Loud hissing from nearly all radiators during this cold spell

Comments

-

Trying to make up 4 degrees in Zero degree weather is something you should avoid doing .. you want to maintain your temperature, not increasing it 4 degrees daily and letting the home cool down 4 degrees at night.. especially at Zero degrees

One way to get familiar something you know nothing about is to ask a really smart person a really stupid question4 -

-

I'll note also that after we got our pipes insulated in the basement, there does appear to be more pressure in the system. We used to do a significant setback at night, like down to 62, and then I would turn the temp up to 72 in the morning. I had no idea this was an issue since we've always lived in houses with forced air, and it never caused issues in the system before the pipes were insulated.

After the pipes were insulated and I tried this one morning, the radiators were all hissing, and I heard some gurgling on some of them. A few were actually leaking water at the intake vales, and one had leaked through a rusted area on the botton of the radiator.

Since then, we've moved to setting back only 1 degree at night, and the radiators no longer leak at all.

Not sure if these issues are related.

1 -

-

I do that. My contact info is below

Not sure if these issues are related.

Yes, they are related

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

-

-

from here, I would first verify the pressure regulation was working

Then if vents are leaking under normal conditions, they have to be replaced

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

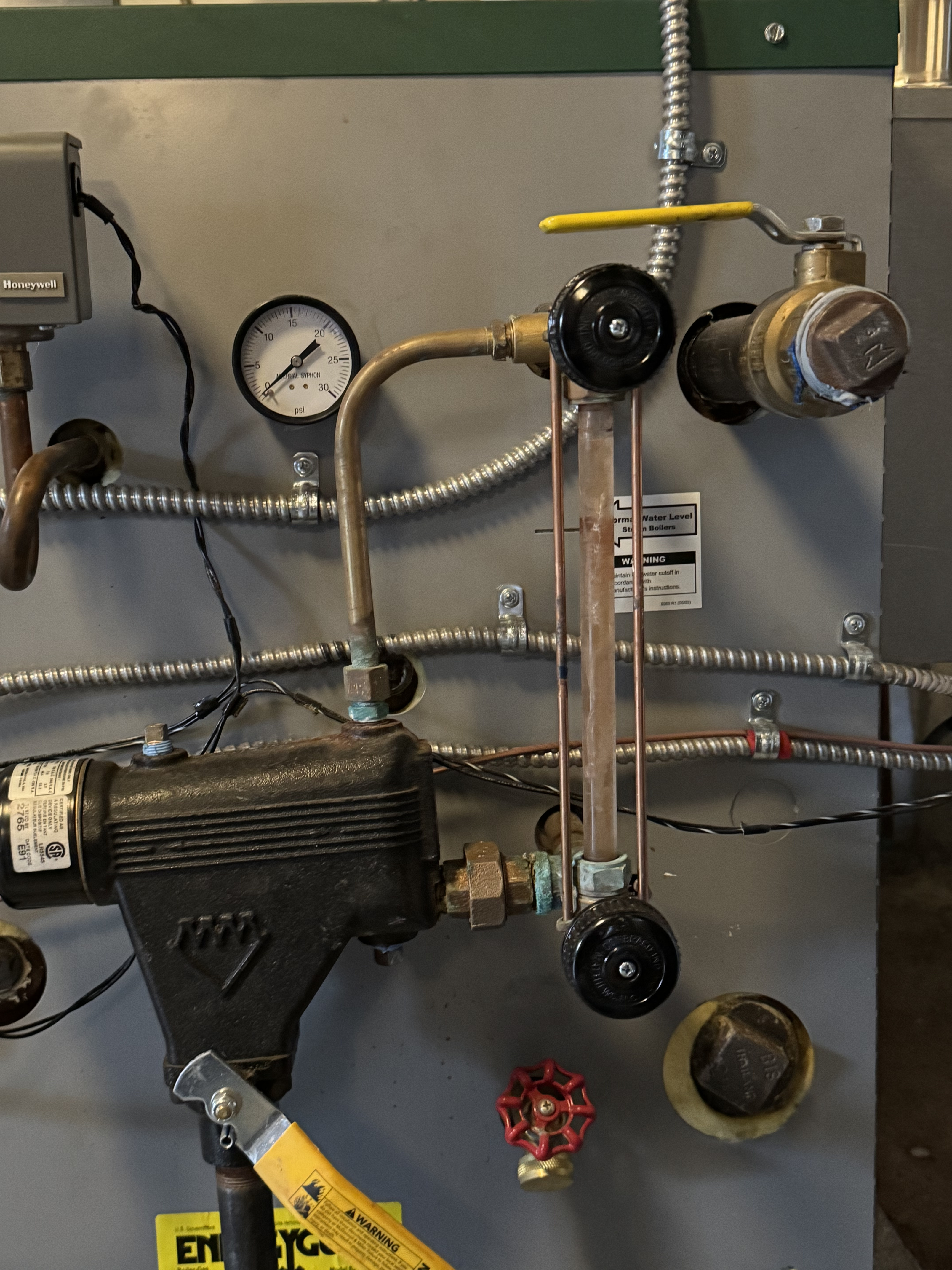

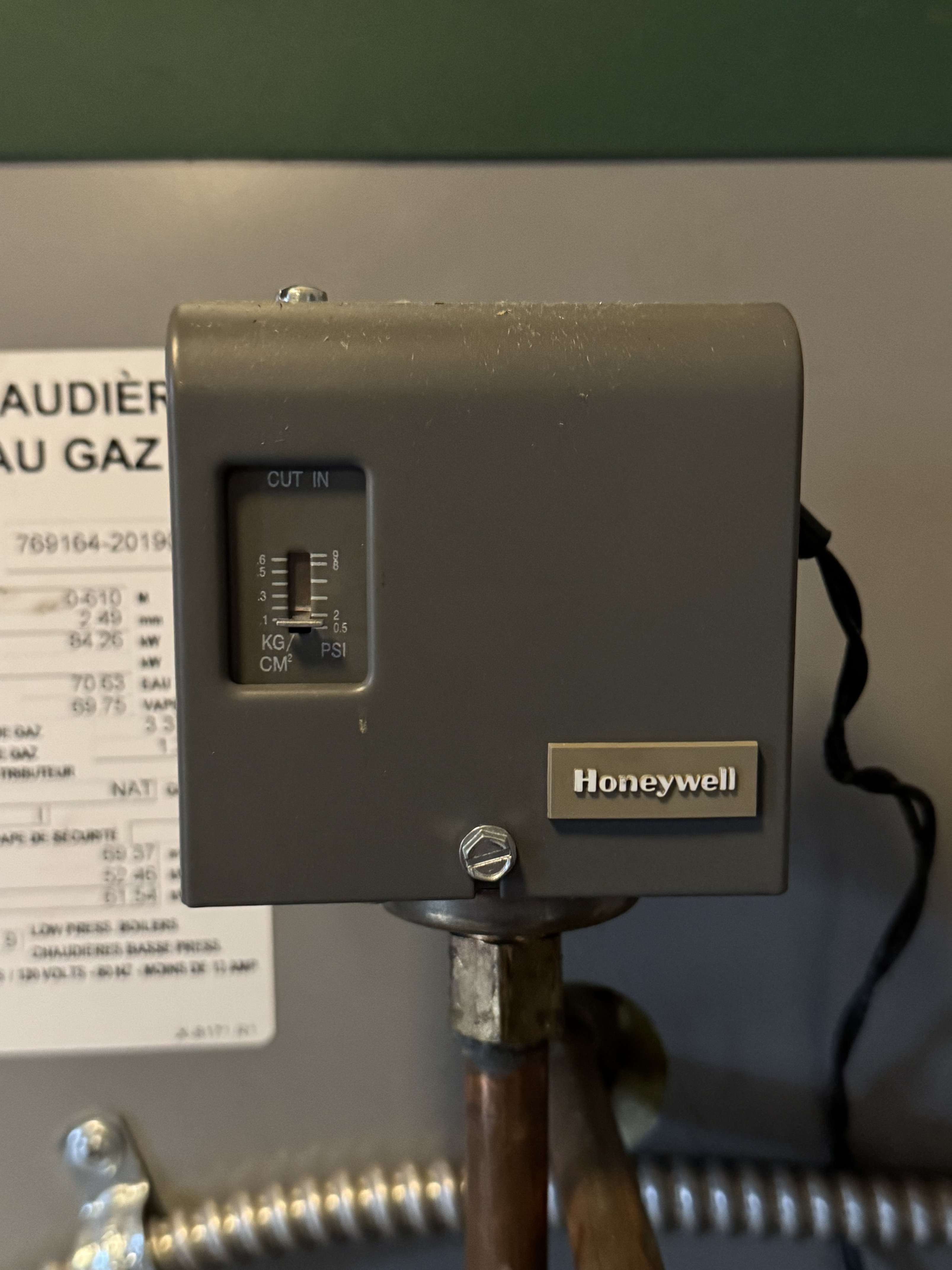

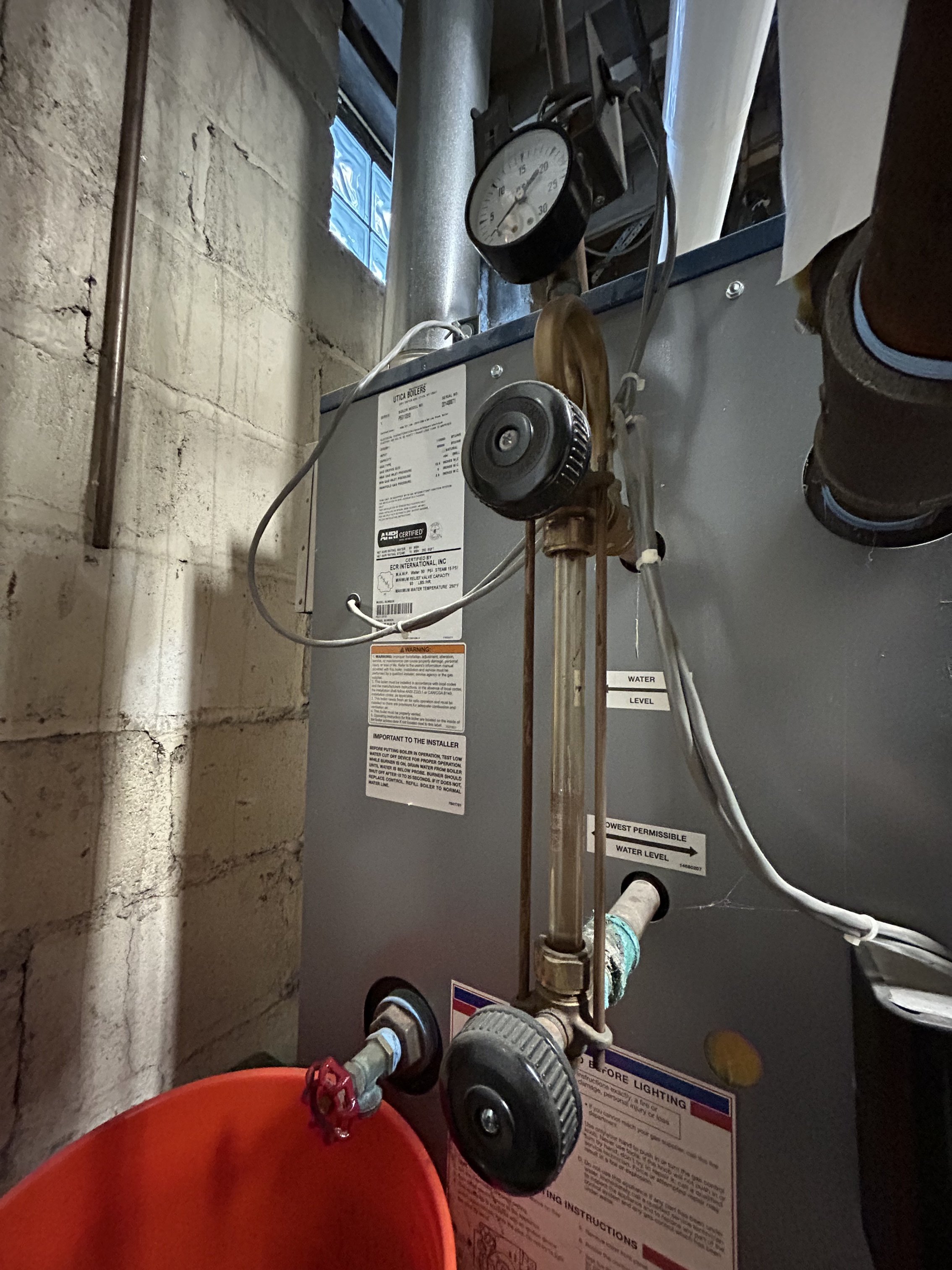

I don't remember if I mentioned this, but I do indeed have a pressure gauge, and it never moves at all whatsoever (Not sure why Utica uses a 0-30PSI for their pressure gauge assembly). I fully disassembled and cleaned the piping down to the top of the sight glass and replaced the pig tail last off season. This is why I keep saying I think something is wrong with the POS Honeywell pressuretrol. I looked at every piece including the brass tee, the 1/4" nipple. I ran a pipe cleaner and water through it. I watched every single Silent Steam video. Nothing. Thanks!

Also ignore the absolutely disgusting water, this is a picture I took right after we moved in. I doubt the previous owners even looked at the boiler except to dump endless cold water make up water from the manual valve.

0 -

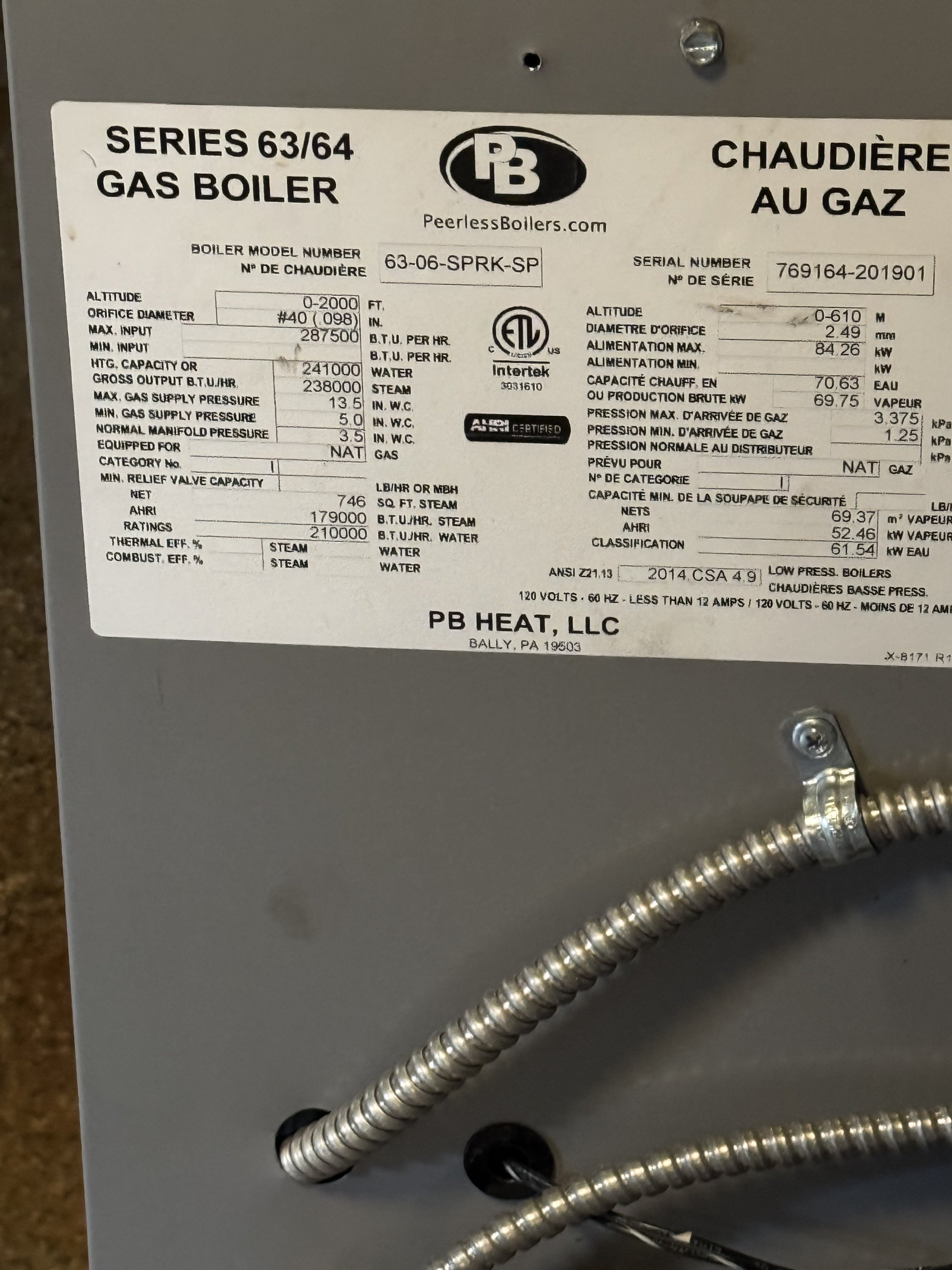

All the manufacturers supply a 0-30psi gauge because it is code that the gauge must be rated to twice the maximum operating pressure of the boiler (I have been told). The pressure relief valve on a residential steam boiler is at 15 psi so that's why the gauges are always 30psi.

If you doubt the pressuretrol, then it would be good to purchase a low pressure gauge to put in that spot (temporarily) or in another spot (could be permanent) to see what the actual operating pressure is when you are hearing the hissing.

Then you'll know if you the vents are bad, or if the pressure is just too high.

I will add that your boiler water is extremely dirty and although I am not a fan of unnecessary draining and refilling, in your case I would consider it necessary.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

@ethicalpaul I was thinking of buying this off of Supply House: https://www.supplyhouse.com/Bluefin-GLP25-5-BM-2-5-Steel-Low-Pressure-Gauge-Bottom-Mount-w-Brass-Internals-0-5-PSI to replace the 0-30.

Also, I edited my previous post about the water. That was basically after we moved in. I keep our water clean with a flush as needed.

0 -

I don't know why the link is no good. Trying again:

https://www.youtube.com/@gordonschweizer5154 /search?query=pressuretrol

Go to youtube. search on Silent Steam Team. Go to "videos". Search on "pressuretrol". That should get you to the ones for your pressuretrol.

We need more pictures. Front, and other side of the boiler, showing all the piping going out of and into the boiler.

Better picture of the pressuretrol, closer up and in focus, with and without the cover (only one screw to remove cover)

1 -

For convenience, you might consider a back-mount one like the one you currently have. I couldn't find a reasonably priced back mount gauge on supplyhouse, but this one on amazon should be fine:

https://www.amazon.com/BOGERDACK-Diaphragm-Capsule-Pressure-Adjustable/dp/B0F7WZ2DZZ/

Oh I didn't recall your earlier post about the water. I probably already advised don't flush more often than you really need to. edit: ahh I see it was in that last paragraph just above, sorry about missing that

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

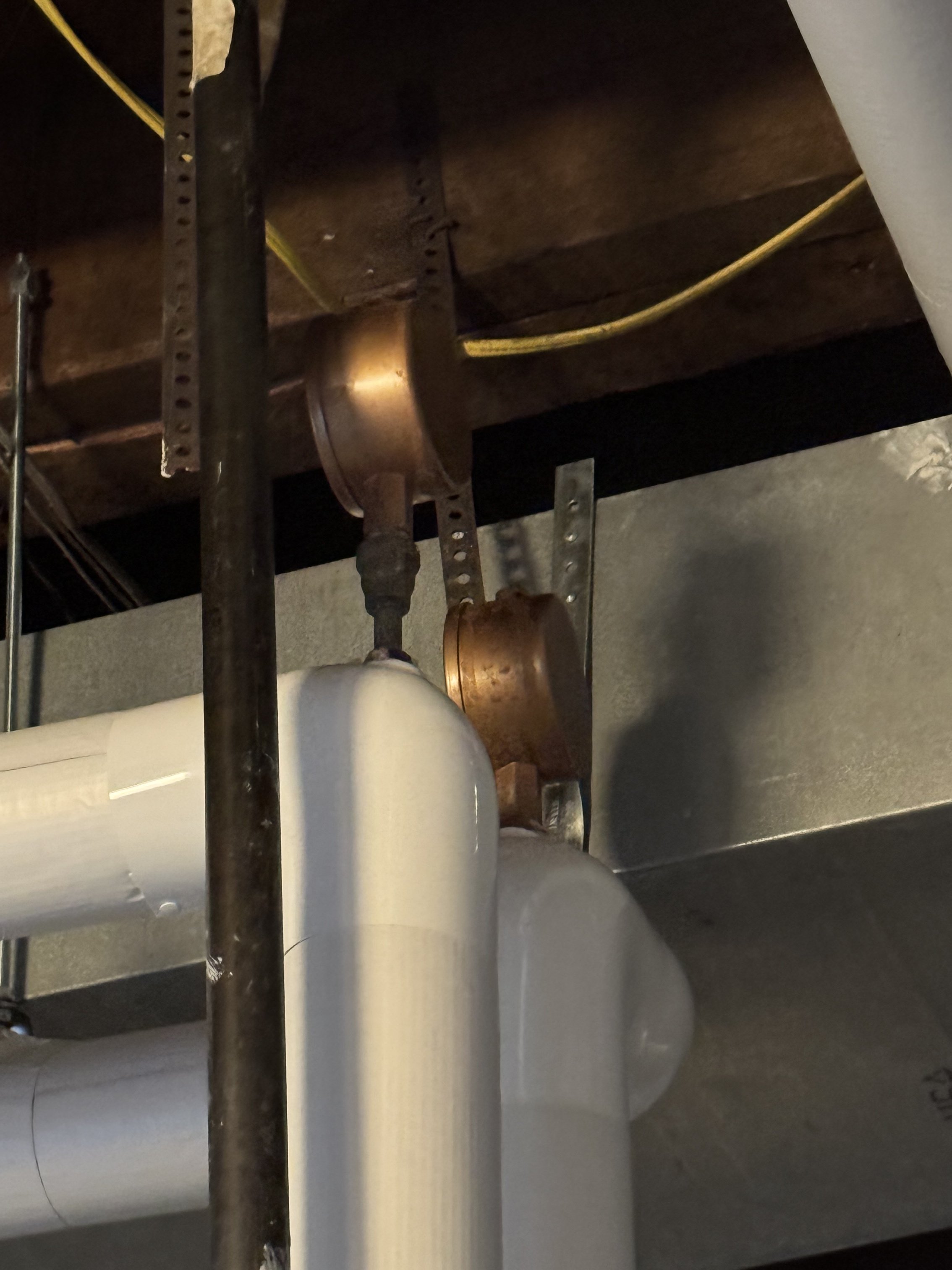

Here are some pics of the system when running

0 -

one radiator in our bedroom has been “hissing” all night, but it’s coming from the intake valve

0 -

Can't tell what I'm looking at with your boiler piping photos. Need pictures a bit further away and from multiple angles. But, it looks like your header goes into a bullhead tee with one side going up to the main and the other becoming the equalizer. That would be super wrong.

We need photos of the other side of the boiler showing the Hartford Loop. Measure with a liquid level (clear tube with water in it and a helper) or something, from the top of the Hartford Loop close nipple or elbow to the normal water line of the boiler (should be marked by manufacturer)

We still need that crucial photo of your pressuretrol with the cover off (remove one screw at the front bottom), showing the internal dial setting. It looks like your cut-in may not be as low as it could go.

0 -

-

Just walked into another room this morning, and the valve (TRV) leaked a ton of water overnight, soaking the rug underneath — despite this particular radiator being entirely off! I turned it off several weeks ago, because this is the one that rusted through the bottom and was leaking out. How can water still be getting to it if it is completely off??

0 -

If the valve isn't shutting off completely, steam will still get into that radiator, albeit slowly. But then when that steam condenses it can fill the radiator with water up to the vent. If it isn't a type of vent that can shut off in the presence of liquid water (My Heat Timer Varivalves do not), the water will escape the vent. I feel your pain.

0 -

-

Would someone I hire be able to do that repacking? I'm not really equipped for it.

0 -

Did you watch the video? If money is not an object sure but plumbers are crazy expensive. It is a pretty easy repair. It is really a handyman friendly job so you wouldn't have to hire a plumber and pay the trip charge and all that.

0 -

0

-

it seems like a larger issue though. Like how is the radiator that is completely off getting steam and leaking tons of water ?

I now how towels down by the intake valves of about 4 of our radiators

0 -

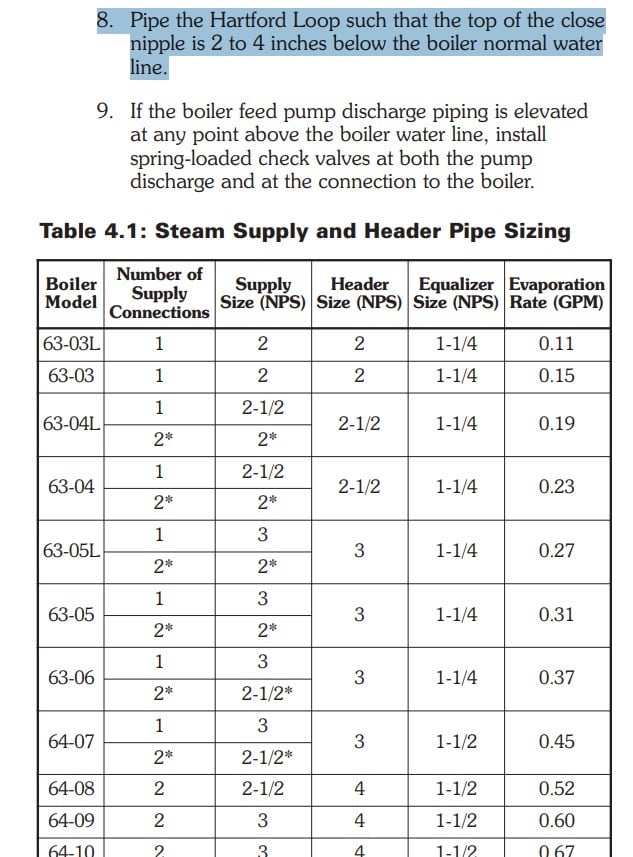

Now we're getting somewhere with those pictures. Supposed to have a 3 in. riser and header on your boiler, for only using one riser. See if you can find out what you have. My 63-04L is supposed to have 2-1/2 in. but only has 2 in.

That different angle shows what I suspected is not the case, with a bullhead tee.

We still need the pictures of the critical Hartford Loop side and the inside of the Pressuretrol showing the dial. I feel your pain with dirty water on carpets.

0 -

So do I need to get someone to replace the intake valve? That would fix the issue for that one?

0 -

What can I do? Water is basically pouring out of the thing. It's soaked through multiple towells already this morning.

0 -

Probably better off opening it back up because it may be acting as a one way valve, letting steam in but not letting condensate back out, except for the vent. On second thought, if you want to keep it turned off for now though, I'd remove that vent and put a plug (pretty sure it is 1/8 in. NPT) in it's place and keep the valve closed until you can replace that valve.

0 -

-

Yes any supply valves that are hissing or leaking are bad and need to be repacked or replaced. Any vents that continually hiss after steam has already reached them are also bad and need to be replaced. If steam has not reached the radiator vent yet and it hisses it is just releasing air from the radiator as steam advances and the hissing in this case would be normal if the pressure is much more than a couple tenths of a psi.

I don't know what your overall connected sqft of radiation is relative to your 746sqft of boiler rated steam capacity but if your boiler is at all oversized you have to make adjustments for extreme cold weather. I have a 35% oversized boiler yet most of the winter am able to do 5 or 6 degree setbacks and recoveries without issue because I manage those recoveries broken up into controlled on off cycles that limit continuous firing time of the boiler thus avoiding pressure rise. Pressure only rises in the system as radiators one by one start to completely fill up since then there is less place for the steam to go and the boiler doing what boilers do continues to make the same amount of steam until either the thermostat, the pressuretrol or the low water cutoff tells it to stop. So, to avoid all this in extreme cold weather think about what you can do to avoid all or most of your radiators completely filling and thus building pressure. Answer:

- Minimize the required heat - Lower or eliminate your setback if weather is going to be extremely cold. Only you can define what extreme cold is for your system based upon your experience. I am one of the few proponents of setback on this forum but where they do save me money on normal winter days, once night time temperatures get below 15 degrees or so they don't do anything for me but make morning recoveries noisy. If your system only needs to raise the home temperature a degree it is going to take less cycle time than 2, 3 or 4 degrees. I normally go from 59f to 66f but last night and the night before here in Michigan I just set the temp on hold a 65f and went to bed… (-14F this morning)

- Run more shorter cycles - Setting your pressuretrol or vaporstat lower will do this to some extent but they are both still reacting to some level of pressure rise which indicates you are already running a longer cycle than optimal. One simple thing most people can do depending upon your thermostat is to adjust your thermostat control to help minimize cycle time. If a cycle per hour type setting then set it for the cold snap on 2 instead of 1. If a swing temperature range type control set it on +/- 0.5 degrees instead of +/- 1 degree. You can always switch it back if you care to after the polar vortex has passed.

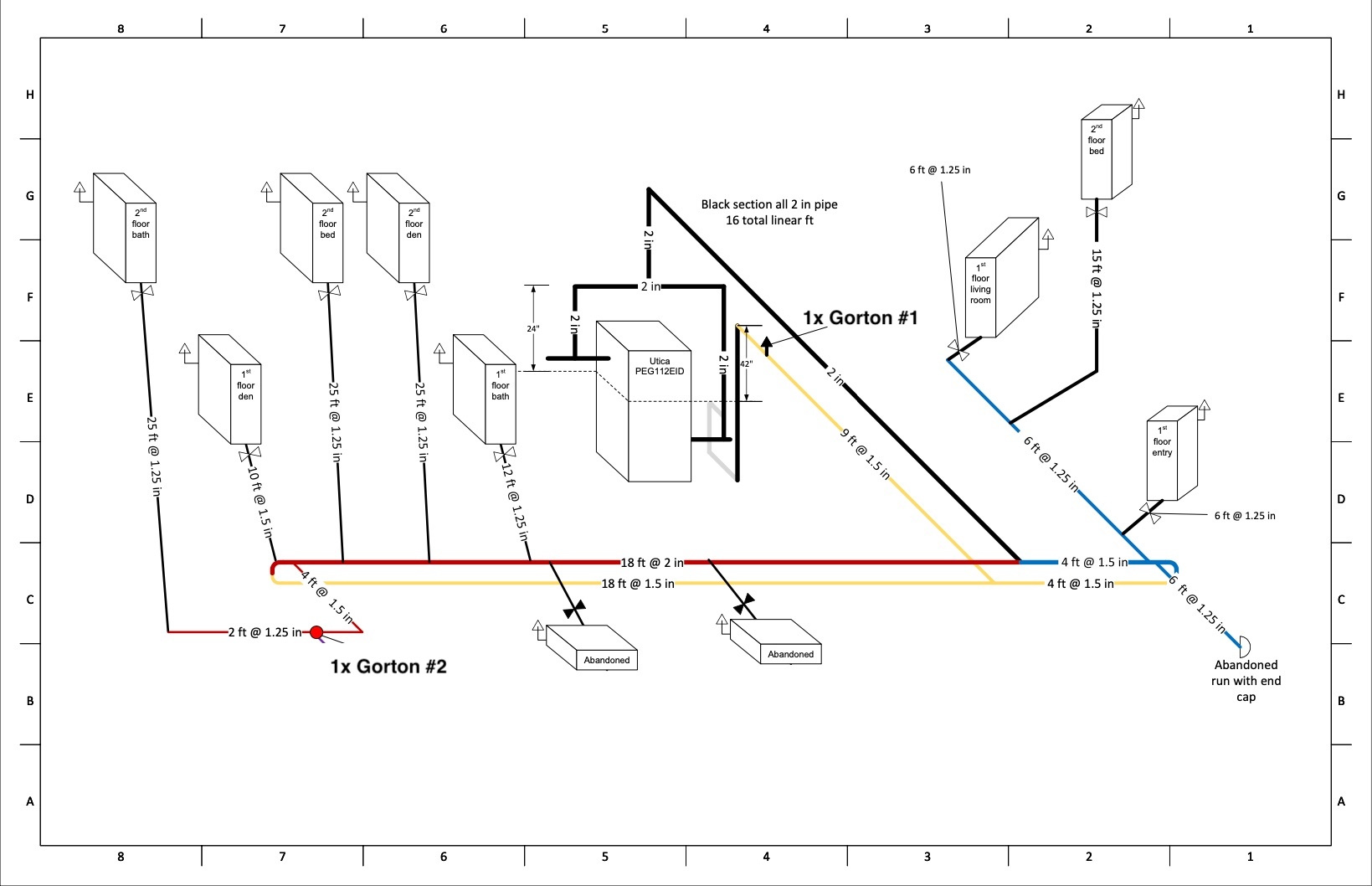

When it comes to the main venting it looks like you have a Gorton #2 on each main which may be sufficient. Have to know your total steam main lengths and pipe sizes to know for sure. Where more main venting makes the most difference on a system is during extreme cold snaps because most of the heating cycles start off with very warm steam main piping and thus the rate of steam advance is less hindered by condensation in the mains themselves from heating up the mains. This isn't going to change your late cycle hissing though, only any hissing that may occur early in the cycle after the boiler starts creating steam and before the main vents closed.

0 -

After holding the temp at 72 during the day, and 71 at night the hissing has mostly subsided. When it does hiss it's much shorter. Putting my finger or phone near the vent fogs just a bit. I just spent $500+ last season to replace all my vents so I'm not spending another dime on these POS.

The dial on my pressure gauge on my boiler never moves during operation and the pressuretrol doesn't do anything during operation. It is completely broken. I have every setting correct and have checked the piping from the close nipple through the pigtail to the top of the sight glass. The pressuretrol is f*cked. There is no reason my vents should be hissing if my settings are correct because the system should never operate above 1.5PSI.

Thanks again for all the help guys

1 -

-

Thanks @dabrakeman I have a low pressure gauge ordered and on the way. It's just odd that the needle never moves even a mm off of 0 even if the range is 0-30. I feel like I should see the needle a bit in the 0-5 range of my current gauge. Reducing setback during the cold stretch has helped with the hissing.

1 -

-

We didn't set back at all last night, kept it at 67 and haven't turned it up this morning.

0 -

@dabrakeman ok so if my gauge is worthless what, if any functionality, should I see from my pressuretrol? Should the normal cycling operation take the system pressure from 0.5(1st heat cycle start) to 1.5(1st heat cycle stop/temp not yet reached) back to 0.5(2nd cycle start) back to 1.5(2nd heat cycle stop/temp reached) etc or something like that. It shouldn't just run the entire time until the intermittent low water check stops.

0 -

That single Gorton #1 is way undersized for all that piping that it has to vent (mains plus dry return). You could do a tree and add a second one or you could just put a Gorton #2 in, which is about equal to 3 #1 and only slightly more expensive. Also, I'd insulate the long nipple you have going up to that vent.

I don't like that type of main where it tees off in two directions but that would be super expensive to change so you are probably stuck with it. So hard to balance, especially with only one shared vent location after the dry returns tee back together. Would be much better to have separate main vents at the ends of each subsection after the tee in the main.

What is the height of the top of the close nipple in your Hartford Loop relative to the normal water line in the boiler. That one photo showing the level in your sight glass looks like it could be below the Hartford Loop. That will cause water hammer and prevent proper return of condensate to the boiler. My opinion is too many clown installers are putting the Hartford Loop way too high.

1 -

I have a #2 at the end of my 'red' line. I addressed this when we moved in with the help of the forum (https://forum.heatinghelp.com/discussion/201019/need-help-balancing-steam-system). I need way more venting on my 'red' line because it's much longer than the 'blue' line. So i tried to balance this with a #2 at the end of the red and a #1 at the return so the steam wouldn't wrap around a trap the red line. As you said it would be quite the expense to repipe this.

I can't get an accurate measurement of the height from the hartford loop close nipple to the water line because the indicator is opposite the loop. My guess is it's between 1" and 2". I looked at the utica manual for my model and figured it was ~2" and then said it doesn't really matter because I'm not repiping s*it. We don't really get any water hammer fwiw. Thanks again.

0 -

My bad missing that other main vent. I'd prefer to see another vent at the end of the blue line but I see your runners are exceedingly long. And then you could do away with the one at the end of the shared dry return. Kind of a tough call.

You need to get a section of clear vinyl tubing and make a water level. Have a 2nd person help you. It will wrap around the boiler and you will be able to find out where that Hartford Loop is installed relative to the NWL. Look at your boiler manual for further guidance as to where they want it to be. My Peerless manual says top of close nipple 2 to 4 in. below the NWL. Dan Halohan video had a different take and was even lower than that. You won't necessarily get audible water hammer. You could still have serious problems from this without hearing that. Condensate has to be able to return freely to the boiler.

I don't know if you have mentioned whether or not you have checked all the pitches of all the pipes. 1" per 20 ft. downward pitch for mains and returns and 1" per 10 ft. for runners.

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements