Viessmann vitodens 222 not modulating properly

Hi everyone,

I've seen some excellent comments in this forum from experts while reading about my boiler issue, I hope to get some help.

I have a vitodens 222-F BSB boiler, it was purchased in the house by the previous owner.

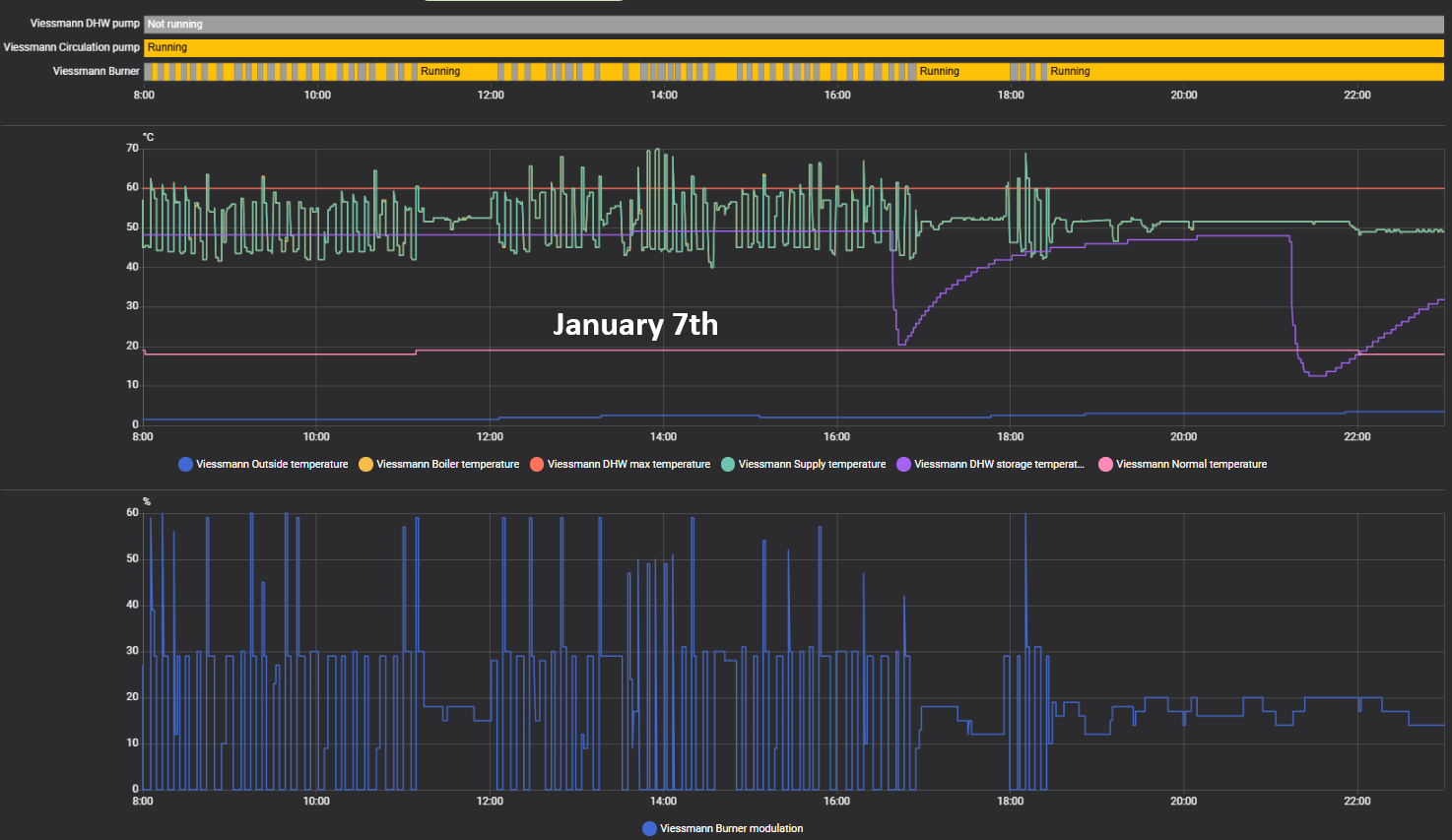

The boiler does not seem to be able to modulate properly in order to keep a stable water temperature. The house is rather old (70 years) and there is a constant heat demand in winter thought the boiler is probably too powerful for my need, most of the time the boiler should be working at around 10-20%.

As you can see that the burner modulation is not stable, starting at 60% (like every start) but then instead going to 10-15%, it keeps the power to 30%, this caused the water to spike and the boiler thinks that it reached the target temp and stops. While the water had no time to really circulate.

3 times over that day (at 11.30, 17.00 and 18.30) the boiler managed to work properly as it was maintaining a stable water temperature. Why is it not doing this all day long?

I tested the relays, as the manual recommends and the base load relay only set the boiler to 30%, like if there was something preventing the boiler to go lower than that. Is this the root cause issue? Thought sometimes it manages to go lower than 30%.

Over the worsts days, the burner can start more than 100 times! It seems to be worse when the temperature outside is above 5deg C.

Some additional info if needed:

- 3 floors house, with always 2-3 ratiators fully open. The other radiators have themostatic valves

- The regulation is using the outside temp & heating curve, I have no indoor thermostat

- I tried to play with the circulation pump and increase the speed in order to limit the spike in temp when the boiler starts, with no success

- The data shown above are coming from Home assistant, which is connected to the viessmann API

- Last year I had the same issue, I asked a pro do to the service and cleaning (I'm not sure what exactly he did) but it did not solve the problem

- I went through this old post but nothing really worked for me

Let me know if you have any clue!

Comments

-

These come with a supply sensor that is intended to go in the low loss header, can you locate the supply sensor and show where it is installed? also a photo of the install might help. And just to confirm the boiler is set up to run on a constant supply temperature based on ODR with no end switch or call for heat to the actual boiler control?

to add a possibility, if there are flow issues (pump dropping out, flow restriction intermittently air etc) the flow switch will shut the burner down with no error code. this would also be accompanied by a temperature spike at the boilers internal temp sensors. when the flow switch makes again the burner will fire and possibly repeat the process. I don't necessarily think this is the issue I am just throwing it out there since its a bit unique to viessmann boilers with flow switches.

2 -

Thanks for helping.

As far as I can see there is no low loss header in my set up. Yes the boiler is running on a constant supply temperature based on ODR, no other call for heat.

How can I identify if the flow is the issue?I tried to map the pipes, there is also an hydraulic accumaltor on the heating circuit.

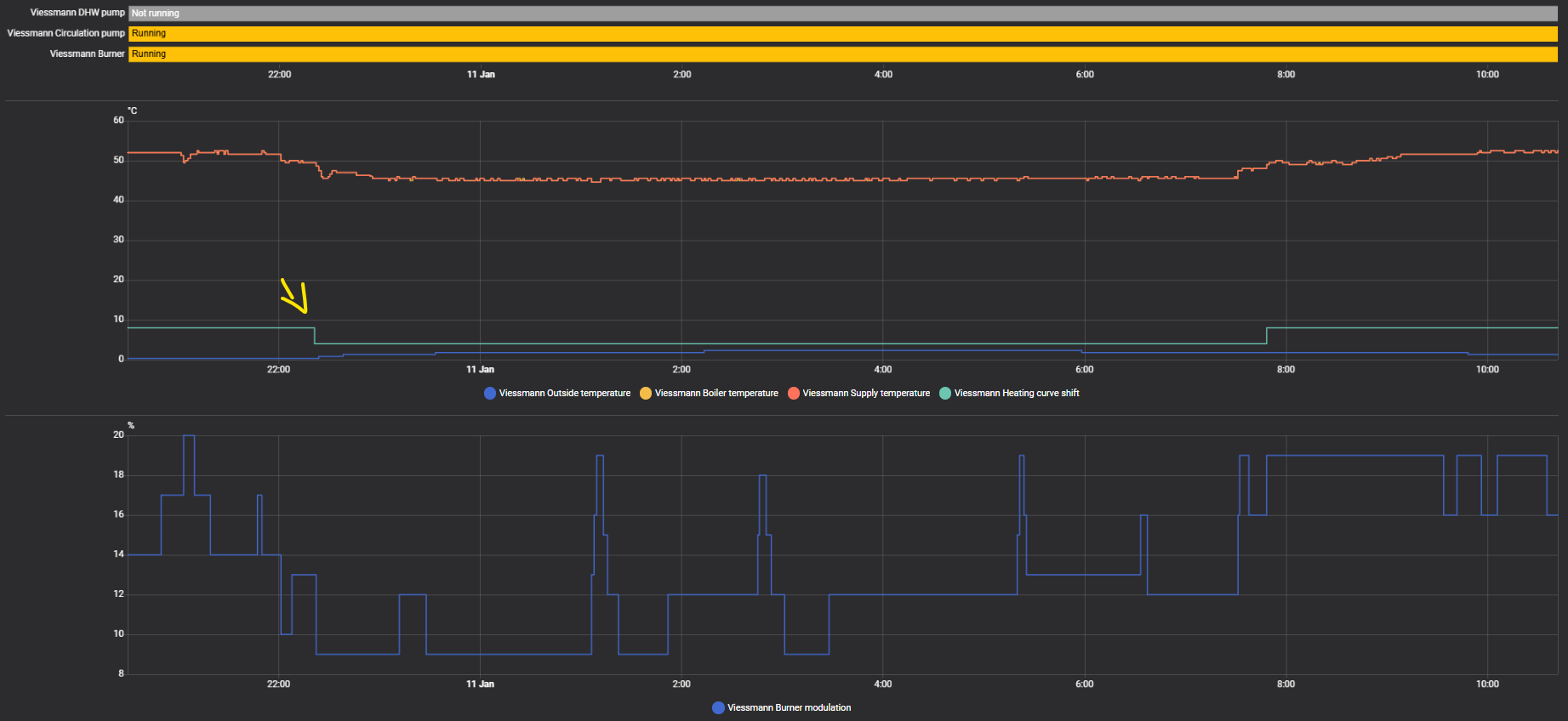

Over the last few hours the temperatures dropped (from 5 to 2deg) and the boiler seems to better like it:You can see that the supply temp can be super stable and the boiler just modulate perfectly.

Now that the boiler seems to be able to work at a low power, I tried again the "relay test" on the base load and it works, the boiler goes to 9% (the min) after about 1minute.0 -

-

-

Regarding the ODR settings, I was quite happy with them, the shift of 8°C and a slope of 1.3 worked pretty well to keep my place at 19/20°C in all conditions.

Though I did a test yesterday evening and dropped the shift by 4°C:The burner reacted just fine, although this morning it was a bit cold inside so I set it back to 8.

Note that the current outside temperatures are quite low, around 1°C and the burner works like a charm.

I'll wait for the boiler to short cycle again when the temperatures will reach 5/6°C and try the suggestion of @Eastman. What will this test trying to show?0 -

If the system is piped without a low loss header, it's possible there could be insufficient flow. I would like to see a data plot with the TRVs essentially disabled, and no longer regulating system flow through the radiators.

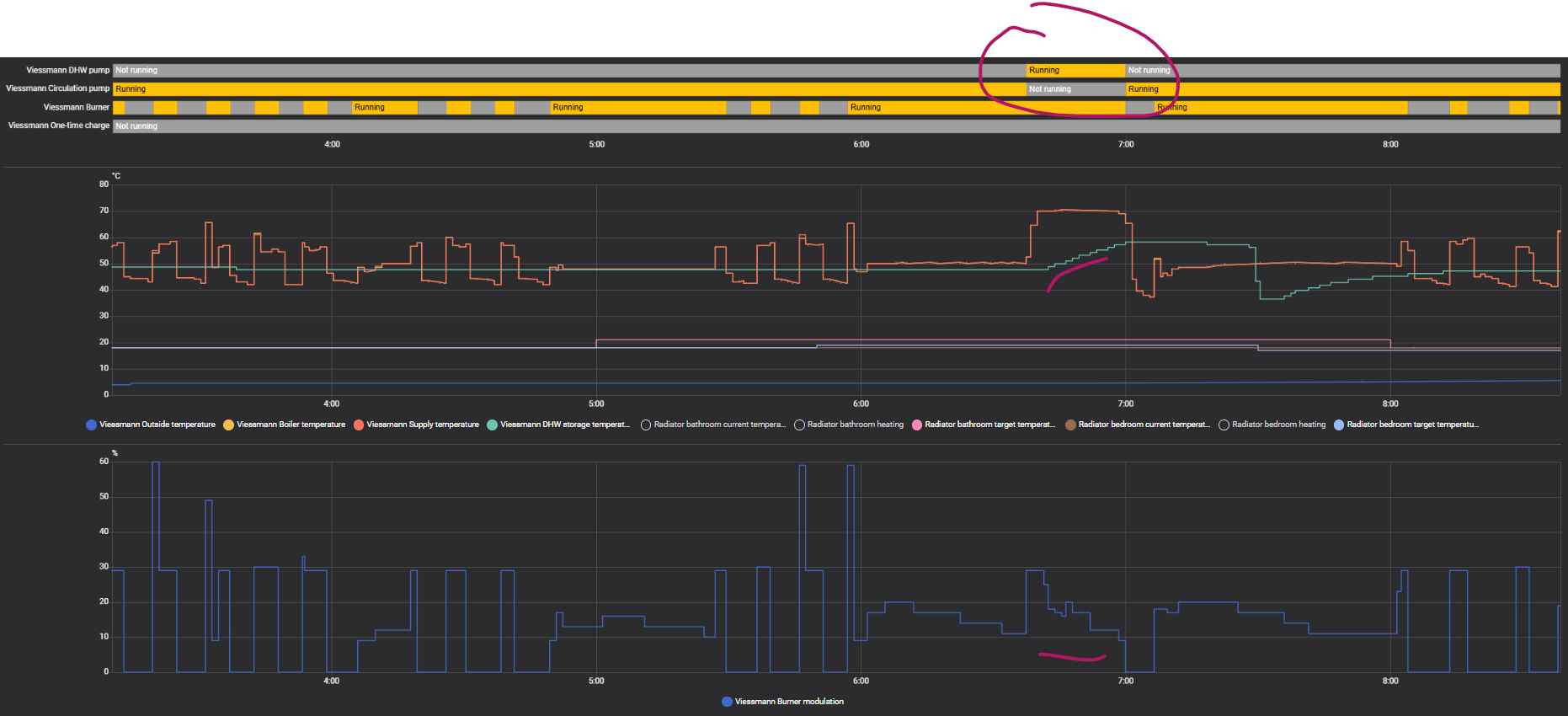

What happened at 16:40 in your original data plot? The DHW storage temperature drops to 20C and then takes a long time to recover with continued intermittent short cycling.

1 -

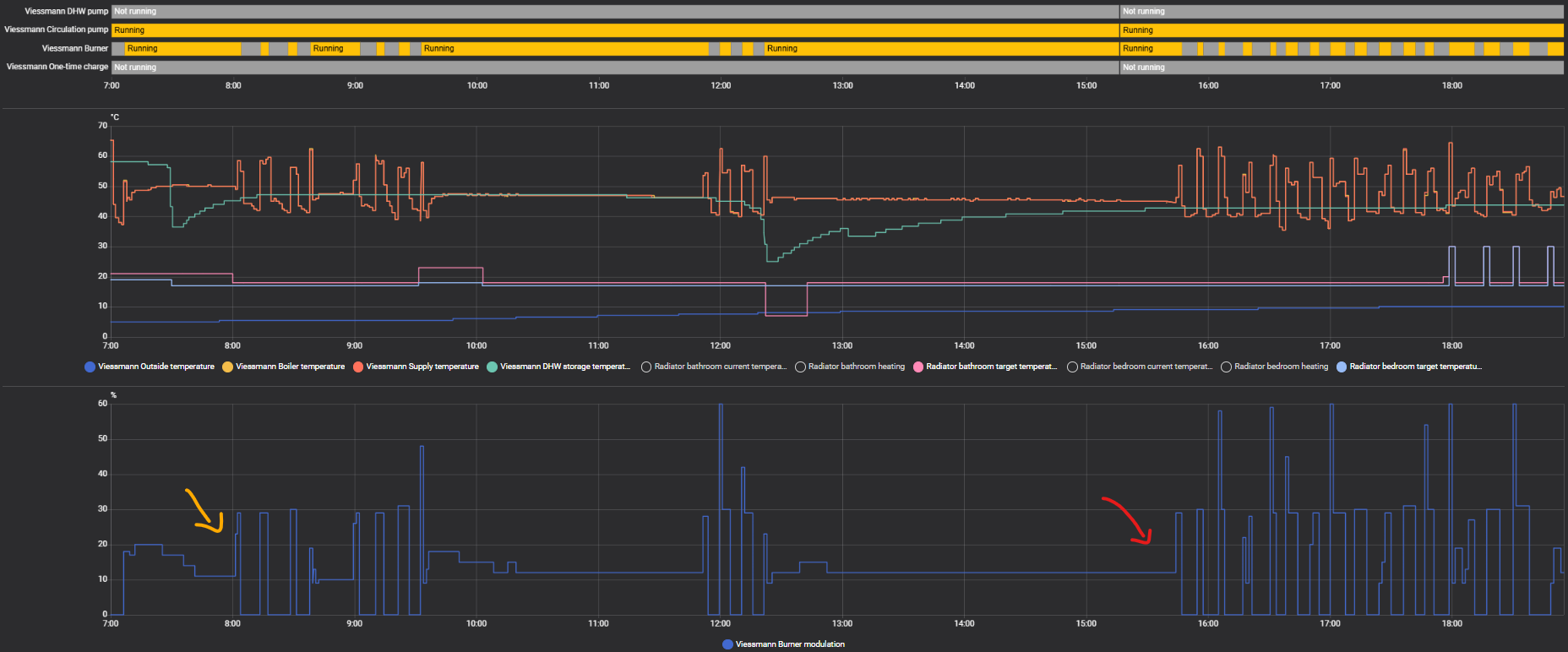

I made a couple of tests over the last few hours. Since the outside temperatures are up these are "ideal" conditions for the boiler to short cycle.

1/ In the below screenshot you see that the boiler was running smoothly for an hour until the power goes up to 30% (yellow arrow) for no apparent reason and then stops. After some analysis, at 8am two things happen, my smart TRV in the bathroom closes and the target indoor temperature goes from 19 et 18°C. I understand that this flow reduction might be the issue. But what I would have expected is for the boiler to simply run at a lower power, from 11% to 9% for instance and not go up and stop eventually.

To confirm this I made a new test at 15.45 (red arrow), the boiler was running smoothly and I intentionally closed 3 TRV, same behaviour.2/ I tried to leave more TRV fully open. In total there are 11 radiators, all with TRVs.

Before I had- 2 always fully open (5/5)

- 2 at 4/5

- 2 at 2/5

- 3 are on and off demanding on our usage (two are smart TRVs)

- 2 are always closed

Now I changed to this:

- 4 always fully open (5/5)

- 2 at 2/5

- 3 are on and off demanding on our usage (two are smart TRVs)

- 2 are always closed

Also I added a rule that does this:

When the burner starts, immediately open fully two smart TRVs for 5 min and increment the indoor temp setting by 4°C for 8 minutes.

The goal is to increase the flow when the burner starts, to help him evacuate the starting heat (since the boiler always starts at 60% power) and give him a change to stabilize to a lower power.This seems to improve the situation but not drastically, here is the graph with this logic implemented:

3/ @Eastman regarding the drop for the DHW storage temp in my initial post, this is simply a shower. I guess that the slow increase folowing the shower is simply the fresh cold and hot water left in the tank mixing over time. The tank is heated only at specifit times, you clearly see when, and at that point it is really fast:0 -

How accurate is that burner modulation % plot? That line looks pretty blocky, like the data is being recorded at only 1 or 2 minute interval. Is there anything on the Veissmann display indicates the current burner modulation? And does that match the data plot?

0 -

Yes the viessmann api provides a datapoint every minute. A typical burner start hits 60% for a few seconds, but in my graphs you can see that they are not always captured. Despite this, the graphs show some pretty interesting data.

And they always match the data from the app or the boiler display.0 -

Here are my thoughts:

Many modulating boilers go through a regimented burner ignition at startup. They will often start around 50% modulation even if the system knows less heat is needed. This is likely what we are seeing in your data plot. The boiler is simply going through it's ignition process and that limits it's ability to fully modulate during this period. Having said that, if your using TRVs, I would probably be using a low loss header or primary/secondary piping. The fixed flow with a low loss header might work better with the boilers modulation algorithm.

1 -

-

Thank you for the feedback, this must be indeed a flow issue, I'm wondering why a low loss header was not installed with the boiler…

For now the modulation seems to work better with the automation that I set up (fully open two TRV for a few minutes as soon as a boiler start is detected).

I'll see in the future if I need to add the low loss header0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements