Ghost flow help please

Comments

-

The flo checks that you removed, when you inspect them, do they appear to be functioning well with a good seal?

0 -

Isolating which valve stops the gravity flow? the supply, return or both? Believe it or not water can circulate (thermosyphon) through a single pipe without a direct return path. what's going on with the tankless coil that's not being used anymore right? maybe would help to set up the boiler for a cold start?

1 -

-

if I close either the valve just distal to the circ pump or the valve at the return the g flow stops as water cannot move. The thumb valve on top is all the way down (CW).

0 -

I know you already checked - but - if they are installed backwards that will happen.

0 -

A Spring Check on the return should solve it. I've seen it even using all IFC circulators. I'd replace the internal check, and the problem is still there. And coincidence or not, they've always had Speed Headers. Yours in only using one on the supply. The zone usually effected is the one next to the indirect.

1 -

That is highly unusual to see a check like that not be able to stop flow in an installation like yours. Be that as it may.

Screwed down, arrow facing flow direction? There isn't another pump on the system, maybe at the boiler return?

If closing those iso valves downstream of the flo check stops the ghosts, then… you choice is adding spring checks to the pumps if they can accept them, or remove the flow checks and replace them with hydronic type spring checks.

Ideally check valves are installed about 10 pipe diameters downstream of the circ.

Do not use swing checks!

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

do you think if I installed a new taco circ pump with a built-in IFC that would solve the problem?

0 -

@plumbworker brings up a good point that a constantly hot boiler is going to exacerbate your ghost flow issues. Do you know what your low limit temperature setting is? High limit? Were these settings changed at the beginning of this heating season? Have this temperature settings been validated on your system with separate gauge?

Adding an IFC in a circulator may help some but if the ghost flow is overcoming your current Check than you'll probably need something with more resistance to opening than the IFCs

0 -

All circs would need the same check, not just the over-heating zone.

Boilers with tankless DHW coils are hot all the time and those can and have worked with flow checks, something is not adding up here.

At some point you get weary of the troubleshooting quest and just change to a different check.

I believe the checks used in circulators ICF, are .35- .50 psi pop. So they could in fact be less pop psi than what those flo checks are? But there spring assures that they do in fact close.

I don't see a spec at B&G or Taco for the "pop" of flow check. It would be equal to the weight of the plug if the opening it closes is 1 square inch.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Guesstimating Opening PSI for your Taco flo chek.

I estimate the diameter of the closing disk (cylinder) to be 1", height 1/2", and using average density of stainless steel..... Over an opening of 7/8” diameter. Accounting for buoyancy of water. I come up with opening pressure between 0.15 to 0.2 psi. This is Lower than my initial impression but still should be able to hold down typical thermosiphoning. Although I have read some sites suggesting thermosiphoning pressure delta in taller homes reaching 0.5psi.

If swapping in a different circulator with IFC is easy for you, it's worth a try.

Another option is to reduce the effect of thermosiphoning but these can come with their own problems. Adjust boiler temps down. Insulate the return piping particularly in the overheating zone. Blocking off some airflow through the baseboards in the overheating zone (do your baseboards have dampers?). Cold start boiler setting (I'll defer to oil experts if that's wise for your set up).

Good luck

0 -

If closing the valve to the return on the affected zone stops the "ghost heating" then to me it's pretty apparent there is thermosiphoning through the return, i would then simply add a spring check. Also as @bjohnny has stated look at the low limit settings on the aquastat control if your not using the tankless coil and have an indirect you shouldn't need to be keeping the boiler hot and i would suggest operating the boiler as a cold start..

1 -

boiler temp is about 170 degrees.

0 -

I do not have a tankless dhw set up.

0 -

I also do not believe there is any g flow going up the return pipe so not sure a spring check would help but I'm not sure on that. I'm no where near a plumber but the g flow is going in the same direction the circ pump would push the water.

0 -

I would narrow down which valve stops the ghost flow.

Is the valve downstream of the circulator and flow check?

Or is it the valve on the return piping?

Don't turn off both at once to determine the flow path of the ghost.

That will answer where a new check may be needed.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

The spring check on the return helps because it prevents (if opening pressure of check valve is high enough) the cold water from coming down and completing the thermosiphon loop. And you also previously mentioned that the ghost flow stops when you close the valve on the return.

0 -

@plumbworker astutely noticed was your boiler appears to have a tankless coil in it. Presumably this was used before the indirect tank was installed. When these tankless coils are used, it is common to keep the low limit temperature setting of the boiler higher than what is truly needed (even through the summer months). So, even though, you are no longer using the tankless coil, the aqua stat settings may not have been adjusted to accommodate the upgraded & efficient indirect tank.

0 -

-

read through this tread, and the only thing that changed was adding 5th zone for DHW. It’s possible you’re creating a higher differential pressure overcoming the .5 psi to open check and allow flow into that zone. What negates my theory is it would happen in your other zones too. I like Hot Rod’s suggestion to take the power off the circuit to validate the thermostat. You can call Taco at 401-942-8000 for support.

Joe Mattiello

N. E. Regional Manger, Commercial Products

Taco Comfort Solutions1 -

I wondered about that too. The indirect was added over 13 years ago. He mentions that in fine print

0 -

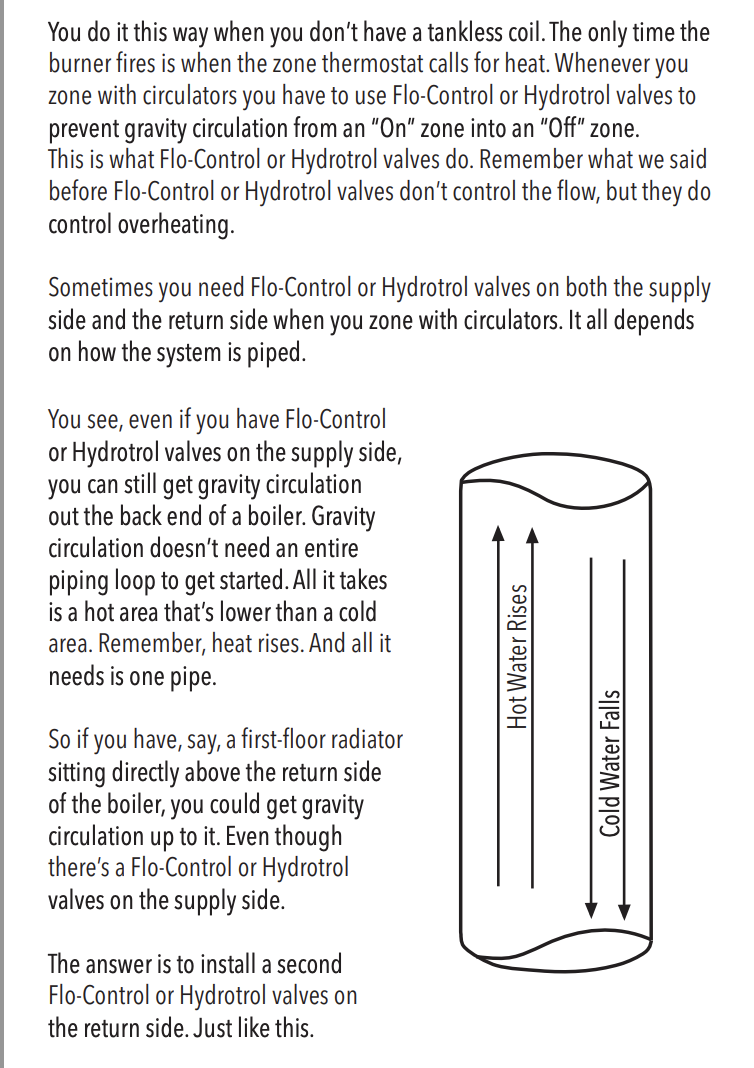

But if the supply check is not, you could have 2 directional flow, heat going up and cold coming down the same pipe. So a return check still may not solve the problem. A graphic of that concept.

As silly as it sounds or looks we have had instances where we are told only a zone valve after the pump has corrected a ghost flow??

If true I would rip, out all the zone pumps and use a single delta P circ and zone valves. Cure the problem and reduce energy consumption 50- 80-% Most zoned pumped systems are way over-pumped anyways. 007's moving 1 or 2 gpm as example

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

Yeah, I'm still not clear if this means just turning the valve off on the supply after the flo check stops flow? If so the flo check, must not be holding. Which is very odd, to me?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

if I close valve just beyond the taco Flo check the g flow stops. If I close the valve on the return at the boiler the g flow stops. If the valve beyond the circ pump is closed and the return valve is open hot water does NOT flow up the return.

If either valve is closed then the loop is closed so water cannot flow.0 -

Any chance you installed that Zone 2 pump backwards? Which way is the arrow pointing on the volute? It looks correctly oriented from the pictures but I cannot say for sure.

0 -

As I posted above a zone valve is the fix.

0 -

arrow on the zone 2 pump points in same direction as the other 4

0 -

-

I have had the g flow zone closed for the last several hours so pipes are cool. I will shut the boiler off, flip the breaker to off and then open valve to see what happens.

0 -

so with the boiler off and breaker off as soon as I opened the return valve the pipe distal to the Flocheck got hot almost immediately

0 -

And this is with your boiler already hot at about 170 to 180F. So you confirmed it is thermosiphon effect. And the thermosiphon requires the entire zone loop. Did any of the other zones get hot past their Flo Chek?

If it was my house, depending what the high & low temp limit are set to, I would try reducing each of them by 15 degrees to reduce the thermosiphon forces. It sounds like your heat emitters have plenty of output to accommodate a lower temp. You can easily change the settings back.

1 -

no other zones have the issue which is odd. If I close a valve on zone 1 the g flow does not move to a different zone.

0 -

I just cannot comprehend why the Flocheck isn't stopping it…

0 -

-

So you just replaced the internals of the flow control i'm i correct? maybe the valve body has pitting or corrosion at the seating surface? If so maybe then consider replacing the entire flo-check if you haven't already?

0 -

The entire flocheck is new (x2). Taco 218-3 flocheck

0 -

-

The flow check could be too small for the rise….

There was an error rendering this rich post.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements