Excited about Boiler Design

Comments

-

-

I forgot about this place. I was searching on DIYChatroom for this thread bc I honestly forgot this place existed. I had a few r22 AC issues with my high velocity systems over the summer, but was able to handle them DIY.

And I STILL didn’t get that triangle tube combi 155 even hung on the wall yet. Back yard redesign and this project are the two that I was supposed to get done over the summer and did not. Now the heat is on with the old system.

And it looks like my fear of draining the system will be gone shortly, bc at this rate, without the inlet water on, the bad bell & Gossett bearing is losing ~3 gallons per day. I estimate this bc I emptied the paint bucket around midnight and it was 1/2” from the rim at 8 am. It’s going to drain itself, and I will have to put in one of those taco pumps. Well, I do need to assure the system is flushed before connecting the new boiler.

I decided to go out the basement window that’s already been used for a dryer vent. I am redesigning the laundry room now and still choosing the heat pump water heater. 80 falling will simply not fit. So 40, 50, or 65 gallon are my options for the low ceiling room with a floor above that I plan to re-do, making for easy airflow. I guess I could put the water heater in the main room and duct it. So that might enable the 80 gallon and also just be a bit smarter for service than a tight closet in the basement.0 -

Thank you. I don’t know what a one-pipe mono flow system is, but I would guess it usually has one zone. I think my system just has three return pumps all feeding into the boiler drain (no primary loop) and no significant thermal mass. When temp is set to 180 F, it will pop and bang and gurgle bc the boiler keeps firing until the water reaches 180 even if no zone is calling for heat (resulting in unwanted boiling). Briefly, I had my taco 3-pump zone regulator setup to restrict it from firing when no zone called for heat, but one zone is so small, even then I was getting tons of short cycling and maybe some other problems. So I returned it to it original setup.

Anyway, last night I finally swapped out the pumps, moving the small zone BG100 to the big zone with the leaking pump, and putting a taco on the small den zone.

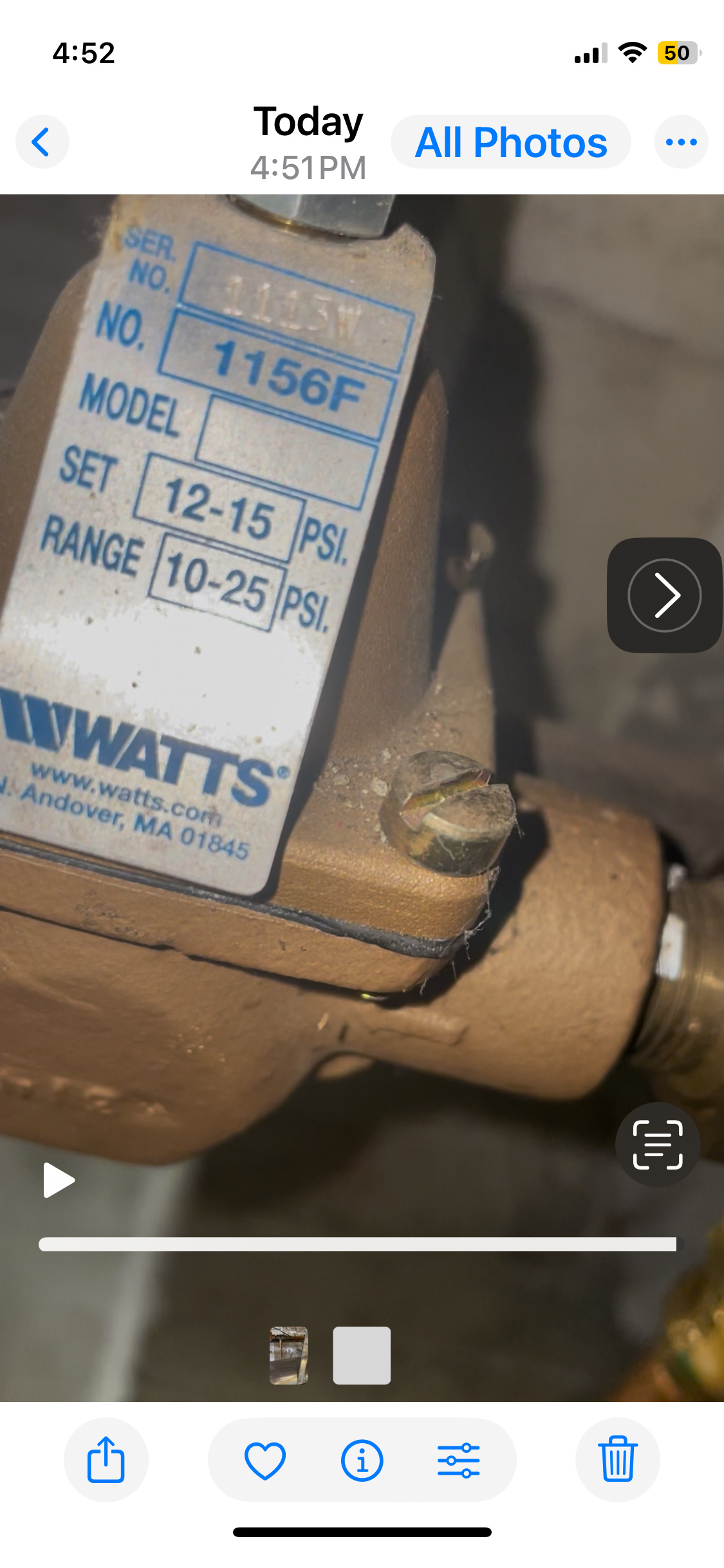

Now I am struggling to bleed. I think my input water regulator must be set at a low pressure bc it’s been 12 hours now, and I’ve got only 2 of 5 second floor radiators fully bled, and no heat at all on the third floor. I’m pumping up the water temp from the 140 F to 170+ F to see if that helps with the bleeding.Also, I just shut those. I wonder if that helps or hurts when bleeding. I guess if all zones are pumping, then maybe it shouldn’t matter. I don’t know. I’m leaning.

https://youtube.com/shorts/vBqKv9u2K50?si=lQb7FyLHDTdDRUTt

0 -

this thing hisses while the tab is flipped up. Should I leave that flipped up until water comes out? I’m surprised at how long I can leave it open with constant hissing. It’s below the first floor radiators that are pushing water out of their bleeders. So I can’t imagine it is sucking air in right now, must be lowing it out. To the water main side of the pipe is something that has a drain to the ground, which I assume is a backflow preventer for potable water.

0 -

Flipping that thing up to when it hissss must allow it to send in line water pressure and not limit it to the 10-15 PSI I guess… bc after flipping it up for a few minutes, the line was ice cold from municipal water and I was able to bleed all the radiators easily. Fortunately the last one wasn’t giving fire hose pressure like the previous ones. So hopefully it wasn’t over pressured. I have a few leaks that will surely decrease pressure over time. I think my pressure gauge on the boiler is bad. It always says ~20 psi apparently, even when empty.

0 -

So while I wait for the leaks to fix themselves (like the leak at the old bump from bumping the pipes), I tightened down the union and got that to stop leaking. The BG100 pump might need to come out to fix themselves others though. I will wait until after our deep freeze to do that.

Since the water that came out was so sooty and dirty, I wonder if that acts as a water softener to minimize sediment deposits or whether that’s a serious problem. Here’s what my water looked like after all the black soot settled to the bottom of the buckets:

I estimate that I would have had about 13 or so of those tubs filled like the ones you see. I will have to check how many gallons they are, but let’s assume 30, and only filled to 25. So maybe 300 gallons or so will need to be treated. I will need to learn how that gets added, maybe pushed in with an air compressor through the boiler drain (before the system is bled obviously).

0 -

-

Ha!

Retired and loving it.0 -

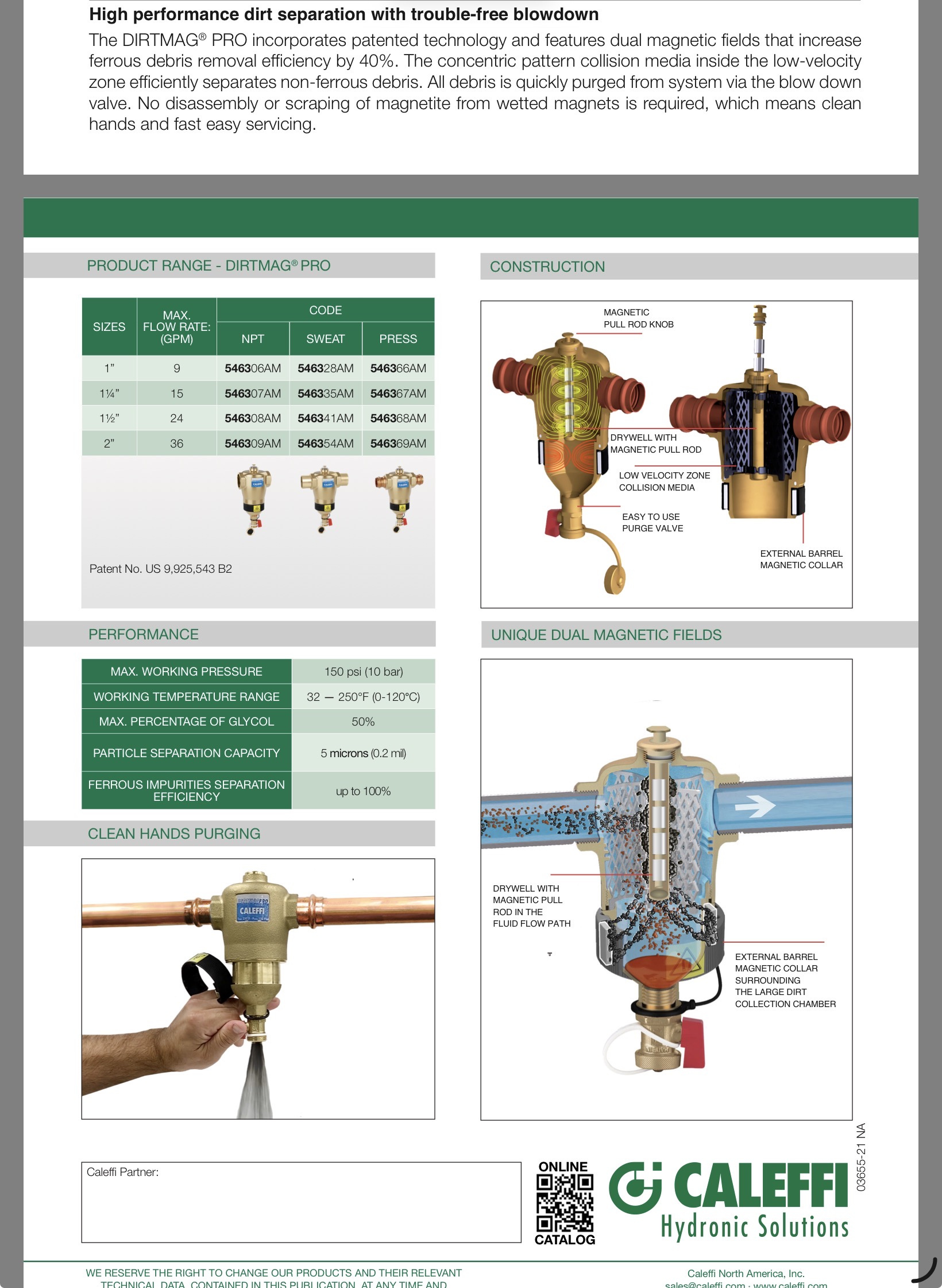

the black deposited could be magnetite, a breaking Dow of the ferrous metals.

Stick a magnet in the sludge to see if it sticks.

Magnetic separators are becoming popular for removing magnetite. If ever the system gets an ECM circulator you need a magnetic separators. Or else the pump becomes the place where the magnetite collects.

This version acted as a dirt and magnetite seperator

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

thanks again @hot_rod ! Exceptional information for a guy like me! I am very lucky to have all this help here.

It’s probably a good thing I am on the slow boat with this project… aside from the company I bought $4500 of boilers from going out of business before I installed them. Oof!

0 -

post mortem on the pump shows a bent shaft in the bearing piece. I wonder if it overheated.

Leaks persist in my “plumbing” to the left of the pump. Bucket is catching it all, and I should not have to empty the bucket this year if it continues at this rate. Hope it doesn’t get worse though.0 -

I am now getting one drop every ~10 seconds from the bad leak I created when replacing the pump. I think the other one to the left, running vertically down the pipe to a dry rag MIGHT resolve itself. I am going to guess that the things likely to get damaged by these leaks are not too much to worry about. Next system flush should be fine, good enough.

0 -

-

Sizing:

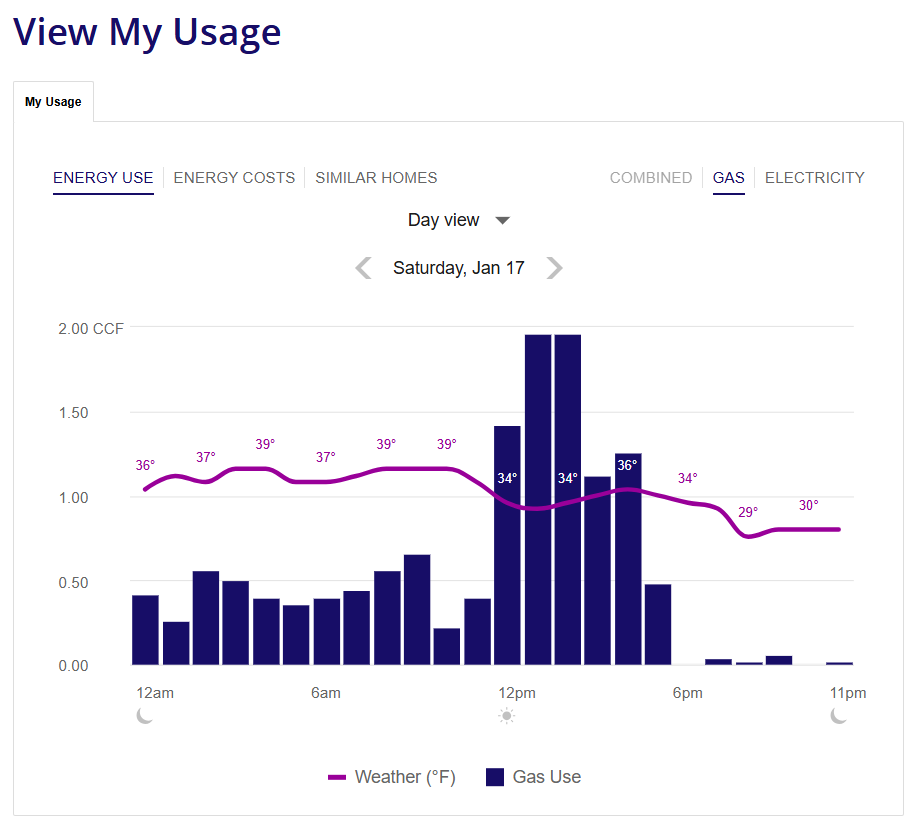

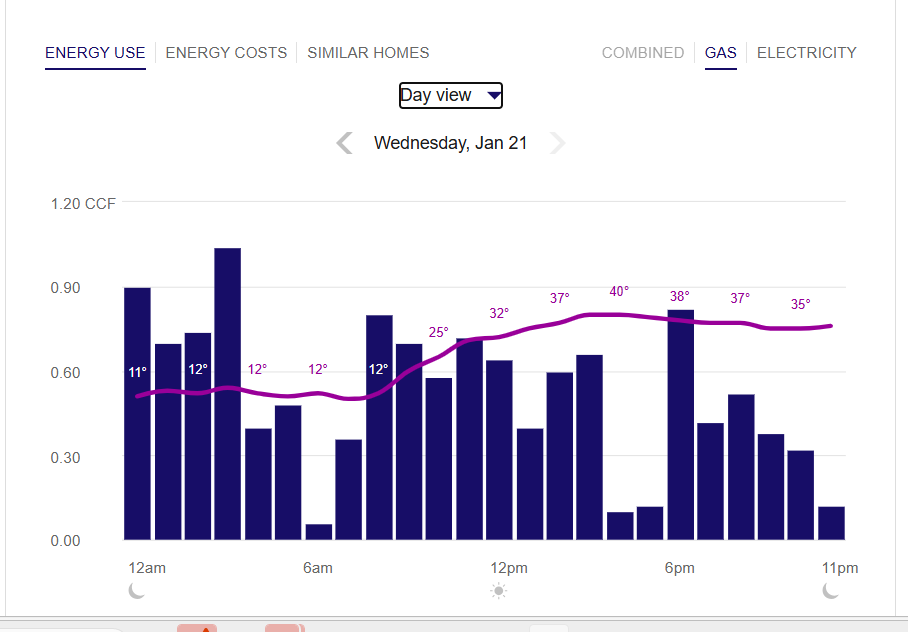

With the ramp-up of the temps and trying to heat the house as quickly as possible to a crazy high temp (on a warmer day) to assure I have the longest possible time to have the heating system down, I think I can see that something may have topped out a 1.96 CCF of natural gas. I think the boiler might have been trying to get the water temp up from the ~140 F up to 170 F.

I see now that the tubs I was filling with water were 18 gallons, not 30. So that brings my estimate of the amount of water in the system from about 300 gallons down to a more realistic 180 gallons.If it takes 8.33 BTUs to raise the temp of one gallon of water by one degree, then 180 gallons would be 1,499.4. Let's say 1500 BTU per degree. And if I was just raising water temps only, not heating the whole house, about 30 degrees or 30x the 1500 = or 45,000 BTU. 45 kBTU. The whole house went up by at least 10 degrees though, and there's a lot of stuff in the house.

If you look at those heating hours:1.42

1.96

1.96

1.12

1.26

0.48

before I shut down the system.

Total: 6.94 CCF

Convert to BTU I put into the house:

CCF: 7 CCF

BTU: 718900.00 BTU

Assume 20% went right up the chimney: ~575,120 BTU went into the house over about 6 hours, and raised the temp by about 10 degrees when it was about 34 F outside. It looks to me like under most circumstances, 100k BTU/hour should be plenty to heat the house. Maybe it will get bad when really cold, but I will continue to look for those really cold times.Looking also for CCF usage at coldest times, when 14 F, I see we used 1.04 CCF in a single hour. And while increasing the temp at 6 am another time at 14 F, we used 1.32 CCF, and there are times in the history where I can certainly see that we used more than 2 CCF in a single hour, but they look like times when we were making hot water with the hot water heater(s). So, with a 155k BTU Combi boiler, I can see how it might be necessary to have a heat pump water heater (or natural gas conventional tank) kick in. Long showers when cold out taking demand might end up creating a cold house otherwise. Things to think through. Or maybe now that I know Triangle Tube is out of business, I should just install both units inside the house maybe. Things to consider. I've also thought maybe a pellet stove would make sense because feeding a wood stove is not always fun.

0 -

Since I want to open the room with the chimney, old boiler, and old water heater, I am looking at moving a High Velocity duct from the center of the room closer to the center of the house. It's about 25 feet of a loop of 9" (or 8" or 10"?) trunk with 10 flex leads coming off it. Today I got my first quote, and the guy started with a $4000 ballpark, but upped that to $6700 after he went to the truck. That sounds like enough for me to at least start into DIYing the job. I don't need AC right now, and I figure I've got nothing to lose.

He also said he wouldn't recommend switching to conventional, even for just this basement first floor unit. I know it could be done, but if the duct work would need to be a lot bigger, I guess it would likely get in the way of everything.

This all started because I've got a few things all going on at the same time. We are going to redo out back patio, and I just took down a big tree. So, we now can get equipment into the back yard and potentially dig up shallow geothermal loop(s). That offers a second option to the vertical drilling that could be done in the driveway. So, I made some calls to see if adding a geothermal heat pump loop to our boiler and/or AC might make some sense. $50-65,000 was the phone call number, but we will see if they actually send out someone who knows how to install these systems.

So, I am hoping to have a path forward on the ductwork by March this year. Maybe we end up with some heat coming in through the air, maybe some geothermal heating added on another loop attached to the radiant heat. I don't know which way this will lead.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements