Whistling air vents

I have a one pipe steam system. I was having a huge problem with multiple vents hissing and spitting wet steam. I eventually changed out the main vents (2 Hoffman 75s) I have changed out all the air vents on every radiator (Hoffman bullet style 40s). I flushed the boiler because it had dirty water and now it’s all clean. I checked and made sure the pitch was right on all the radiators which stopped some water hammer. I still have 2-3 radiators that whistle when the system heats up. How can I stop this?

Comments

-

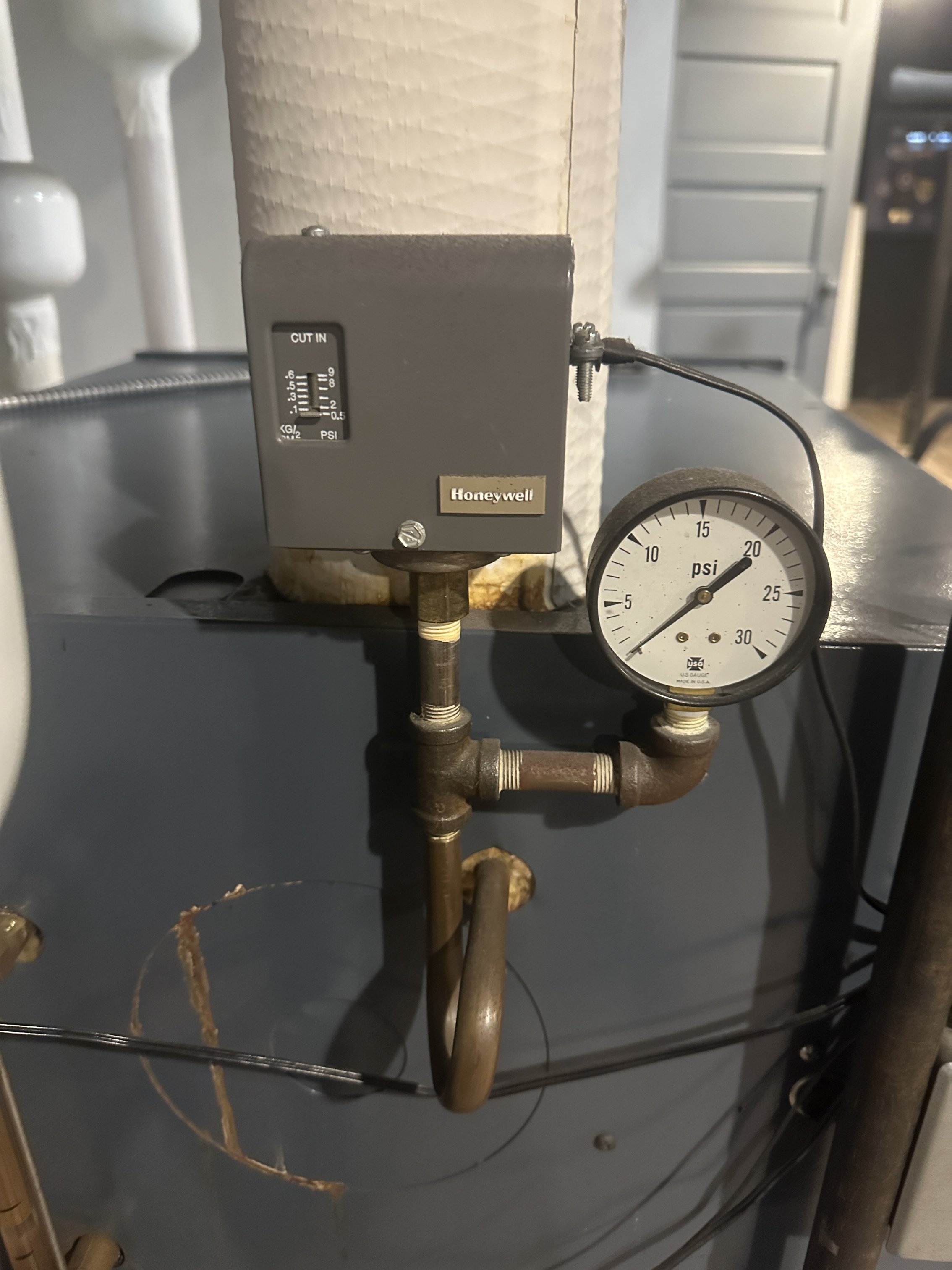

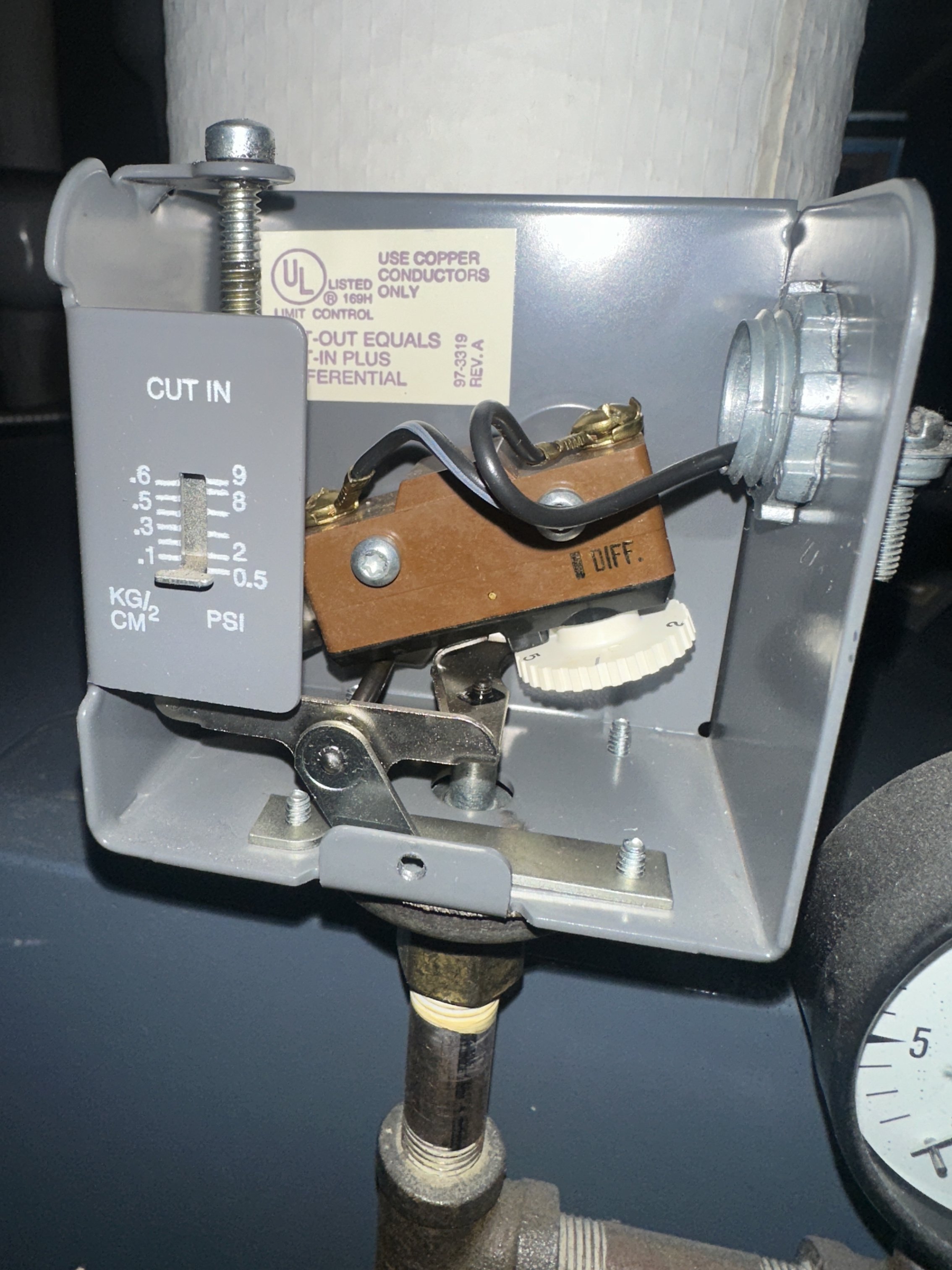

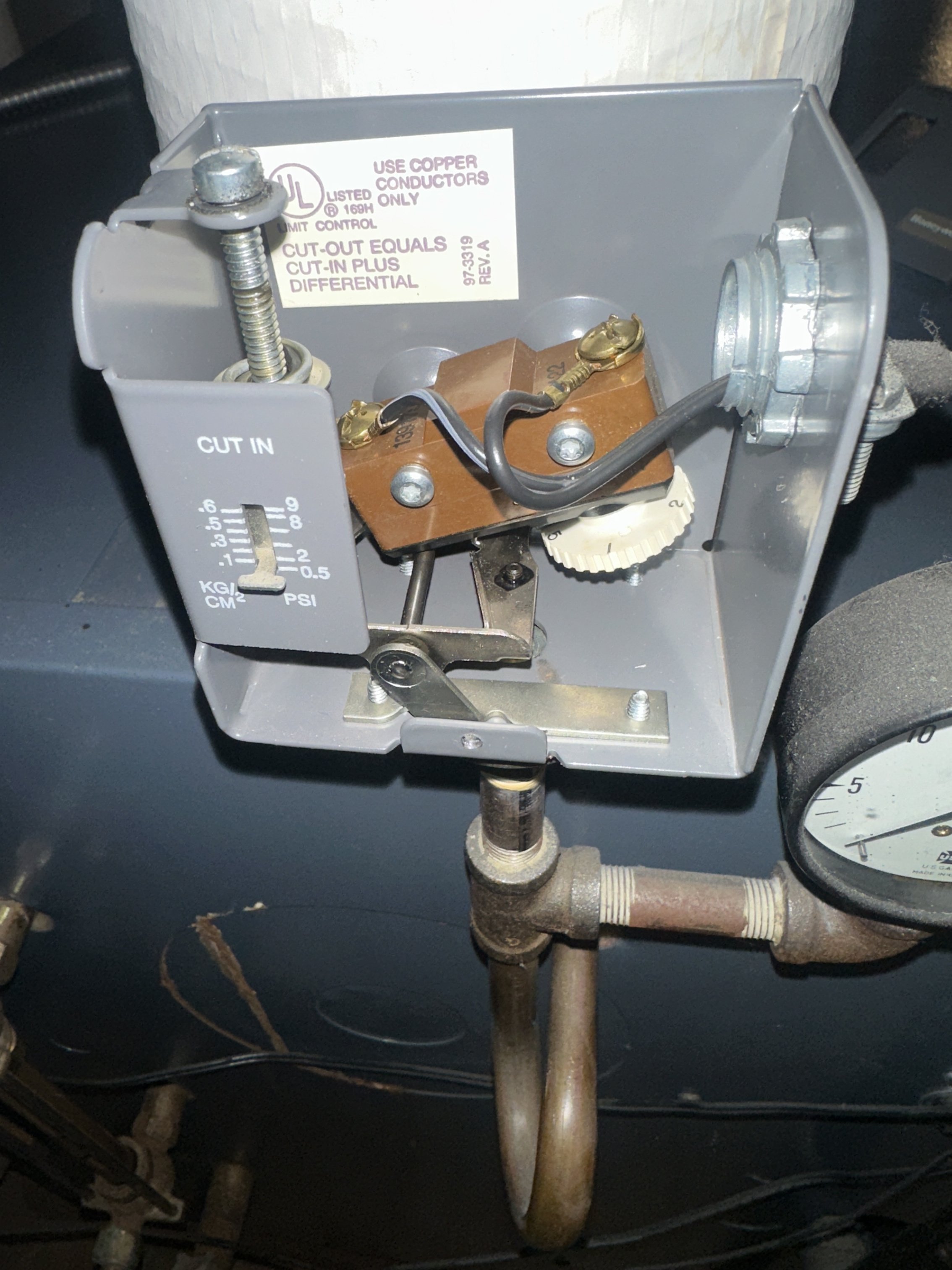

Possibly the boiler pressure is too high. This can be caused by adjustment of the pressuretrol, or the pigtail that connects the pressuretrol to the boiler may be clogged and not reading the pressure correctly.

Most steam heating systems should run at less than 2 psig; if you have a "vapor" system it may need to run at just a few ounces of pressure using a more sensitive control called a vaporstat.

We can best advise you if you show a photo of your pressuretrol, both from the outside and with the cover removed. Also photos showing the boiler and the piping above it from several angles; step back so we can see from floor to ceiling.—

Bburd0 -

0

-

0

-

0

-

0

-

Looks like pressuretrol is set as low as it will go. To verify that it is functioning you really need to get a 0-3 or 0-5psi gauge to go on that tree. It ought to be the way the boilers come. I'm assuming you have made sure the pigtail is clear. The 0-30 has to remain there (actually see if you can relocate it though or change that tee to a cross) due to the code requiring a pressure gauge that can go twice as high as the pressure relief valve requirement of 15 psi. They usually clog and are non-functional. Mine is right on the boiler where it easily clogs. I cleared it once and then stopped bothering.

0 -

What is the boiler model and size? You can check the installation manual to see where they advise the height of the close nipple on the Hoffman Loop be. Make sure yours is not too high. If your floor and the boiler are both level it is a matter of measuring from the floor to the top of the close nipple and also measuring from the floor to the NWL normal waterline mark that they usually have on the boiler.

0 -

Water is very dirty. Did you ever reflush that out, add fresh water, run a few cycles and then skim?

Has the hissing just been bad since the colder weather here in MI or was it persistent even in milder weather?

0 -

The water is crystal clear now, I did a lot of work to get it that way. I literally just took of the pigtail and it was absolutely clogged. I cleaned it out and am now testing. So far seems a lot better. Can you guys suggest a better pressure gage or gauges? I had a little whistle from one radiator vent but it’s significantly better! I have never observed that pressure gage to actually work.

2 -

Now that the pigtail is clear, upon the first firing of the boiler I’m noticing a little steam coming out of one of the main vents. The pressure gauge is actually working a little too.

0 -

Did it successfully reach a cut-out pressure, ie. did the pressuretrol break, and then properly make the circuit at cut-in, even if you can't tell what the actual pressures are on that 0-30 gauge?

I have one Gorton #1 that is allowing a smidgeon of steam to leak before it successfully completely shuts. I'm going to remove it and soak it in vinegar, maybe in my ultrasonic cleaner.

0 -

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

Thanks Paul I ordered that one. Should I put it on a tee with the one I already have?

0 -

Apparently you have to keep the 0-30psi one on there, so you could add another tee to have them both on there

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

so the whistle was gone for a few days and us back at 2 or 3 radiators. It’s even more high pitched now but less venting for sure. What else can I do?

0 -

is it making noise during steam production or is it after the end of firing?

You told us you changed main vent. To what?

And what is the pressure during the whistling?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

This story reminds me of when I was a kid growing up with a house with one pipe steam.

When in bed falling asleep at night, I could hear and know the sound of each radiator in each room coming up to temp. They all had a different sound. One would whistle for a short time then stop, then the next would whistle and stop and the next and so on till all were satisfied.

@mhjaq8603 after your repairs, has the system improved? You may have nothing wrong. Your system just might sound the way it's supposed too.

0 -

The cheaper bimetal style radiator vents can create a whistle noise when venting ..Stay with the float type for flood safety ..

There was an error rendering this rich post.

0 -

@Big Ed_4 what vents are float type? Don't think I've ever seen a float type vent on a rad.

0 -

Yeah I think so many report "sounds" from their vents but nobody sits there and reports the sound of a vent and how it changes from boiler startup through the whole boiler cycle. Lots of what they are hearing could be normal. Vents make a noticeable sound when the steam is just hitting the vent and it is closing the aperture off, producing that sound. When the vent is wide open there is very little audible sound, unless you put your ear really close to it. It's pretty hard for the forum to advise when they don't babysit the vent through the whole cycle. 🤷♂️

1 -

Float type have a brass float with alcohol bottle inside , when steam comes in contact with the bottle the alcohol inside will flash and push out the bottom and seal the vent . If the system is flooding the water level will lift the float and seal the vent .. You can hear the float rattle inside when handling .. The bimetal style will only close with steam , not rising water .. The bimetal will sometimes act like a reed and vibrate into noise ..

There was an error rendering this rich post.

1 -

@Big Ed_4 manufacturer? Model?

0 -

Yeah the "floats" in the bimetallic type don't float. Nope, not even Gorton. And I have my doubts about the "float type" but I haven't tested them.

But how often does your system flood? Never, and if it does, the vents aren't really going to hold back all the water. And if they could, wouldn't you rather know your system was flooded??

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

-

I don't think Gorton cheaped out, it's a nice durable vent. I have never opened a Hoffman, I'm waiting until I win the lottery

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Hmm. Im not so sure that they are supposed to "float" in a body of water, but rather float and move in the surrounding vessel the "float" is encased in.

0 -

But if that cup does not float it is useless ?

There was an error rendering this rich post.

0 -

Sure. But when it is in the encapsulated vessel it is designed to be in, it will move as designed. Its not designed to float in a body of water like a fishing bobber.

0 -

I guess in theory it was designed to float but does not …

There was an error rendering this rich post.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements