Radiant Concrete Garage Slab with Burnham Alta and Tekmar 561

Hi everyone,

I'm completing a detached garage with 1,200sf, 5" thick concrete slab. I ran 1,200' of 1/2" PEX in the slab, in 5 loops. (stapled on top of 3" rigid foam insulation, on top of vapor barrier). There is no water supply line to this building. Climate is cold down to down to the teens Fahrenheit in January.

I would appreciate professional "sanity check" on the boiler and T-stat configuration. (And I hope this might help someone else in the future.)

- Burnham Alta 80,000 BTU Boiler

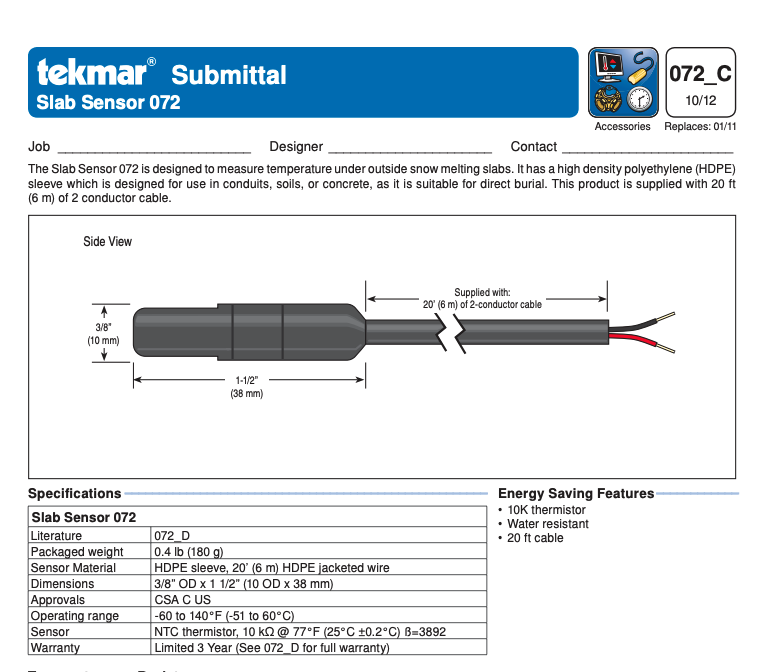

- Tekmar 561 WiFi Thermostat with Tekmar 079 Slab Sensor

- Burnham Outdoor Sensor (108681-01)

- Axiom DMF150 Digital Feeder

Installation Plan:

- Install T-stat, boiler and Axiom feeder. Boiler is in back corner of building, T-stat will be in front corner near entrance door.

- Once floor is heating, map PEX lines using a TOPDON TC001 Thermal Camera

- Use a 3/8" Bosch Blue Granite bit in a standard hammer drill to go ~2" deep in a "cool spot" between pipes, about a foot away from wall.

- Use Super Lube Heat Sink Compound in the hole for the sensor tip, then seal the top with Sikaflex+ Self-Leveling Sealant.

Questions for the experts:

- Any comments, concerns, questions?

- Advice on how to fill the system the first time?

- Any Alta-specific settings? (to play nice with the Tekmar floor sensor logic?)

- Is the Axiom DMF150 unnessary?

Thanks in advance for the feedback!

Comments

-

are you planning on using Glycol? what %

First step before filling is a pressure test. Air would be the safest test this time of year to prevent a freeze up if you do need to correct some leaks

The slab sensor adds some control options, but the system will work fine with air sensing until you get the sensor located

Put the sensor in a copper tube so it can be replaced, I would not glue it into the slab

A heat load and design would indicate what that temperature to run the system. Program that into the outdoor reset settings

The load number would also indicate where to set the boiler maximum firing to prevent short cycling

It may take some time to get the settings perfect if you do not have design numbers?

Maybe start with a 120f swt

You have 18 yards or more of cold concrete, with tube at the bottom of a 5” pour will take some time to warm up the mass.

Wise decision yo use 3” foam under, and hopefully around the edges

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thank you! I appreciate the input.

I'll look into copper tube for the sensor. Would you put some Super Lube Heat Sink Compound in the hole, then a 2" length of 1/2" copper tube, then more Heat Sink Compound, then the sensor?

And I'll check on heat load calc with the contractor who will install boiler.

Pressure test - yes, we pressurized with air to about 50psi before concrete was poured at the end of July, and it's been sitting like that ever since. (dropped over time to about 45 I think but holding steady)

Slab insulation - frost wall insulated vertically on outside w/2" rigid foam and horizontal out from building

Here's a video of the concrete pour - https://youtu.be/ihFhJlgkdUI?si=VPXEQ9pajjgI5Y0o

33% Glycol:

I got 15 gallons of Cryo Tek 100 antifreeze - Plan on adding 10 gallons of water = 25 gallons total, 33% glycol, freeze protection to 0 deg, pumpable to -10F

System Volume Estimate: 11 gallons in tubing (1,200 ft of 1/2" O2 Barrier Heatlink PEX-a, at .0092 gallons / foot) + 1 gallon in boiler? + 3 gallon in piping around boiler? + 0.4 gallon in expansion tank? + 4.5 gallon reservoir = 20 gallons total

0 -

The tekmar slab and universal sensors are all 3/8" OD.

Get a 1/4X 4" brass nipple and cap. Run a 3/8 drill inside it to clean out the burr.

Next hit the end with a Unibit to put a taper in the brass, this allows the sensor to slip in easily.

If you warm a piece of 1/2 pex it will screw over the 1/4" nipple thread to run up to the stat location. A piece of stiff wire or a fish tape, heat shrink it to the sensor wire behind the sensor, to push the sensor in.

Some heat transfer grease assures a good contact. Auto parts, even Home Depot has these small transfer grease tubes.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I like to run a cleaner in the system first, especially if the copper was soldered, you have flux residue, oils, etc. inside which reacts with the glycol.

Most all solder flux is water soluable these days.

Then you will need compressed air to blast all the water out before you add glycol.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

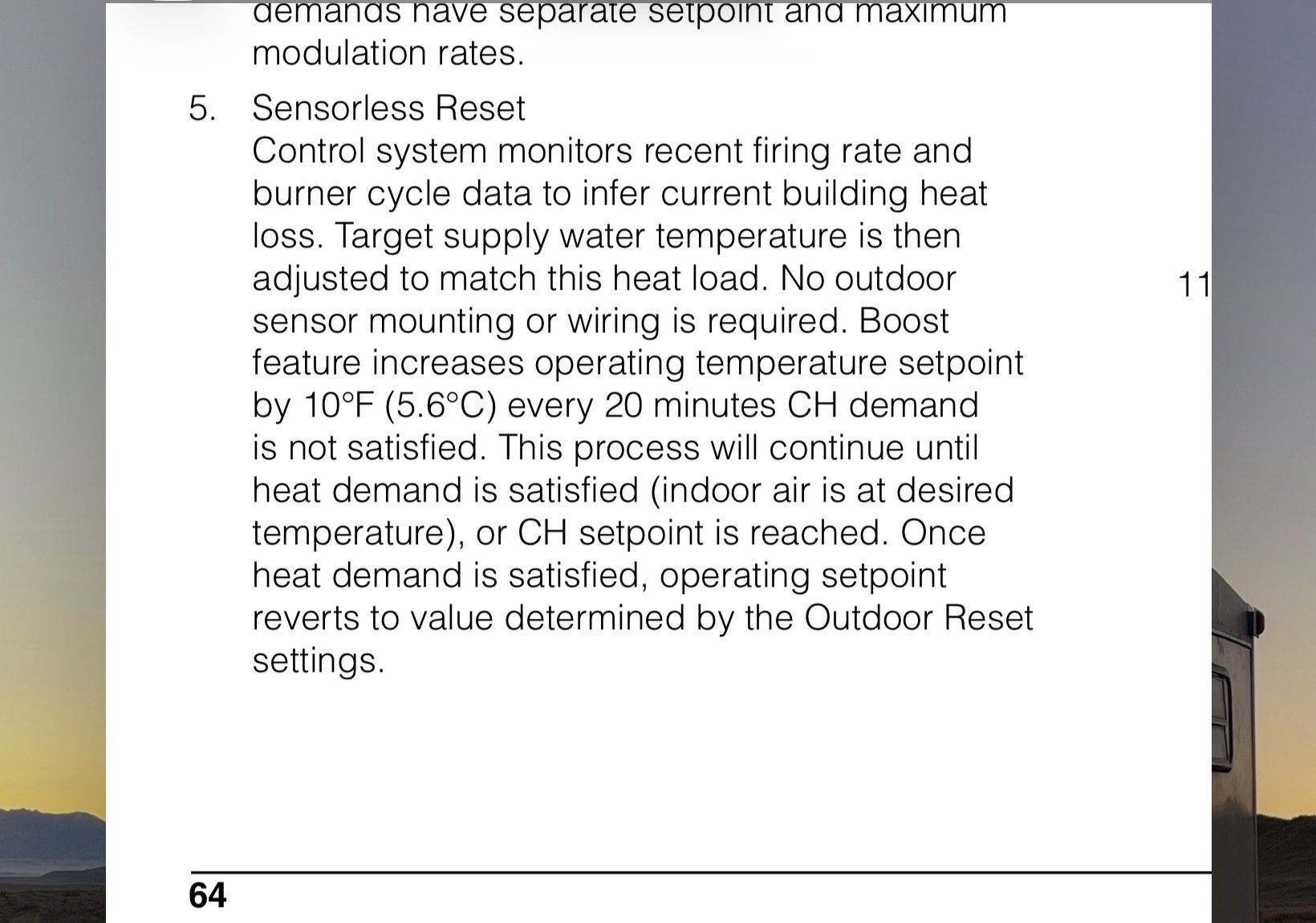

just fyi a Burnham Alta doesn’t actually require an outdoor reset/sensor, it controls that on it own

0 -

do you have the boiler piped yet. That is a water tube type boiler and needs primary secondary or a hydraulic separator. Or the factory header.

Interesting about the sensor less reset. Did it come with an outdoor sensor also?

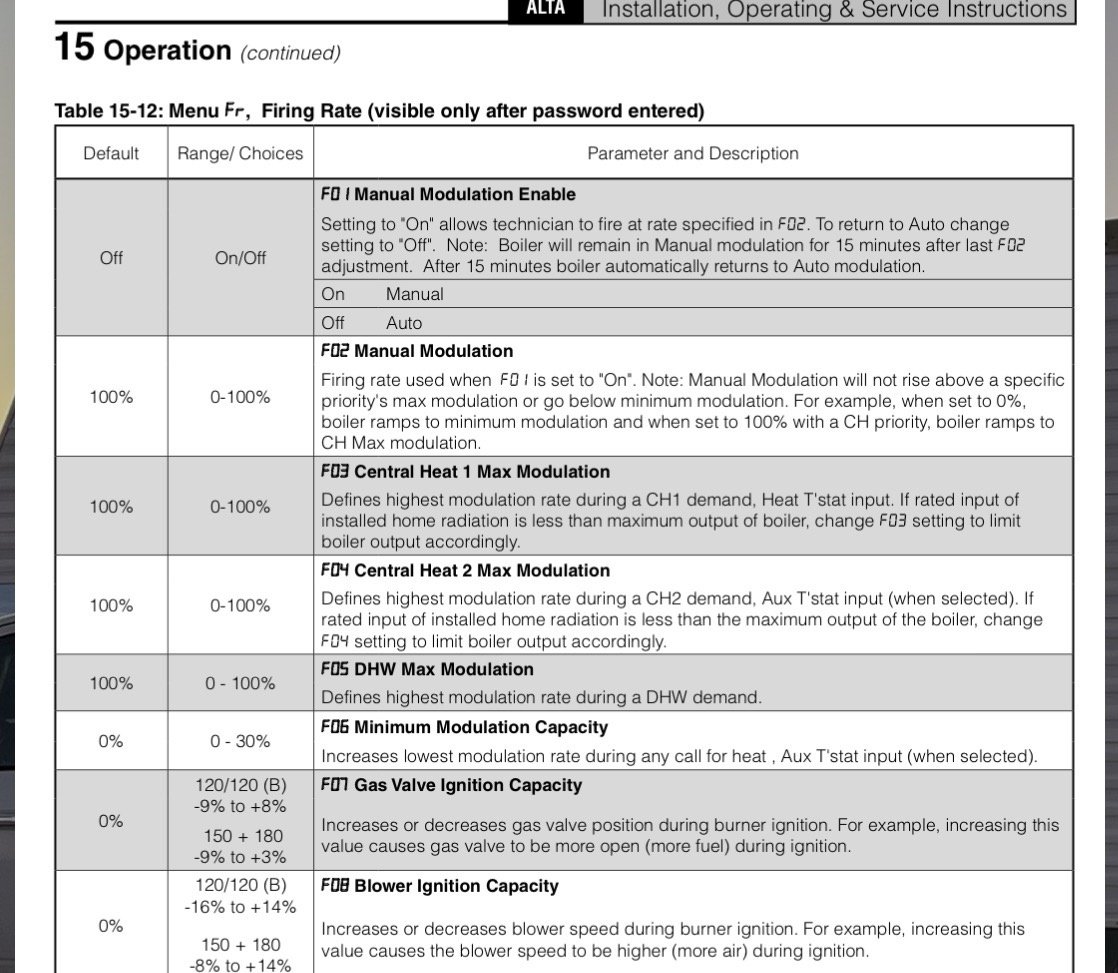

The F04 is a useful setting if you have an idea of the heatload. It basically limits the boilers firing rate, which can help eliminate short cycling

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

A Burnham Alta doesn't come with an outdoor sensor. They do a pretty good job of figuring out the heating requirements without it. They have connections for the ODR thermistor and all the settings for that are in the controller if you want to spend the time doing all the figuring and then setting up the slope, water temperatures, etc. I think with the Alta, Burnham is going after a unit that is quick and easy to install with no ODR and the self-adjusting gas valve and IIRC just turning a screw and changing a control setting to convert to LPG. I have installed a couple of them and like them better than the previous K2 model if there is an indirect water heater involved. Personally I like my own K2 because I enjoyed tweaking all that ODR stuff to make it work the way I want it.

0 -

Not piped yet.

Thanks for the reminder about a primary/secondary or a hydraulic separator. And pointing out setting F04

I read about the sensorless reset, but I'm thinking having an outdoor sensor will help with:

- Freeze Protection: Tells the Alta to circulate water based on external temp before pipes in slab have a chance to drop too low.

- Warm Weather: So boiler doesn't fire during a warm spring day

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements