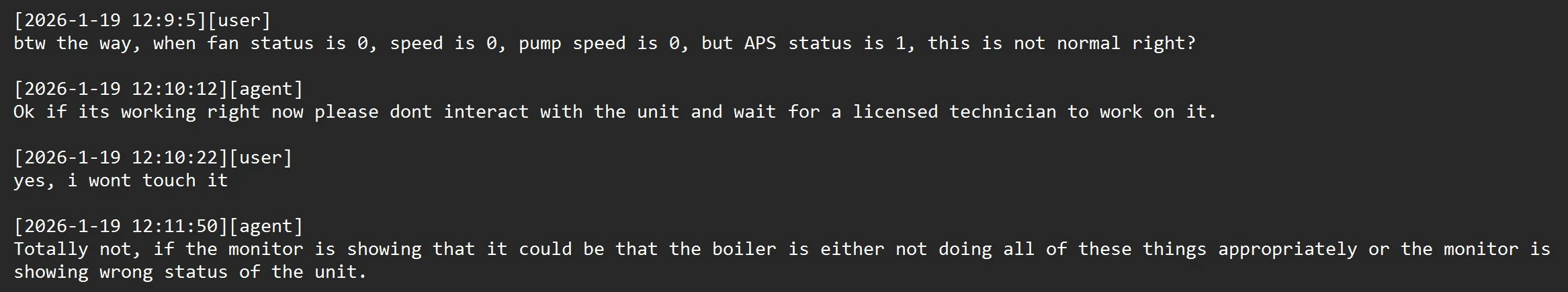

And again, here’s a transcript from the manufacturer stating that when the boiler is not running, the APS status should not be 1.

0 -

To me this above is way too ambiguous, and you have know idea who you are having a conversation with.

This below is pretty matter of fact.

"It’s just the logic of this status: “APS is ON = APS switch is closed.” The boiler should be running, right?

However, that’s the same status shown when the boiler is off… if you get what I mean."

So ??? That is probably normal for this unit and logically irrelevant.

It is running correct ? The APS is not to detect if the boiler is running or not. It is to detect a certain problem or issue which seems to be not present.

It appears the APS switch only opens when there is a problem or issue with the system, that the APC switch in the system is designed to detect that specific issue. No problem, it will not open.

If its normal state is open the control logic can't easily detect the presents of the APS switch, so the normal state is closed. Being closed (boiler off or running normally) until there is an issue is the best simple switch supervision.

Other units that don't have inducer fan / blower RPM feedback need a way to prove the inducer is actually working. With this unit it monitors the motors RPM I saw it on your display 2617 then 2620.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Putting it another way. Item #2 defines the switch is closed when the boiler is off, since resistance is not measures on live equipment, and 'not zero' means defective with a resistance test. Also 'not zero' means it should be zero or closed. Since when the boiler is running (and normal) it is also closed.

So the only time the APS should be open is when there is an issue with the boiler that the APS was intended to detect.

Yes the tech could have jumpered it somewhere and worked real hard to hide it. But since they did such a poor job with the install I think they may not be that crafty.

Disconnecting the APS at the connector would prove the control logic (disconnected means open), further inspection would discover a wire that does not belong, although I do not believe it actually exists.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Hey, thanks for the insight!!!! Sorry, I’ve been in intense communication with the manufacturer about this recently and missed your post.

Your point about the switch state now makes perfect sense. If the intake cap was never removed (100% blockage), the APS physically should have opened, and the boiler should have reported a lockout/error, right?

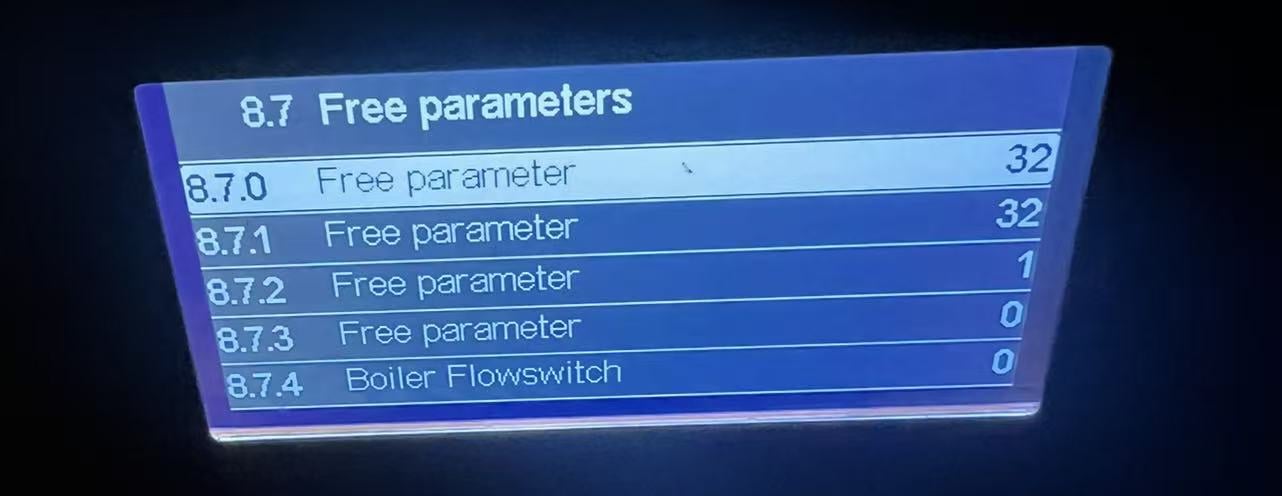

The fact that it kept firing for 6 weeks with a blocked intake is exactly why I suspect the control logic. When I asked the manufacturer for the factory defaults of those 'read-only' parameters (8.7.0 and 8.7.1) as you can probably see in the manual, they were extremely evasive and refused to reply back to me.

I highly suspect the installer hard-coded this integer '32' into those parameters to force-mask the APS status. By doing this, the control board is tricked into seeing a constant 'Closed' state, effectively lobotomizing the safety lockout feature. This explains why the boiler never reported an error despite being choked for air. Thanks for confirming the hardware logic!!

it bridges the gap between the physical failure and the software bypass I'm seeing!!!!!!!!!

right now, I do not plan to perform a physical disconnect test myself for safety and liability reasons as I am not a certified technician. Instead, I am requesting that the appropriate authorities step in to validate this 'free parameter' logic. This level of intentional safety suppression is honestly getting scary... It bridges the gap between the physical failure and the software bypass I'm seeing and what you mentioned.

once the regulatory authorities conduct their on-site inspection and unplug the APS Molex connector (that specific white connector inside the unit), which will take place very very soon, and if the boiler continues to fire, the deliberate suppression of life-safety protocols will be exposed. At that point, everything will come to light……..

Thanks again for the technical confirmation!!!!!!! I cannot appreciate your explanation enough!

0 -

OK good luck.

Still I'm sticking with my statement above;

" Yes the tech could have jumpered it somewhere and worked real hard to hide it. But since they did such a poor job with the install I think they may not be that crafty."

" I highly suspect the installer hard-coded this integer '32' into those parameters to force-mask the APS status. "

I think you give the installer way more credit than he deserves.

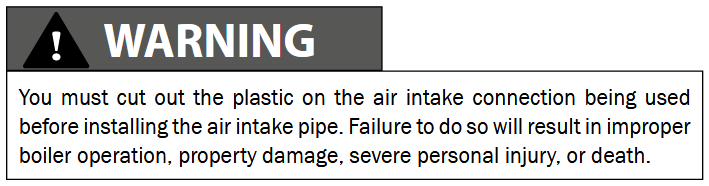

The warning in the manual states improper operation not no operation

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Oh yeah… they’re going to get what they deserve this time. They didn’t even send me the commissioning report and, of course, they didn’t. How could they have one when the primary air intake was 100% blocked!

Again, thank you so much!!!

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements